Aluminum finned water tank of water-cooled engine

A water-cooled engine and aluminum tandem technology, which is applied to engine components, machines/engines, engine cooling, etc., can solve the problems of complex structure of heat pipes, reduced service life, and high production costs, and achieves simple structure and improved service life. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

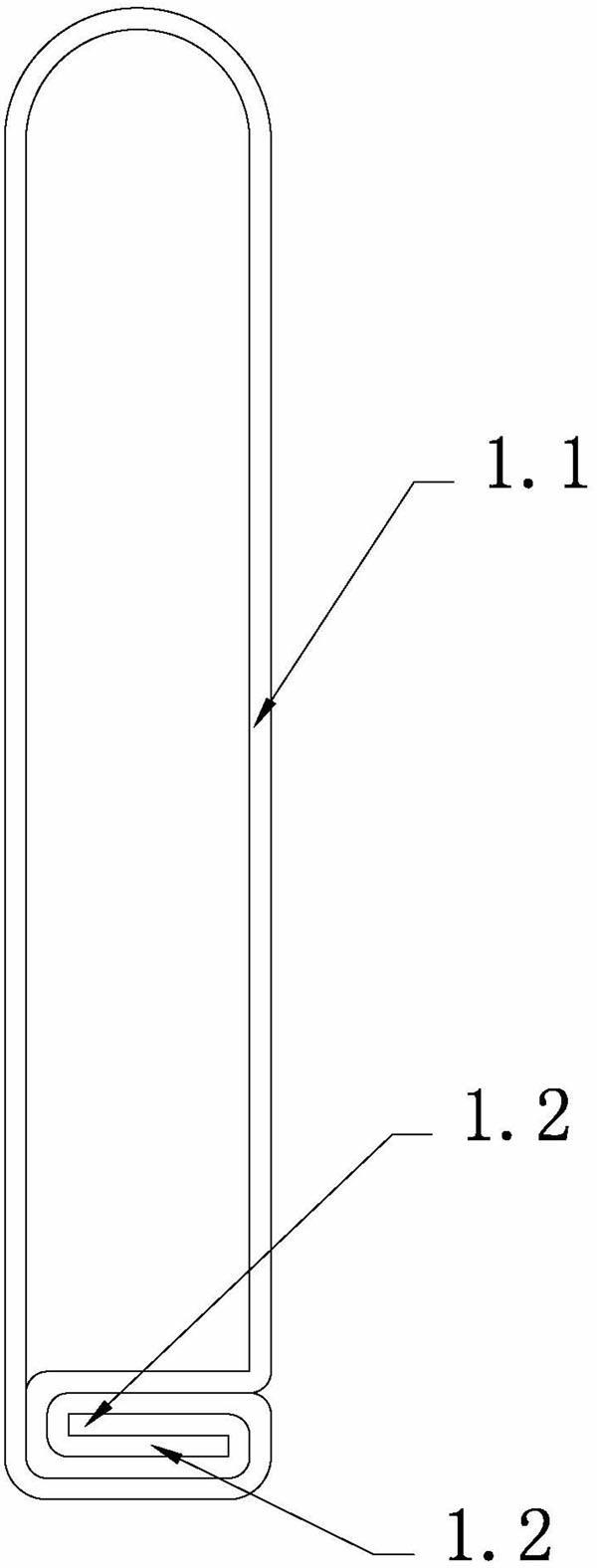

[0012] Such as figure 1 The heat pipe in the prior art shown is that the two ends 1.1 and 1.2 of the copper sheet 1 are bent into a G shape and then locked together.

