Water-based high-weather-resistance fair-faced concrete protective coating system and preparation method thereof

A technology for fair-faced concrete and protective coatings, applied in coatings, epoxy resin coatings, etc., can solve the problems of limited protective durability, poor UV aging resistance, low cohesive strength and hardness, and achieve excellent bonding performance, Good weather aging resistance and excellent weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

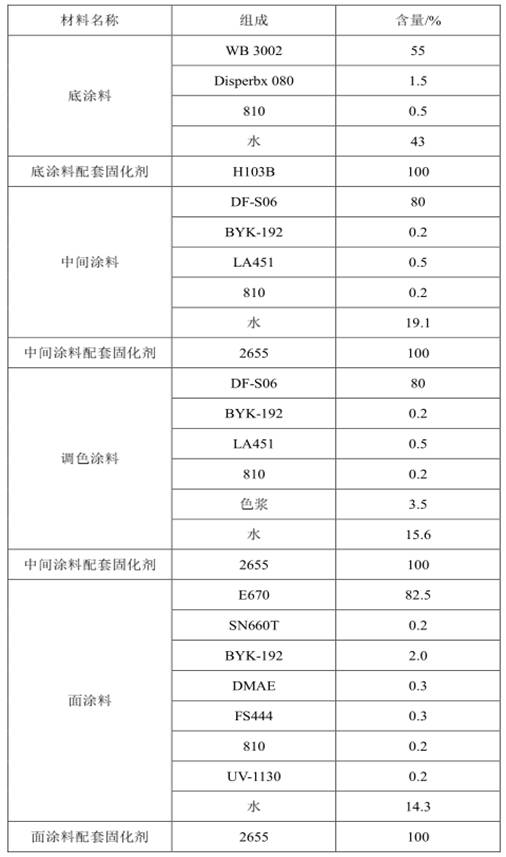

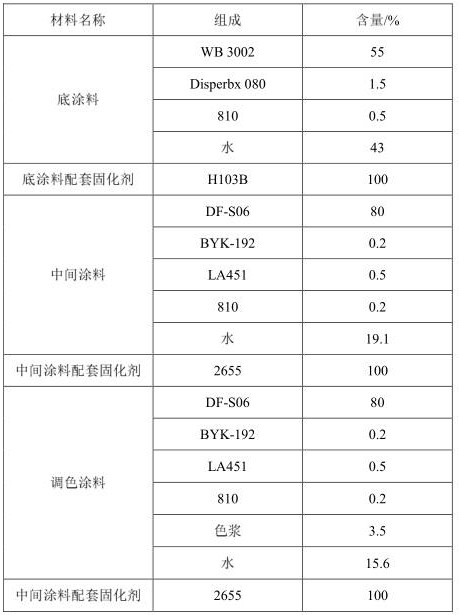

[0050] The water-based high-weather-resistant fair-faced concrete protective coating system provided in this implementation, its material formula is shown in Table 2.

[0051] Table 2 Example 1 material formula

[0052]

[0053] Among the above:

[0054] WB3002 water-based epoxy resin, produced by Dow Chemical;

[0055] Disperbx 080 wetting and dispersing agent, produced by Sipson Chemical;

[0056] H103B water-based epoxy curing agent, produced by Shanghai Hanzhong Chemical;

[0057] 810 defoamer, produced by Tego;

[0058] DF-S06 water-based fluororesin, produced by Dongfu Chemical;

[0059] BYK192 dispersant, produced by BYK Chemicals;

[0060] LA451 wetting agent, produced by Aohan Chemical;

[0061] 2655 curing agent, produced by Bayer Chemical;

[0062] E670 water-based fluororesin, produced by Huatong Rich;

[0063] SN660T thickener, produced by Nopco;

[0064] DMAE neutralizer, produced by Hemings;

[0065] FS444 leveling agent, produced by Hemings;

[00...

Embodiment 2

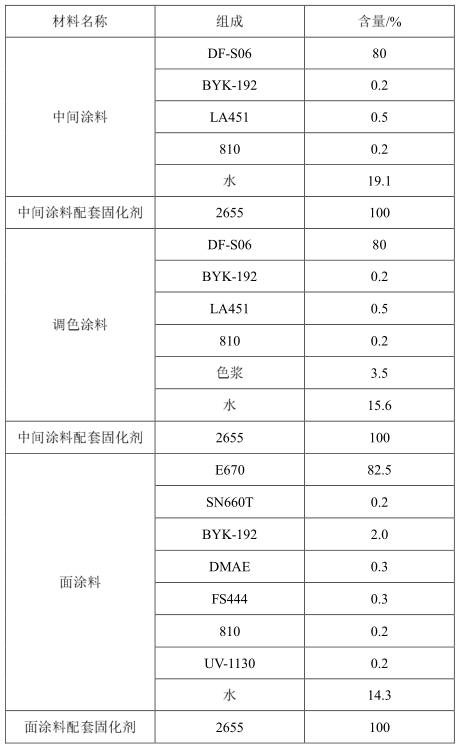

[0082] The water-based high weather resistance fair-faced concrete protective coating system provided in this example has a material formula shown in Table 4.

[0083] Table 4 Example 2 material formula

[0084]

[0085] The product preparation method and construction process of a water-based high weather resistance fair-faced concrete protective coating system described in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com