Patents

Literature

41results about How to "Efficient construction methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of three parallel metro tunnels with ultra-small clear distance

InactiveCN104196537AAdvanced and reasonable construction methodsEfficient construction methodsTunnelsSocial benefitsEconomic benefits

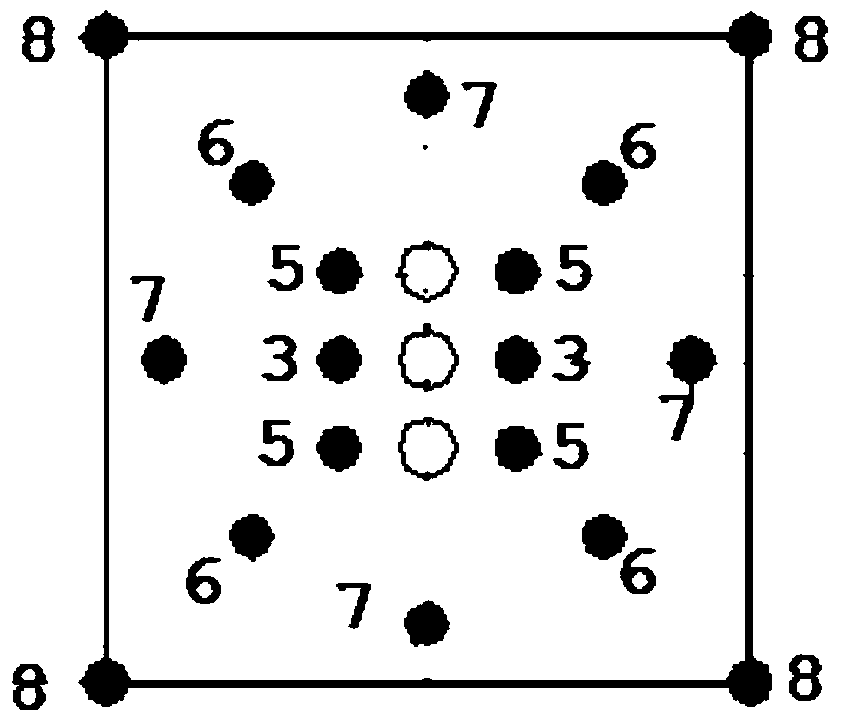

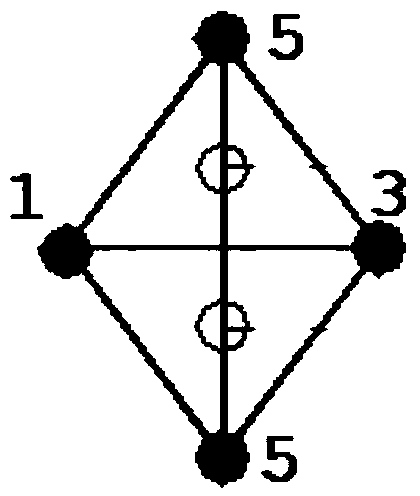

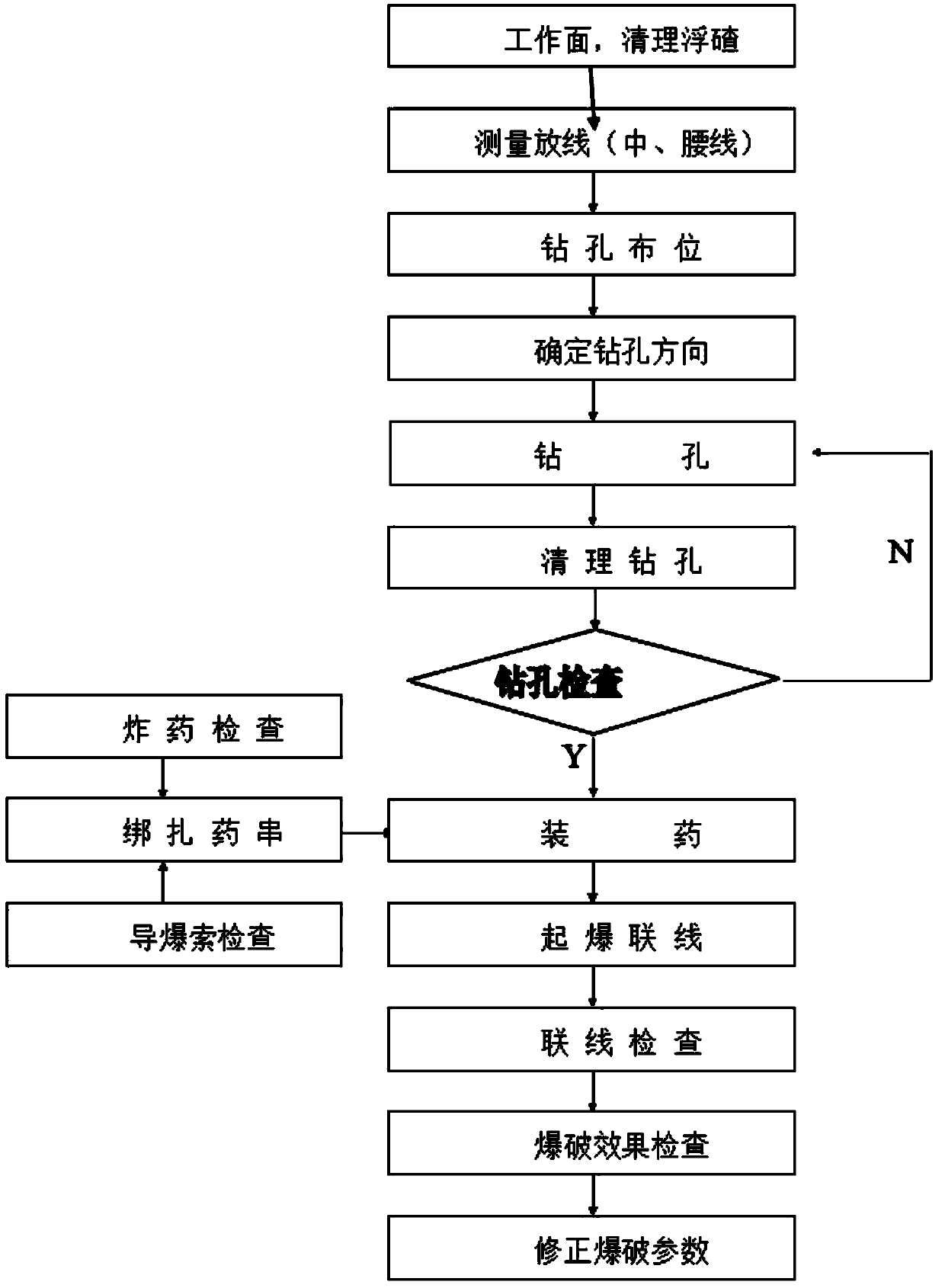

The invention discloses a construction method of three parallel metro tunnels with an ultra-small clear distance. The method includes a tunnel portal and open-cut tunnel construction method, a barrel digging method, an explosion method, an advanced small pipe construction method, a steel mesh hanging method, a vertical steel frame erecting method, a combined anchor rod construction method, a primary lining supporting construction method, a tunnel waterproof construction method, a secondary tunnel lining construction method, a pouring method, a geological advanced forecast method and a monitoring and measuring method. Compared with the prior art, the construction method is advanced, reasonable, efficient and concise; on the basis that stability of surrounding rocks, constructed tunnels and surrounding buildings and safety of construction personnel in a construction area are guaranteed, engineering quality is guaranteed, construction cost is effectively lowered, the constriction time is shortened, and social benefits and economic benefits of enterprises are remarkable.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR

