Three-axis long auger and construction method of occlusal pile

A technology of auger drilling rig and construction method, which is applied in the direction of rotary drilling rig, drilling equipment and method, rotary drilling, etc. It can solve the problems of stringing holes, difficulty in construction, difficulty in occlusal of B piles and moving A piles, etc. Achieve the effects of easy occlusal, shortened and simplified construction procedures, and simple and easy construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

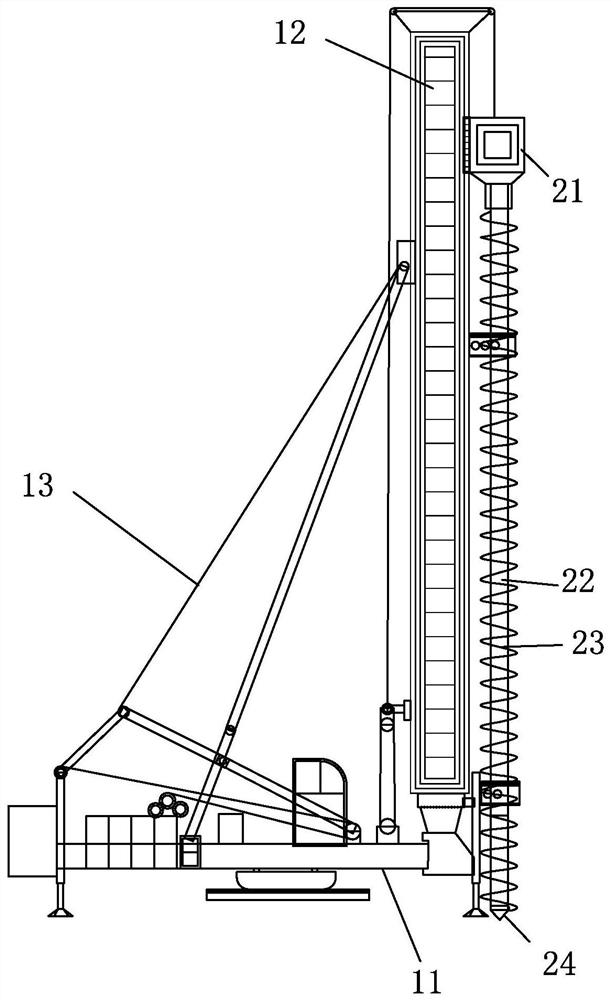

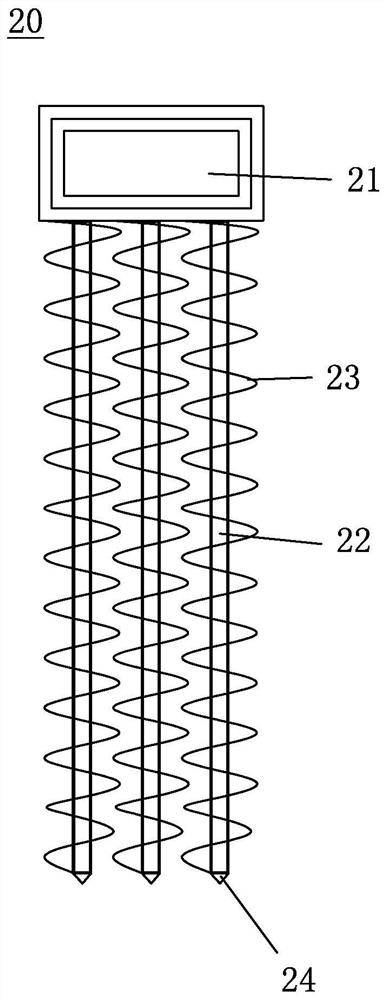

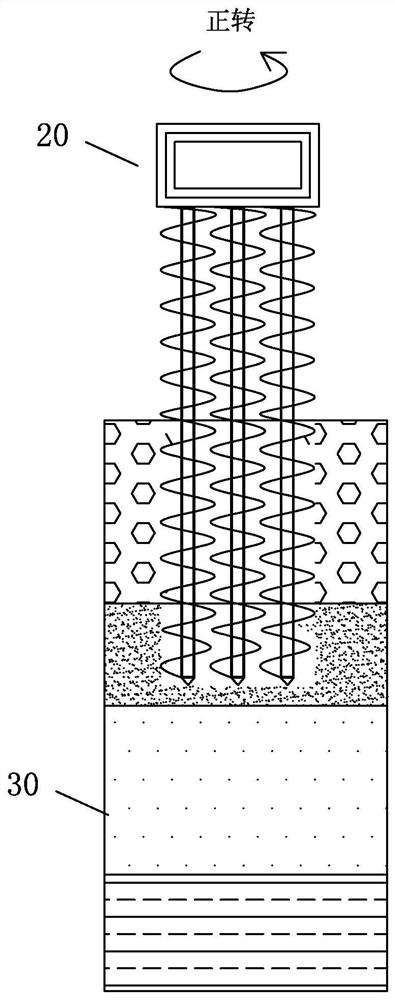

[0029] Such as figure 1 and figure 2 As shown, the three-axis long helical drilling machine of the present invention comprises a frame 11, a guide mechanism 12 is installed on the frame 11, a drilling mechanism 20 is installed on the guide mechanism 12, and the drilling mechanism 20 is driven by the transmission mechanism 13 under the guide mechanism 12 can do up and down vertical movement, of which: such as figure 2 , the drilling mechanism 20 includes three hollow drill rods 22 arranged side by side, the drill rods 22 have a long hollow hole along the axis, the three drill rods 22 are installed under the power head 21, and the power head 21 drives the three drill rods 22 to do synchronous forward rotation and synchronous reverse; the top port of the drill rod 22 is connected with the concrete pouring device (not shown in the figure) through the conduit; The drill bit 24 opened during rotation, when the drill bit 24 is opened, the concrete slurry poured from the top port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com