Processing method of prestressed composite slab with bracket

A processing method and a technology of laminated panels, which are applied in the field of building component processing, can solve problems such as low construction efficiency, high equipment cost, and complicated construction methods, and achieve the effect of convenient application of prestress and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of processing method of band support prestressed laminated plate of the present invention, this processing method is carried out according to the following steps:

[0051] A processing method for a prestressed laminated plate with a bracket, the processing method is carried out according to the following steps:

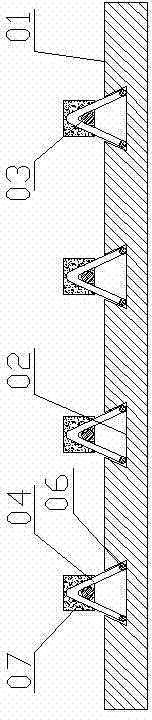

[0052] 1) using a top-grooved laminate processing equipment to manufacture the top-grooved laminate body 01, and at the same time, weld and fit the bracket placed in the groove of the laminate body 01;

[0053] 2) Put the bottom of the bracket into the groove of the laminated slab body 01 and then pour high-fluidity filler, or place the bracket after pouring high-fluidity filler in the groove of the laminated slab body 01;

[0054] 3) Conservation forming laminated panels with brackets.

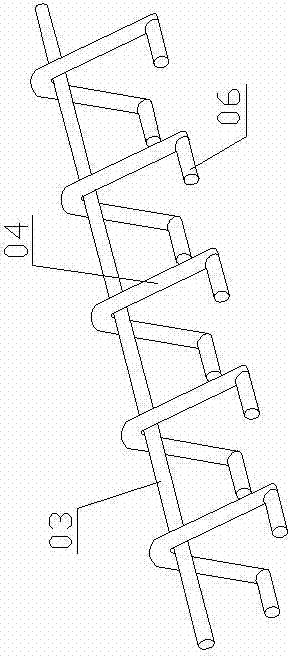

[0055] combined with figure 1 , 2 , the support in the above step 1) includes a compression bar, five sets of V-shaped stirrup supports 04 are arranged on the compre...

Embodiment 2

[0074] A kind of processing method of band support prestressed laminated plate of the present invention, this processing method is carried out according to the following steps:

[0075] A processing method for a prestressed laminated plate with a bracket, the processing method is carried out according to the following steps:

[0076] 1) using a top-grooved laminate processing equipment to manufacture the top-grooved laminate body 01, and at the same time, weld and fit the bracket placed in the groove of the laminate body 01;

[0077] 2) Put the bottom of the bracket into the groove of the laminated slab body 01 and then pour high-fluidity filler, or place the bracket after pouring high-fluidity filler in the groove of the laminated slab body 01;

[0078] 3) Conservation forming laminated panels with brackets.

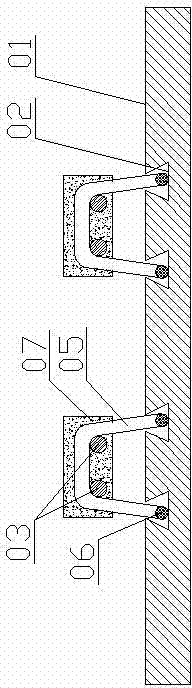

[0079] combined with image 3 , the bracket in the above step 1) includes two compression bars, five sets of U-shaped stirrup supports 05 are arranged on the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com