Construction method for rapidly constructing local underground two-layer well in primary lining stage of subsurface tunnel

A construction method, local technology, applied in tunnel lining, tunnel, shaft lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present application will be described in detail below in conjunction with the accompanying drawings and specific implementation methods of the application, but the following embodiments are only used to understand the present invention, and the embodiments in the application and the features in the embodiments can be combined with each other , the application can be practiced in a multitude of different ways as defined and covered by the claims.

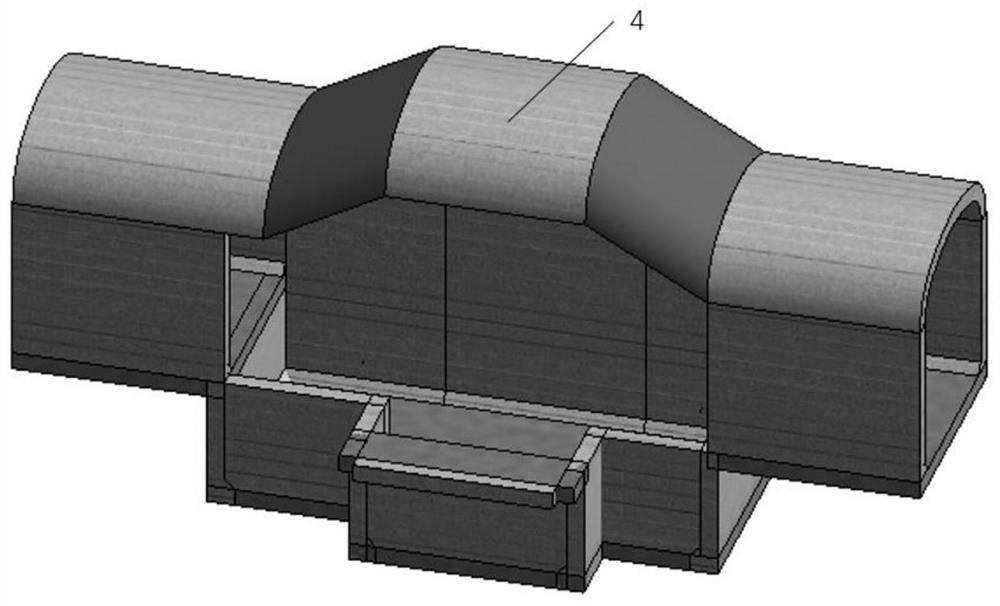

[0030] see Figure 1-7 , a construction method for quickly constructing a partial underground second-story well in the initial lining stage of a buried tunnel, comprising the following steps:

