Branch crushing vehicle

A branch crushing and shredder technology, which is applied to grain processing and other directions, can solve the problems of inconvenient replacement of machine maintenance parts, difficult sorting of branches and branches, and urban traffic impact, and achieves low working noise, good crushing quality, and reduced operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

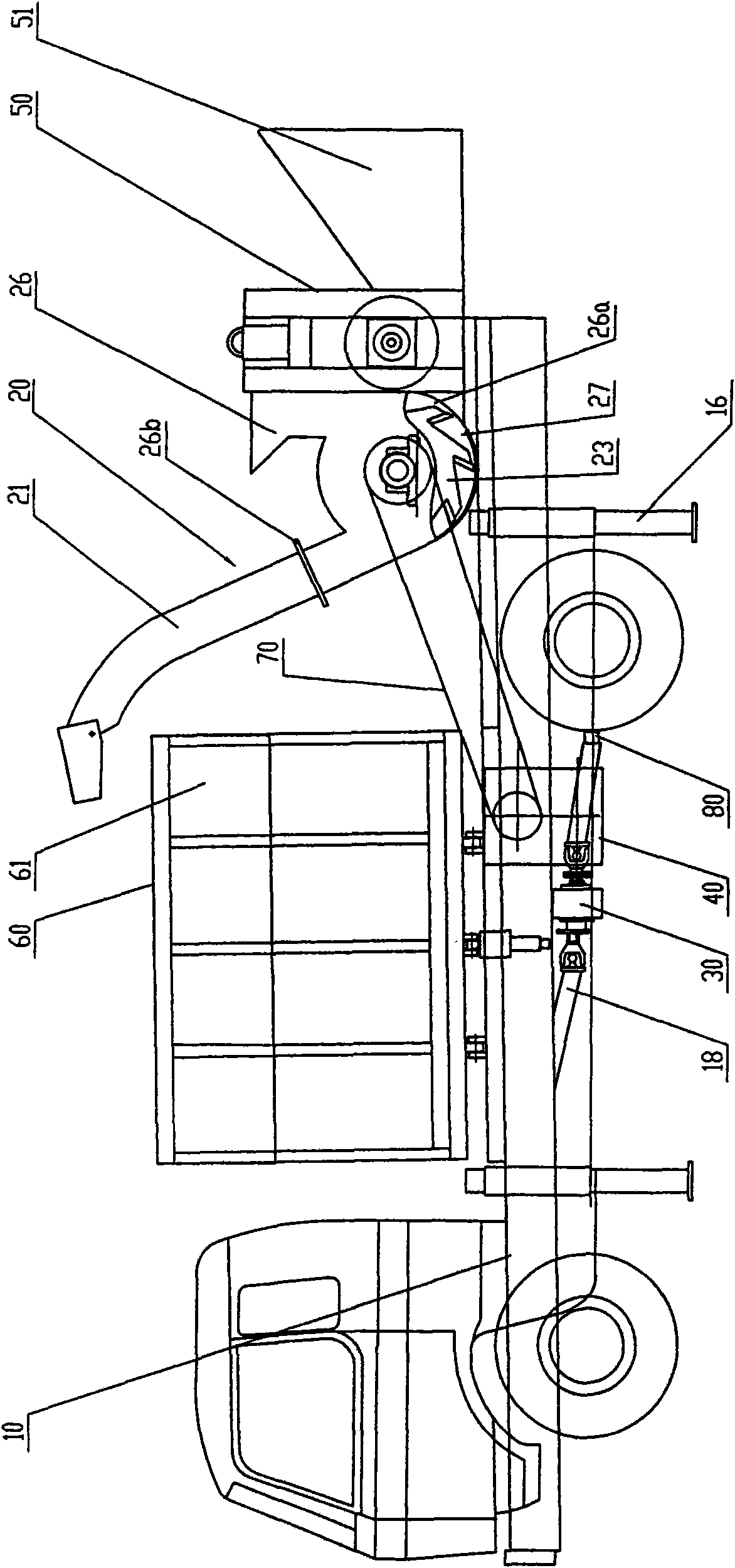

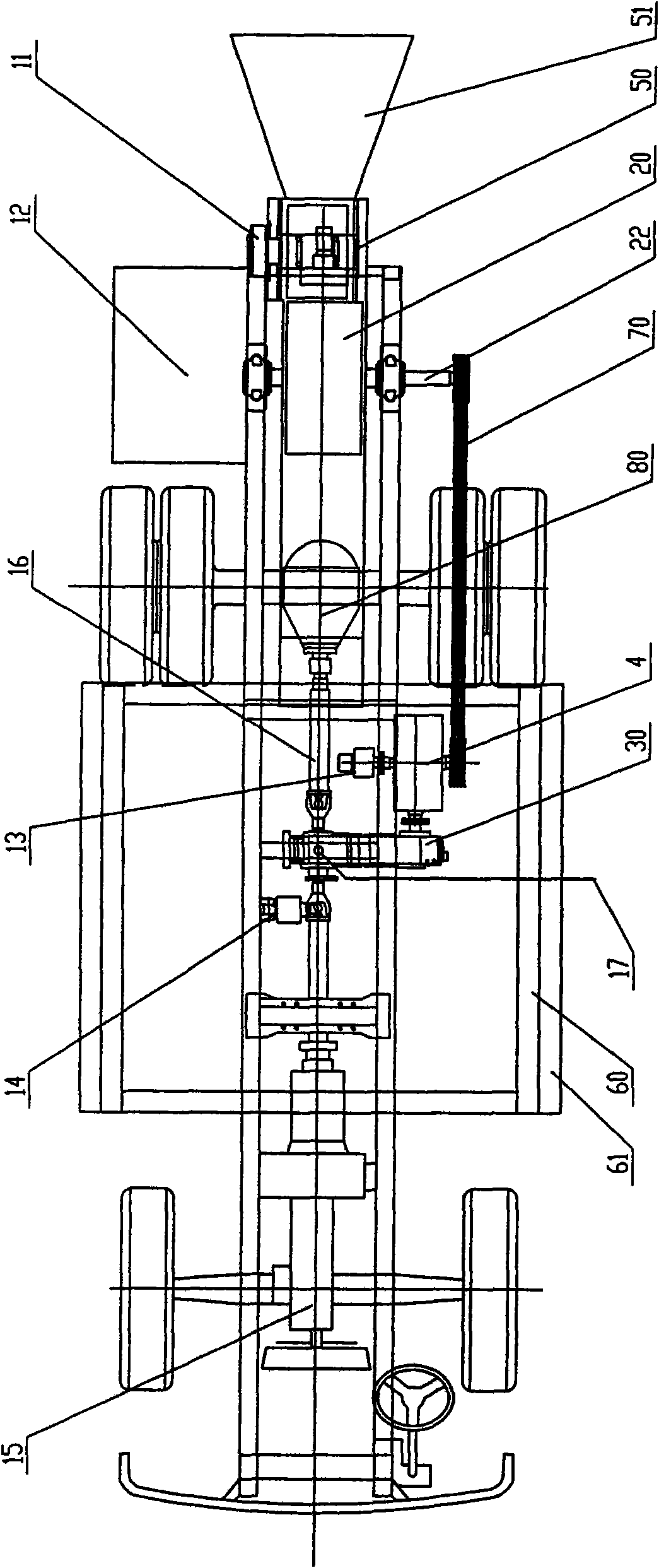

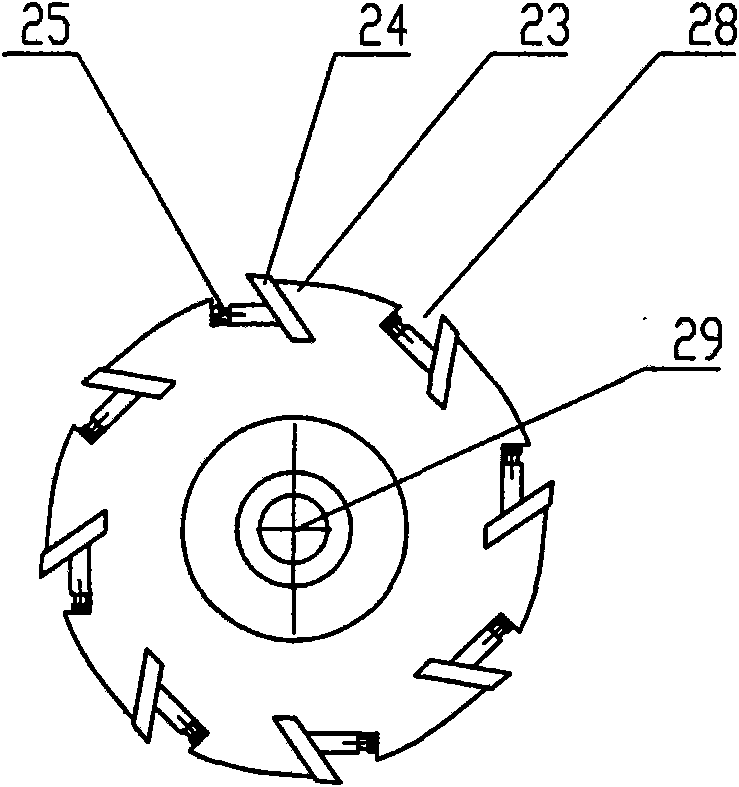

[0026] control figure 1 , figure 2 , the crushing car of the present invention is mainly composed of automobile chassis 10, transmission shaft 18, power splitter 30, gear transmission box 40, material storage compartment 60, transmission chain 70, pulverizer 20, hydraulic pump 13, hydraulic motor 11, hydraulic valve ( Not shown), engine 15 and support leg 16 are made up. The engine 15 , the hydraulic pump 13 , the power splitter 30 , and the gear transmission box 40 are fixed below the chassis 10 . The pulverizer 20 and the storage compartment 60 are placed above the chassis of the automobile, and the discharge port 21 of the pulverizer 20 is placed above the feed opening of the storage compartment 60 .

[0027] The power of the engine 15 is input to the input shaft 36 of the power splitter 30 through the output shaft of the gearbox and then through the transmission shaft 18 . The first output shaft 34 of the power splitter 30 is connected to the input shaft 45 of the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com