Trenchless built-in sleeve pipeline repairing equipment and method

A pipeline repair and non-excavation technology, which is applied in the direction of mechanical equipment, pipes/pipe joints/fittings, pipe components, etc., can solve the problems of limited construction volume, easy collapse, lack, etc., and achieve low overall project cost and short construction time Short, less impact on traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

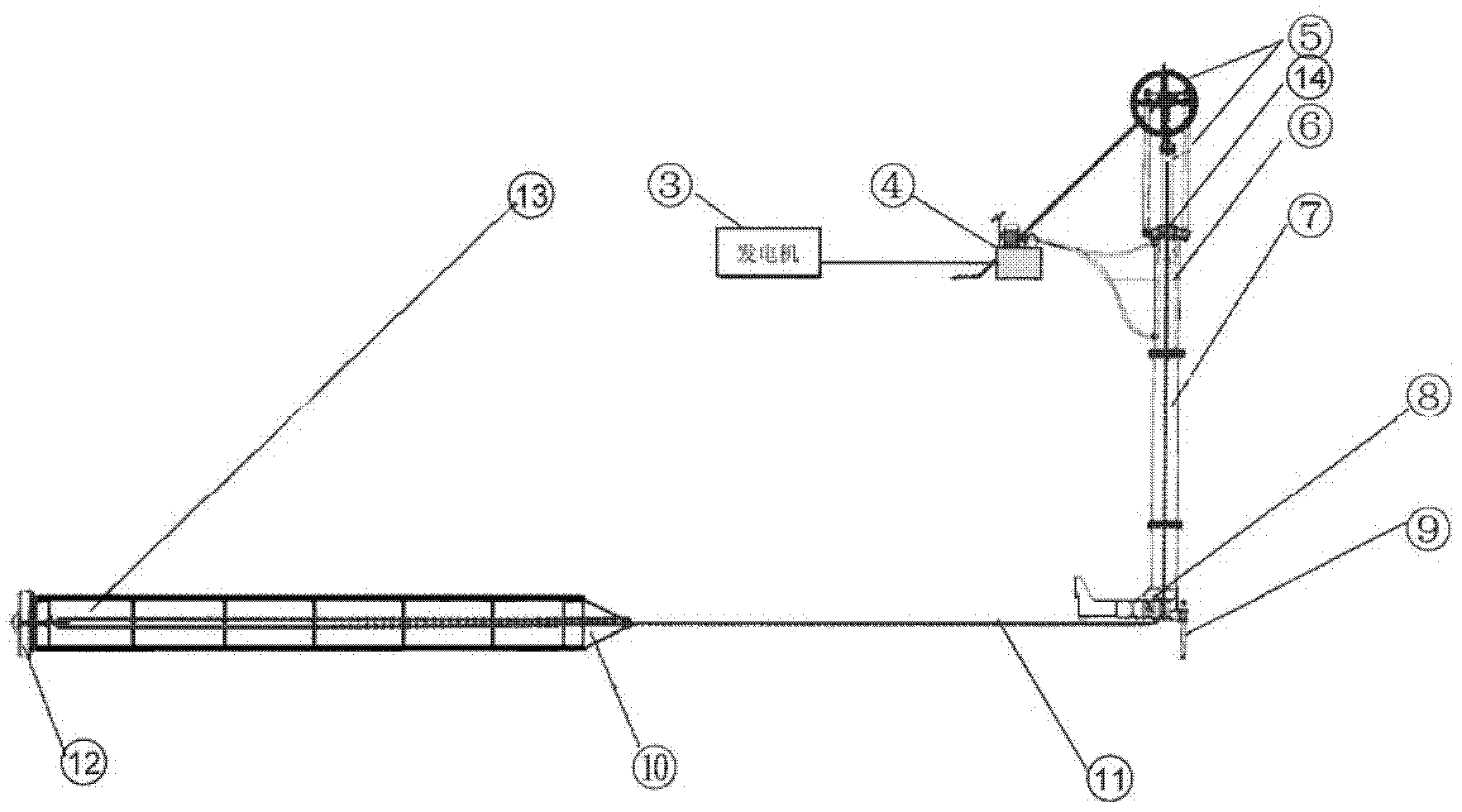