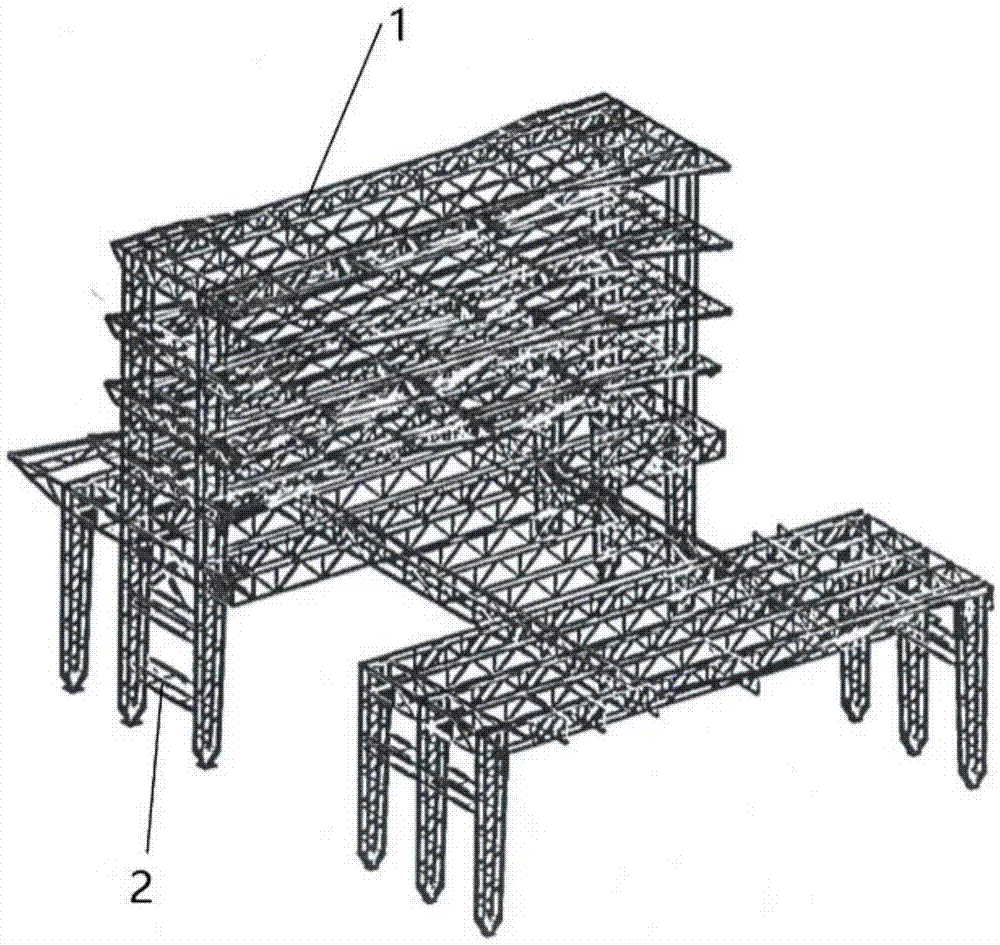

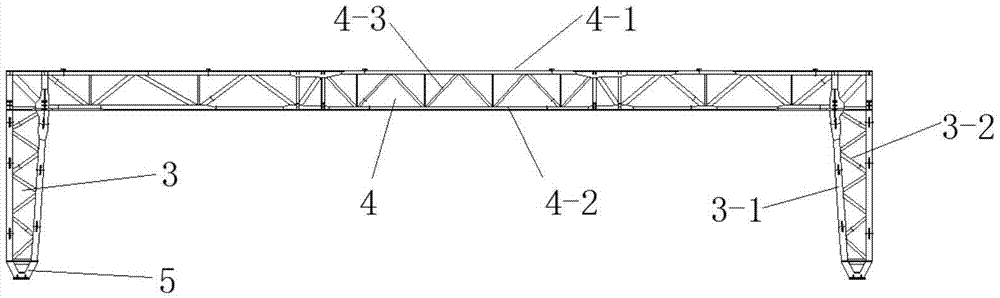

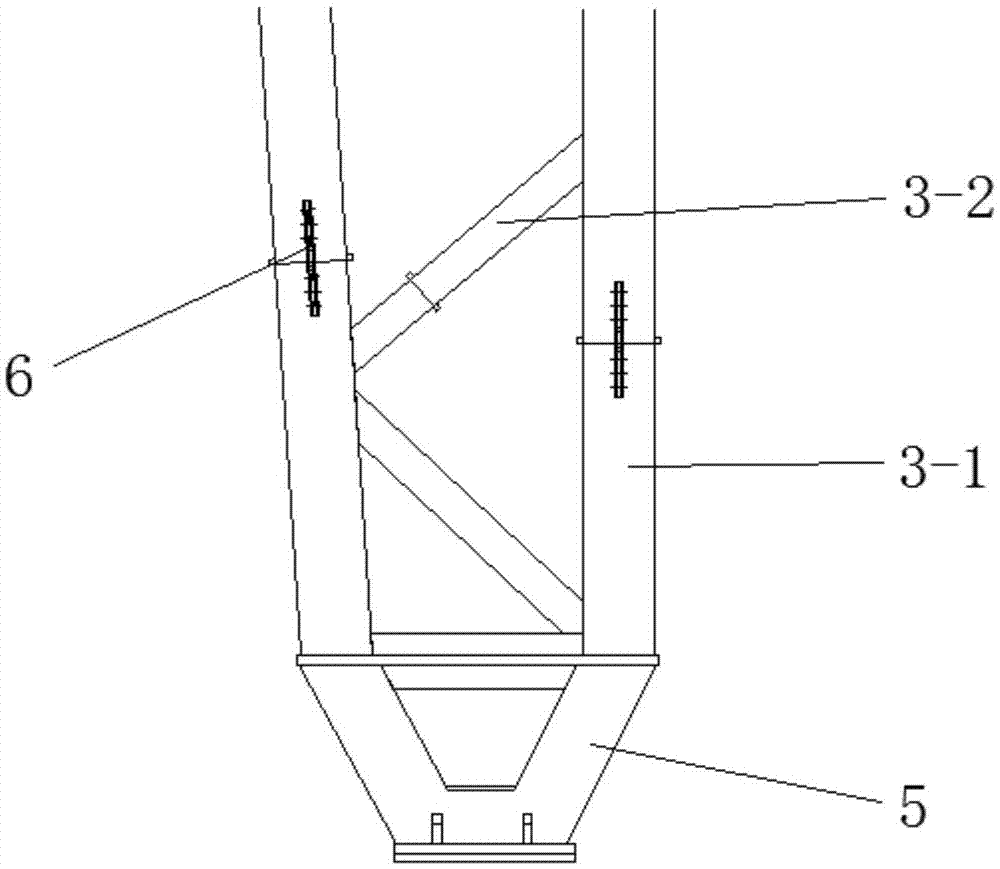

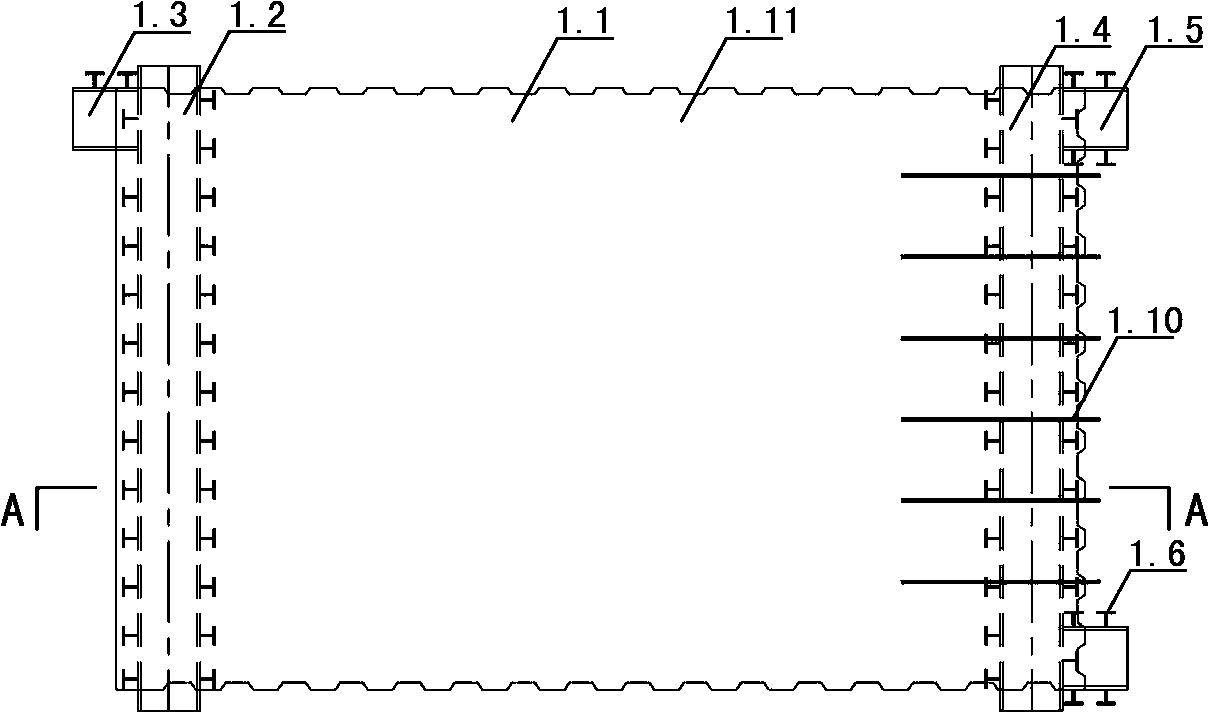

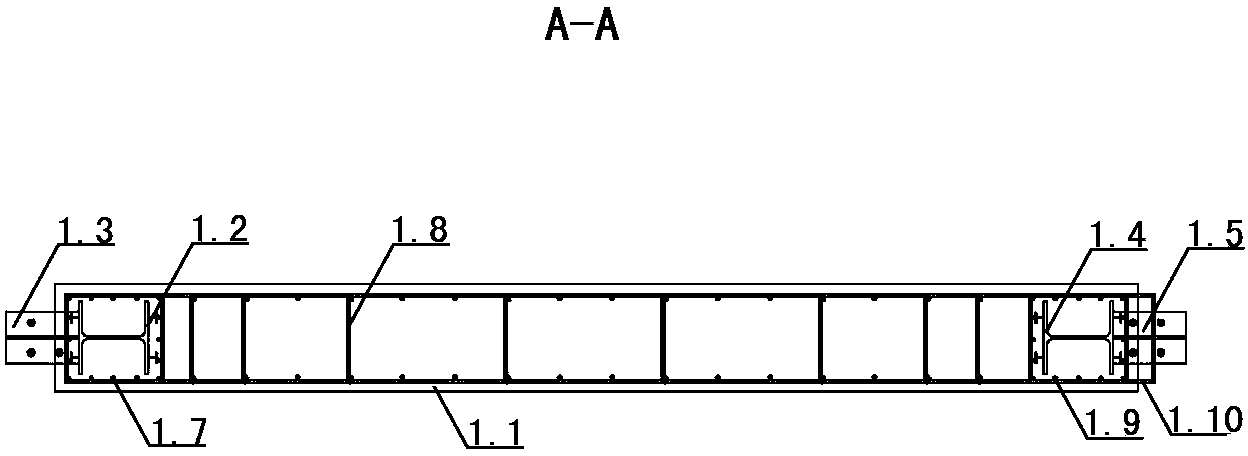

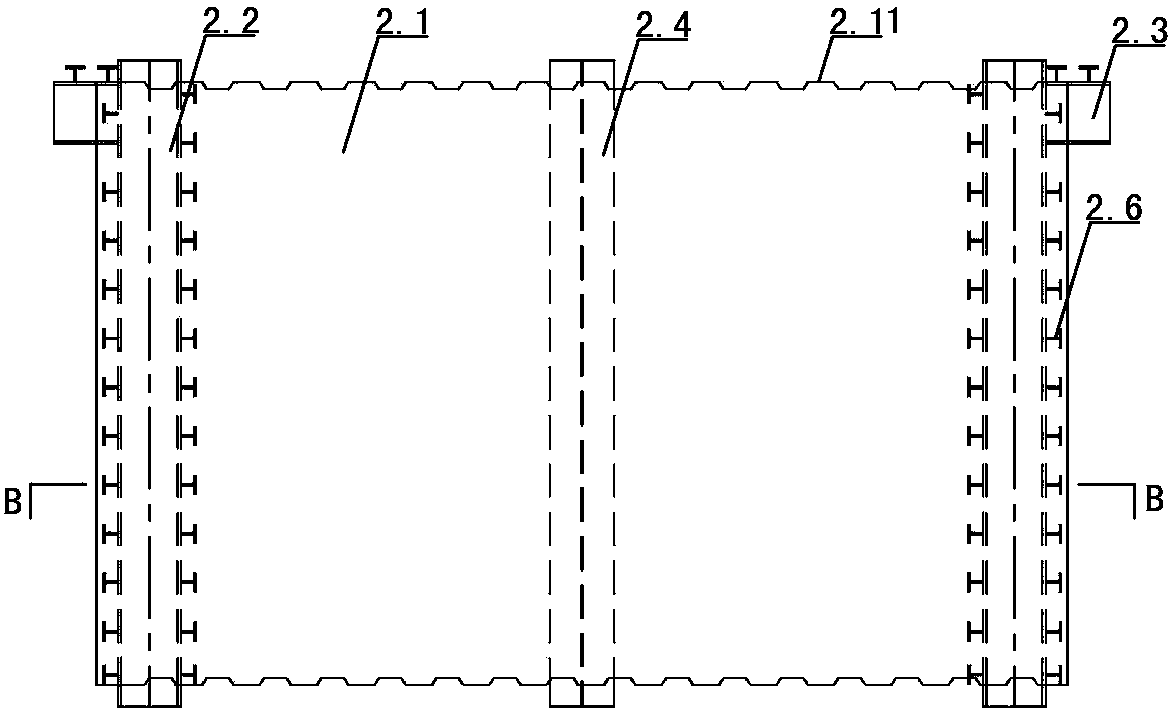

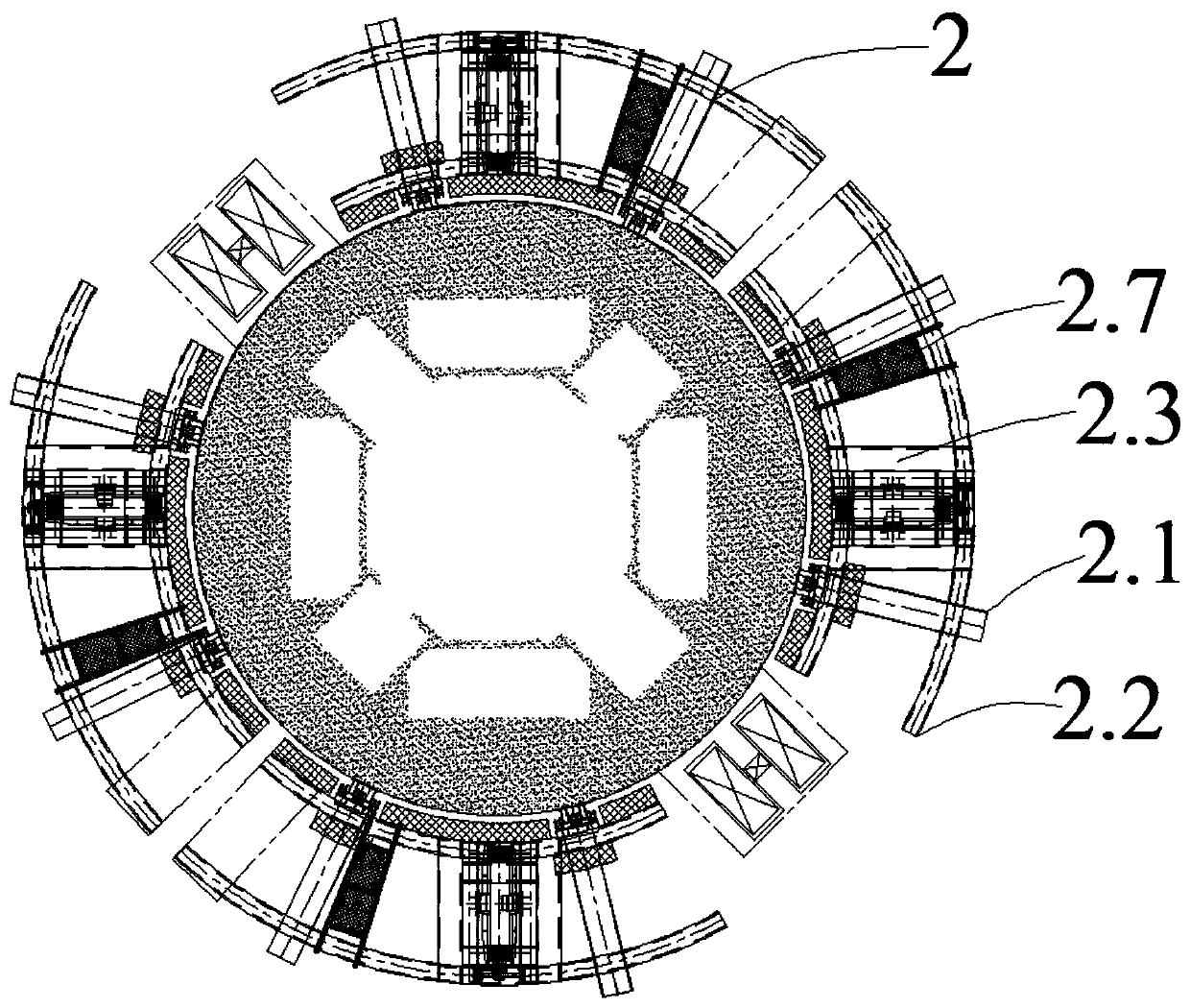

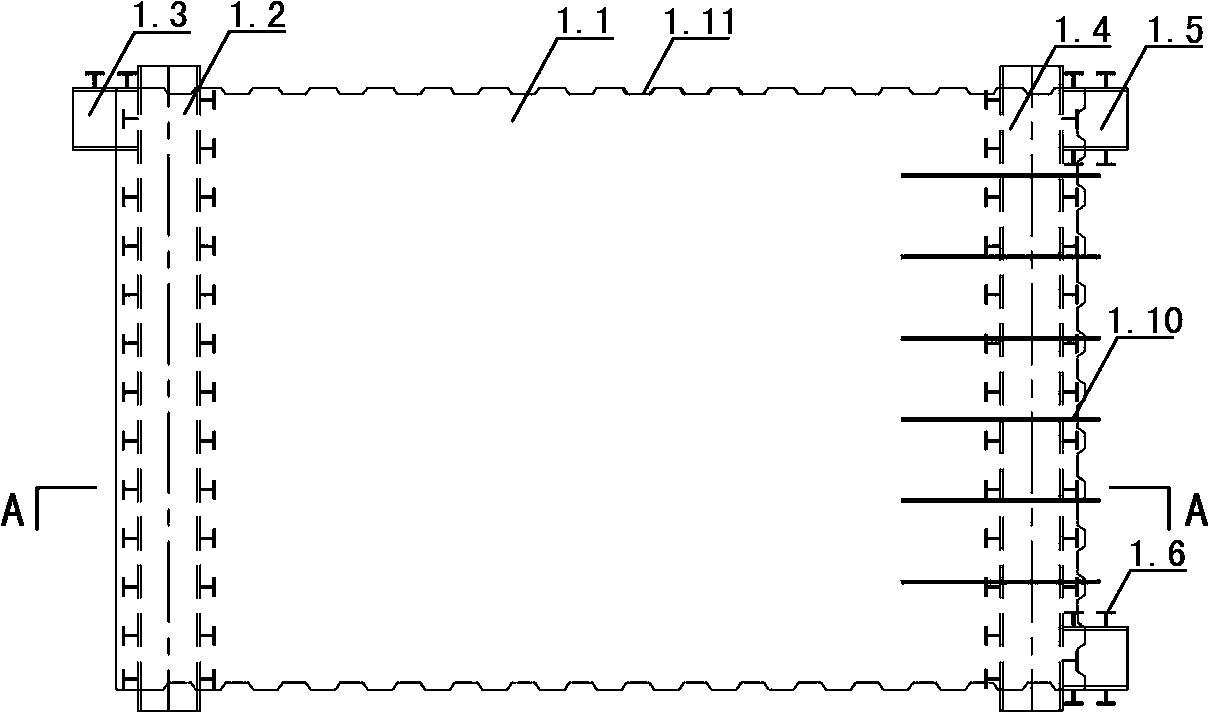

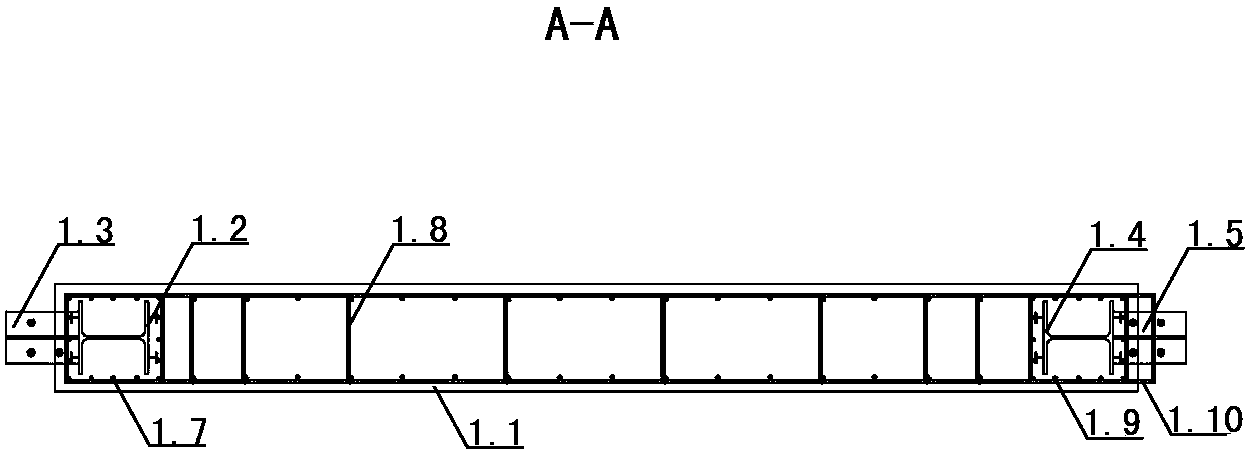

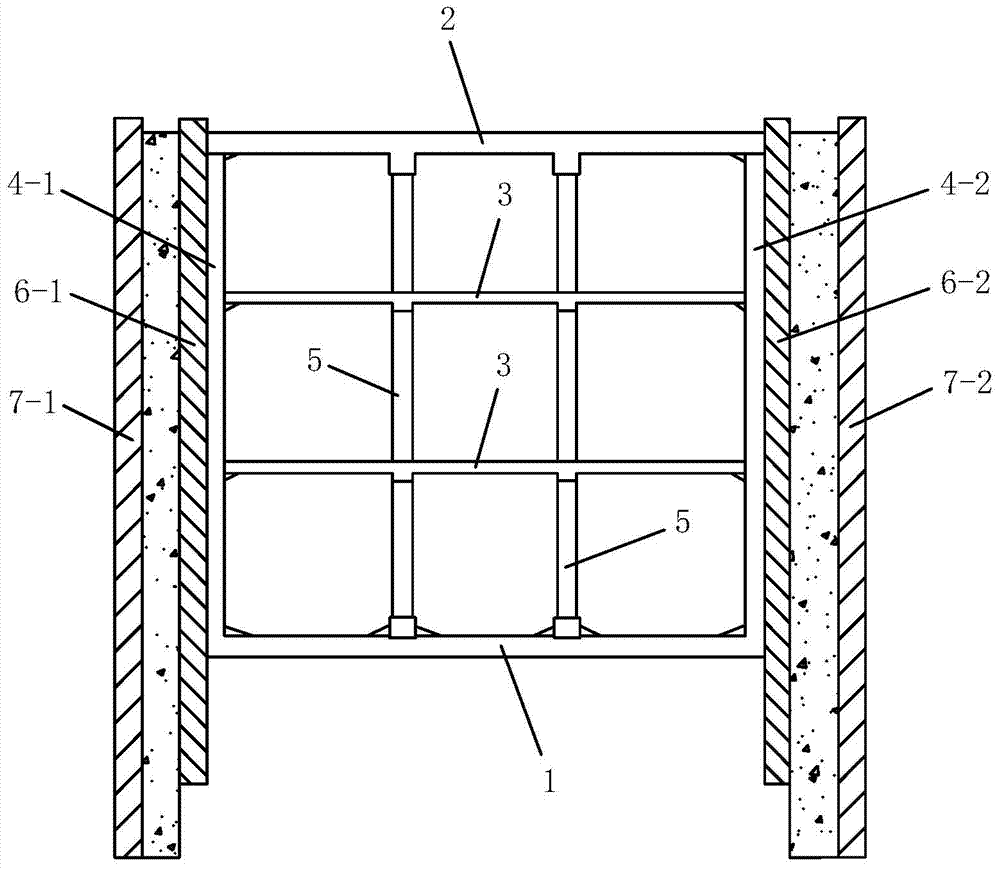

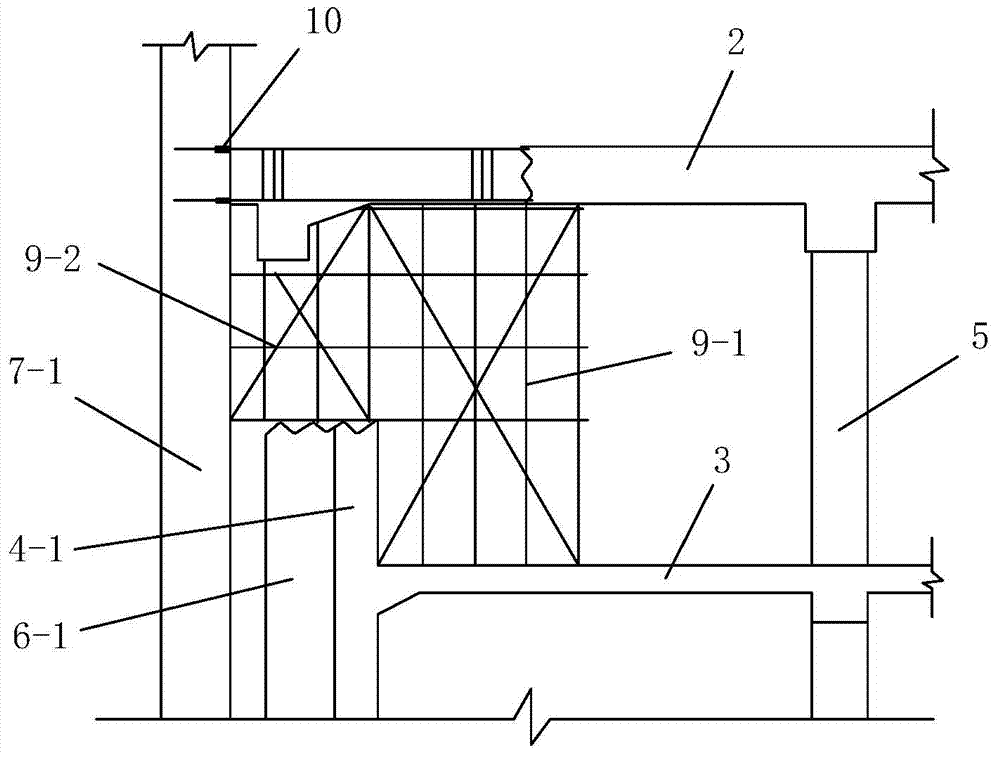

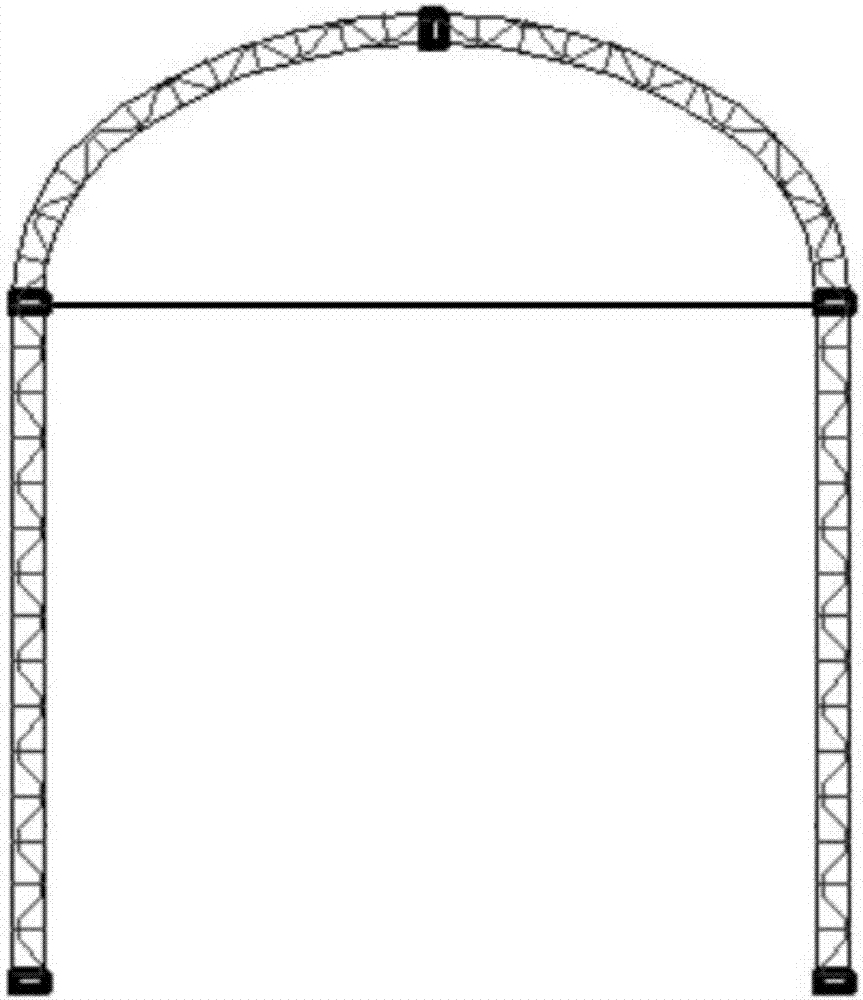

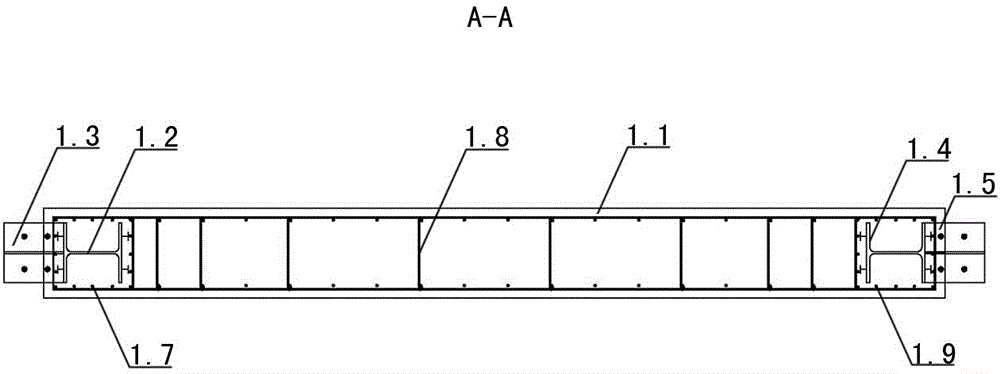

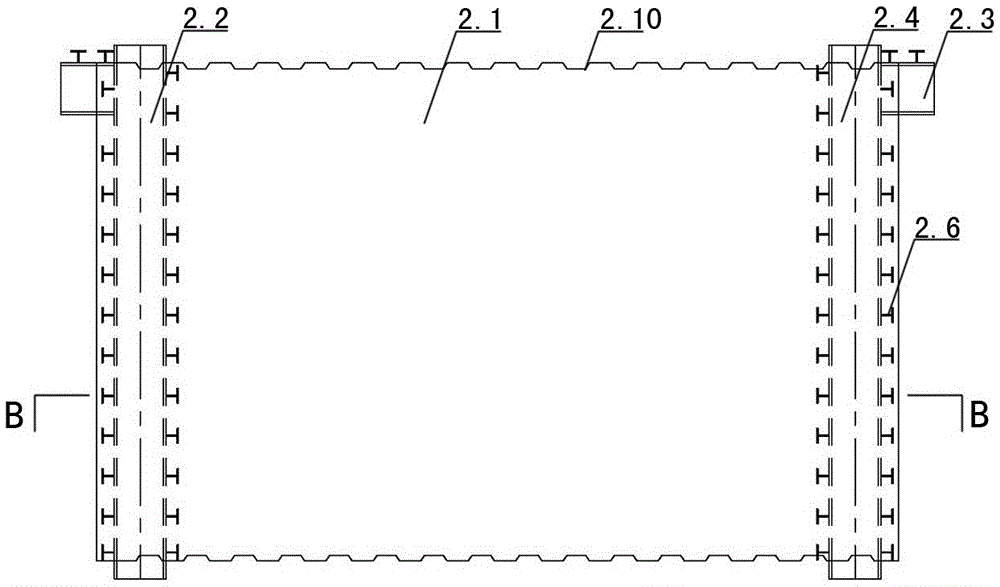

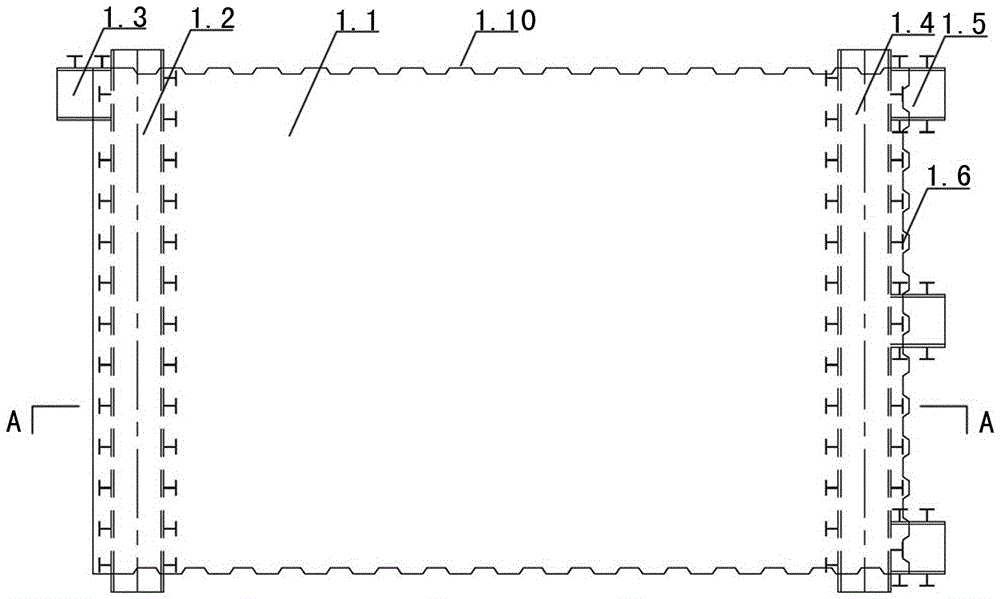

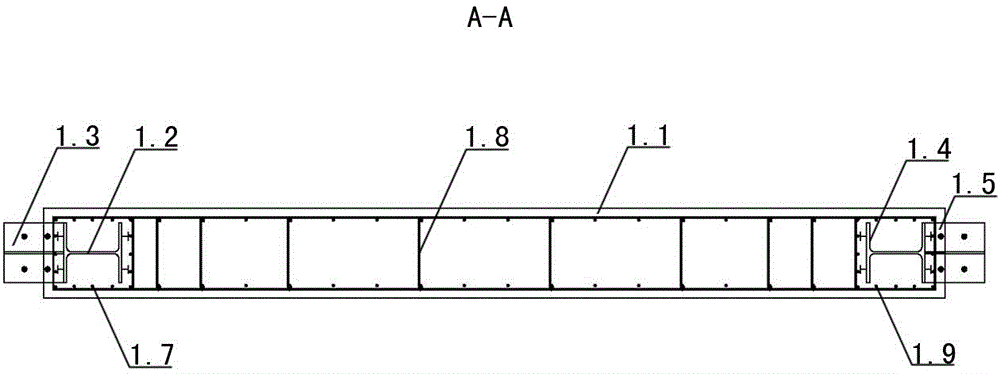

Large-span steel truss structure and installation method thereof

The invention discloses a large-span steel truss structure and an installation method thereof. The large-span steel truss structure comprises one group of steel frames and secondary trusses which are located between the adjacent steel frames and are vertically connected with the steel frames; each steel frame adopts a double-truss combined truss and comprises two supporting columns and a main truss located at the tops of the supporting columns; column pins are arranged at the lower parts of the supporting columns; each supporting column comprises one group of steel columns and reinforcing ribs which are alternatively distributed between the steel columns; each main truss comprises one group of upper chord plates, one group of lower chord plates and webs located between the upper chord plates and the lower chord plates. According to the installation method provided by the invention, a long slippage rail is paved at the lower part and a lot of labor force is alleviated; the whole structure can be divided into different construction regions according to different structures so that the construction is more convenient and rapid.

Owner:JIANGSU HUNING STEEL MECHANISM

Assembly-type T-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type T-shaped mixed coupled wall and a construction method thereof. The assembly-type T-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form a T shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type T-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved, building operating requirements can be met conveniently, and assembly procedures can be simplified conveniently; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

