HDPE double-wall corrugated pipe online drilling method

A corrugated pipe and wave ring technology, which is applied in the field of online drilling of HDPE double-wall corrugated pipes, can solve the problems affecting the performance of the pipe and achieve the effect of smooth inner wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

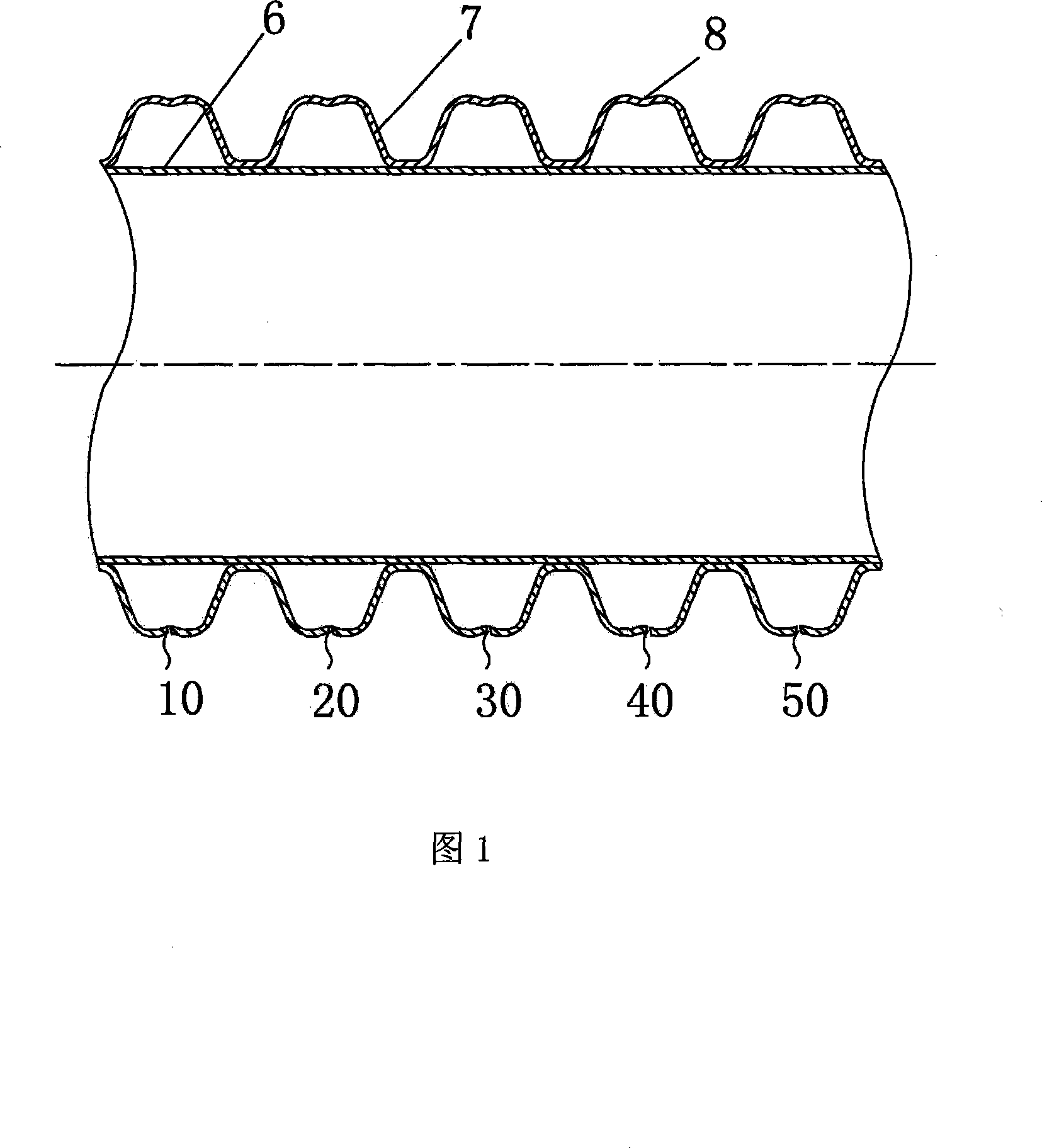

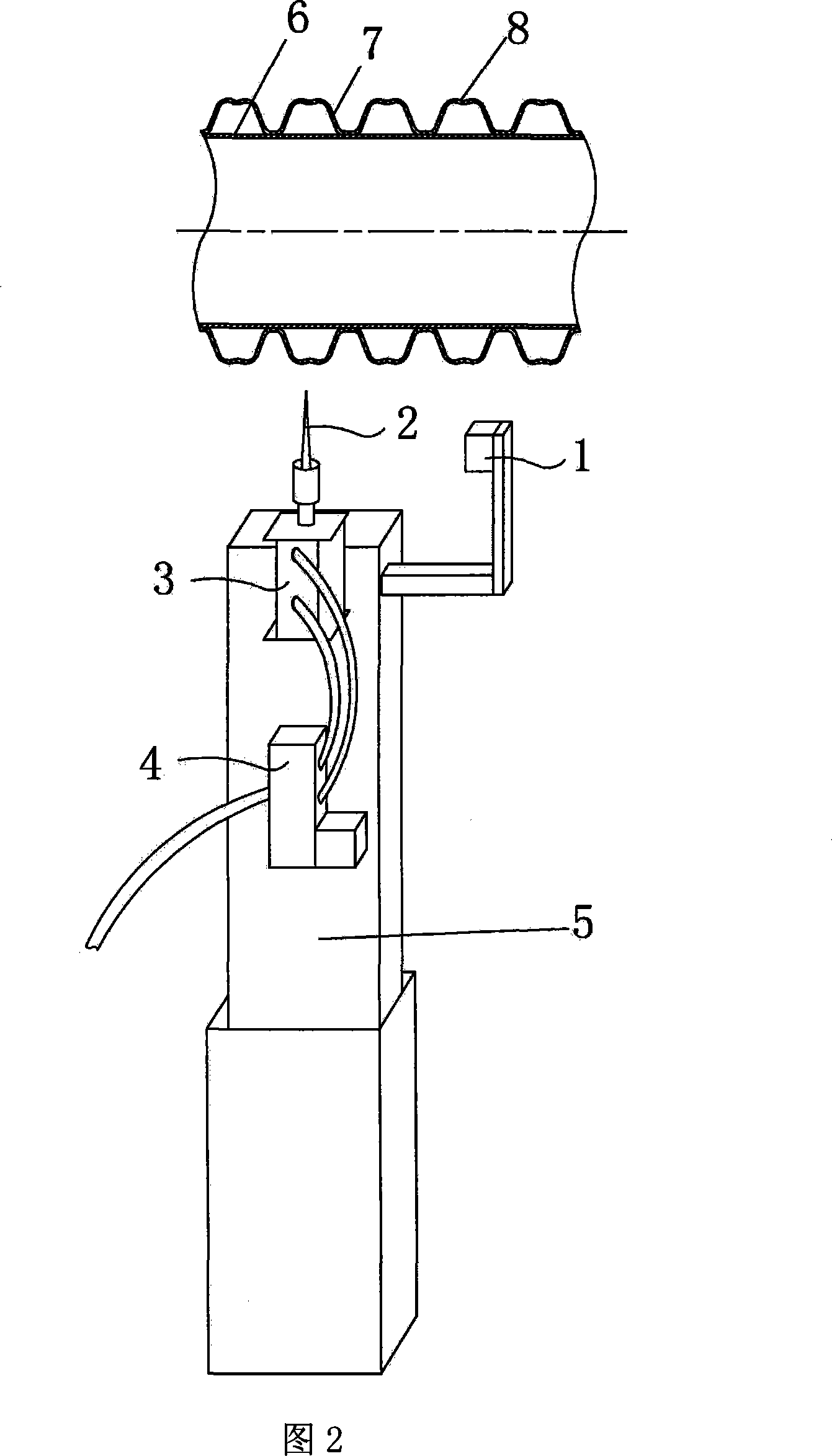

[0017] As shown in Figure 1, a HDPE double-wall corrugated pipe of the present invention has been perforated. The inner wall 6 of the corrugated pipe is provided with spaced hollow outer wall corrugations 7, and the top surface of each outer wall corrugation 7 is provided with a small wave trough 8. , there are process holes at 8 places in the small wave valley, such as process holes 10, 20, 30, 40 and 50 in the figure. In the pipe production process, the inner wall 6 and the outer wall corrugated ring 7 are extruded by two extruders. During the production process, the molten inner and outer wall materials are bonded together by the head mold and the forming module. After the pipe is formed, the outer wall is corrugated. The process hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com