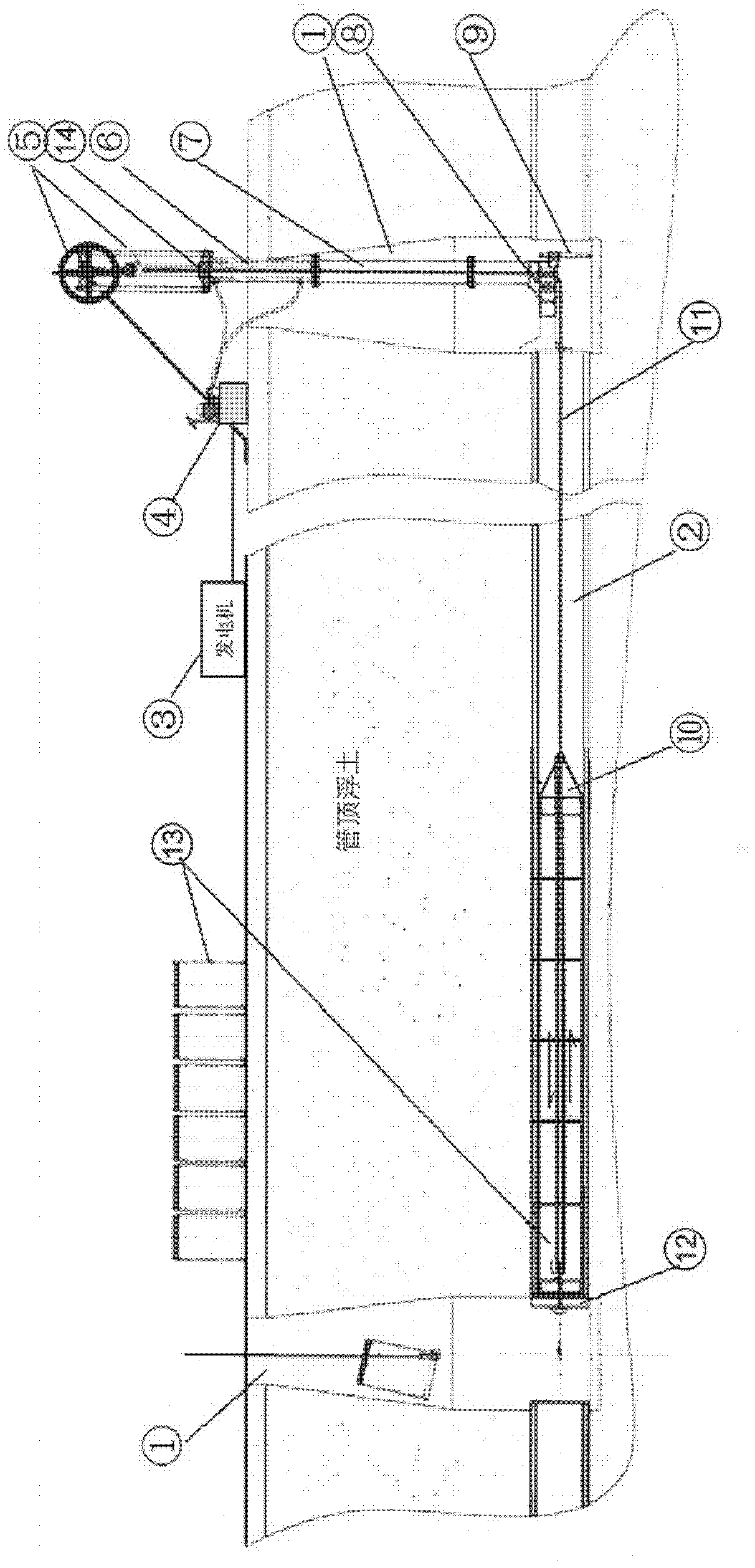

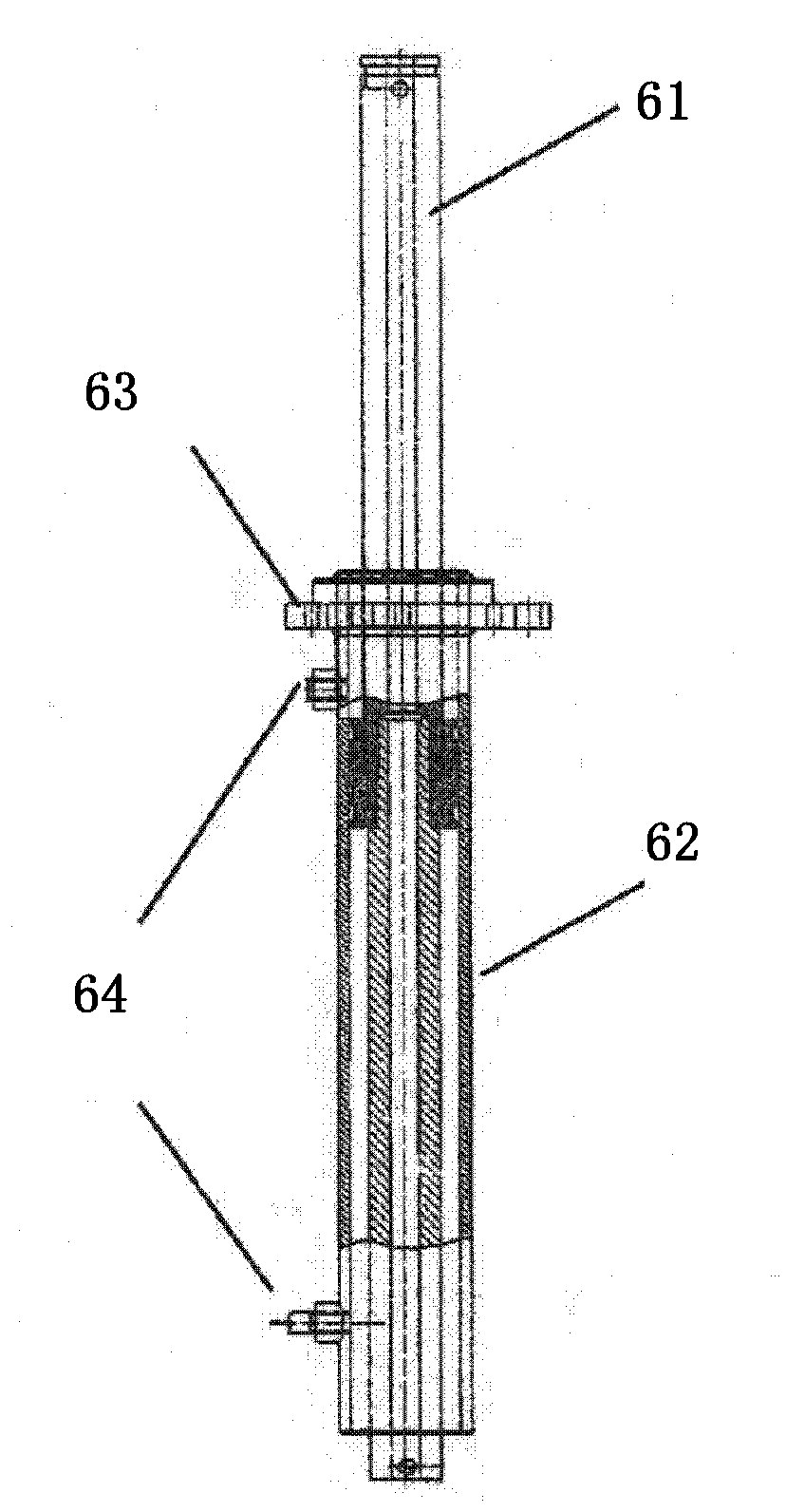

[0051] The invention proposes a non-excavation built-in casing pipeline repair method. The method is to use two adjacent inspection wells as the working space and use the pipeline to be repaired as the carrier to transport the short pipe to the In the pipeline to be repaired, use the traction device to pull the short pipe forward, and complete the collision and connection of the next short pipe and the previous short pipe one by one during the process of advancing, and then use the traction device to drag the combined pipe after collision Move to the desired position, repeat the assembly of short pipes in the pipeline to be repaired, and finally form a new pipeline, and drag the new pipeline to a suitable position; then fill the gap between the new pipeline and the pipeline to be repaired with cement mixture , so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com