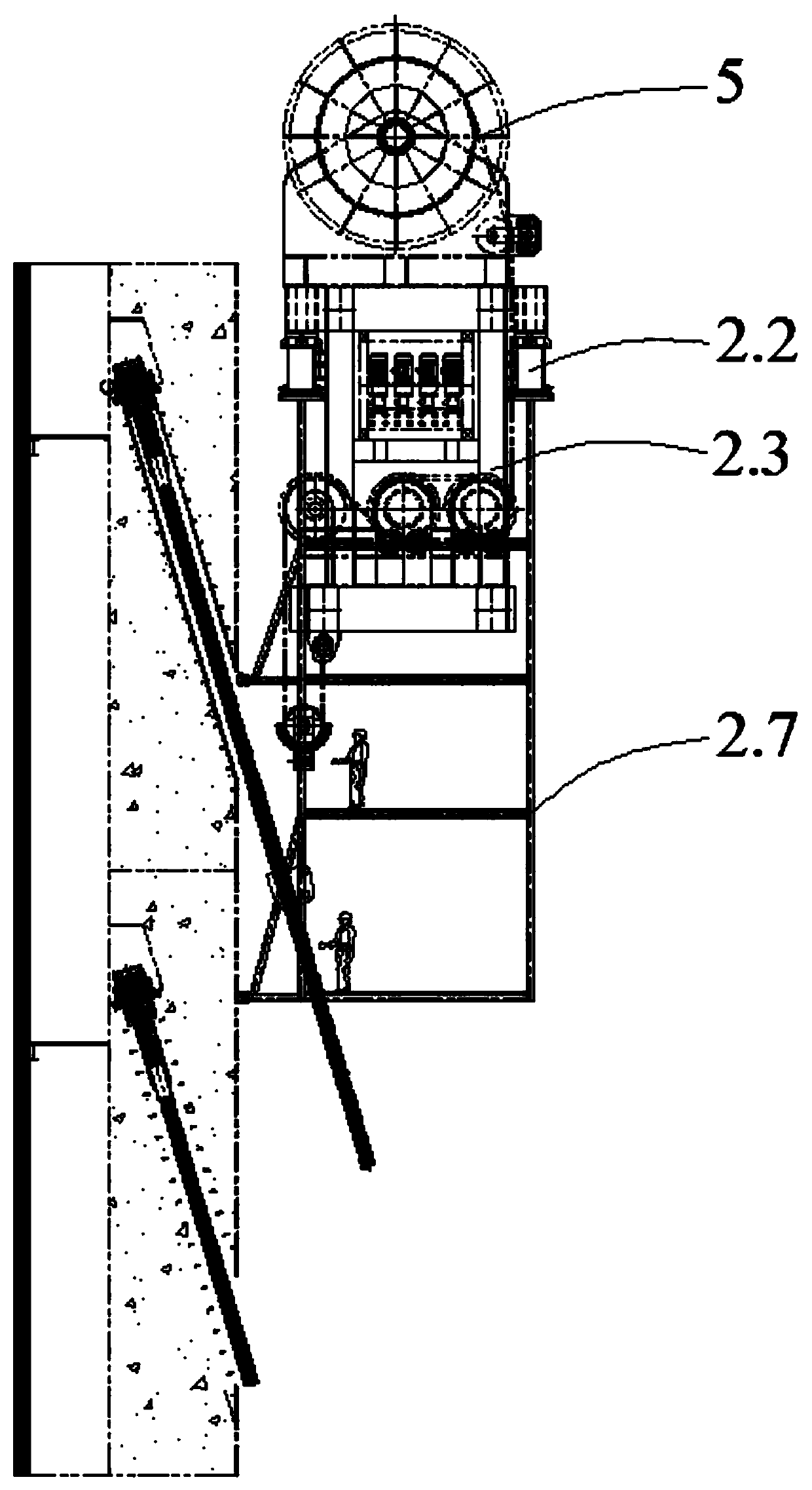

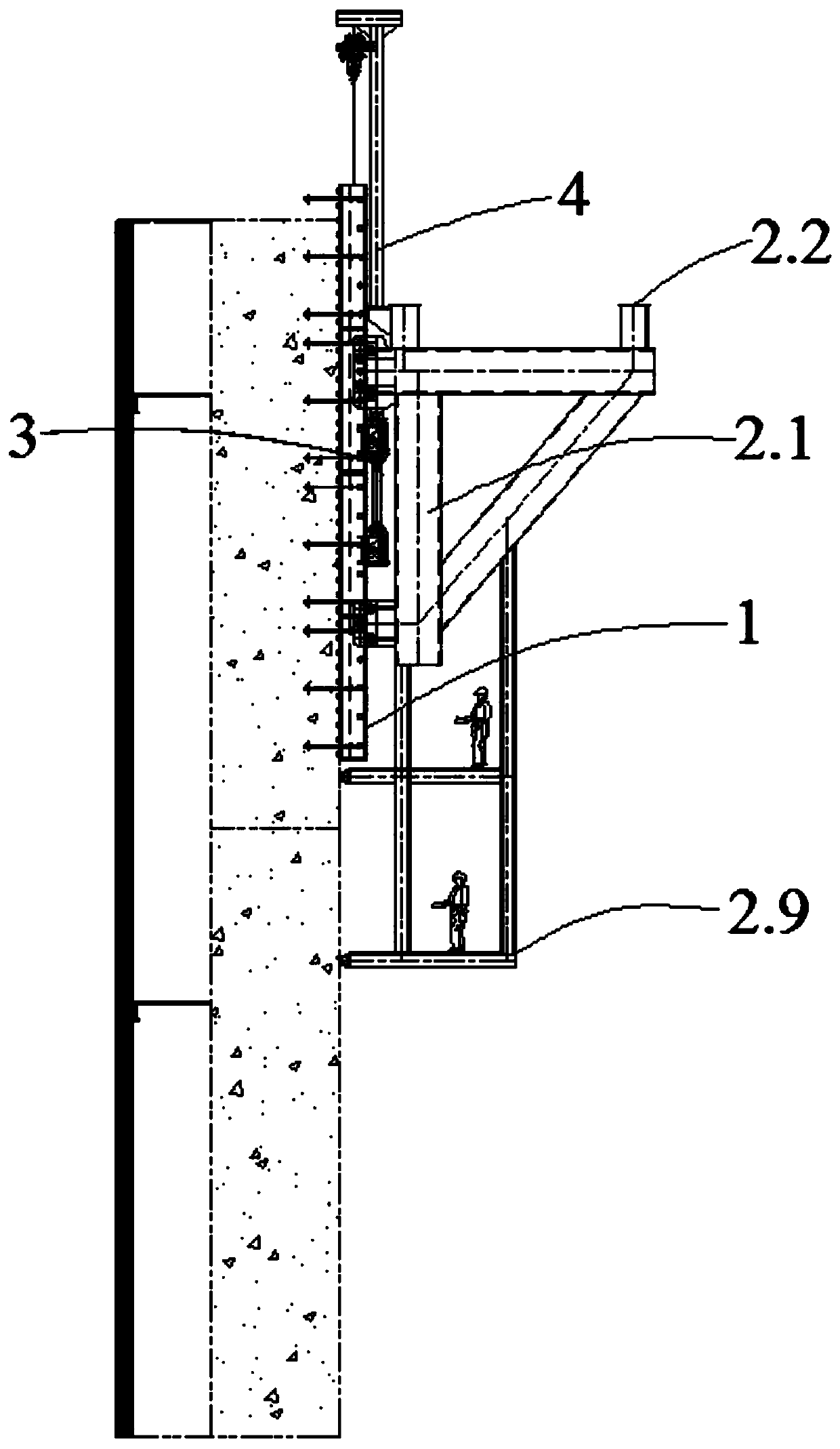

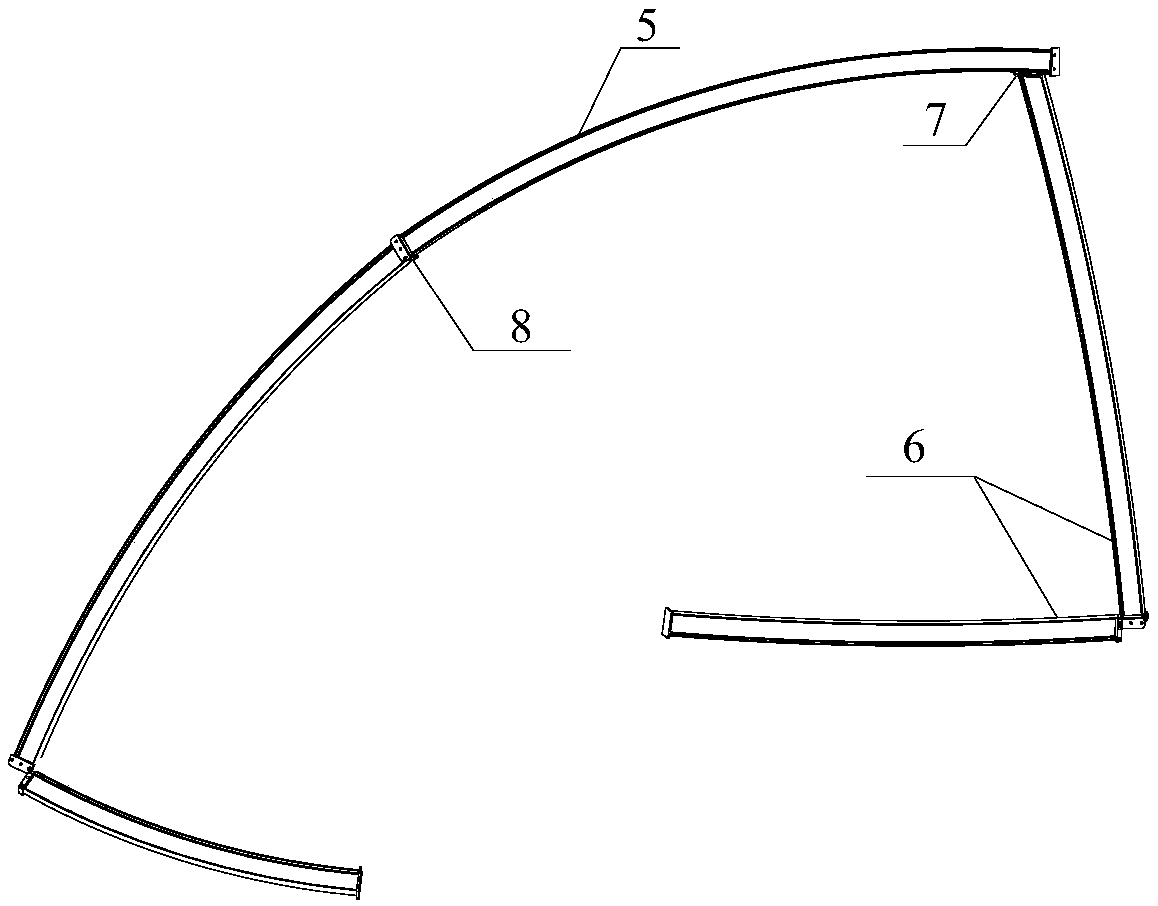

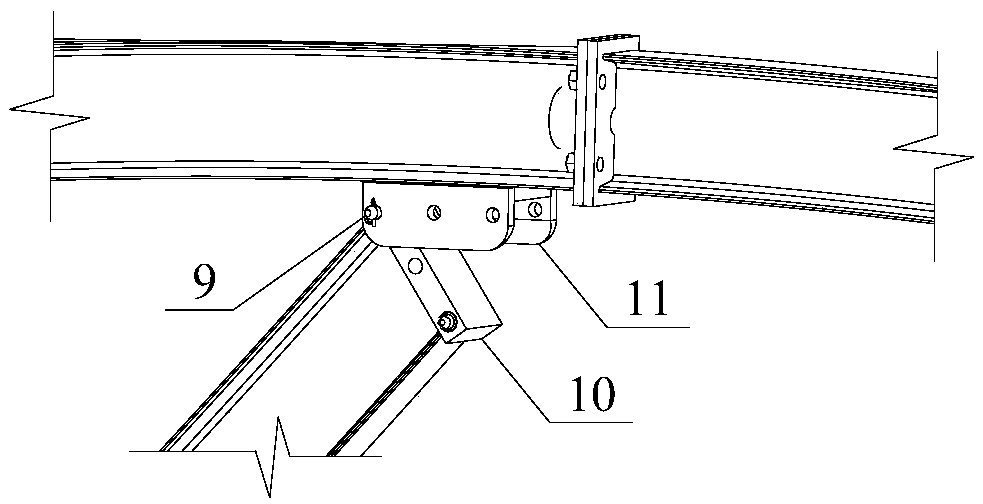

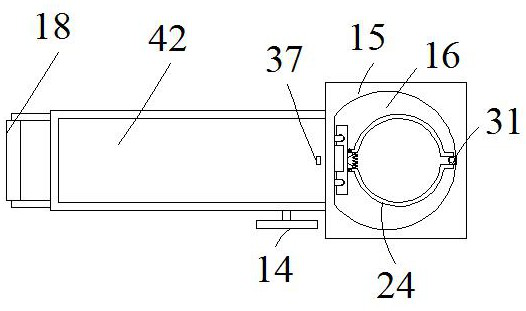

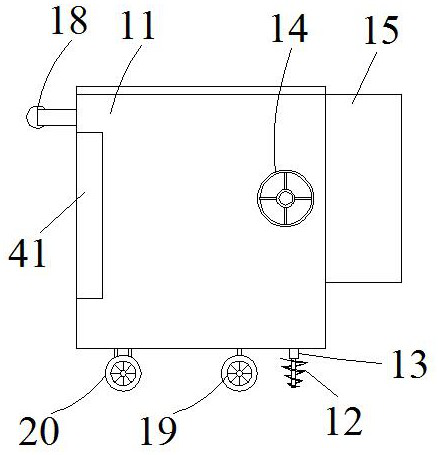

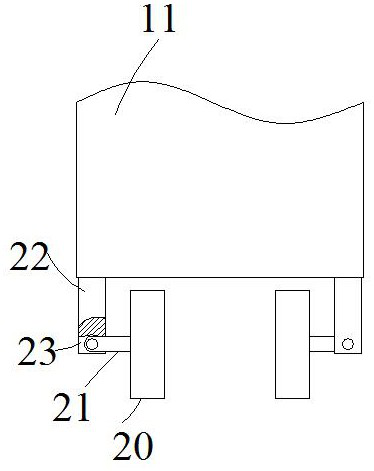

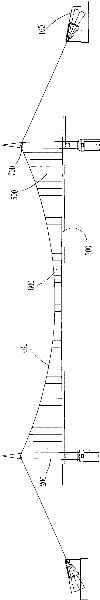

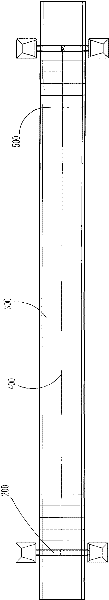

Automatic climbing platform for cable hanging construction

PendingCN110004834ASimple construction methodImprove construction safetyBridge structural detailsBridge erection/assemblyArchitectural engineeringTower

The invention relates to the technical field of bridge construction structures, and specifically discloses an automatic climbing platform for cable hanging construction. The automatic climbing platform for cable hanging construction comprises a platform bracket and is characterized in that the automatic climbing platform for cable hanging construction further comprises a detachable vertical rail anchored on the side wall of a cable tower, therail comprises a plurality of rail unit members connected end to end in the vertical direction, the platform bracket is connected with the rail and is driven by a climbing device on the platform bracket to climb along the rail, and the platform bracket is provided with a hoisting device and a lifting device used for hoistingstay cables. According to the automatic climbing platform for cable hanging construction,the structure is simple, operation is convenient, high tower cable hanging construction can be completed without a large-scale tower cranedevice,the construction cost and the construction difficulty are lowered, the construction safety is improved, the whole platform bracket is fixed on the outer side of the cable tower, wind resistanceperformance is good, and the automatic climbing platform for cable hanging construction is of great promotion value.

Owner:CCCC SECOND HARBOR ENG +1

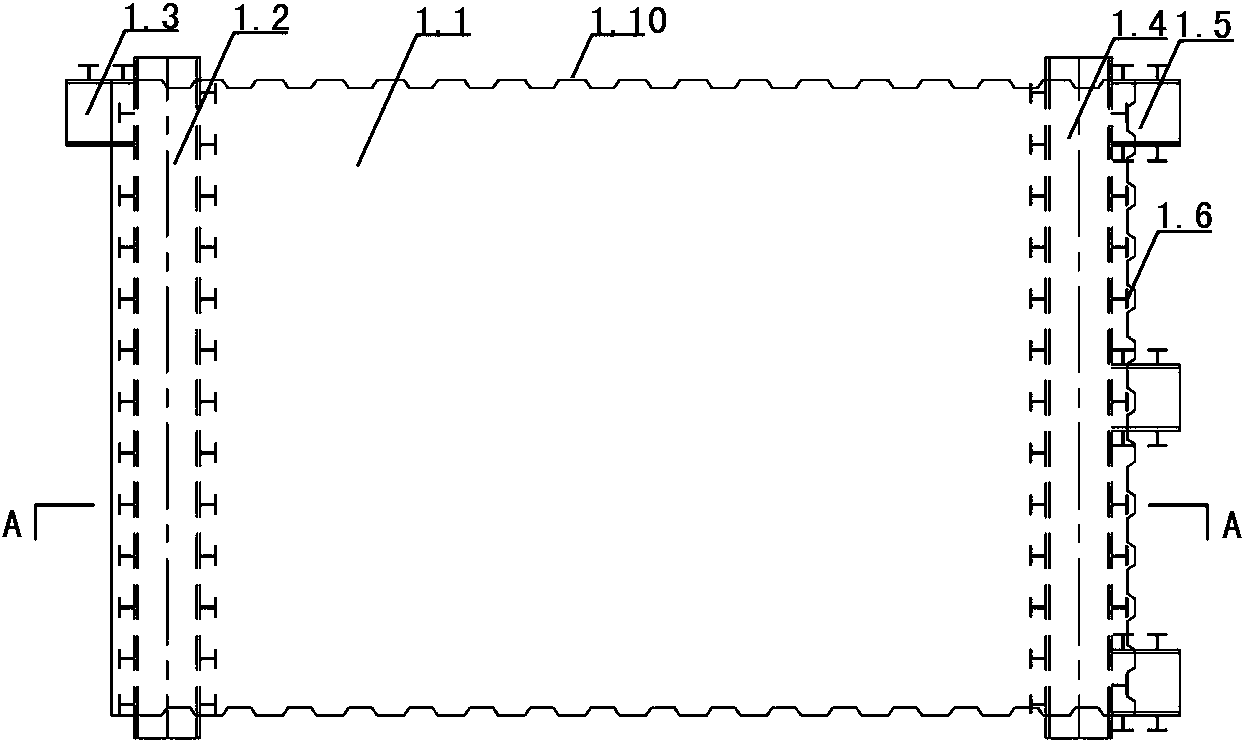

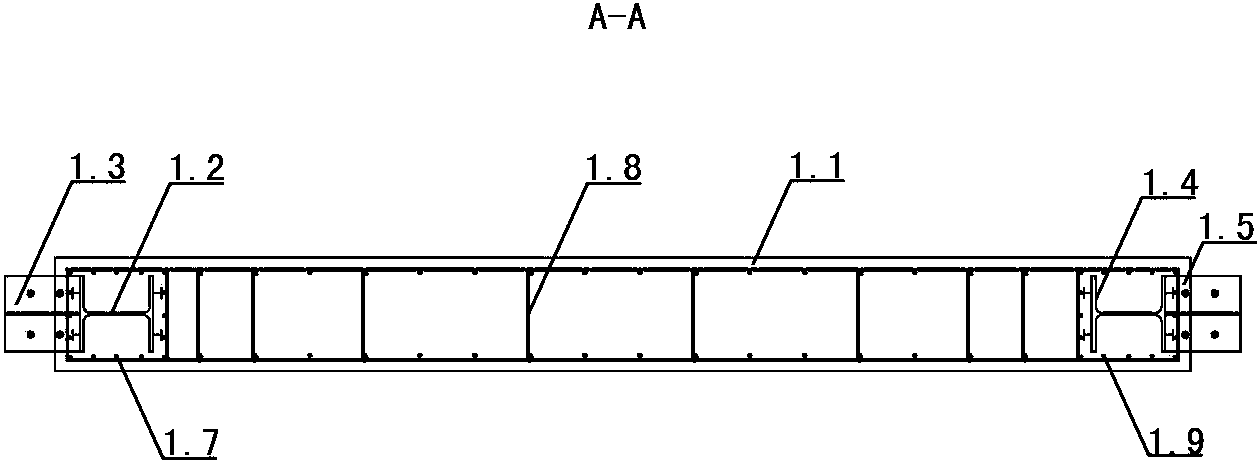

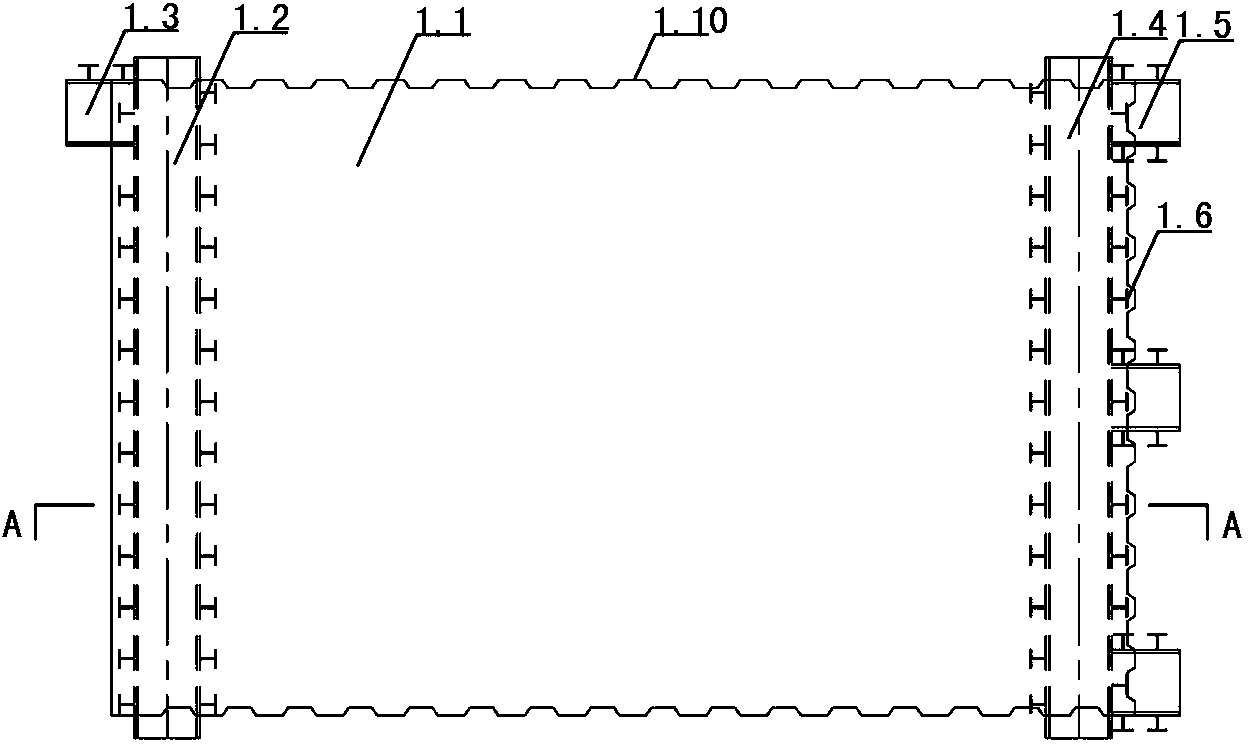

Assembly-type cross-shaped mixed coupled wall and construction method thereof

InactiveCN104032855AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type cross-shaped mixed coupled wall and a construction method thereof. The assembly-type cross-shaped mixed coupled wall comprises first wall units and a second wall unit which are connected together perpendicularly and form a cross shape. The first wall units are symmetrically distributed on the two sides of the second wall unit, the first wall units and the second wall unit are all prefabricated parts, and the first wall units and the second wall unit are connected through joint post-pouring belts. According to the assembly-type cross-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

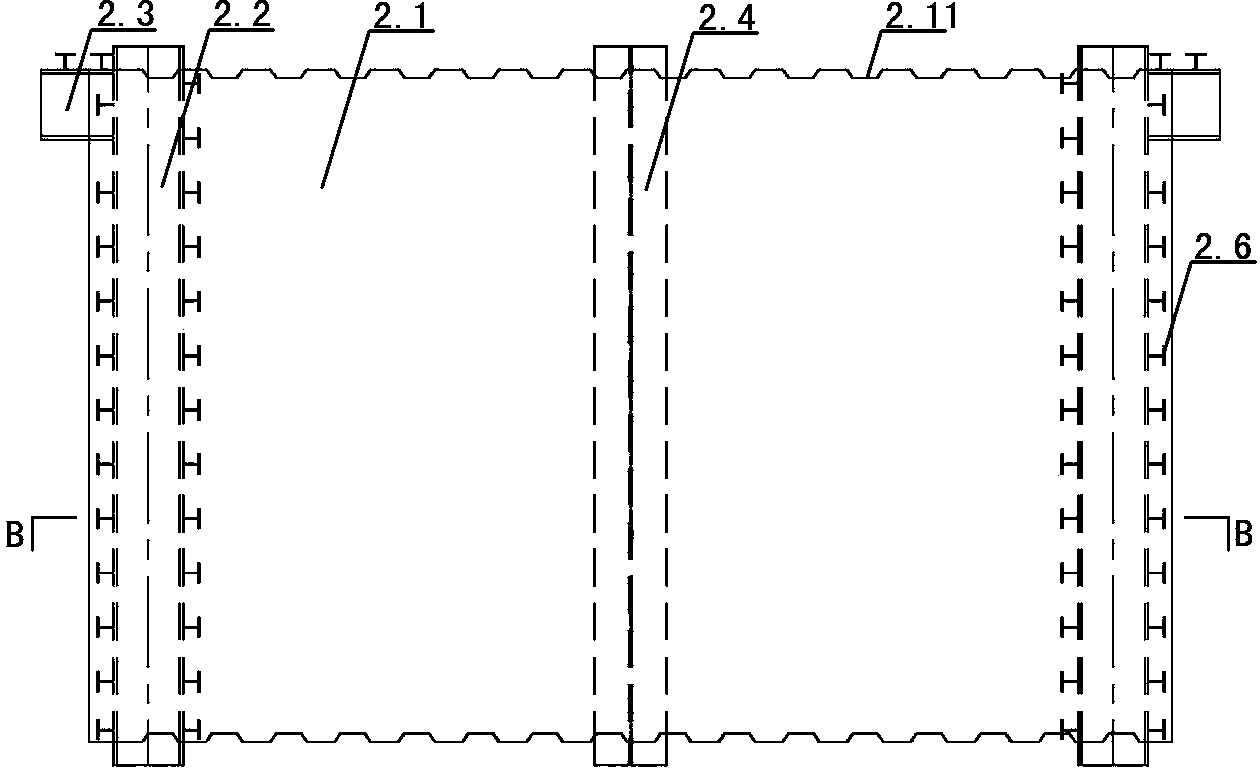

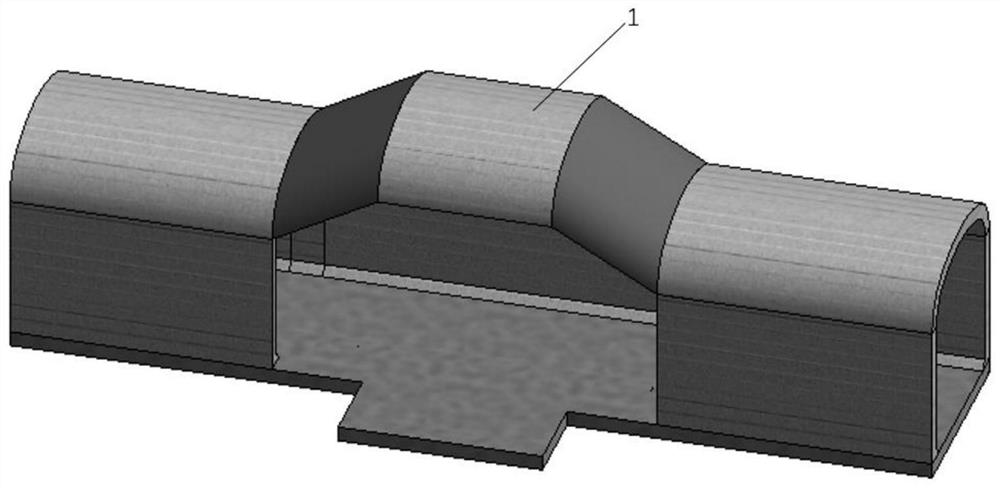

Method for treating unfavorable geology segment of diversion tunnel and major-diameter diversion tunnel structure

