Spirally wound profile and spirally wound pipe

A spiral winding pipe and spiral winding technology, which is applied in the field of spiral winding profiles and spiral winding pipes, can solve the problems of difficult implementation of profile meshing methods, and achieve the effect of easy pipe thickness and no need for construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

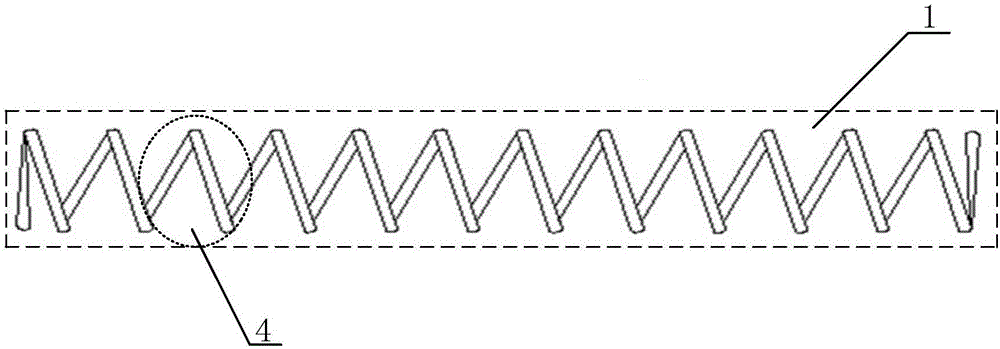

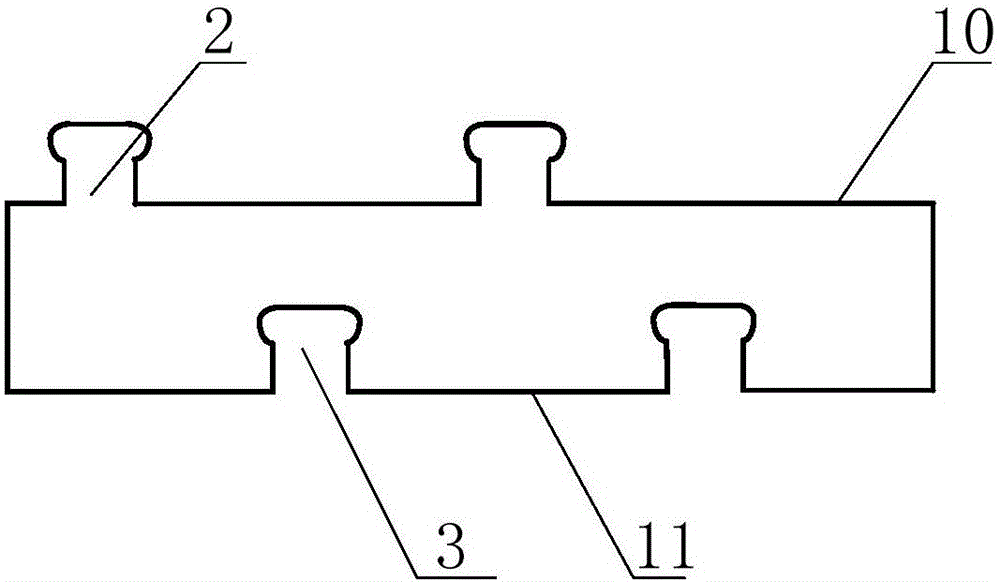

[0028] see figure 1 As shown, it is a front view of a helically wound profile provided by the application, including a helical profile body 1, see figure 2 As shown, it is a schematic cross-sectional structure diagram of the spirally wound profile provided by the present application. The spirally wound profile includes a clamping part 2, a clamping fitting part 3,

[0029] The clamping part 2 is arranged on the first side 10 of the profile body 1 along the radial direction, and the snap-fitting part 3 is arranged on the second side 11 of the profile body 1 along the radial direction;

[0030] Both the clamping part 2 and the clamping fitting part 3 extend along the spiral direction of the profile body 1;

[0031] The profile body 1 includes several integrally formed spiral profile rings 4 , and the adjacent spiral profile rings 4 are fixed by the clamping part 2 and the clamping fitting part 3 .

[0032] Further, the clamping part 2 is a convex part continuously arranged on...

Embodiment 2

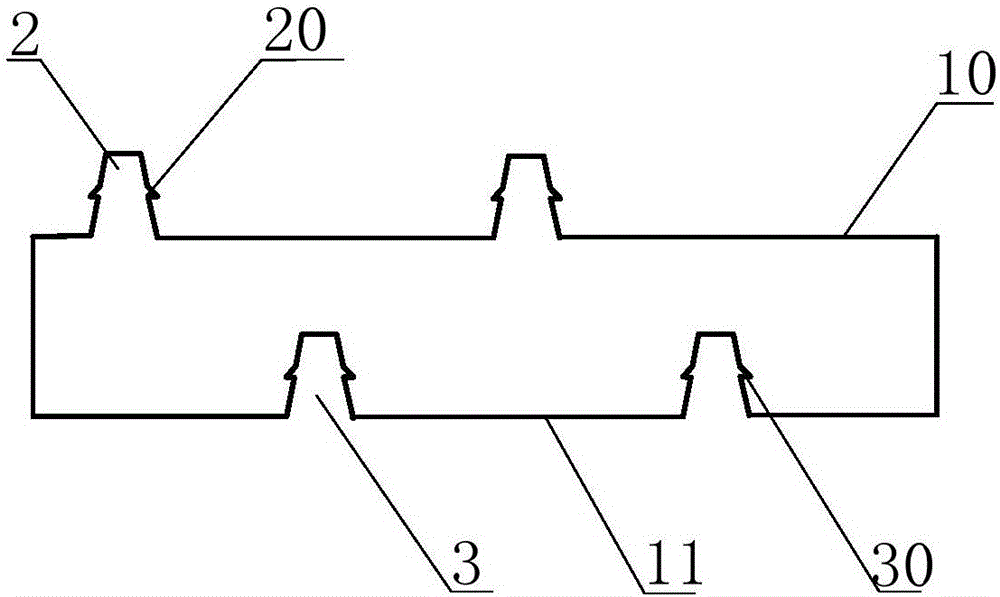

[0035] On the basis of embodiment 1, see image 3 As shown, it is a schematic diagram of an engagement structure of the clipping part 2 and the clipping fitting part 3 provided in the present application. The clamping part 2 is provided with a buckle 20, and the clamping fitting part 3 is provided with a clamping hole 30, and the buckle 20 cooperates with the clamping hole 30, thereby realizing the adjacent spiral profile circle 4 They are tightly fixed by the clamping part 2 and the clamping fitting part 3 .

Embodiment 3

[0037] On the basis of Embodiment 1, the difference from Embodiment 1 is that the snap-fit part 2 is a raised part intermittently provided on the first side 10 of the profile body 1; the snap-fit part 3 is a discontinuous The recessed part is provided on the second side 11 of the profile body 1; the opening end of the recessed part is flush with the second side 11, and the recessed part is engaged with the raised part.

[0038] Further, the protruding parts are T-shaped ribs arranged at equal or unequal intervals on the first side 10 of the profile body 1, and the recesses are arranged at equal or unequal intervals on the first side 10 of the profile body 1. T-shaped slots on two sides 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com