Swirling-eddy-method pipeline inwall fouling cleaning, rust removing and coating corrosion preventing technology

A technology of coating anti-corrosion and rotating air flow, which is applied in the field of coating anti-corrosion, can solve the problems of reducing pipe diameter, no pipe repair, inconvenience in production and life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

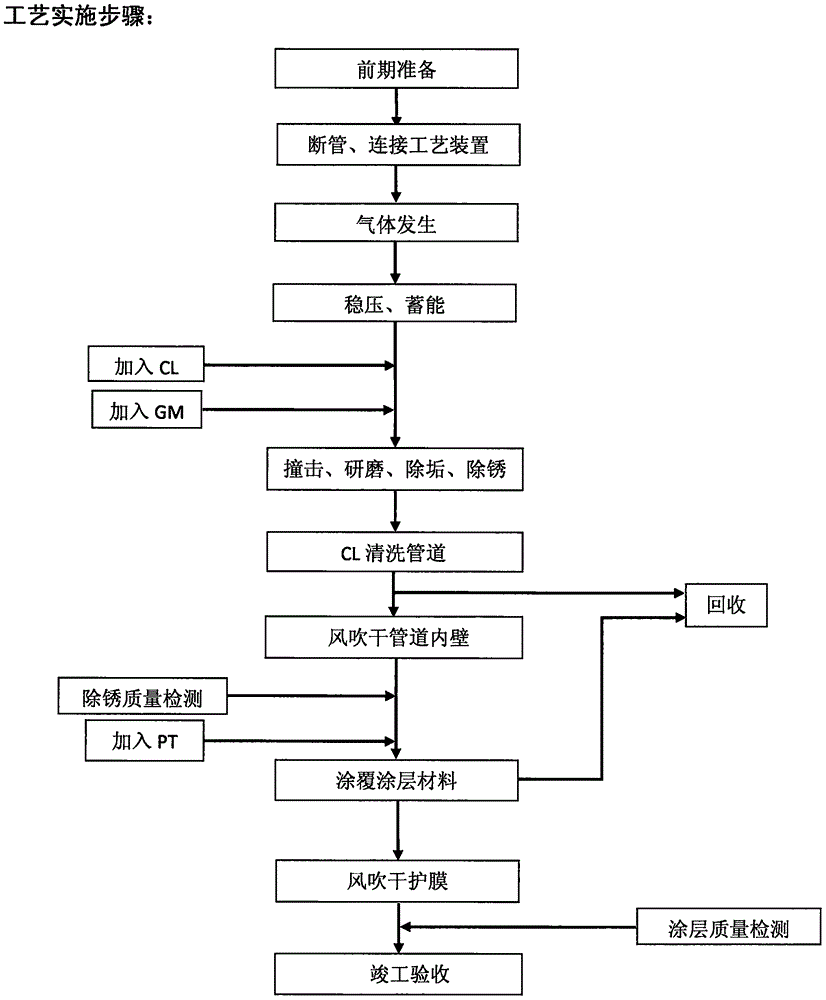

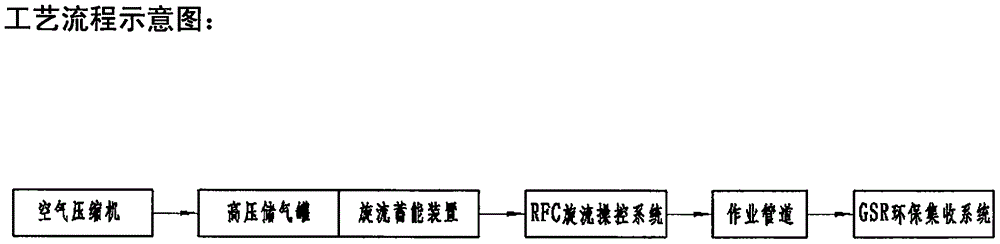

[0018] During the implementation of the present invention, according to the caliber of the pipeline to be cleared, the degree of rust, and the surrounding construction conditions, the positions of the subsection operation points are determined, the positions of the air compressor and the GSR environmental protection collection system are set, and the swirl storage is set. The pressure and gas storage capacity of the energy device, and the working parameters of the RFC swirl automatic control system.

[0019] Firstly, the compressed gas with proper pressure is released through the pressure regulating device, and enters the working pipe section through the RFC swirl automatic control system; secondly, GM series abrasives and CL are selectively added to the RFC swirl automatic control system according to the material of the pipeline and the degree of rust in the pipe. Environmentally-friendly cooling lubricating fluid, the pressure of the compressed gas is controlled by the RFC sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com