InactiveCN105114098AGuaranteed uptimeReduce difficultyUnderground chambersTunnel liningArchitectural engineeringLandslide

The invention discloses a method for treating an unfavorable geology segment of a diversion tunnel and a major-diameter diversion tunnel structure. Combined with self-stabilization of a round tunnel, initial stage support and secondary lining are adopted to prevent a weak rock stratum zone from landslide, so that a diversion tunnel can safely work. The method can treat an unfavorable geology segment having a weak rock stratum zone, difficulty during construction can be reduced, the method is practical and feasible, advanced, reasonable and high in efficiency, so the speed of construction can be raised, the cost of construction can be effectively reduced, the construction can be smoothly carried out, and the diversion tunnel can safely work in the later.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

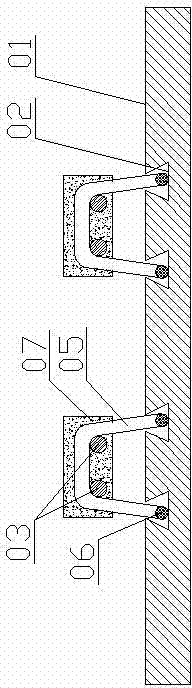

Internal support structure capable of solving pit bias problem in deep foundation pit and shallow foundation pit

The invention relates to the technical field of construction engineering, in particular to an inner support structure capable of solving the pit bias problem in a deep foundation pit and a shallow foundation pit. The inner support structure comprises underground diaphragm walls and a partition wall, and is characterized by further comprising a supporting beam and a middle inner support, wherein the underground diaphragm walls are located at the edge positions of the deep foundation pit and the shallow foundation pit, the partition wall is located at the junction of the deep foundation pit andthe shallow foundation pit, the supporting beam is laid at the bottom of the shallow foundation pit, and the middle inner support is located in the deep foundation pit; the supporting beam is of a reinforced concrete structure laid below a structure foundation in the shallow foundation pit and is supported between the underground diaphragm wall of the shallow foundation pit and the partition wallin the horizontal direction; and the middle inner support is a reinforced concrete structure which is supported between the underground diaphragm wall of the deep foundation pit and the partition wallin the horizontal direction and is flush with the supporting beam; and the middle inner support and the supporting beam are arranged on the two sides of the partition wall. The inner support structure has the advantages that the construction structure is simple, a construction method is efficient, simple and simple, the foundation pit construction in-building stability can be improved, the cost of the inner supporting structure can be lowered, and great popularization values can be achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

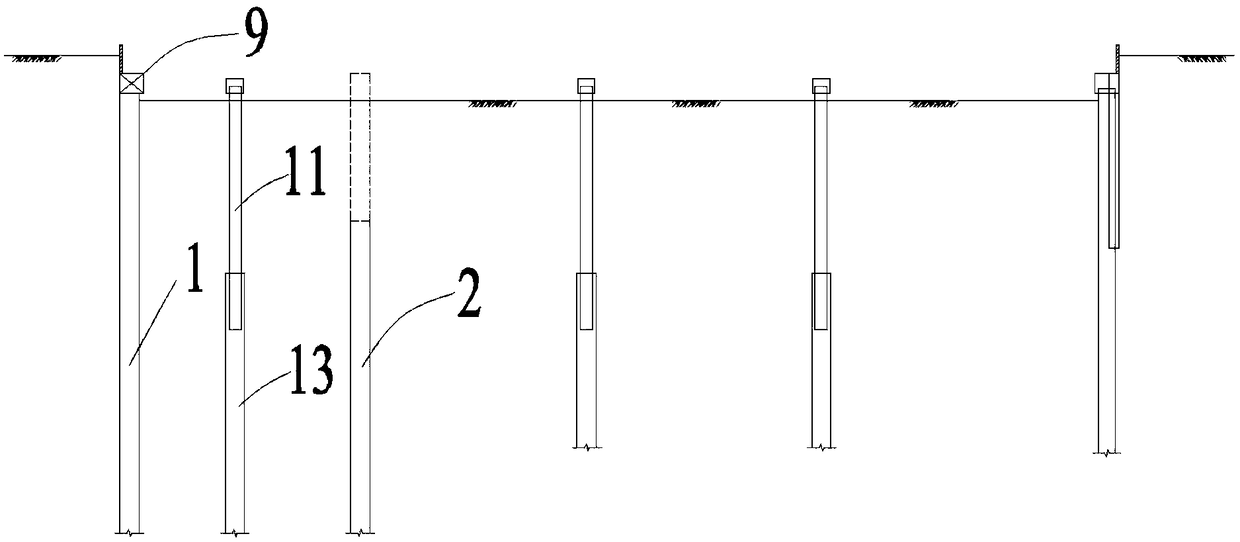

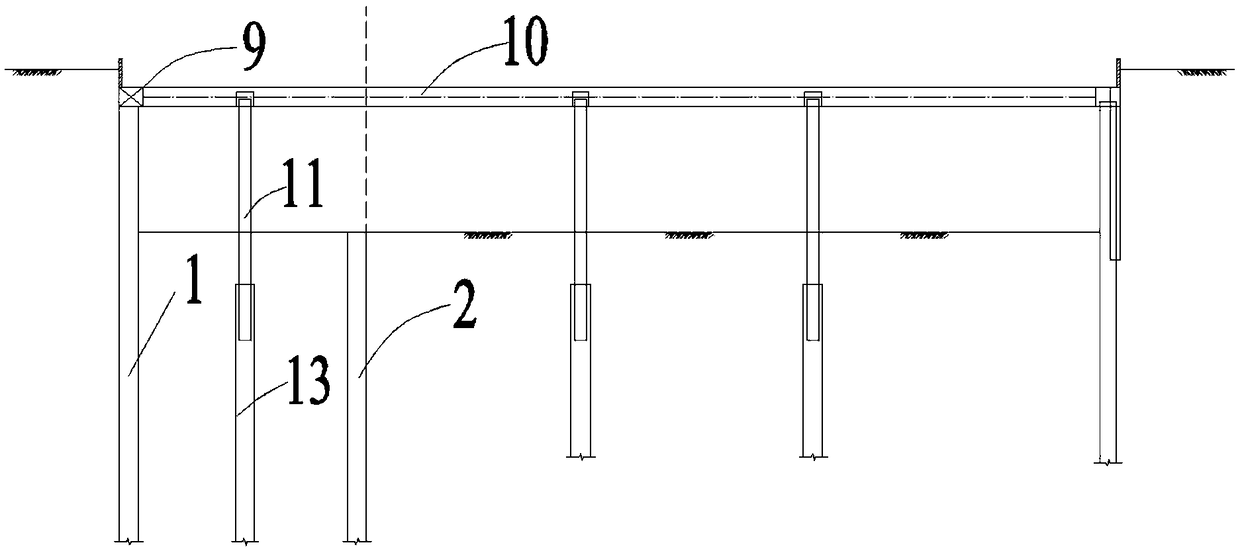

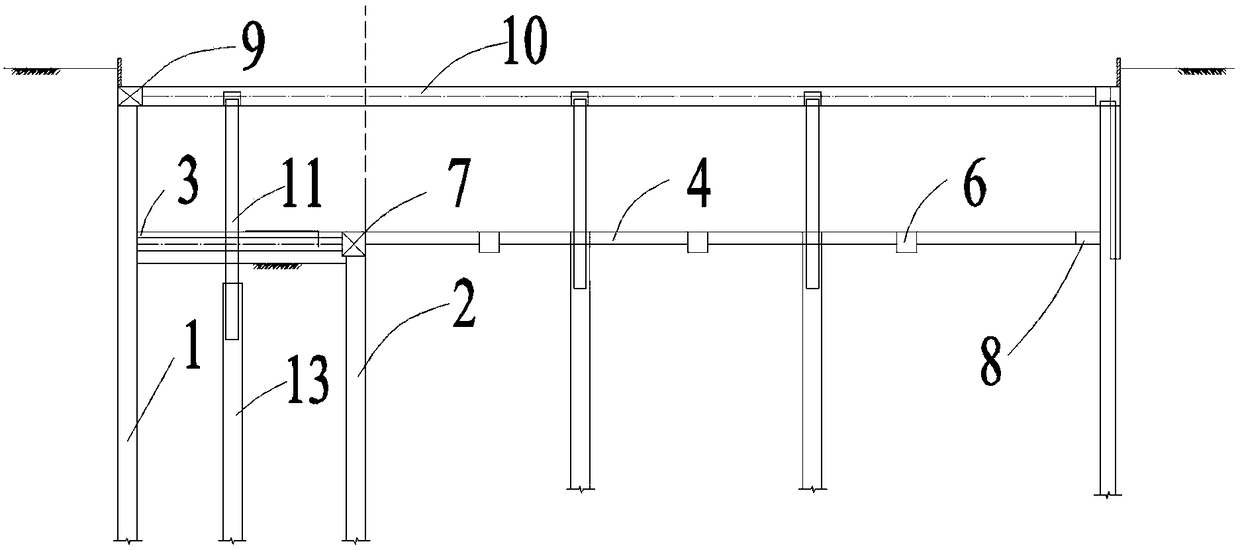

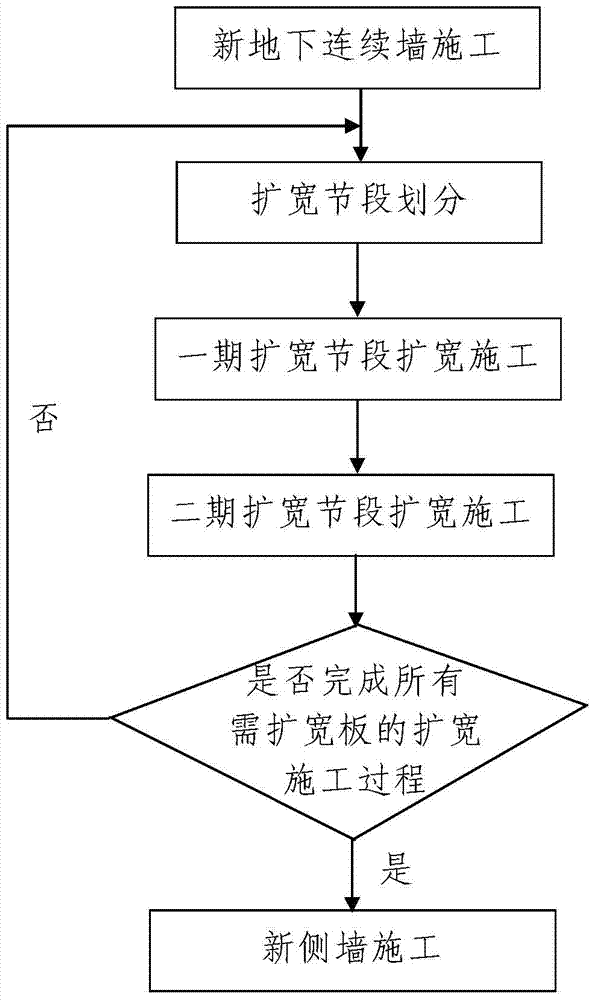

Safe stress conversion construction method for improvement on main structure of subway station

ActiveCN103485366ASimplify construction stepsEasy constructionArtificial islandsUnderwater structuresSlurry wallSubway station

The invention discloses a safe stress conversion construction method for the improvement on a main structure of a subway station. The safe stress conversion construction method comprises the following steps: the first step is construction of a novel underground diaphragm wall; the second step is broadening construction, wherein a top plate, a middle plate and a bottom plate are respectively broadened from top to bottom, the top plate, the middle plate and the bottom plate all need broadening, and the broadening construction method of the top plate, the broadening construction method of the middle plate and the broadening construction method of the bottom plate are the same; an actual broadening construction process comprises broadening segment division, first-stage broadening segment broadening and second-stage broadening segment broadening; the third step is construction of a novel side wall, wherein a second left side wall and a second right side wall are constructed on the left side and the right side of the multiple broadened plates respectively after broadening construction in the second step is completed. According to the safe stress conversion construction method for the improvement on the main structure of the subway station, the steps are simple, the design is reasonable, implementation is convenient, investment cost is low, construction progress is fast, the construction effect is good, and the improvement process of the main structure of the subway station can be completed simply, conveniently and quickly.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

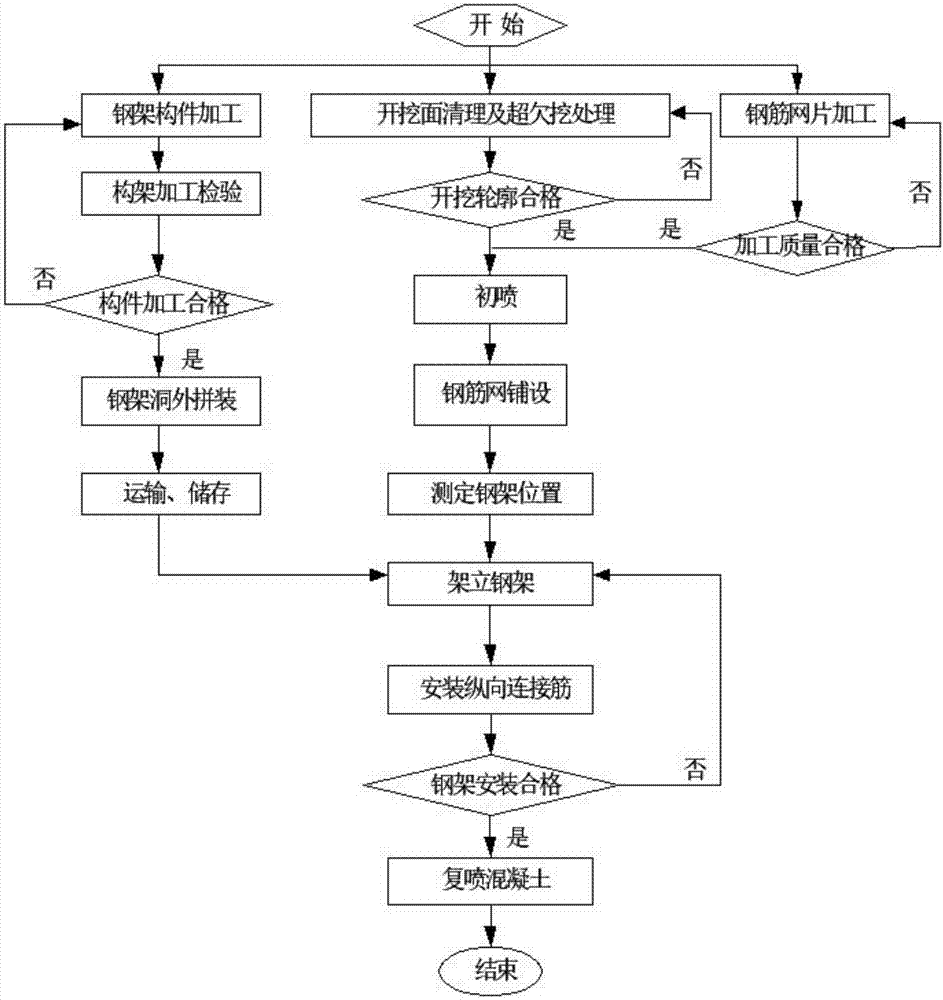

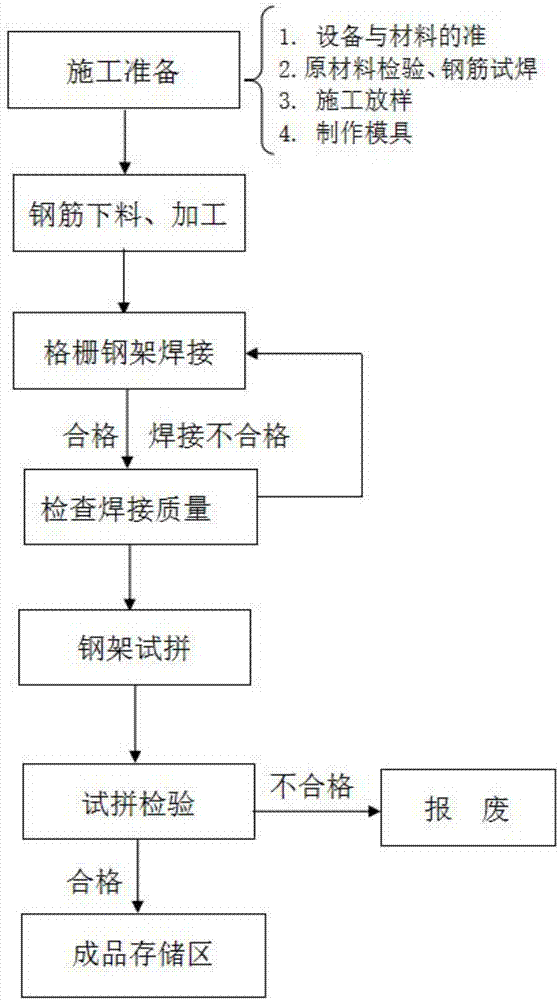

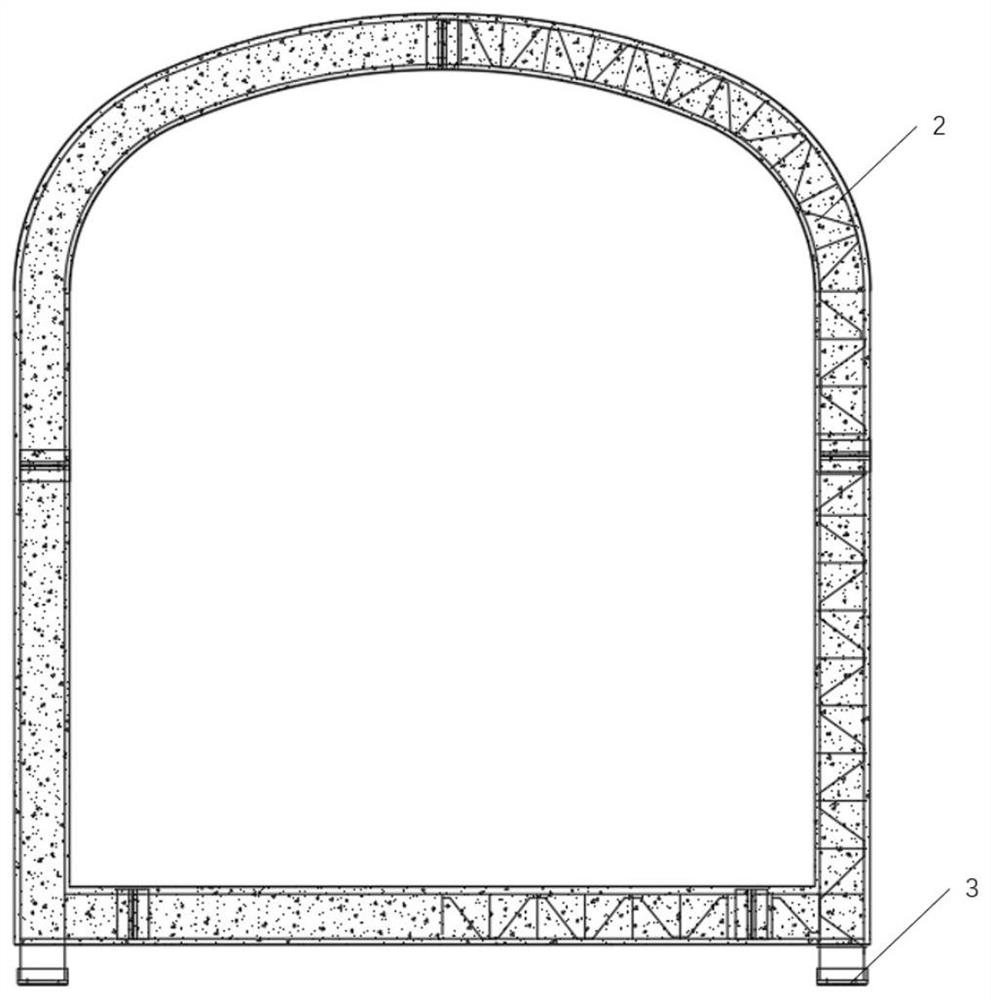

Method for enhancing supporting by grid arch rack during large-section tunnel excavation construction

InactiveCN107130983AEnsure safetyAvoid softeningUnderground chambersTunnel liningEffective solutionRock tunnel

The invention belongs to the technical field of large-section tunnel construction. In the actual engineering construction, for the unstable rock stratum which is soft in soil texture and thicker in accumulative formation, the existing supporting method is difficult to meet the safety and technical quality requirements of tunnel engineering construction, so that the invention discloses a method for enhancing supporting by a grid arch rack during large-section tunnel excavation construction. The method adopts a combined supporting way of initial support of anchor rod reinforcing mesh concrete and reinforced support of the steel grid arch rack, thus effectively guaranteeing the safety of constructors and tunnel structures, preventing the softening action of water on surrounding rock, fully exerting the self-bearing ability of the surrounding rock, and effectively solving the problem that the existing supporting method is difficult to meet the safety and technical quality requirements of the tunnel engineering construction for the unstable rock stratum which is soft in soil texture and thicker in accumulative formation.

