Seal connection method and structure of exposed frame curtain wall

A technology for exposed frame curtain walls and connecting structures, which is applied to walls, building components, building structures, etc., can solve the problems of no leaks, reduced sealing performance, and EPDM strips that do not have waterproof performance, etc., and achieve Improved service life and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

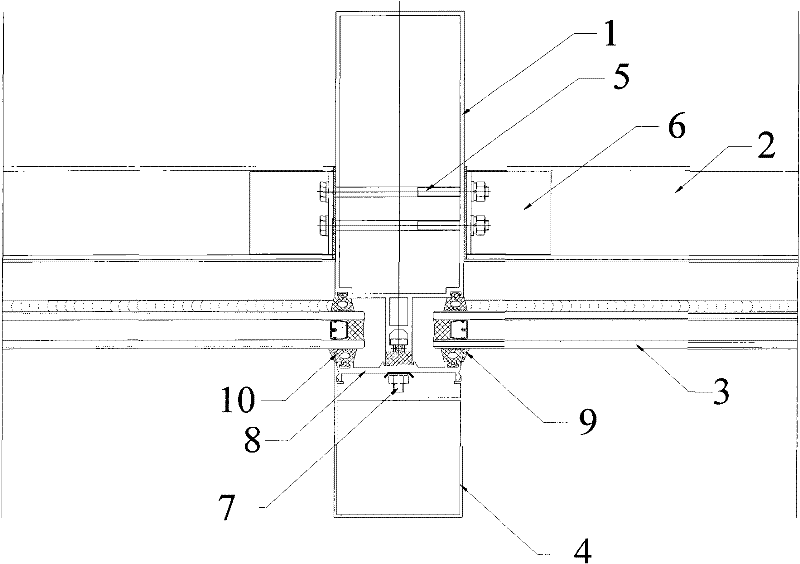

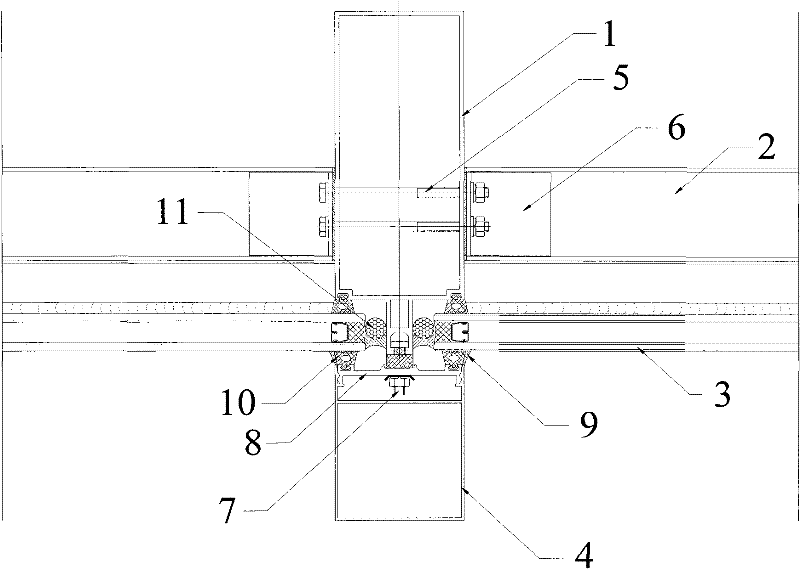

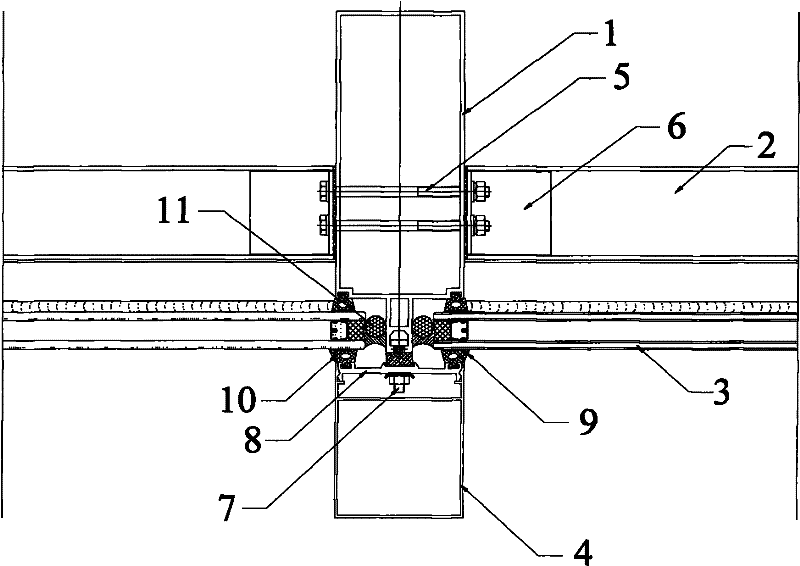

[0021] Such as figure 2 As shown, a sealed connection structure of an exposed frame curtain wall, the device includes an aluminum alloy column 1, an aluminum alloy beam 2, an insulating glass 3, an aluminum alloy decorative cover plate 4, a first M6 stainless steel bolt group 5, and an aluminum alloy beam connecting angle Code 6, second M6 stainless steel bolt group 7, aluminum alloy decorative buckle plate 8, sealant 9, EPDM strip 10 and foam rod 11, aluminum alloy column 1 through the first M6 stainless steel bolt group 5 and the aluminum alloy on both sides The alloy beam 2 is connected, the aluminum alloy beam 2 is provided with an aluminum alloy beam connection corner 6 near the aluminum alloy column 1, the aluminum alloy decorative cover plate 4 is connected with the aluminum alloy decorative buckle plate 8, and the aluminum alloy decorative buckle plate 8 passes through the first Two M6 stainless steel bolt groups 7 are connected to the aluminum alloy column 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com