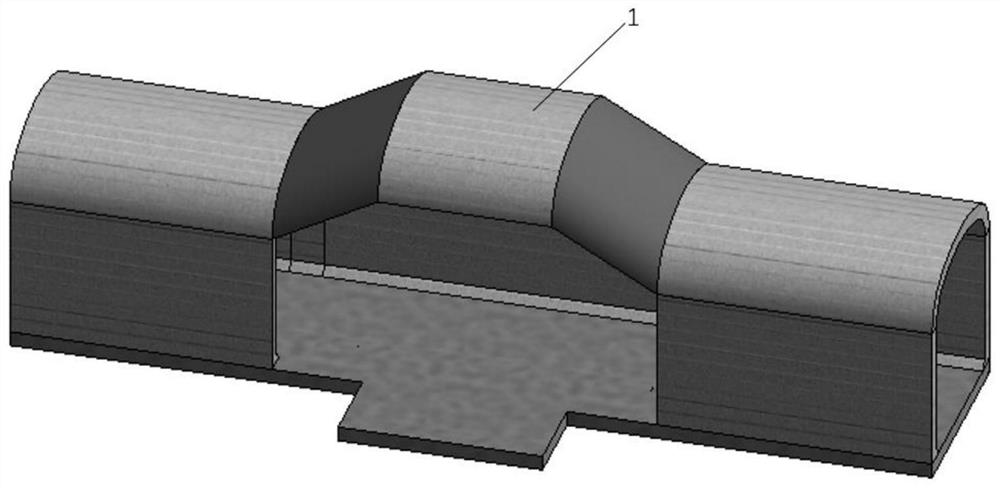

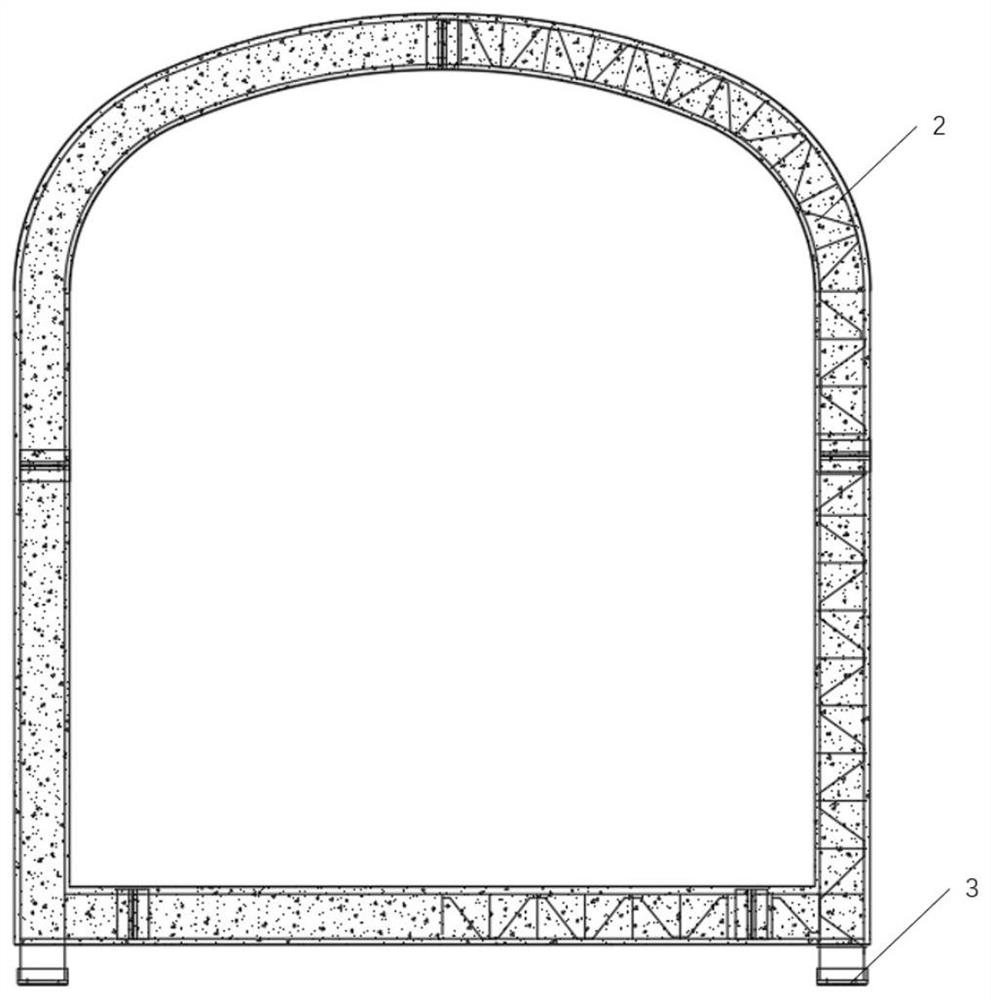

[0031] Step 1: Excavate the two-story well structure of the tunnel in sections; first excavate the first floor 1 of the two-story well structure, and construct the first floor grid 2; the construction time can be flexibly arranged and the construction sequence can be adjusted.

[0032] Step 2: Make the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com