Owner:GUIZHOU KAILIN CONSTR GRP CO LTD

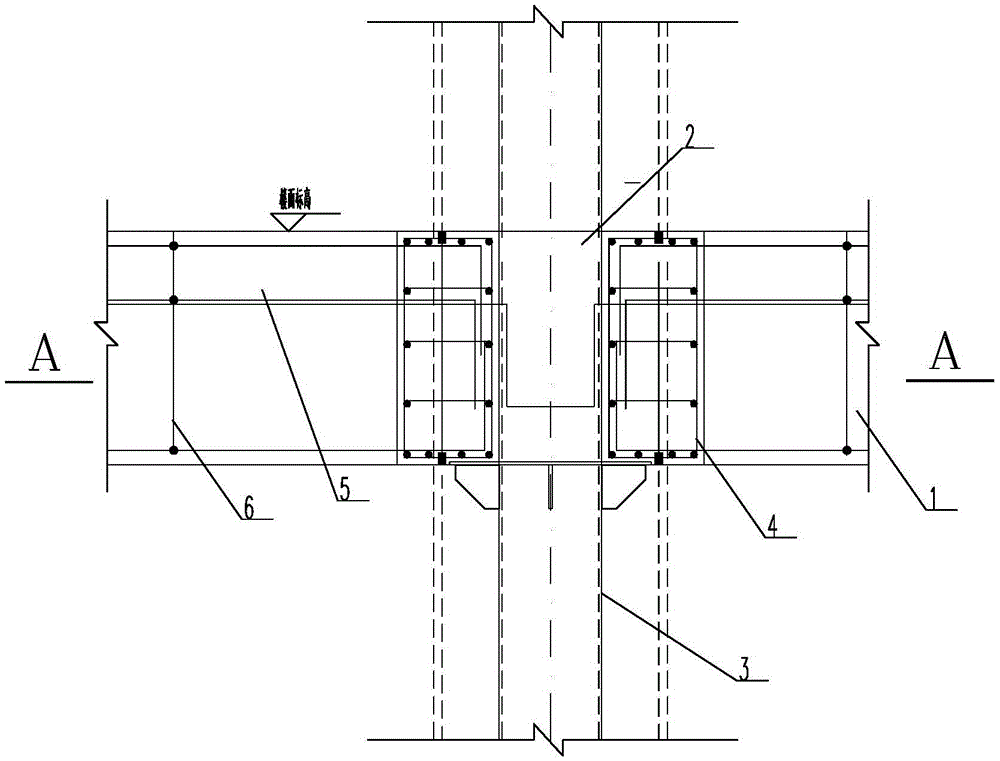

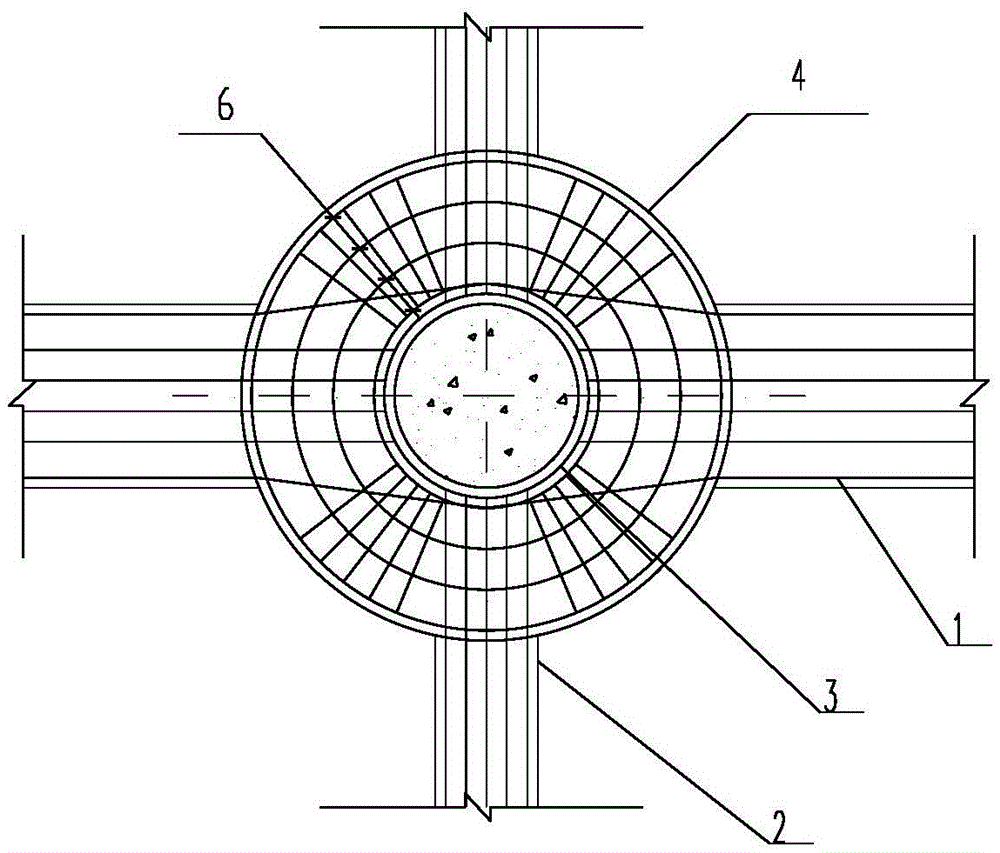

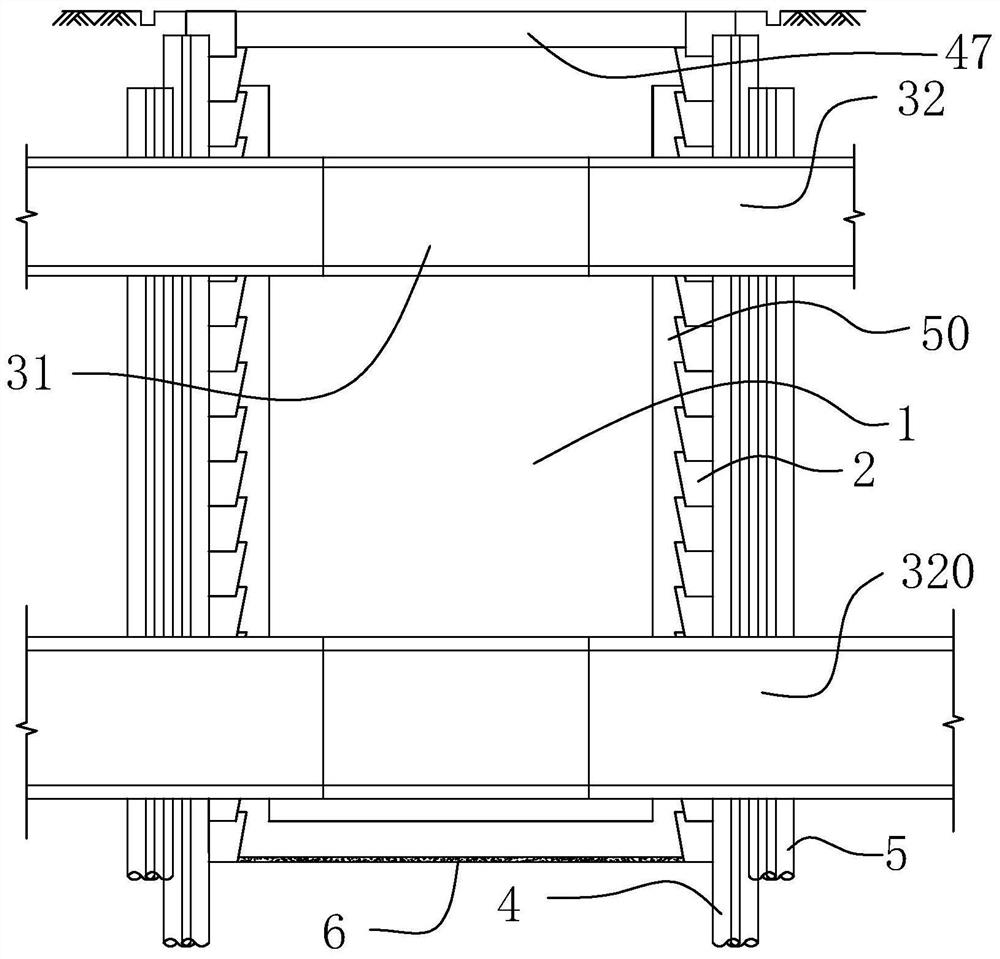

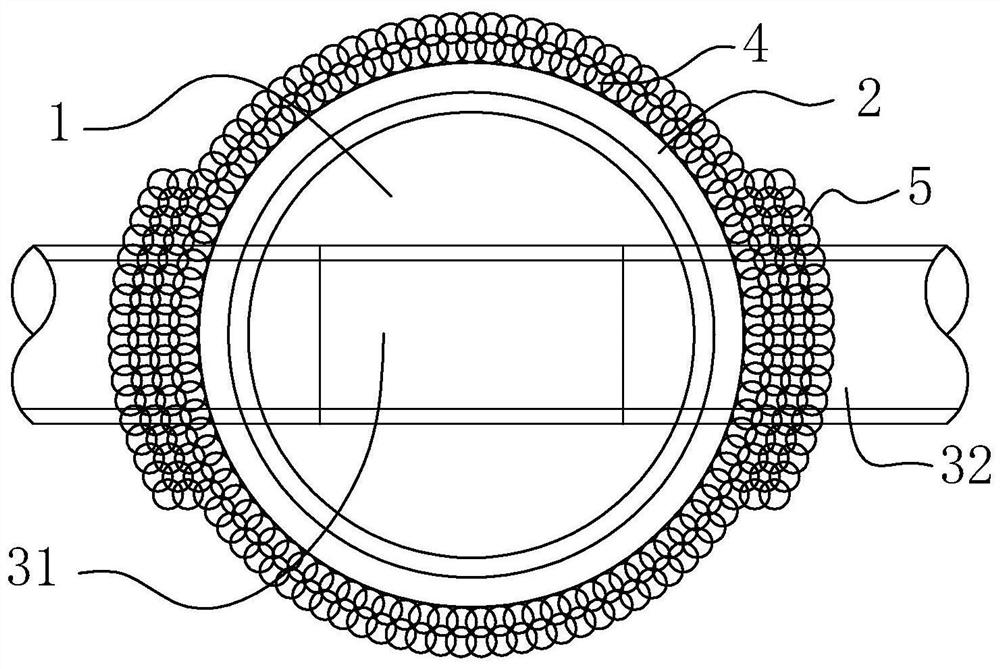

Profiled steel structure beam column joint for reverse construction of stiffened structure and construction method

InactiveCN105649217AEfficient construction methodsReduce construction costsBuilding material handlingRebarSteel plates

The invention relates to a profiled steel structure beam column joint for reverse construction of a stiffened structure and a construction method and belongs to the technical field of building construction. By the adoption of the profiled steel structure beam column joint for reverse construction of the stiffened structure and the construction method, the problems that due to the fact that a concrete ring beam or a column cap is arranged on a traditional beam column joint, the sectional dimension of the beam column joint is too large, a building structure is affected, steel bars on the beam column joint are dense, and beam main steel bars of a frame beam cannot meet the requirement for the anchoring length are solved. According to the beam column joint, two parallel transverse steel ring plates are welded to the outer wall of a circular pipe column located on the beam column joint, the end of an H-shaped steel beam close to the beam column joint is arranged between the two steel ring plates in a clamped mode, and the steel ring plates are further provided with cantilever steel plates in the length direction of a frame beam. The construction method comprises the steps that firstly, the steel ring plates are manufactured for later use; secondly, the steel ring plates are welded to the circular pipe column on the beam column joint; thirdly, longitudinal column main steel bars of a frame column are made to penetrate through the gap between the cantilever steel plates which are adjacent in the axial direction; and finally, the beam main steel bars of the frame beam are arranged and bound.

Owner:SHANGHAI CONSTR NO 1 GRP +1

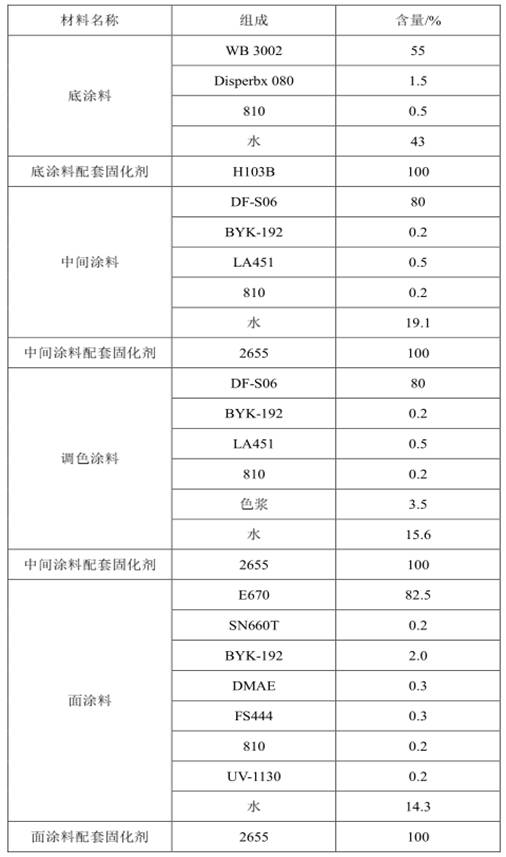

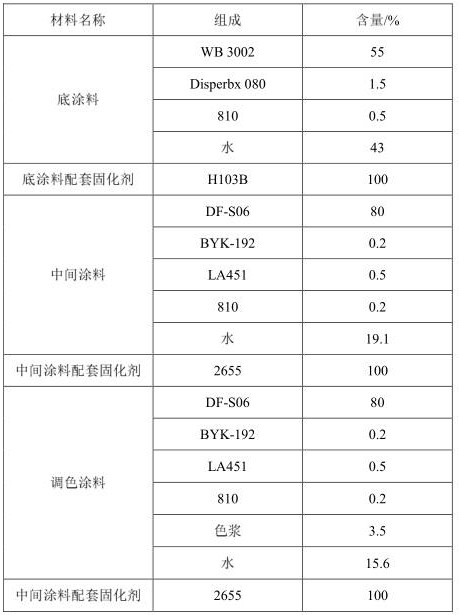

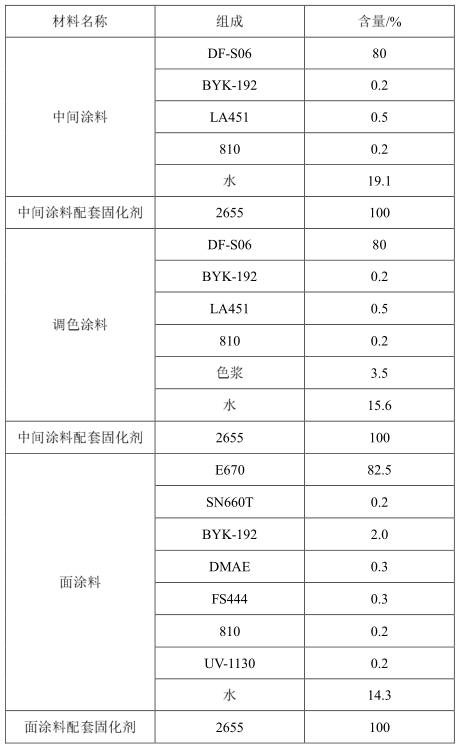

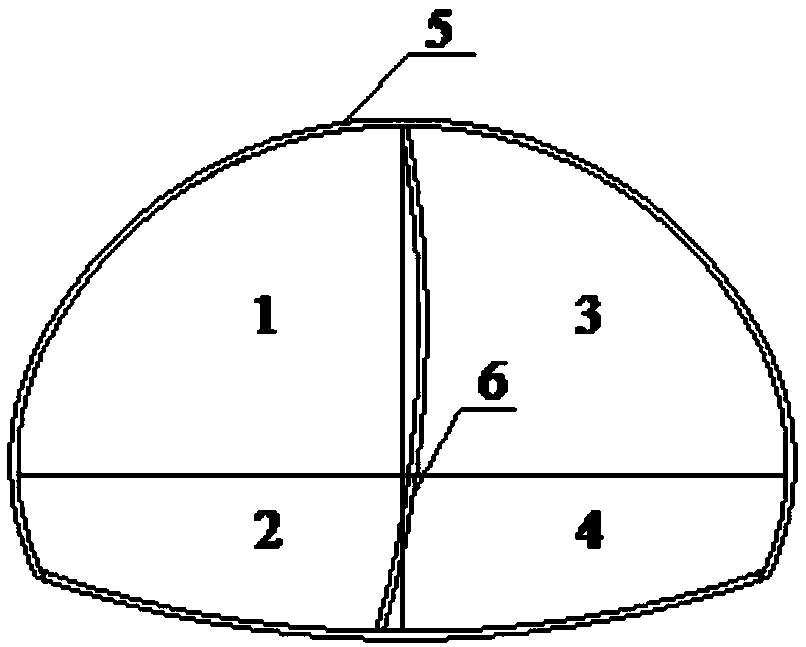

Water-based high-weather-resistance fair-faced concrete protective coating system and preparation method thereof

The invention discloses a water-based high-weather-resistance fair-faced concrete protective coating system and a preparation method thereof, and belongs to the technical field of building materials.The protective coating system is a composite coating system of a water-borne epoxy resin cured coating, a water-borne fluorocarbon resin cured coating, a water-borne fluorocarbon resin cured coating containing color paste and a water-borne fluorocarbon resin cured coating with high fluorine content. The protective coating system is simple in construction process, green and environment-friendly; the excellent performances of strong bonding force, good corrosion resistance, good weather resistance, long service life and the like are realized. According to the fair-faced concrete protective coating, the intrinsic aesthetic feeling of fair-faced concrete can be reserved, the protective effects of super-strong weather resistance, super-strong bonding force and no peeling or falling after long-term use can be provided, the service life of a concrete structure is further prolonged, and the fair-faced concrete protective coating is suitable for long-acting protection of various fair-faced concrete buildings.

Owner:湖南固特邦土木技术发展有限公司

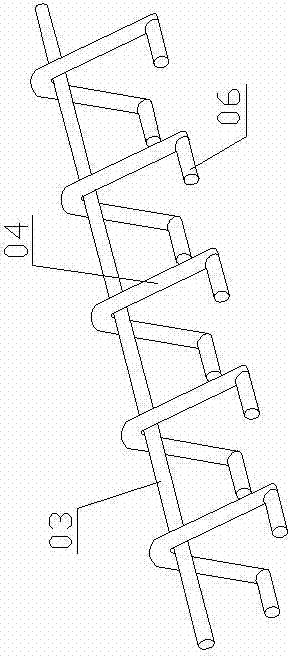

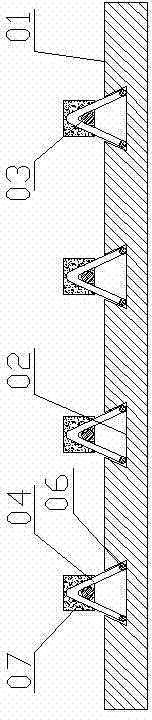

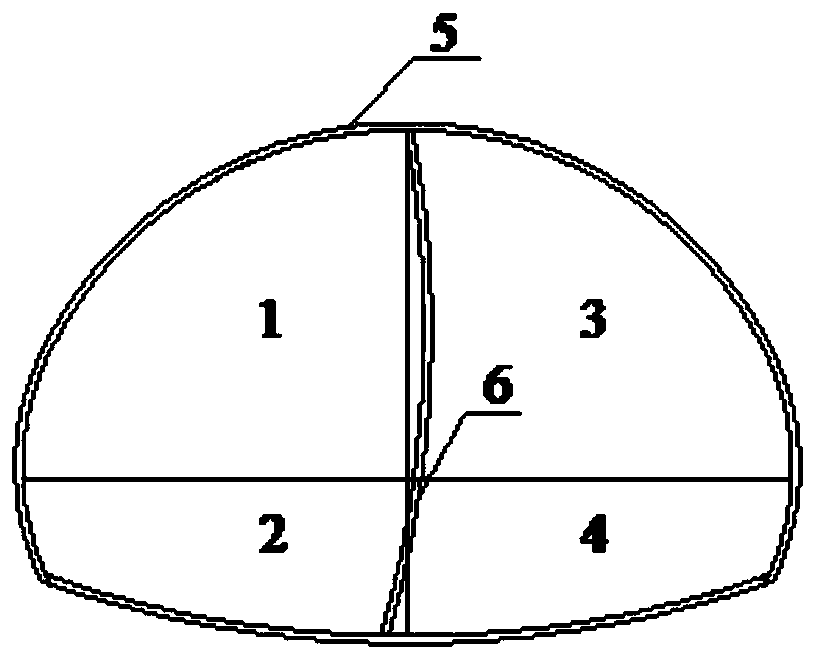

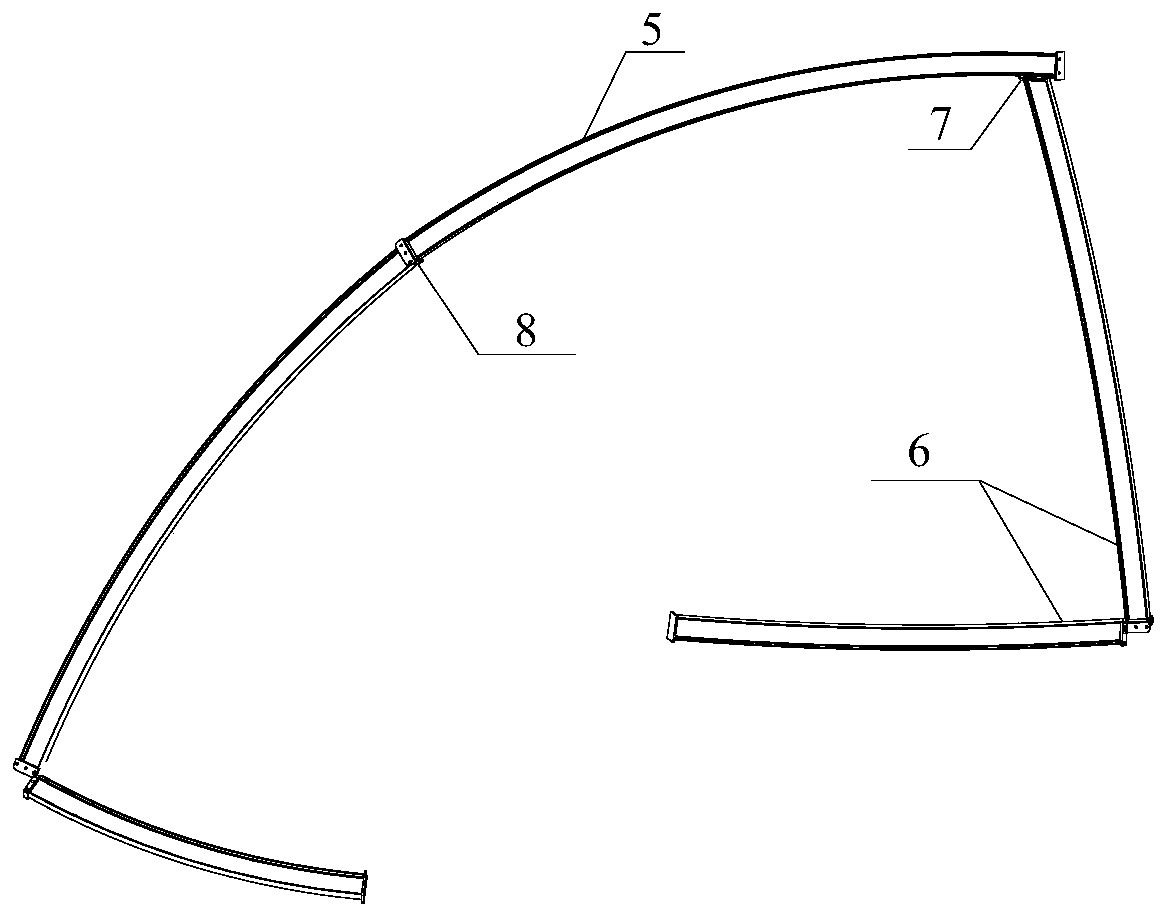

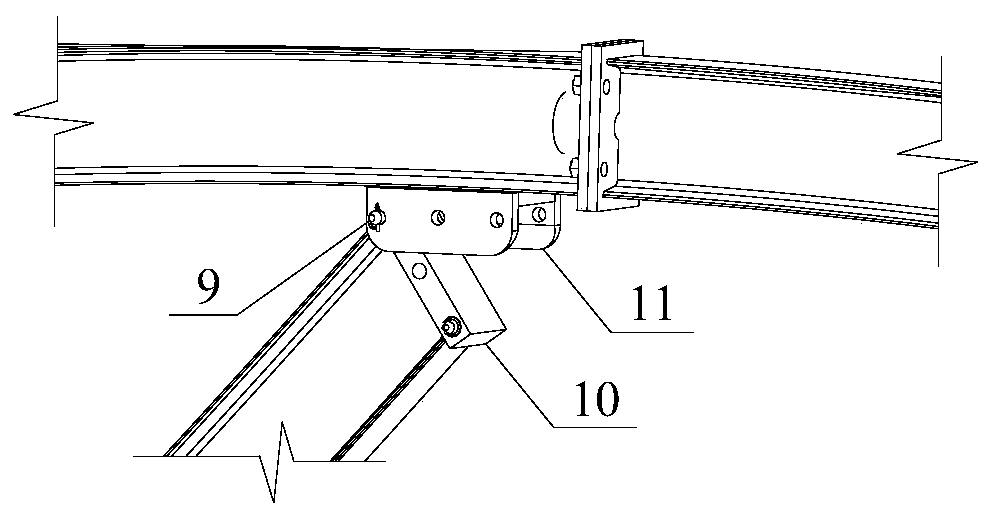

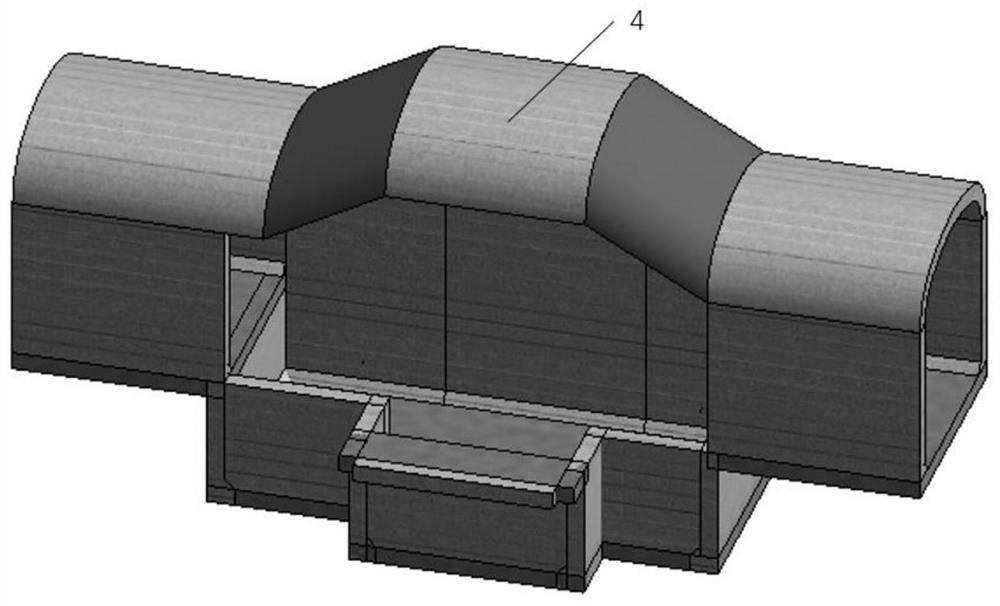

Tunnel sectional excavation assembly-type arch frame and mechanized construction technology;

ActiveCN108643923AImprove construction efficiencyImprove securityUnderground chambersTunnel liningBuilding construction

The invention discloses a tunnel sectional excavation assembly arch frame and mechanized construction technology. An excavation process of a tunnel CD method is taken as an example, the arch frame isfolded according to sectional sections, and an arch frame assembling machine lifts the arch frame to the front of a tunnel face; the arch frame of a first excavation part and temporary support are connected and fixed, and the arch frame is grabbed and lifted by the arch frame assembling machine, and the arch frame and the temporary support are fully spread and positioned; an inverted-arch arch frame of a second excavation part on the lower portion of the left side and the temporary support of the remaining part are installed and are connect with the arch frame of a first excavation part on theupper portion of the left side and temporary support; a supporting arch frame of a third excavation part on the upper portion of the right side is installed and is connected with the arch frame of the first excavation part on the upper portion of the left side; and an inverted-arch of a excavation part on the lower portion of the right side is installed and is connected with and the supporting arch frame of the third excavation part on the upper portion of the right side and the inverted-arch of the second excavation part on the lower portion of the left side. The mechanized installation of asectional support structure is achieved, the construction efficiency is improved, and the construction safety is ensured.

