Colored steel tile roof provided with photovoltaic module as well as manufacturing method and manufacturing device thereof

A photovoltaic module and color steel tile technology, applied in the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation and other directions, can solve problems such as water leakage of photovoltaic modules, and achieve a fixed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

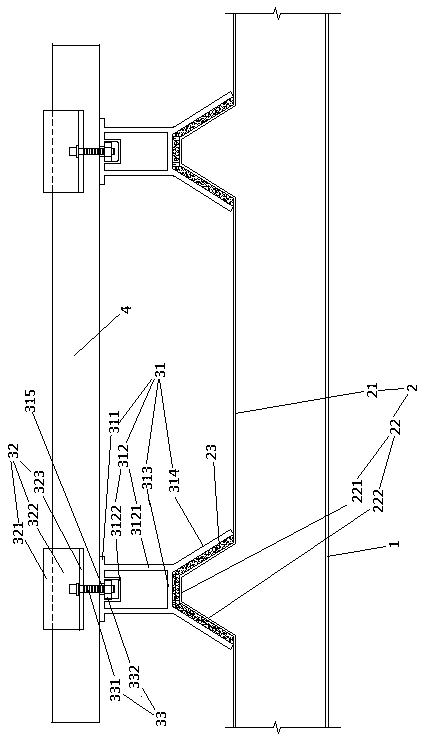

[0027] Embodiment one, see figure 1 , a color steel tile roof with photovoltaic modules, comprising a roof frame 1, color steel tiles 2, a photovoltaic module connection structure and a photovoltaic module 4.

[0028] The color steel tiles are fixed on the roof frame. The color steel tile 2 includes several main body parts 21 and convex strips 22 arranged at intervals. The raised bar includes a top wall 221 and two inclined side walls 222 whose upper ends are connected to two ends of the bottom wall. The lower ends of the inclined side walls are connected with two adjacent main body parts. The two oblique side walls are distributed in a figure-eight shape.

[0029] The photovoltaic module connection structure includes a support base 31 , a pressing block 32 and a connection assembly 33 . The support seat is a profile structure. The support seat includes a top board 311 , a bottom board 313 connected with the top board by a connecting frame 312 and two inclined support boa...

Embodiment 2

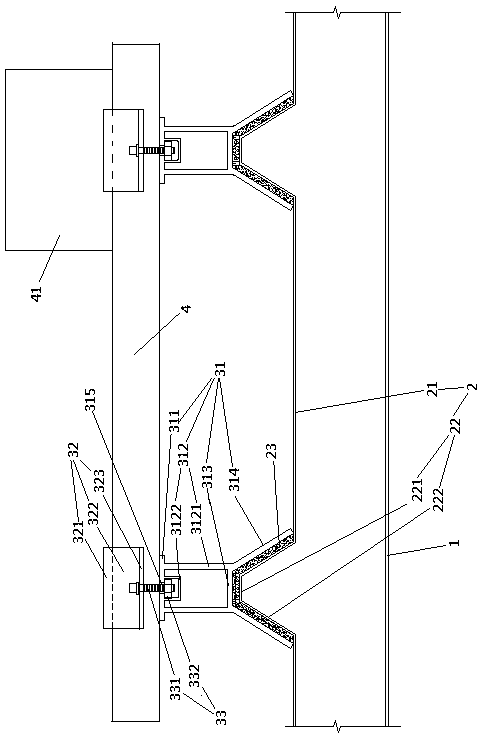

[0034] Embodiment two, the difference with embodiment one is:

[0035] see figure 2One and only one of the two photovoltaic module connection structures located at both ends of the same photovoltaic module is provided with a light-transmitting windshield 41 . The distribution direction of the connection structure of the two photovoltaic modules is parallel to the plane where the windshield is located. The function can make use of the wind force to make the photovoltaic module generate torque, thereby further improving the effect of preventing the support seat from sliding on the convex strip.

Embodiment 3

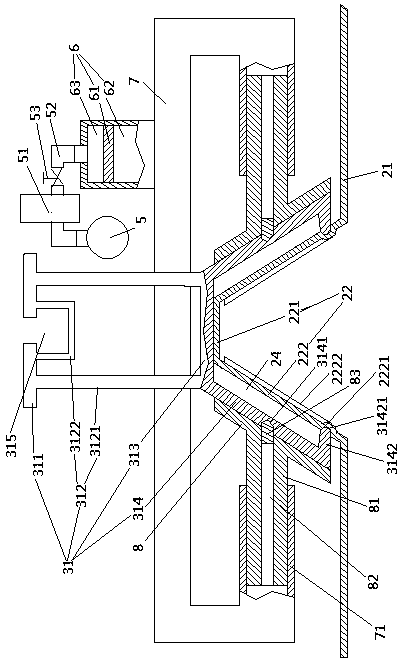

[0036] Embodiment three, the difference with embodiment two is:

[0037] see image 3 , The inclined support plate 314 is also provided with a hole guide hole 3141 for the glue inlet hole. After installation, the opening of the glue inlet hole guides the hole through the inclined support plate to form the glue inlet hole. The inclined support plate is provided with a skirt 3142 bent toward the convex strip. The outer surface of the inclined side wall is provided with a groove 2221 for accommodating the free end of the skirt. The inner surface of the inclined side wall is provided with a protrusion 2223 formed when the groove is formed. A glue-filled space 23 is enclosed between the oblique support, the oblique side wall and the skirt. The glue-filled space is filled with glue to bond the support groove and the protruding strip together. The degree of freedom end surface 31421 of the skirt is an arc surface.

[0038] This embodiment also provides a manufacturing device fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com