Liftable high-bracket trolley and adjacent-span forming and whole-span longitudinal moving mounting process for bridge

A high-support and trolley technology, which is used in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of large traffic impact, hidden traffic safety hazards, and long construction period of local road closures, so as to achieve small traffic impact and uniform pressure. , the effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

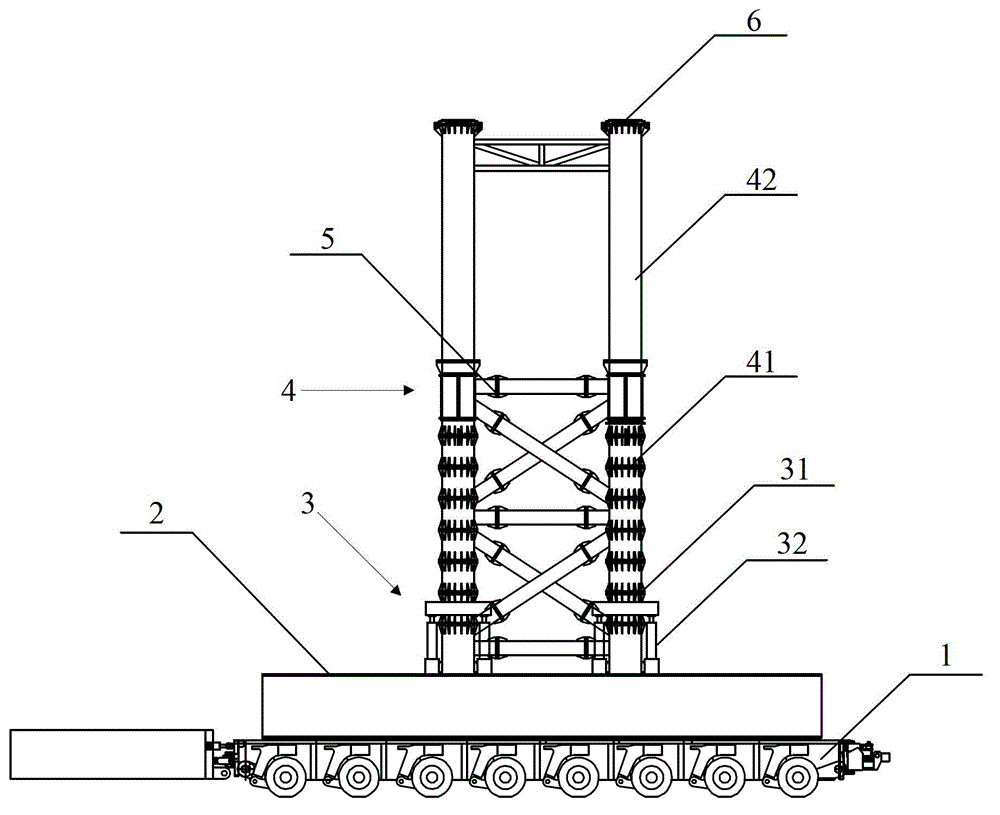

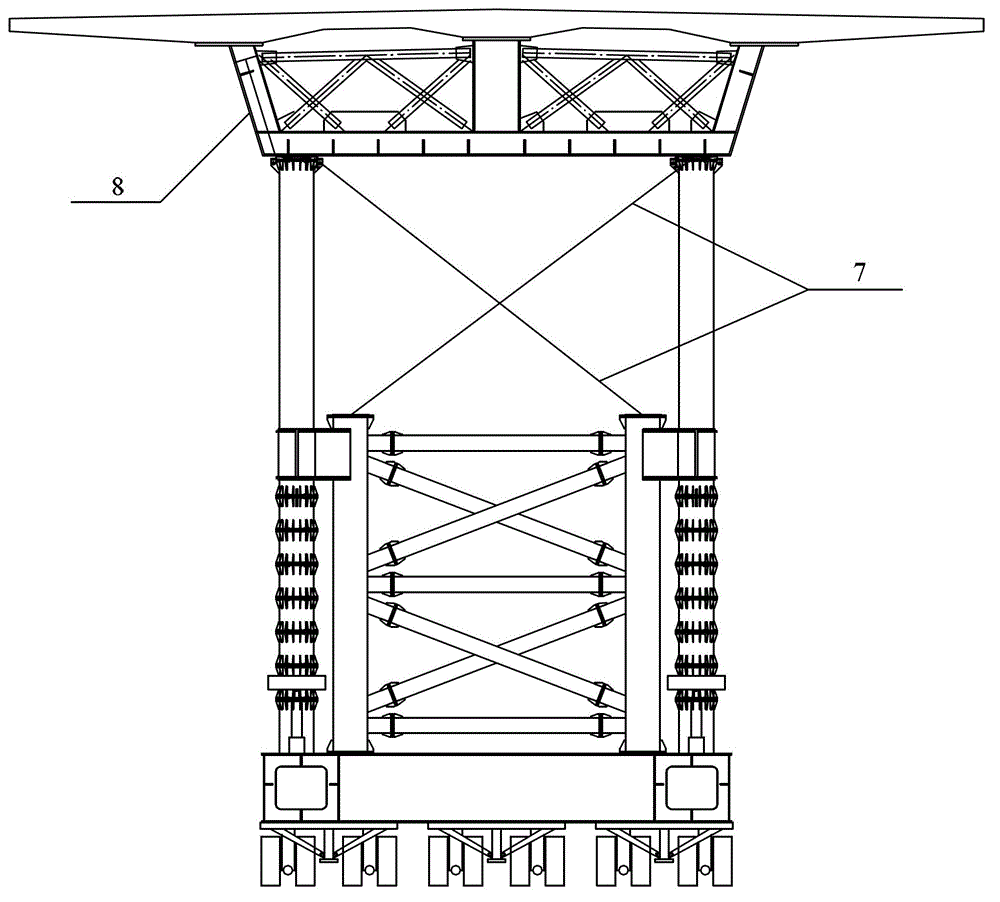

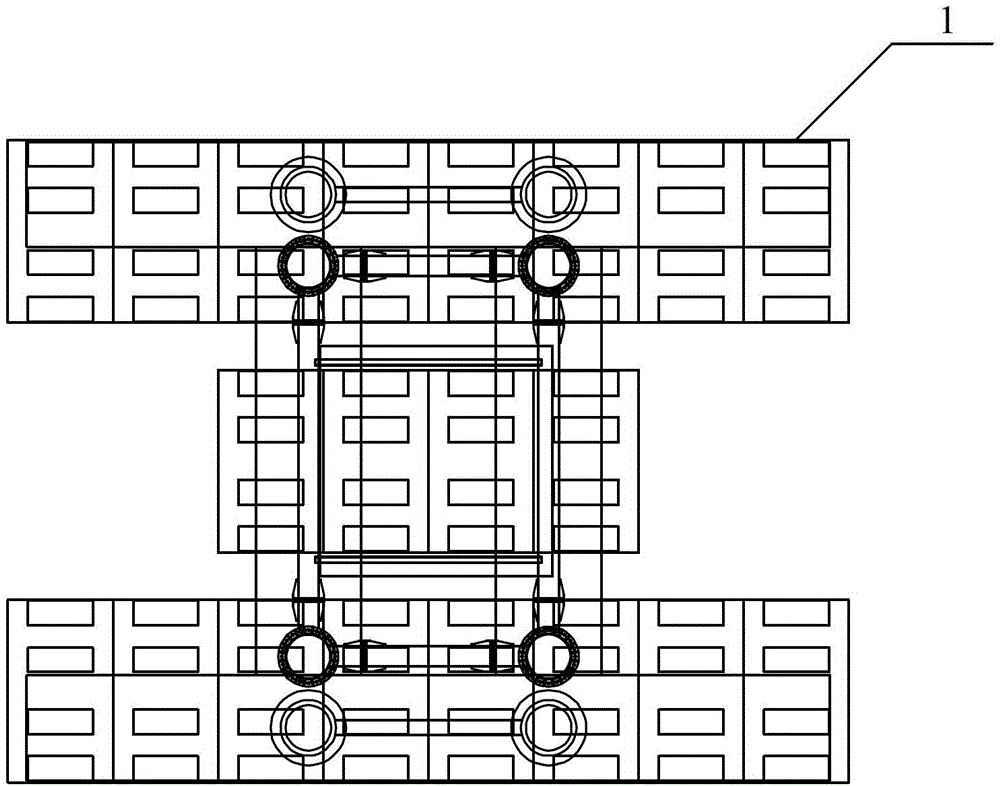

[0043] Below in conjunction with the accompanying drawings and specific embodiments, the liftable high-support trolley and the installation process of bridge span forming and whole-span longitudinal movement proposed by the present invention will be further described in detail. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0044] The core idea of the present invention is to provide a liftable high support trolley and a bridge span forming whole span longitudinal movement installation process. The liftable high support trolley includes a load transport module, a load sharing beam, a hydraulic jacking system, Vertical support system and stable support system, the load sharing beam is set on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com