Owner:SHANDONG UNIV +1

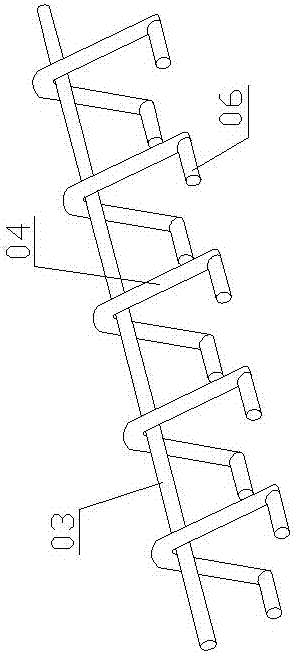

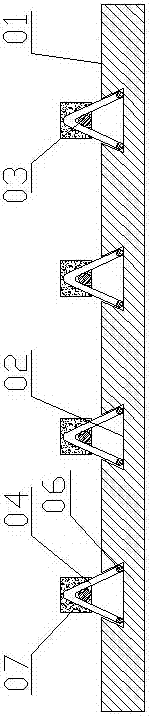

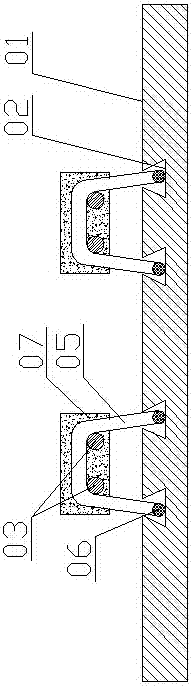

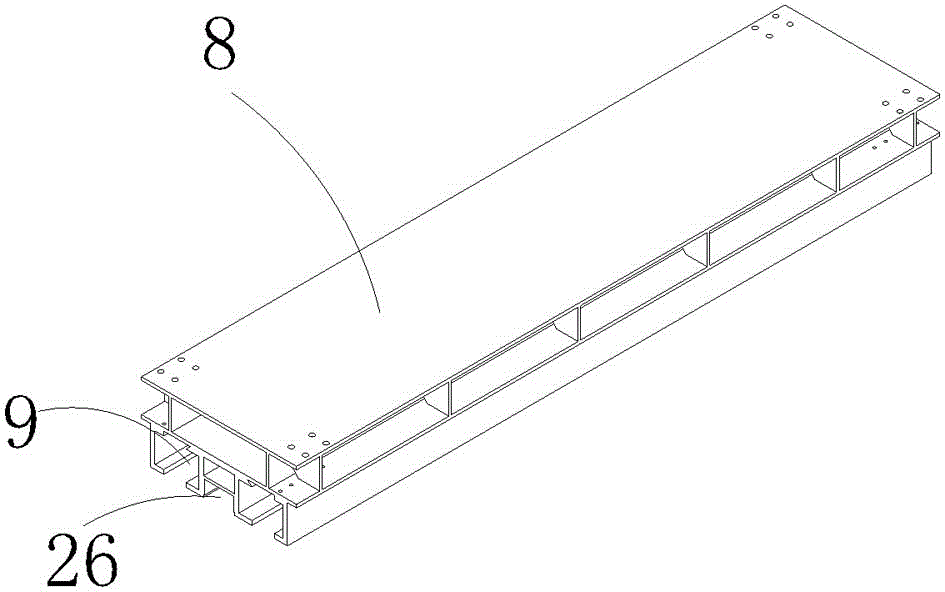

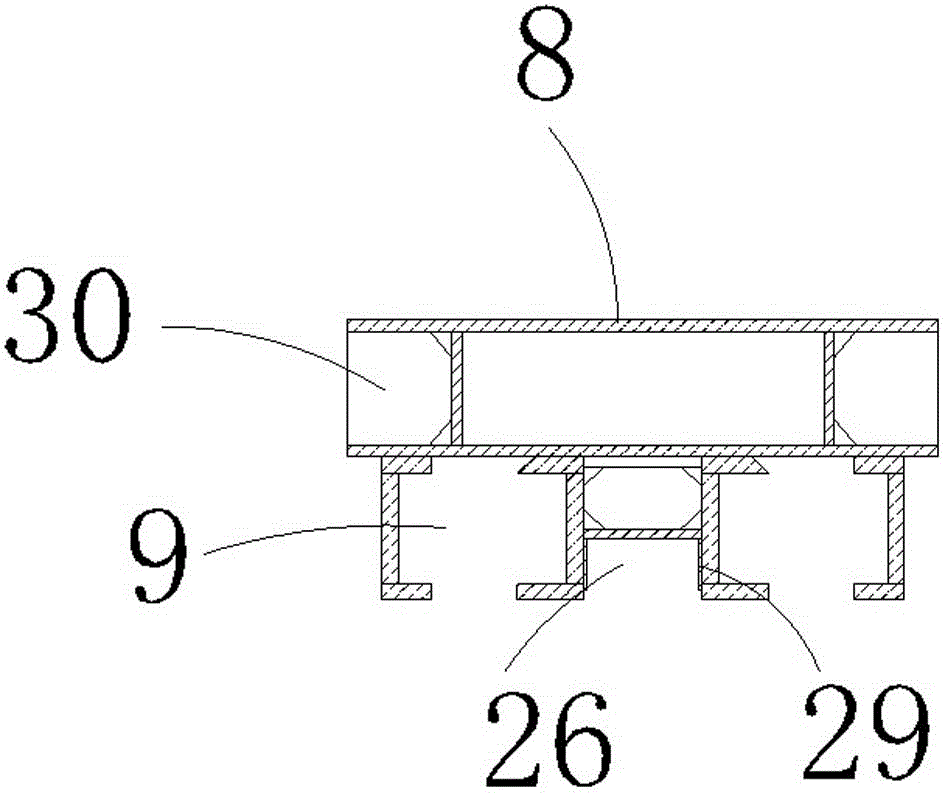

Processing method of prestressed composite slab with bracket

ActiveCN104493973ASimple construction methodEasy to apply prestressCeramic shaping apparatusComposite slabPulp and paper industry

The invention provides a processing method of a prestressed composite slab with a bracket, and belongs to the technical field of processing and production of building components. The processing method comprises the following steps of (1) enabling processing equipment of the composite slab with a top groove to manufacture a composite slab body with the top groove, and welding the bracket which is arranged in the groove of the composite slab body in a matching way; (2) arranging the bottom part of the bracket in the groove of the composite slab body, and casting high-fluidity filler, or casting the high-fluidity filler in the groove of the composite slab body, and placing the bracket; (3) curing and forming the composite slab with the bracket. The processing method has the advantages that the composite slab body with the top groove is manufactured by the processing equipment of the composite slab with the top groove, then the bracket is arranged in the top groove of the composite slab body, and the high-fluidity filler is cast in the top groove, or the high-fluidity filler is cast in the groove of the composite slab body, and the bracket is arranged, so the prestressed composite slab with the bracket is processed completely; the construction method is simple, and the efficiency is high.

Owner:山东乾元泽孚科技股份有限公司

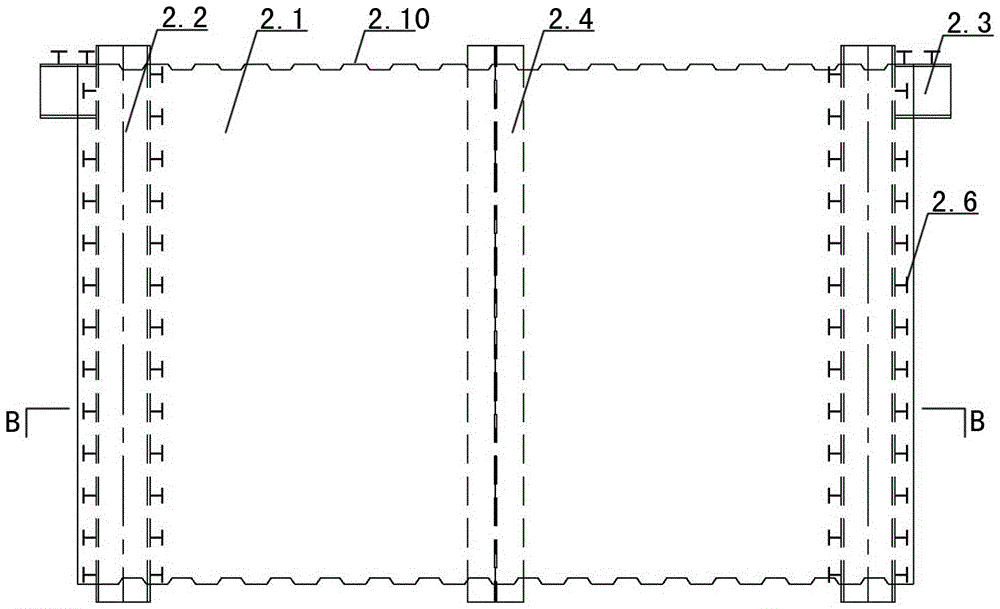

Assembly-type steel beam joint L-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type steel beam joint L-shaped mixed coupled wall and a construction method thereof. The assembly-type steel beam joint L-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form an L shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type steel beam joint L-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

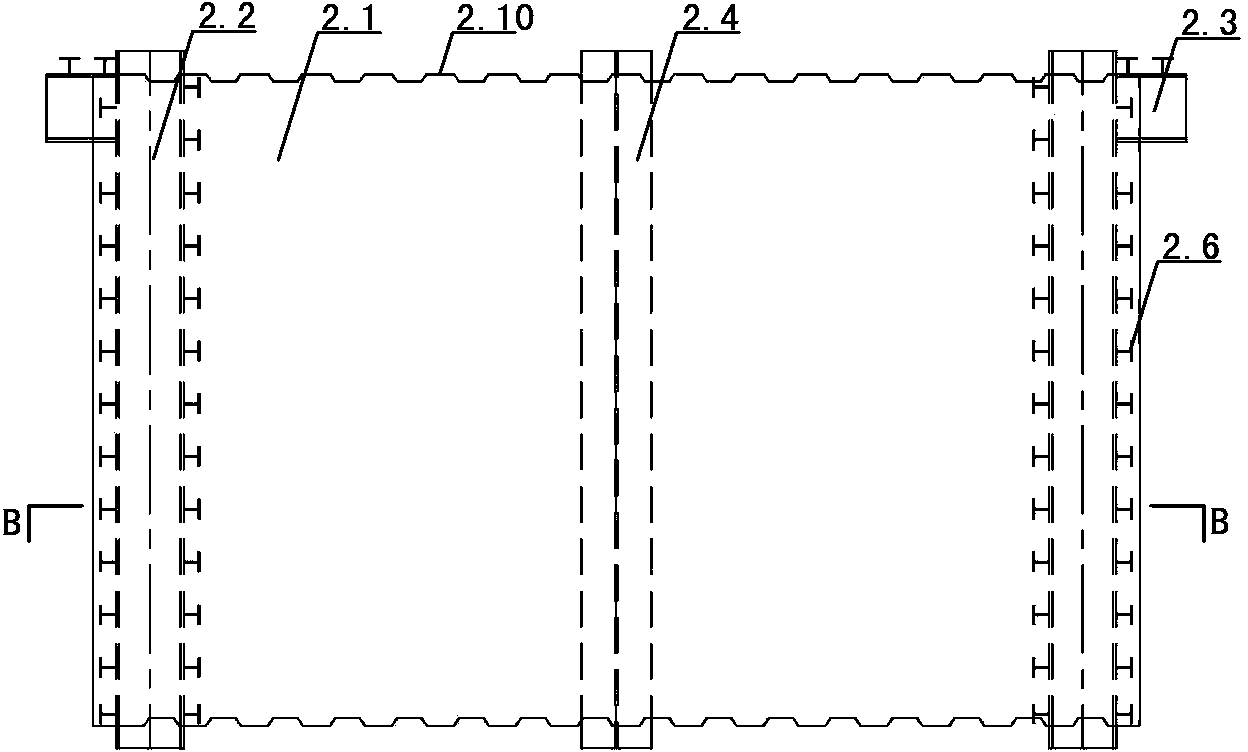

Assembly-type steel beam joint cross-shaped mixed coupled wall and construction method thereof

ActiveCN104032857ASimple construction methodFast constructionWallsShock proofingSteel columnsSteel bar

Disclosed are an assembly-type steel beam joint cross-shaped mixed coupled wall and a construction method thereof. The assembly-type steel beam joint cross-shaped mixed coupled wall comprises first wall units and a second wall unit which are connected together perpendicularly and form a cross shape. The first wall units are symmetrically distributed on the two sides of the second wall unit, the first wall units and the second wall unit are all prefabricated parts, and the first wall units and the second wall unit are connected through joint post-pouring belts. According to the assembly-type steel beam joint cross-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

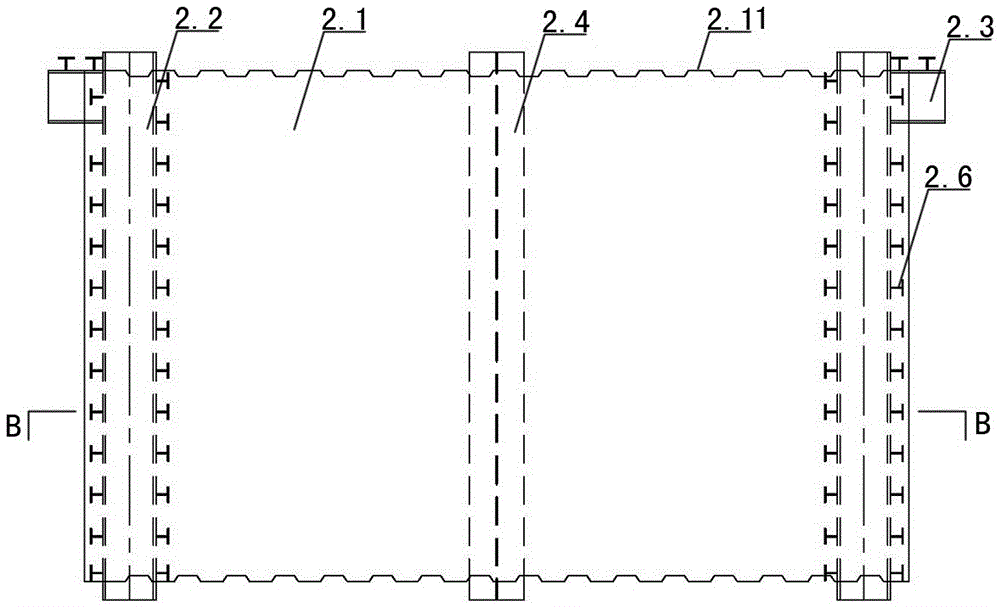

Assembly-type steel beam joint linear mixed coupled wall and construction method thereof

InactiveCN104032858AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type steel beam joint linear mixed coupled wall and a construction method thereof. The assembly-type steel beam joint linear mixed coupled wall comprises a first wall unit and a second wall unit which are connected and are arranged in a linear mode. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type steel beam joint linear mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

