Sandblaster with pipe automatically wound

A sandblaster, automatic technology, used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as low work efficiency and poor product quality, and achieve the goal of improving product quality and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

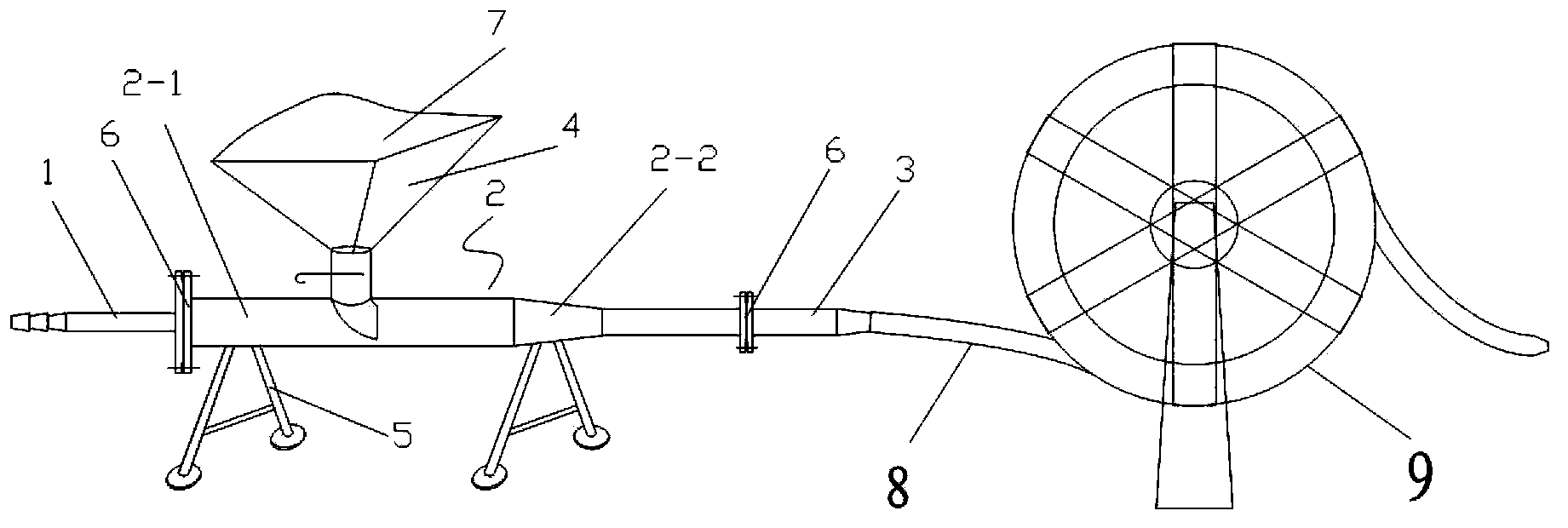

[0016] As shown in the figure, a sand blaster with automatic pipe collection in the present invention is mainly composed of an air inlet pipe 1, a sand storage pipe 2 and a sand discharge pipe 3 which are sequentially connected by a flange 6, and the upper part of the sand storage pipe is fixed vertically. The sand feeding hopper 4 connected with it has a support leg 5 fixedly connected to the lower part of the sand storage pipe, and the sand outlet pipe is connected with a sand outlet rubber hose 8, and the sand outlet rubber hose is coiled on a tube collection disk 9 driven by a motor.

[0017] When in use, firstly block a part of the front end of the jacking pipe, the air inlet pipe is connected with the air pump throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com