Large-span steel truss structure and installation method thereof

An installation method and technology for steel trusses, which are applied to truss-type structures, structural elements, and elongated structural members for load-bearing, etc., can solve the problems of difficult control of cross-section geometry, welding quality, large labor force, and long time consumption. , to achieve the effect of small footprint, large labor force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

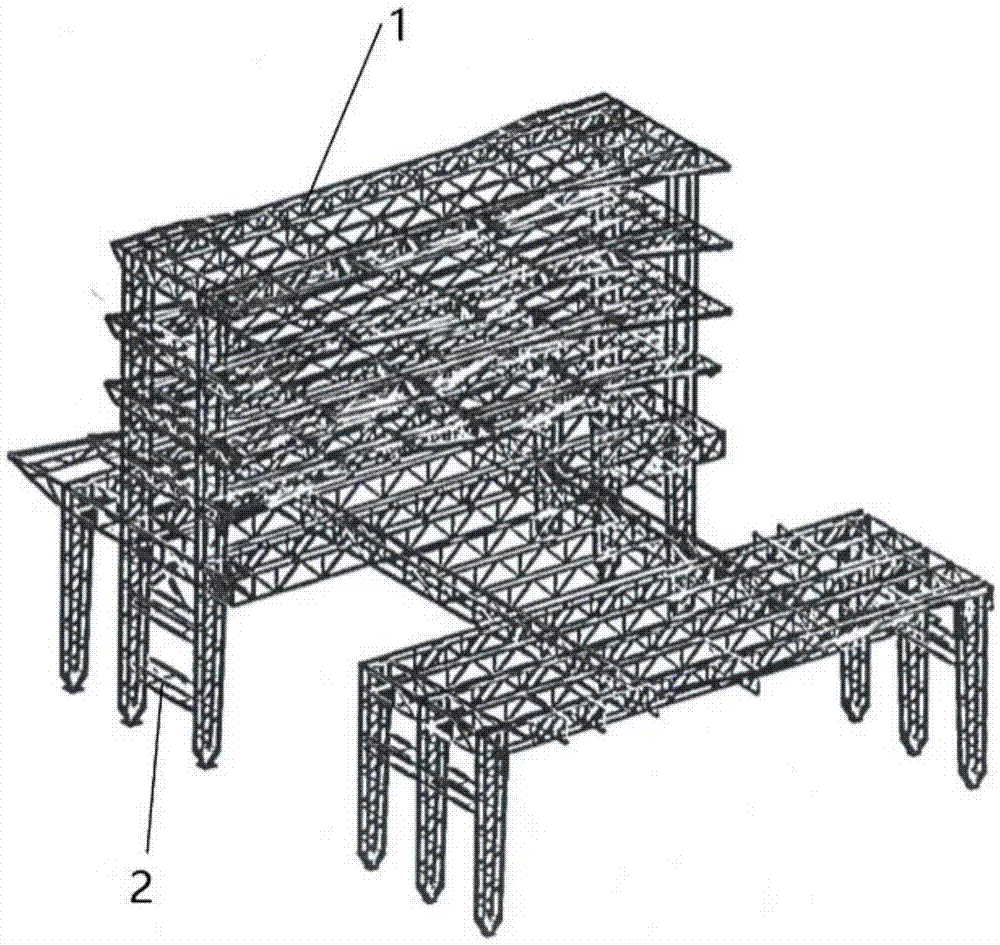

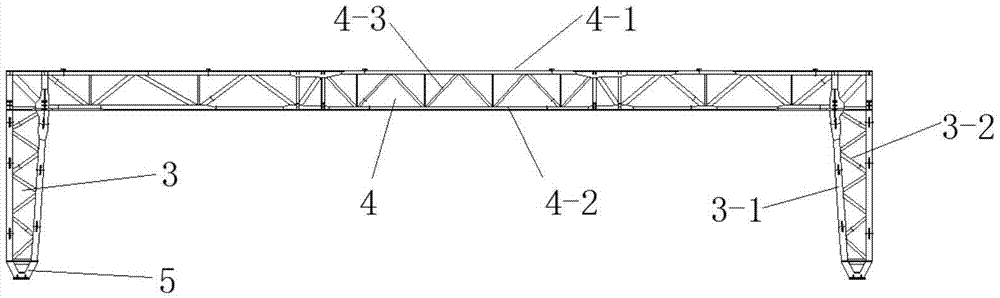

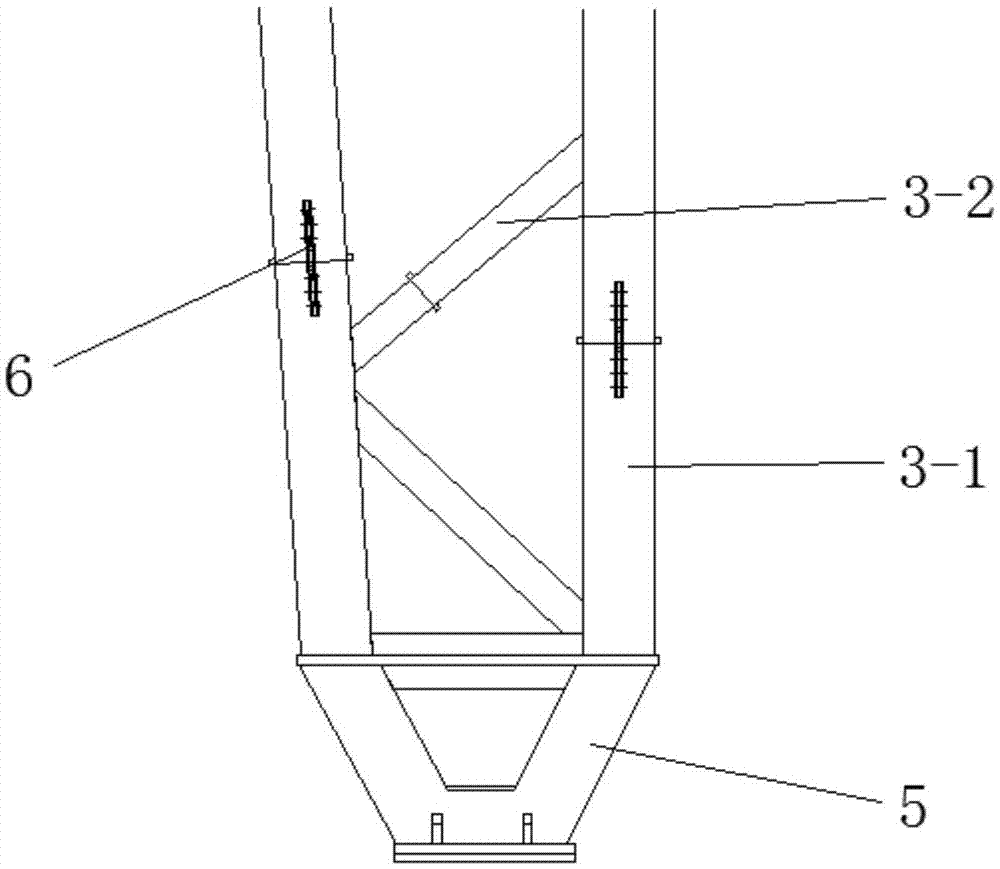

[0033] Such as figure 1 , figure 2 A large-span steel truss structure shown includes a group of steel frames 1 and secondary trusses 2 that are located between adjacent steel frames and are vertically connected to the steel frames; : two supporting columns 3 and a main truss 4 at the top; the lower part of the supporting column 3 is provided with a column foot 5, and the column foot 5 adopts an inverted tapered composite column foot, and is fixedly connected with the lower concrete structure by fixing bolts; The support column 3 includes: a group of steel columns 3-1 and reinforcing ribs 3-2 alternately distributed therebetween. The steel columns 3-1 are formed by connecting multiple sections of steel plates, and the joints are provided with connecting lugs 6 and connecting lugs 6 The bolts are fixedly connected to the steel columns 3-1, and at the same time, the reinforcing ribs 3-2 are alternately fixedly connected to the steel columns 3-1 to form a triangular structure; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com