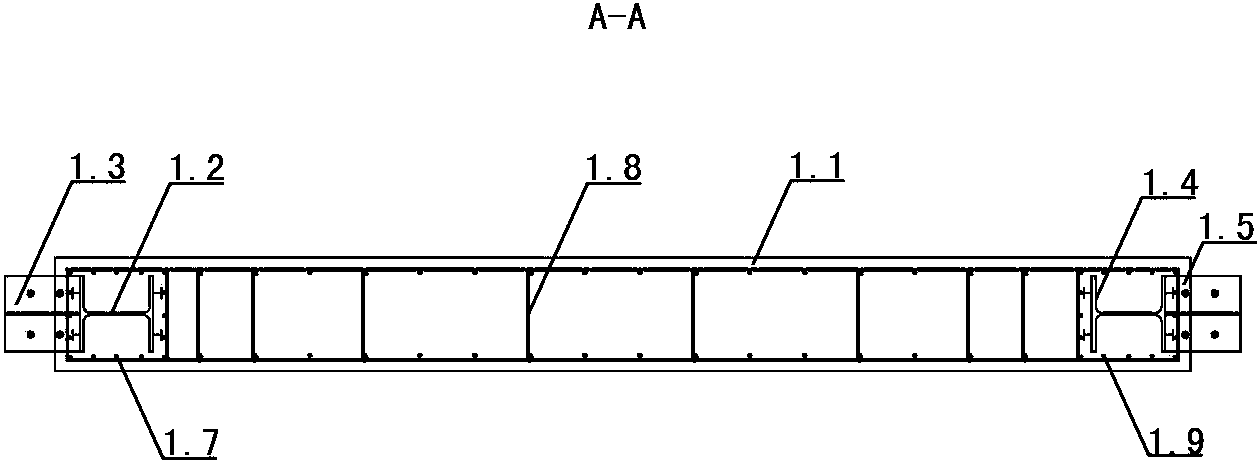

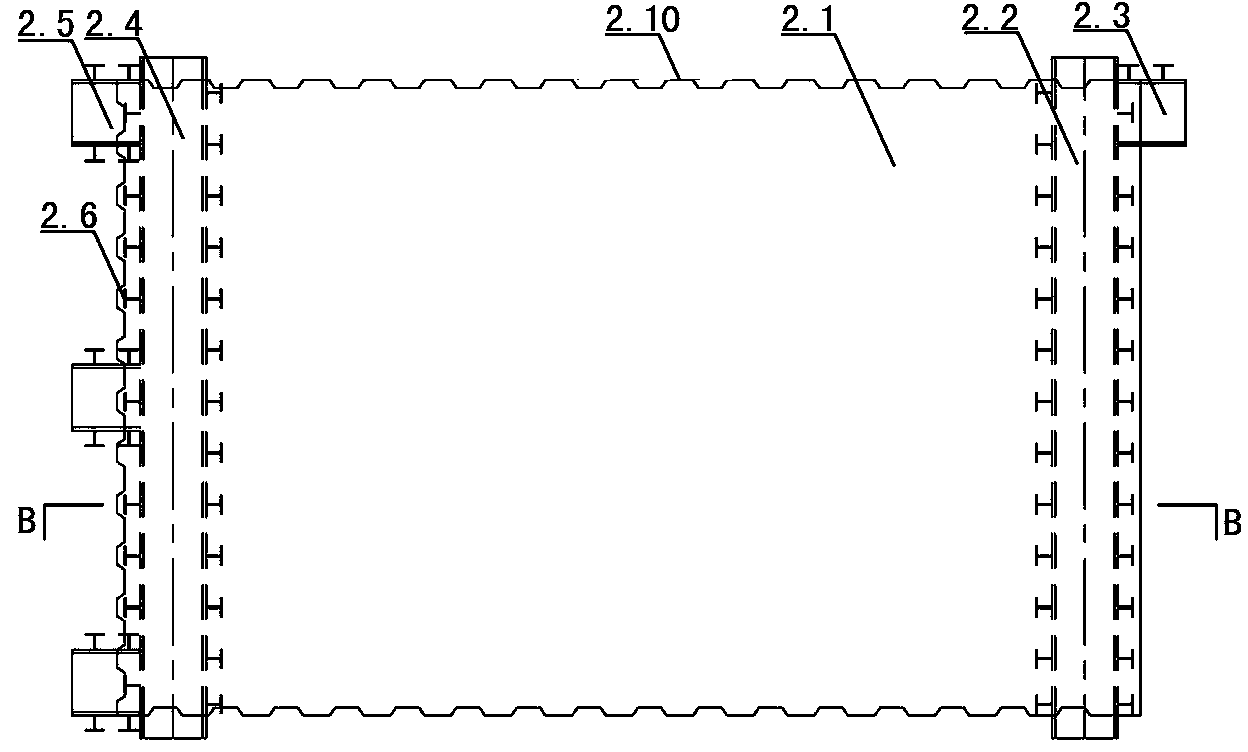

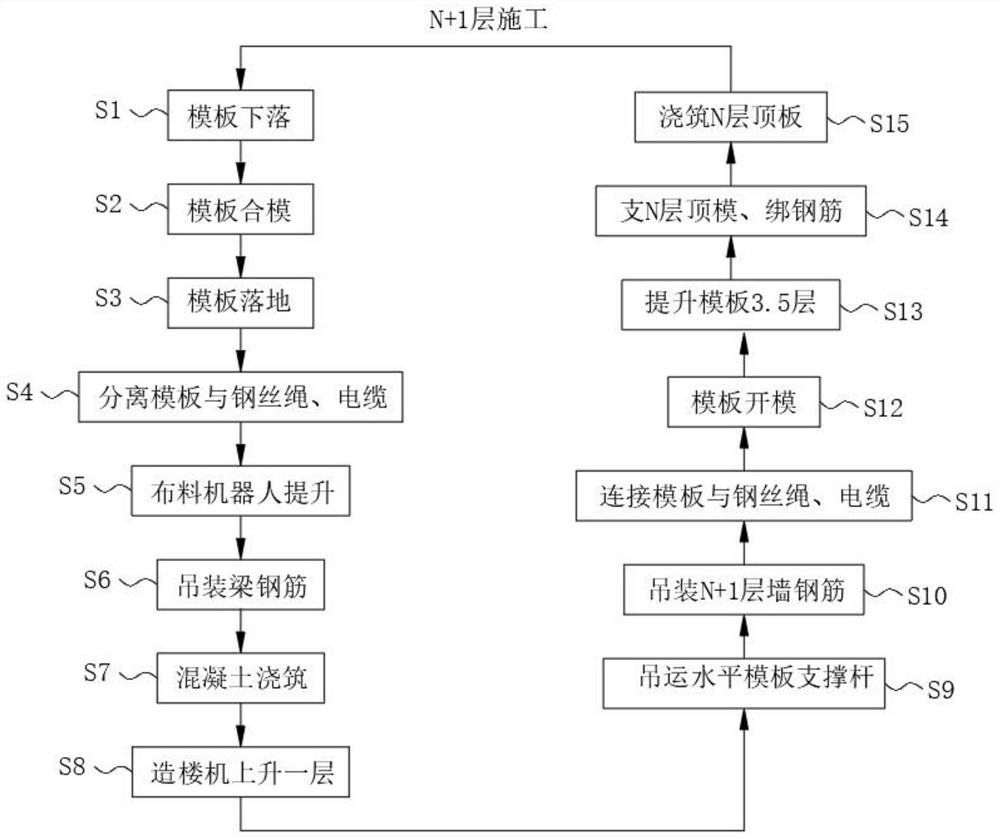

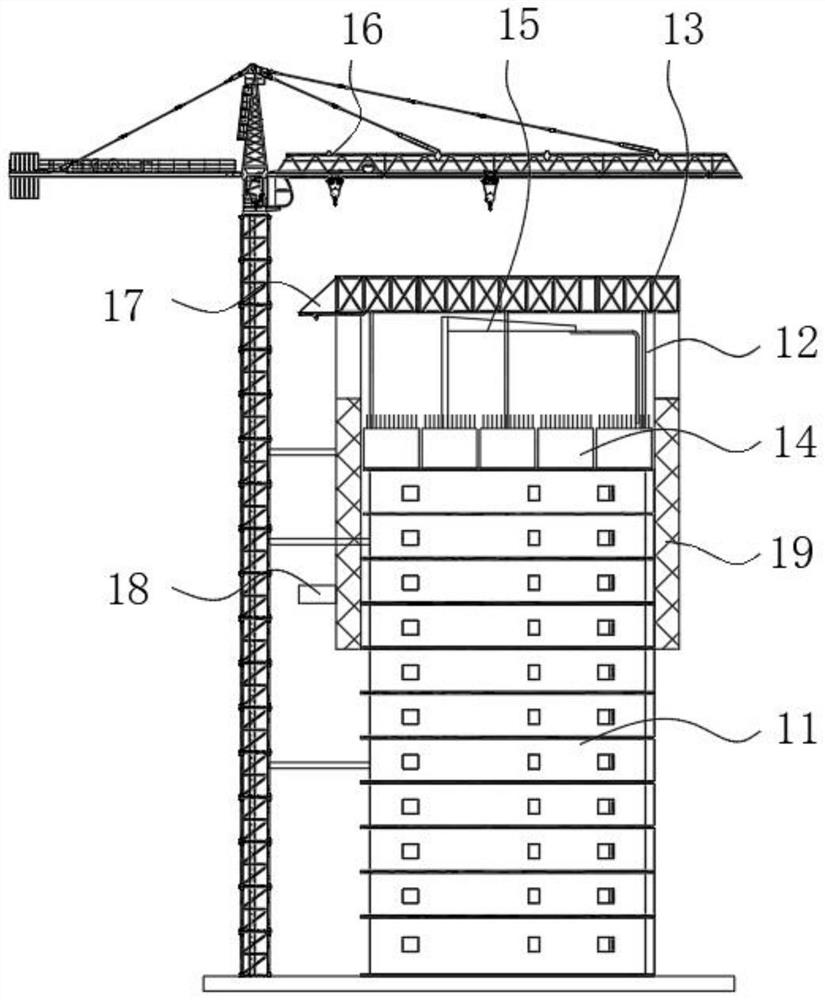

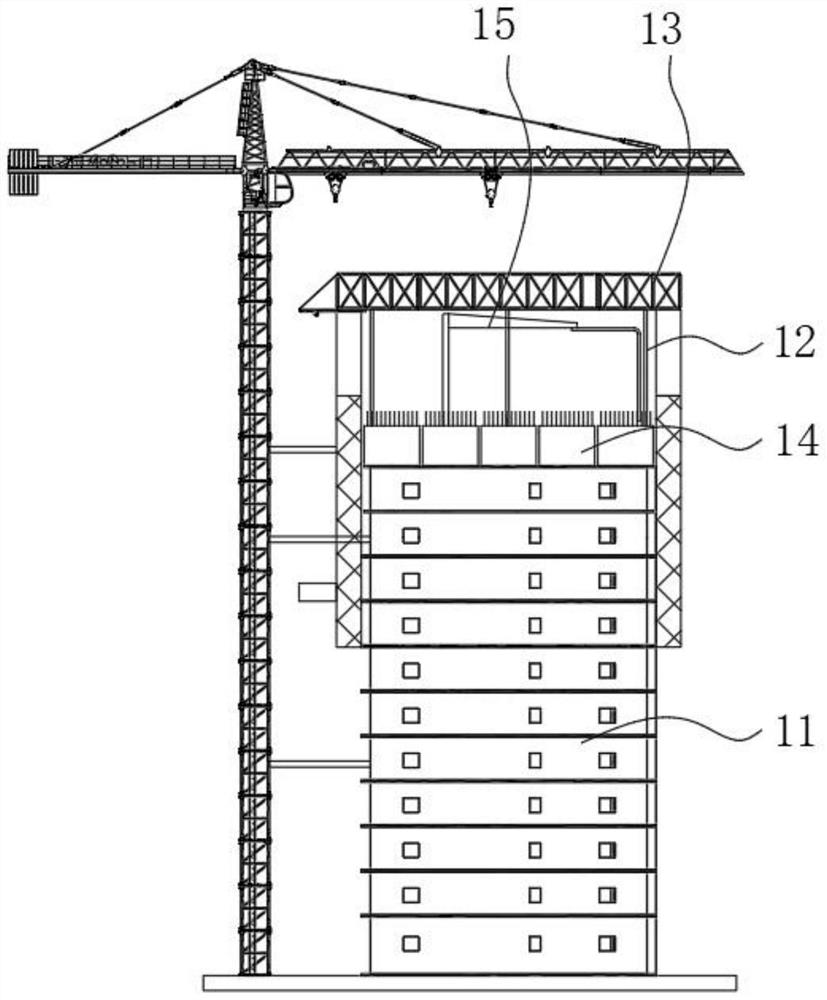

High-rise building integrated construction method and high-rise building integrated construction platform

PendingCN114277942AImprove the level of industrializationReduce the workload of manual operationsWallsForms/shuttering/falseworksArchitectural engineeringManual handling

The invention relates to the technical field of high-rise building integrated construction, in particular to a high-rise building integrated construction method which comprises the following steps that S1, a vertical formwork in a formwork system is driven by a lifting assembly on a top steel structure to descend; s2, the vertical mold plate is subjected to mold closing under the operation of an automatic mold opening and closing device; s3, the vertical formwork falls to the N-layer ground; s4, the vertical formwork is separated from a lifting assembly on the top steel structure; and S5, the concrete distribution robot is lifted upwards by the height of one floor, and the concrete distribution robot climbs from the interior of the elevator shaft in a hydraulic self-climbing mode. The purposes of reducing the manual operation workload and improving the industrialization level of building construction are achieved, the construction method is advanced, reasonable and efficient, the construction cost is effectively reduced, the construction period is shortened, meanwhile, orderly proceeding of all procedures is improved, and the construction progress is improved on the premise that the project quality is guaranteed.

Owner:安徽同湃特机器人科技有限公司

Road greening transformation construction method

InactiveCN111771456AEfficient construction methodsEasy to operatePlantingCultivating equipmentsAgricultural scienceDrive shaft

The invention provides a road greening transformation construction method, and belongs to the field of greening transformation; an automatic hole digging planter is adopted for transformation construction, and the road greening transformation construction method comprises the following steps: hole digging is performed, wherein the automatic hole digging planter comprises a machine body, a driver is arranged in the machine body, the driver is connected with a drill bit through a vertical driving shaft, and the driving shaft is movably connected with the driver; the driver is started, and a rotating wheel is rotated to enable the drill bit to move downwards and a planting pit is dig in the ground; planting is carried out: a throwing part is arranged at the front end of a machine body, a vertical throwing hole penetrating through a throwing part is formed in the throwing part, and the width of the throwing part is larger than that of the machine body; after the planting pit is dug in theground, the machine body is moved, the throwing hole faces the planting pit, and a potted plant is thrown from the top of the throwing hole and falls into the planting pit. The construction method hasthe advantages of being efficient and convenient to operate, and greening construction transformation can be rapidly completed in a road construction area.

Owner:郑国强

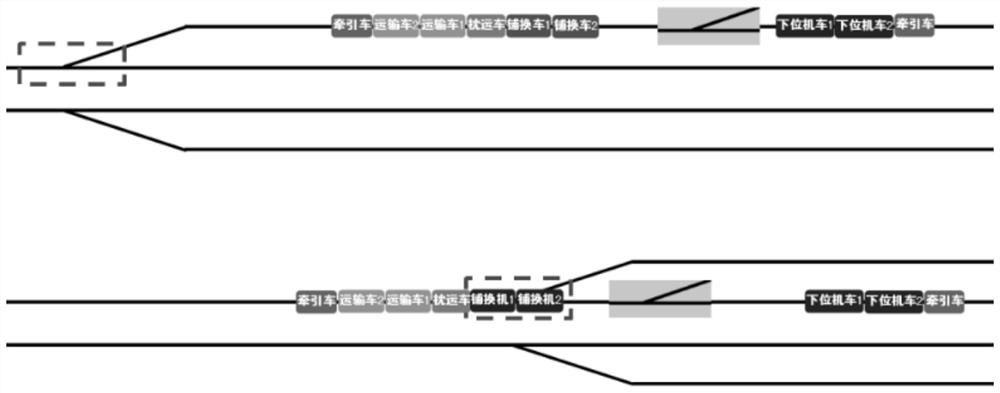

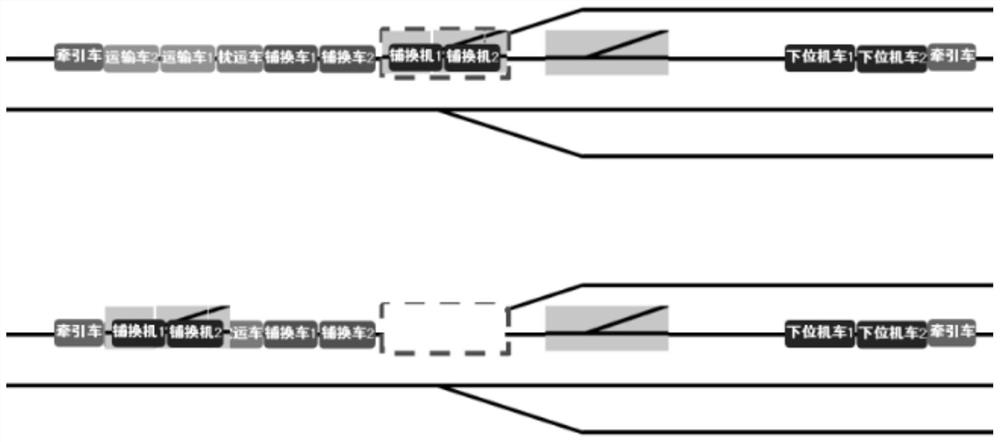

Construction technology for replacing turnout of laying and replacing unit

PendingCN114753194AImprove efficiencyQuality improvementRailway track constructionConstruction engineeringLifting equipment

The invention provides a turnout replacement construction process of a laying and replacing unit. The turnout replacing construction technology of the laying and replacing unit comprises the following steps that S1, preparation work of equipment before construction is conducted is conducted; s2, turnout pretreatment: S2.1, turnout pre-laying; s2.2, turnout transportation; s2.3, welding the whole group of turnouts; and S3, replacing the turnouts. According to the turnout replacing construction technology of the laying and replacing unit, the pre-laying environment is improved, the turnout pre-laying efficiency and quality are improved by using construction equipment such as a turnout transport vehicle and a laying and replacing machine, large hoisting equipment is applied to the turnout replacing construction link, labor intensive operation is completed instead of manual work, and the construction efficiency is improved. The problems of many on-site constructors and high labor intensity are solved, damage to the turnout in the construction process is reduced, waste old materials generated in the construction process can be reduced through overall disassembly and assembly, a large amount of on-site old materials can be taken away through overall transfer, optimization and improvement are achieved on the basis of an existing construction method, and a safer, more efficient and more economical construction method is provided.

Owner:BAOJI CSR TIMES ENG MACHINERY

A processing method of prestressed laminated plate with support

ActiveCN104493973BSimple construction methodEfficient construction methodsCeramic shaping apparatusPre stressPre stressing

The invention provides a processing method of a prestressed composite slab with a bracket, and belongs to the technical field of processing and production of building components. The processing method comprises the following steps of (1) enabling processing equipment of the composite slab with a top groove to manufacture a composite slab body with the top groove, and welding the bracket which is arranged in the groove of the composite slab body in a matching way; (2) arranging the bottom part of the bracket in the groove of the composite slab body, and casting high-fluidity filler, or casting the high-fluidity filler in the groove of the composite slab body, and placing the bracket; (3) curing and forming the composite slab with the bracket. The processing method has the advantages that the composite slab body with the top groove is manufactured by the processing equipment of the composite slab with the top groove, then the bracket is arranged in the top groove of the composite slab body, and the high-fluidity filler is cast in the top groove, or the high-fluidity filler is cast in the groove of the composite slab body, and the bracket is arranged, so the prestressed composite slab with the bracket is processed completely; the construction method is simple, and the efficiency is high.

Owner:SHANDONG QIANYUAN ZEFU POLYTRON TECH INC

Prefabricated supporting structure and construction method using the supporting structure

ActiveCN108643923BImprove construction efficiencyImprove securityUnderground chambersTunnel liningArchitectural engineeringMachine

The invention discloses a tunnel sectional excavation assembly arch frame and mechanized construction technology. An excavation process of a tunnel CD method is taken as an example, the arch frame isfolded according to sectional sections, and an arch frame assembling machine lifts the arch frame to the front of a tunnel face; the arch frame of a first excavation part and temporary support are connected and fixed, and the arch frame is grabbed and lifted by the arch frame assembling machine, and the arch frame and the temporary support are fully spread and positioned; an inverted-arch arch frame of a second excavation part on the lower portion of the left side and the temporary support of the remaining part are installed and are connect with the arch frame of a first excavation part on theupper portion of the left side and temporary support; a supporting arch frame of a third excavation part on the upper portion of the right side is installed and is connected with the arch frame of the first excavation part on the upper portion of the left side; and an inverted-arch of a excavation part on the lower portion of the right side is installed and is connected with and the supporting arch frame of the third excavation part on the upper portion of the right side and the inverted-arch of the second excavation part on the lower portion of the left side. The mechanized installation of asectional support structure is achieved, the construction efficiency is improved, and the construction safety is ensured.

Owner:SHANDONG UNIV +1

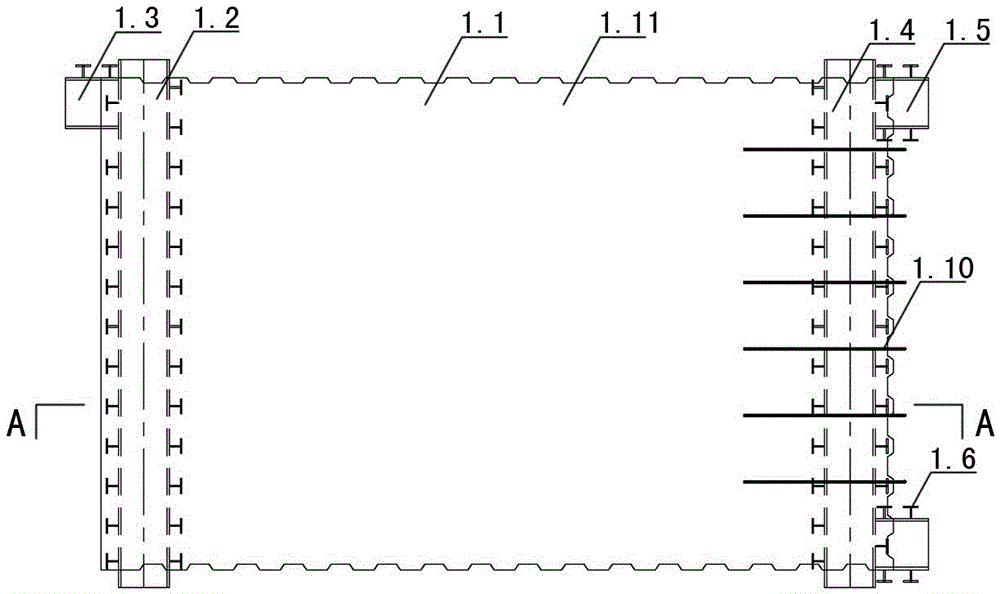

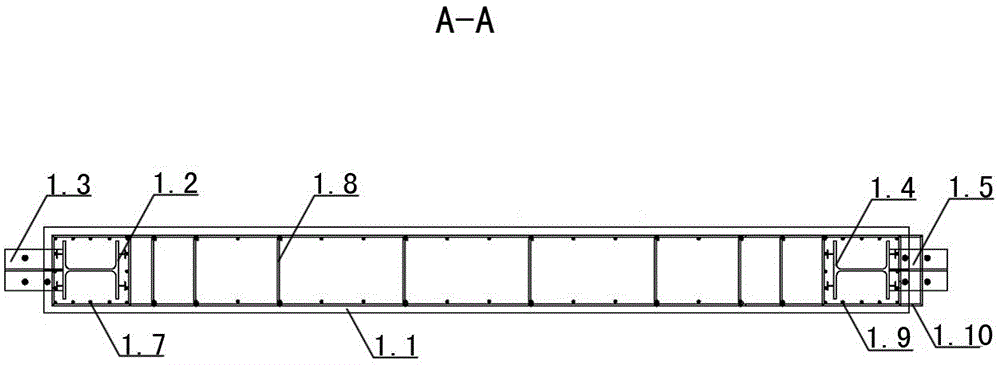

Assembly-type linear mixed coupled wall and construction method thereof

InactiveCN104032863AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type linear mixed coupled wall and a construction method thereof. The assembly-type linear mixed coupled wall comprises a first wall unit and a second wall unit which are connected and are arranged in a linear mode. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type linear mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

