Prefabricated steel beam joint L-shaped mixed limb wall and its construction method

A construction method and technology of connected limb walls, applied in the direction of walls, building components, earthquake resistance, etc., can solve problems such as low efficiency, large construction waste, and large construction workload of connected limb walls, so as to achieve reliable connection, increase construction speed, and good Effect of Progressive Collapse Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

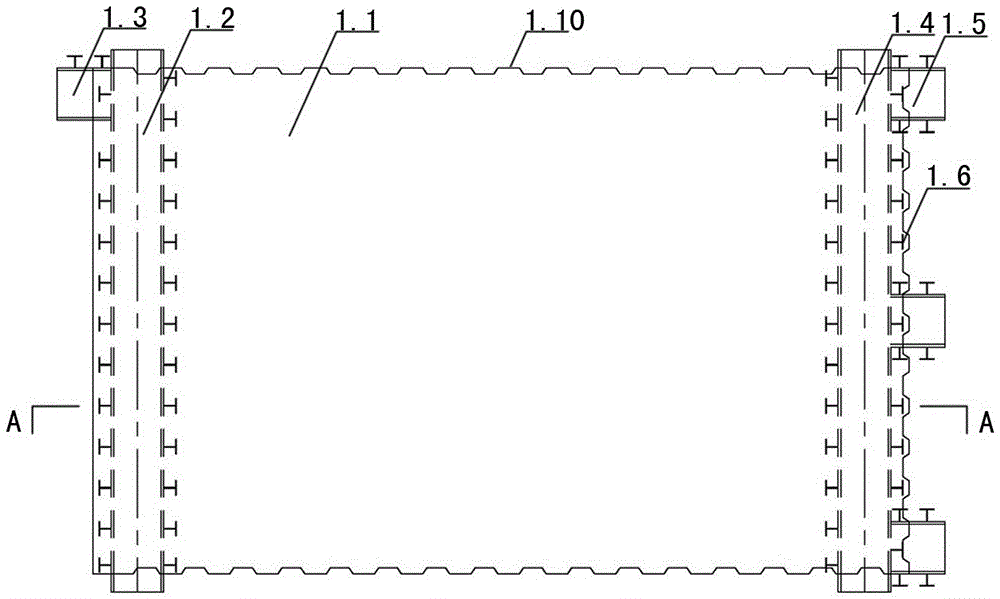

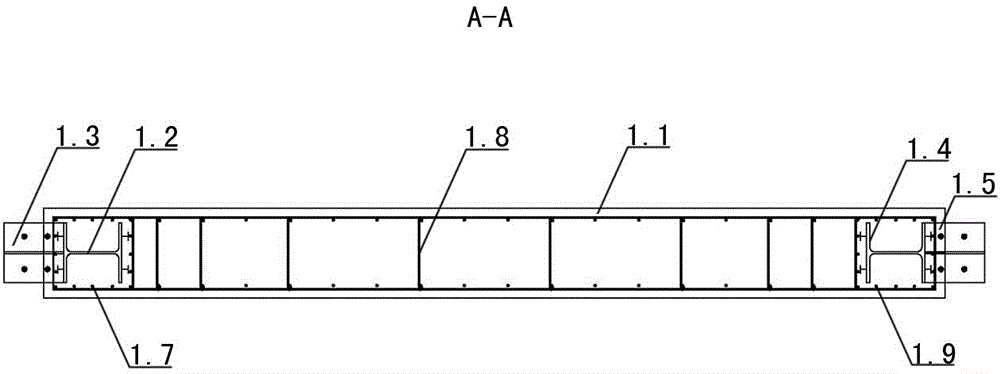

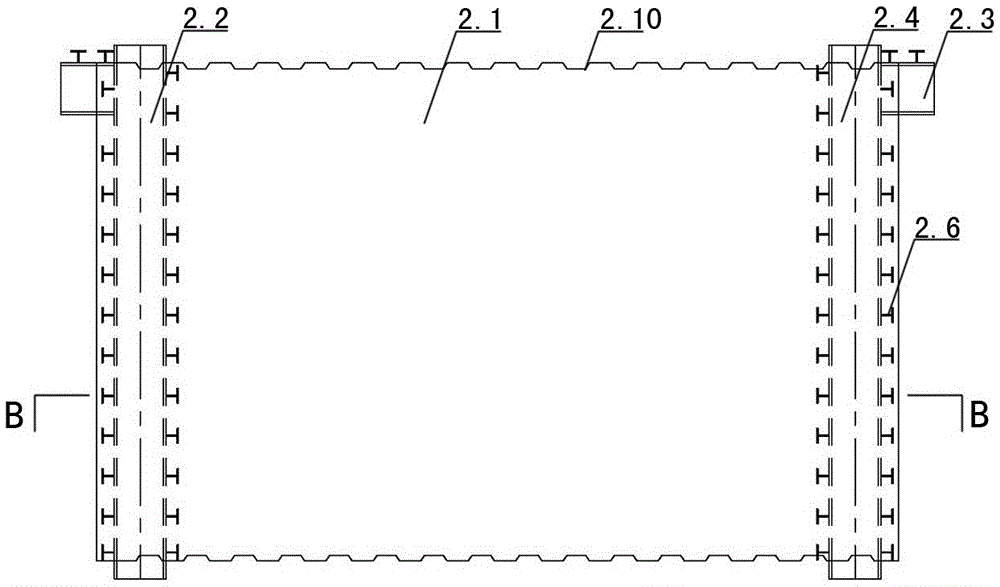

[0058] Examples see Figure 5 , Figure 6 As shown, a prefabricated steel beam joint L-shaped mixed limb wall includes a first wall unit 1 and a second wall unit 2 that are vertically connected to each other to form an L shape, wherein the first wall unit 1 is symmetrically distributed on the second wall On both sides of the unit 2, the first wall unit 1 and the second wall unit 2 are prefabricated components, the concrete strength grade is not less than C30 and not higher than C60, and the two are connected by a joint post-casting belt 3; The joint short beam 1.5 of the first wall unit and the joint short beam 2.5 of the second wall unit are butt-cast in the joint post-casting belt 3, and the joint post-casting belt 3 is also provided with a joint post-casting belt The vertical steel bar 3.1 and the seam post-cast belt stirrup 3.2 placed on the outside of the joint post-cast belt vertical steel bar 3.1, when the joint post-cast belt vertical reinforcement 3.1 is two rows, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com