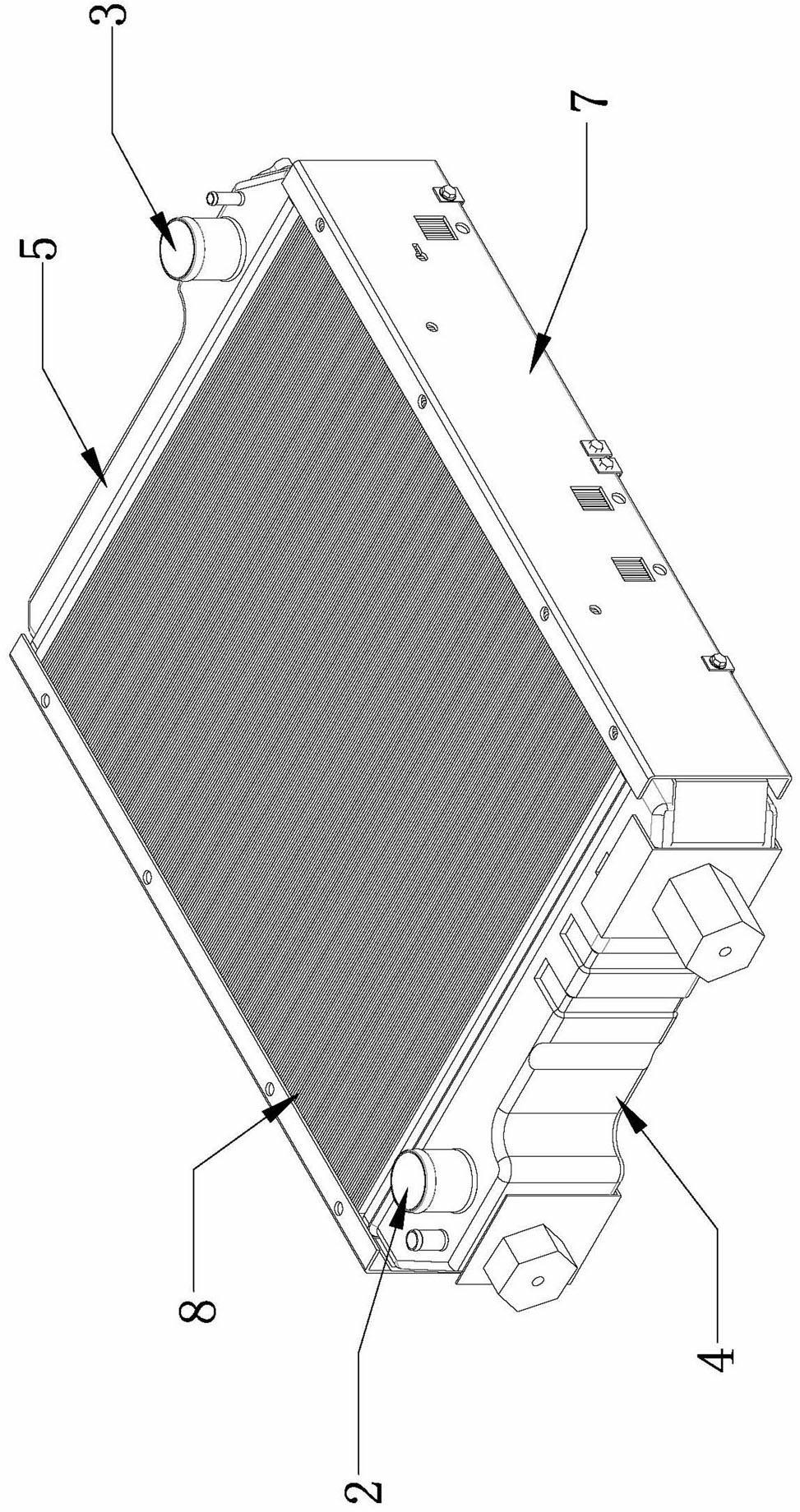

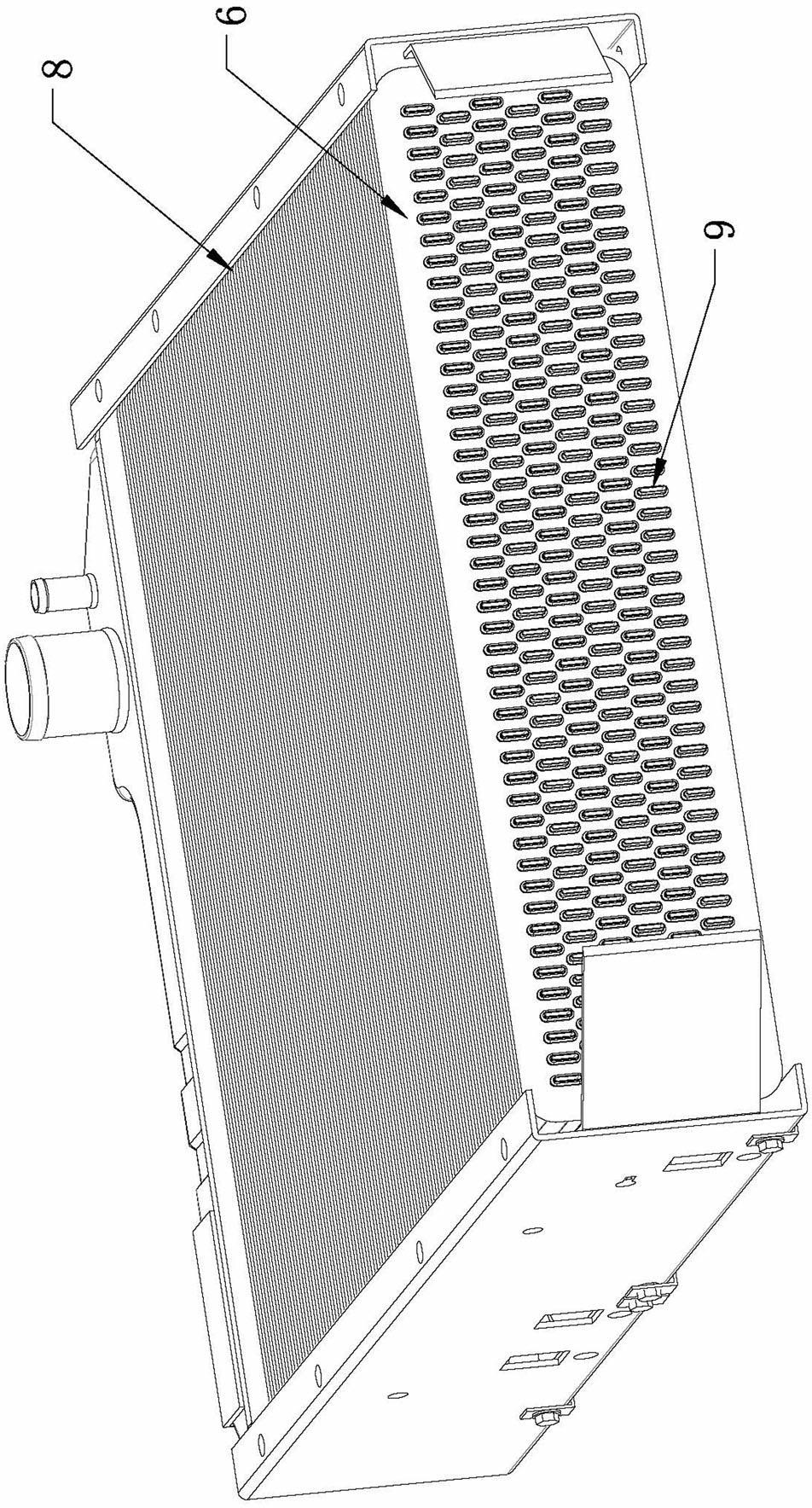

[0013] Such as figure 2 , image 3 with Figure 4 A water-cooled engine aluminum tandem fin water tank, which mainly includes a water inlet pipe 2, a water outlet pipe 3, an upper water chamber 4, a lower water chamber 5, a partition 6, a guard plate 7, a heat sink 8 and a heat pipe 9; The tube 9 is made of a seamless steel pipe after being drawn and pressed. The middle 9.1 is flat, and the two ends 9.2 and 9.3 are arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com