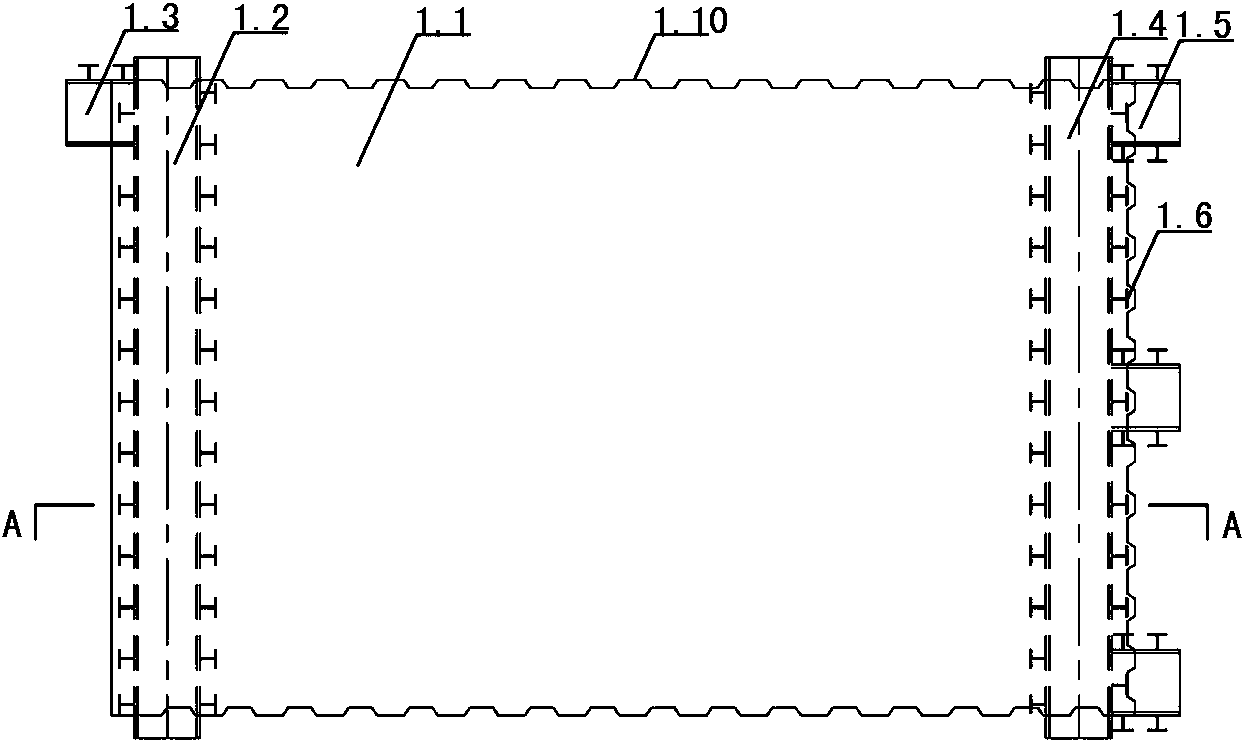

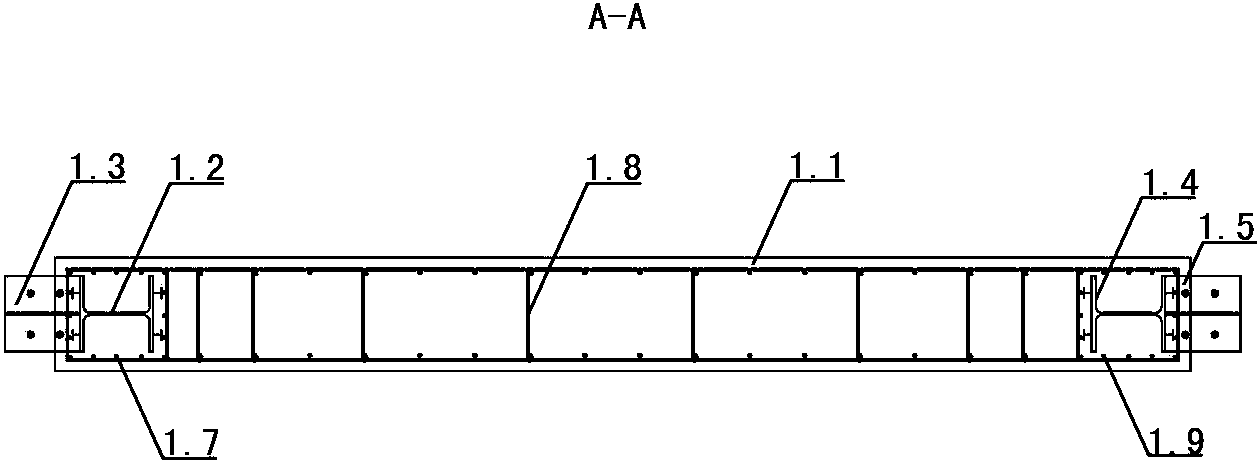

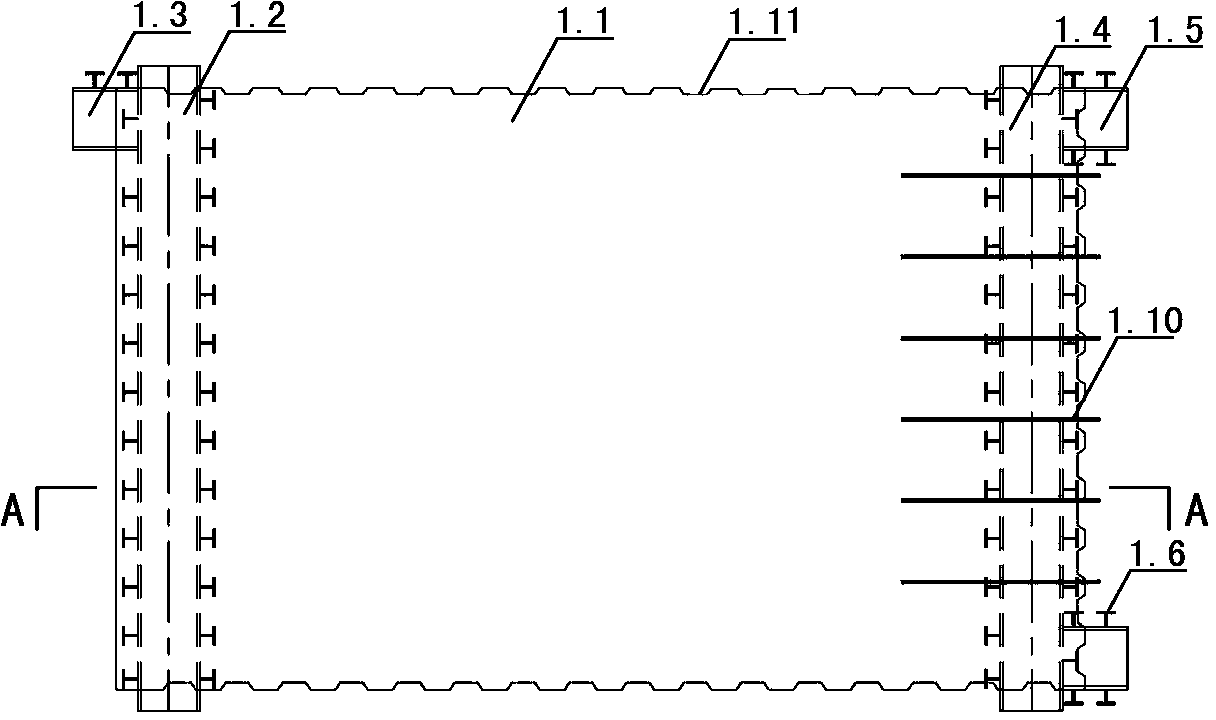

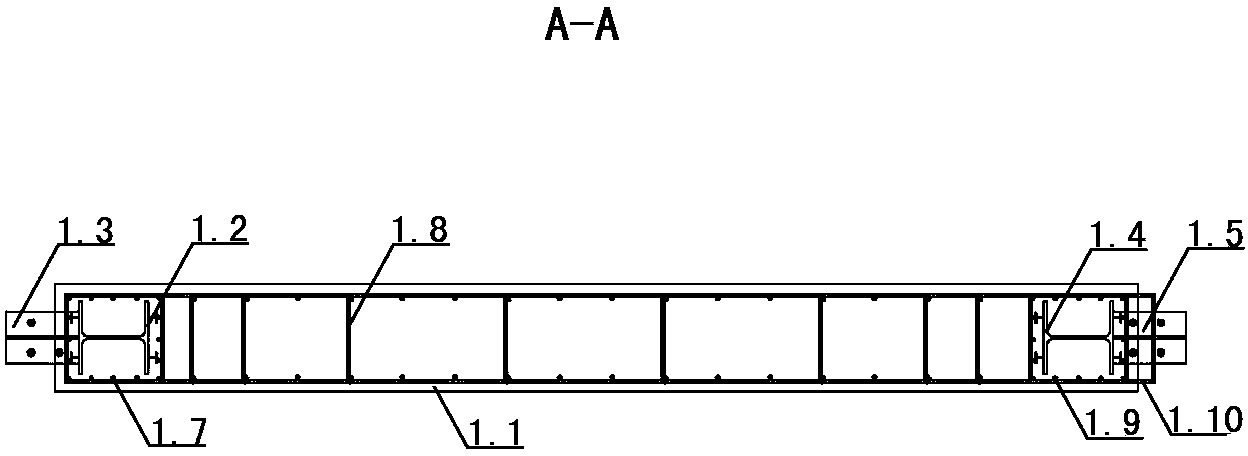

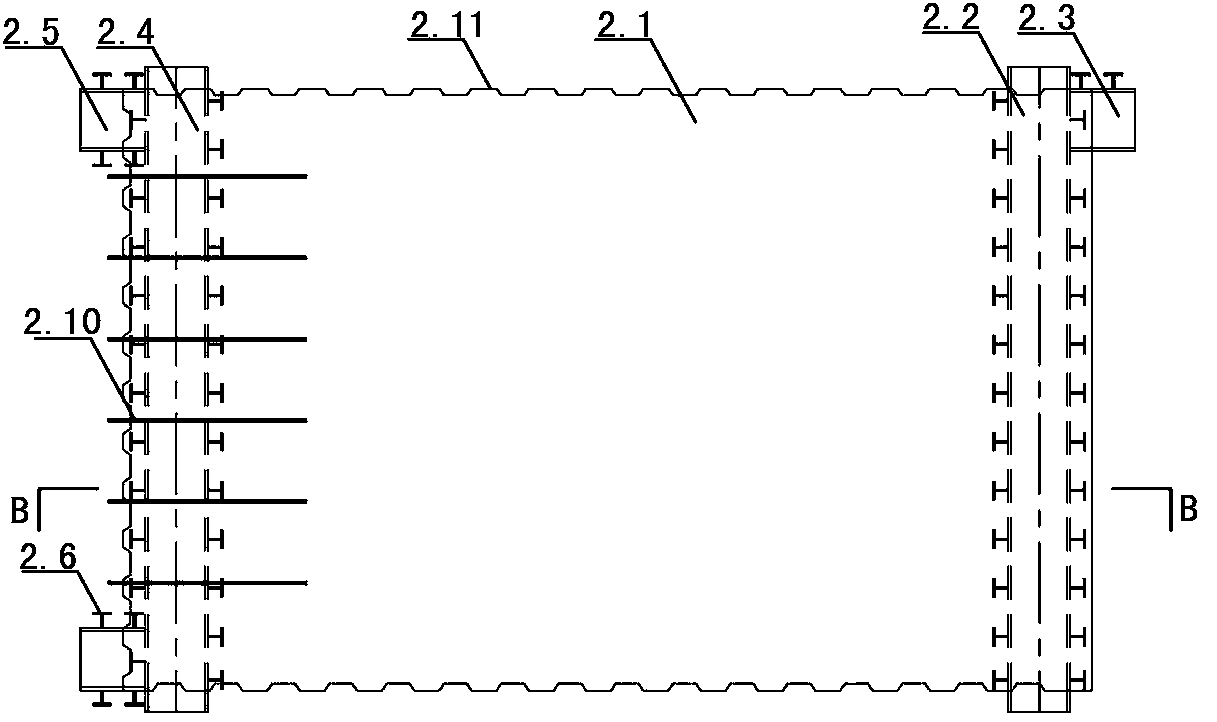

Large foldable open type membrane structure gate lifting system and installation method thereof

ActiveCN106150288AAdvanced construction methodsEfficient construction methodsPower-operated mechanismWing arrangementsArchitectural engineeringComposite beams

The invention relates to a lifting system, in particular to a large foldable open type membrane structure gate lifting system and an installation method thereof and belongs to the field of steel structures. The system comprises a fixed table and a lifting plate, a upper composite beam assembly is arranged in the lifting plate, a transfer beam is arranged between the upper composite beam assembly and the lifting plate, the upper composite beam assembly moves along with a guide device, the lifting plate is lifted by moving the upper composite beam assembly along with the guide device, the guide device is matched and connected through a compensation device, the compensation device is fixed to the fixed table, and the fixed table and the lifting table are movably positioned through a worktable assembly. According to the large foldable open type membrane structure gate lifting system and the installation method thereof, the structure is reasonable, machining is convenient, construction cost is low, construction quality is high, and construction safety hidden hazards are reduced.

Owner:浙江东南网架股份有限公司

Construction method of single main cable inclined-suspender earth anchored suspension bridge

InactiveCN101914897BConstruction safetyGuarantee the quality of the projectSuspension bridgeFoundation engineeringTowerSteel box girder

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

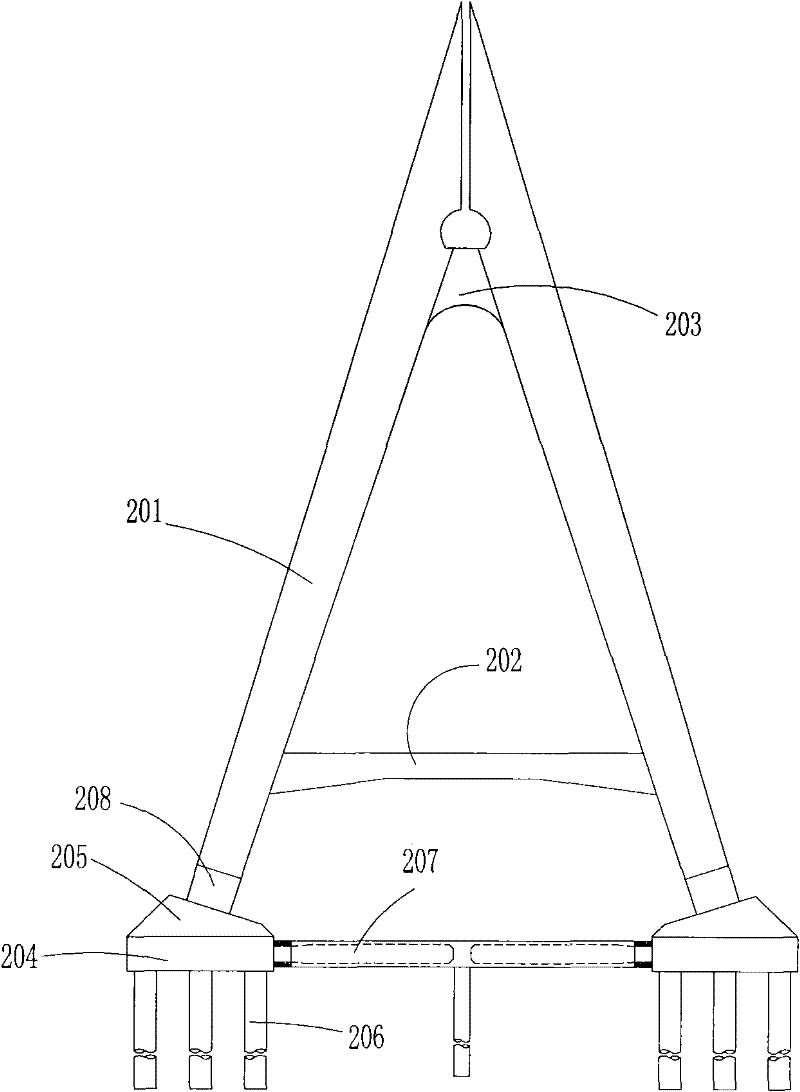

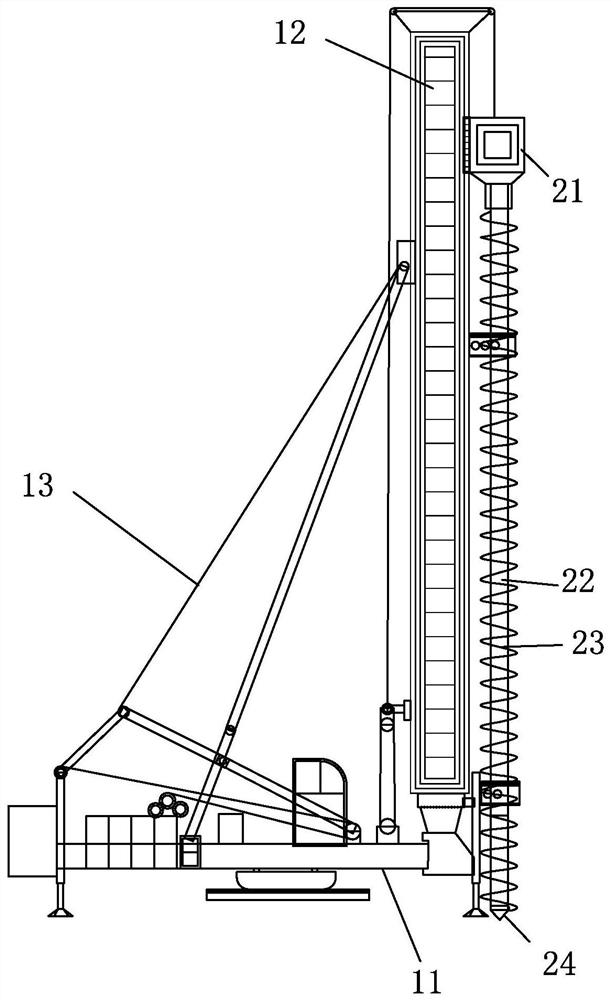

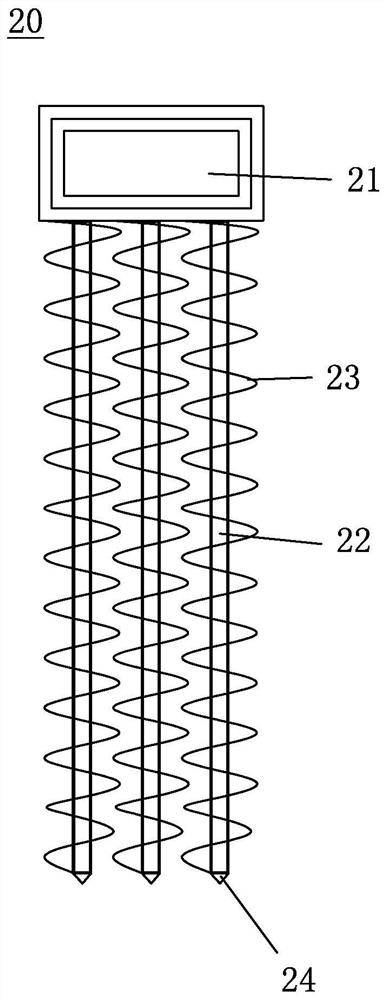

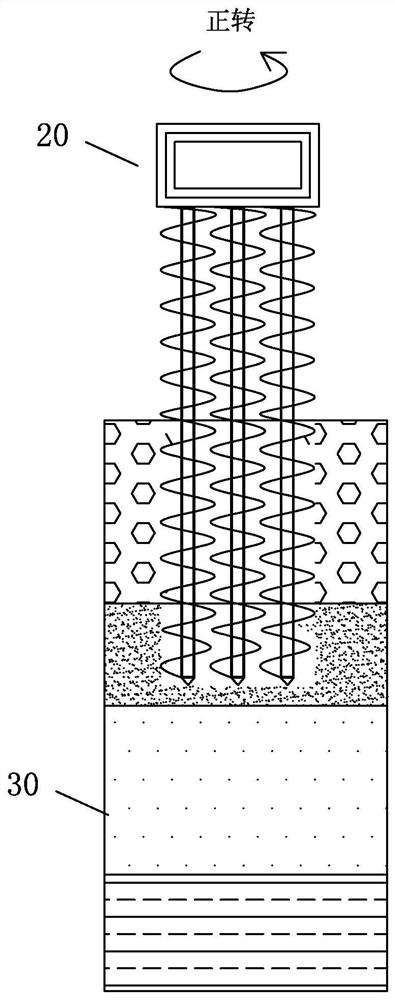

Three-axis long auger and construction method of occlusal pile

ActiveCN106968594BNo water leakageThe construction process is shortened and simplifiedDrilling rodsDrilling casingsSpiral bladeArchitectural engineering

The invention discloses a tri-axial long spiral drilling machine and an occlusive pile construction method which is achieved on the basis of the tri-axial long spiral drilling machine. The tri-axial long spiral drilling machine comprises a rack. A guiding mechanism is installed on the rack and provided with a drilling mechanism. The drilling mechanism can be driven by a transmission mechanism to make vertically perpendicular movement in the guiding mechanism. The drilling mechanism comprises three laterally-arranged hollow drilling rods which are installed under power head, and the power head drives the three drilling rods to positively rotate and negatively rotate in a synchronous mode. Top openings of the drilling rods are connected with a concrete pouring device, and bottom openings of the drilling rods are provided with drilling bits which are opened when the drilling rods positively rotate and closed when the drilling rods negatively rotate. Rod bodies of the drilling rods are provided with spiral blades, and the spiral blades on each two adjacent drilling rods are arranged in a staggered and embedded-fit mode so as to enable the three drilling rods to be able to drill out of three mutually-occlusive pile holes at a time. In occlusive piles obtained through tri-axial long spiral drilling machine construction, occlusion between the adjacent piles is natural and sufficient, holes are not connected between the adjacent piles, and the construction quality is effectively ensured.

Owner:CHINA RAILWAY CONSTR GROUP +1

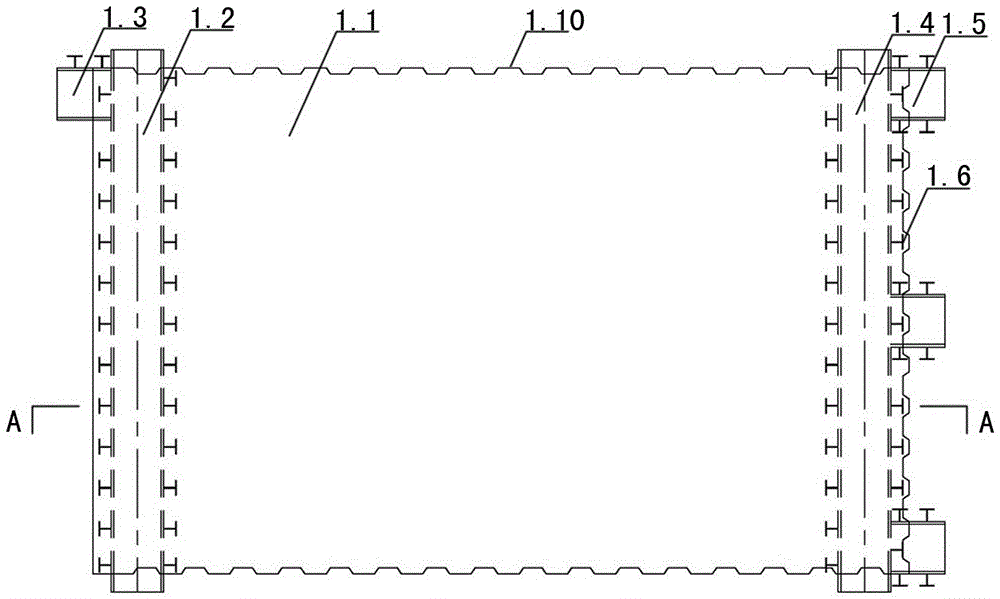

Construction method for rapidly constructing local underground two-layer well in primary lining stage of subsurface tunnel

ActiveCN112796794AImprove securityImprove construction efficiencyUnderground chambersHydro energy generationArchitectural engineeringRapid construction

The invention provides a construction method for rapidly constructing a local underground two-layer well in the primary lining stage of a subsurface tunnel. The construction method comprises the following steps that 1, a two-layer well structure of the subsurface tunnel is excavated in a segmented mode, the first layer of the two-layer well structure is excavated firstly, and a first-layer grating is constructed; 2, a first-layer bottom plate structure is manufactured, and a T-shaped grating reserved connector is adopted at the corner where the first-layer bottom plate structure and the first-layer grating are connected; and 3, a bottom layer structure of the two-layer well structure is excavated, a grating of the bottom layer structure is connected with the T-shaped grating reserved connector in time, a closed structure is formed, and complete construction is guaranteed. According to the construction method, the safety risk in the process of constructing the local two-layer well through the subsurface tunnel can be effectively reduced, interference to various subsequent constructions is avoided, and the purposes of high efficiency, simplicity and flexibility are achieved. The construction method is simple in construction, safe, reliable, high in flexibility and capable of effectively improving the working efficiency and safety of construction of the local two-layer well in the construction process of the subsurface tunnel.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Prefabricated steel beam joint L-shaped mixed limb wall and its construction method

A prefabricated steel beam joint L-shaped mixed limb wall and its construction method, the fabricated steel beam joint L-shaped mixed limb wall includes a first wall unit and a second wall that are vertically connected together to form an L shape The units, the first wall unit and the second wall unit are all prefabricated components, and the two are connected by joint post-casting tapes. The present invention uses steel beams instead of concrete beams, and steel columns instead of edge-constrained reinforced concrete concealed columns, so that the hybrid connected limb wall has better energy consumption capacity and continuous collapse resistance than the traditional connected limb wall, and the factory prefabrication and on-site installation can be carried out at the same time. It solves the problems of large amount of wet work on the construction site and a lot of construction waste, and simplifies the assembly process; after butt welding of the short joints, the wall units have formed a relatively large rigidity, which is conducive to the stability of the wall during the construction process, eliminating the need for The process of prefabricated shear walls as temporary support ensures construction efficiency. It can be widely used in the construction of mixed limb walls in construction projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Prefabricated steel beam joint cross-shaped mixed limb wall and its construction method

InactiveCN104032857BImprove stabilityReduce wet work loadWallsShock proofingCruciformReinforced concrete

An assembled steel beam joint cross-shaped mixed limb wall and its construction method, the assembled steel beam joint cross-shaped mixed limb wall includes a first wall unit and a second wall unit that are vertically connected to each other to form a cross shape, wherein The first wall unit is symmetrically distributed on both sides of the second wall unit, both of the first wall unit and the second wall unit are prefabricated components, and the two are connected by joint post-casting strips. The invention uses shaped steel columns instead of edge-constrained reinforced concrete concealed columns, so that the mixed limb wall has better energy consumption capacity and continuous collapse resistance than the traditional limb wall, and the factory prefabrication and on-site installation are carried out at the same time, which solves the problem of wet operation on the construction site The assembly process is simplified due to the problems of large quantity and construction waste; after butt welding of the short beams at the joints, a relatively large rigidity has been formed between the wall units, which is conducive to the stability of the wall during the construction process, eliminating the need for prefabricated shear walls as temporary supports The process ensures the construction efficiency. It can be widely used in the construction of mixed limb walls in construction projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Prefabricated T-shaped mixed limb wall and its construction method

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

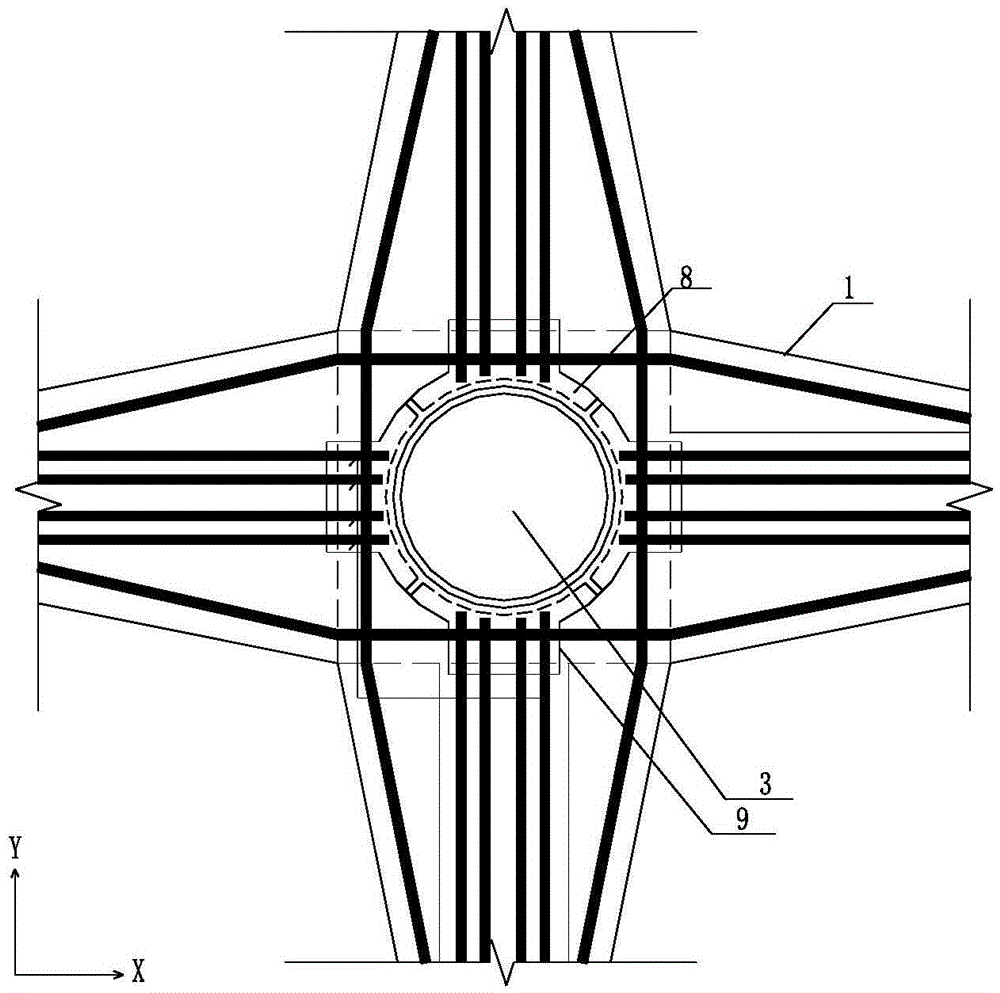

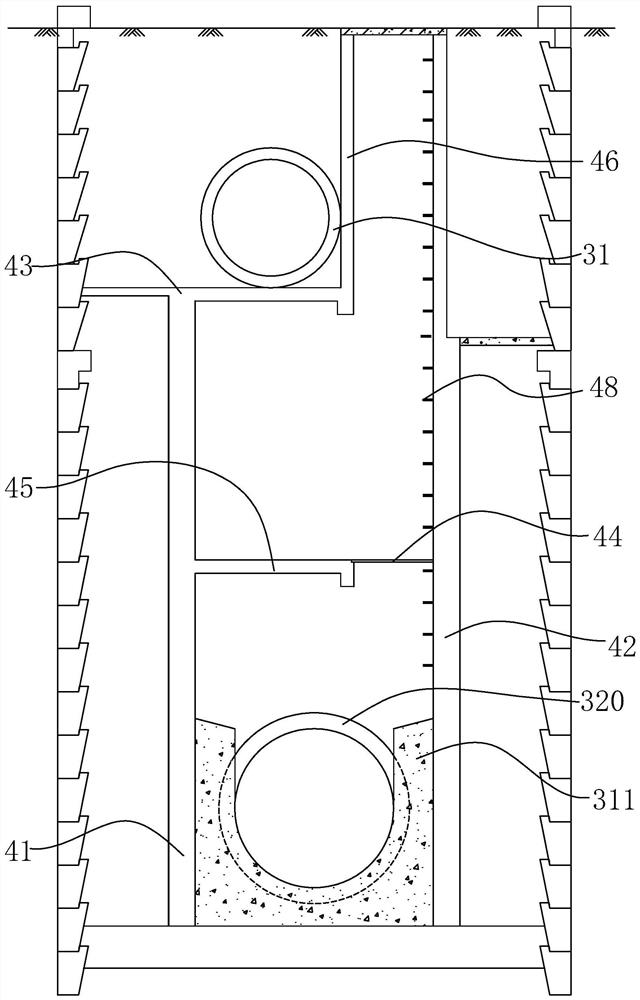

Construction method of an underground superimposed double-pipe common well structure

ActiveCN108867540BWon't collapseAvoid enteringExcavationsMarine site engineeringStructural engineeringSmall footprint

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com