Pre-stress combined well/tunnel module structure construction method and module structure

A technology of modular structure and construction method, applied in tunnels, shaft linings, tunnel linings, etc., can solve the difficult construction of underground long-span tunnels and rectangular tunnels, can not meet the construction requirements of deep underground tunnels, and rectangular shield tunnel segment load bearing Problems such as poor ability to achieve the effect of easy promotion, fine construction quality, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

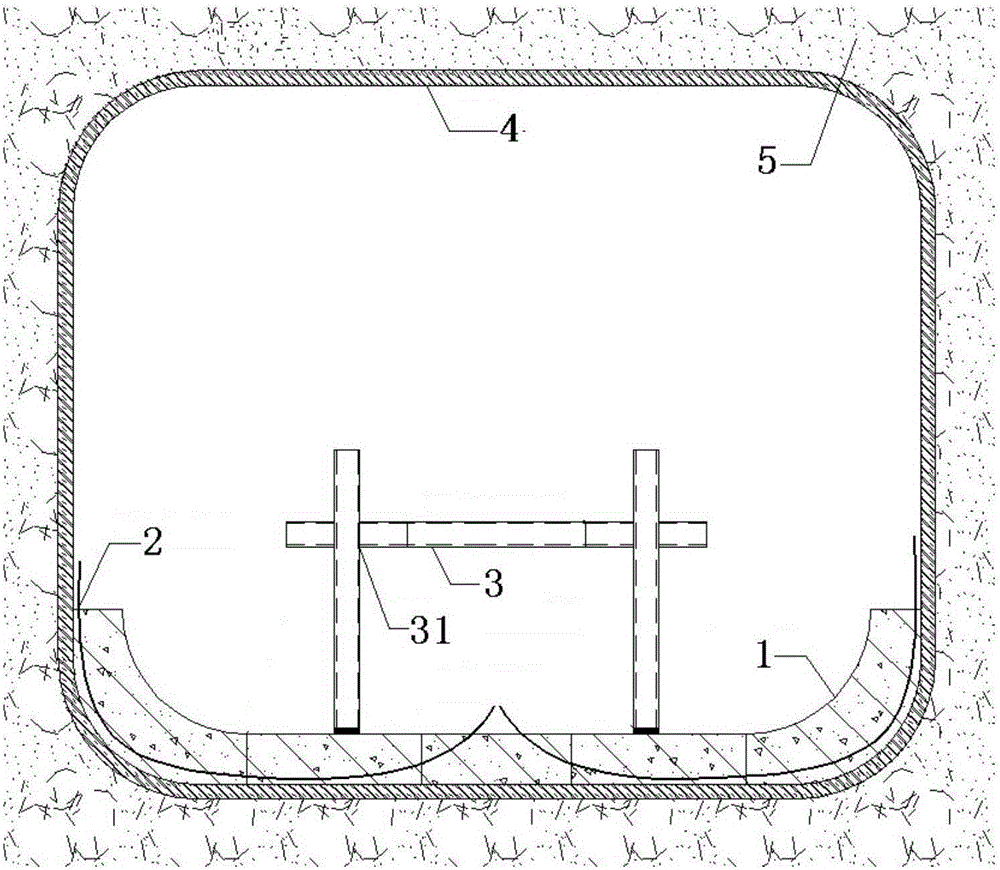

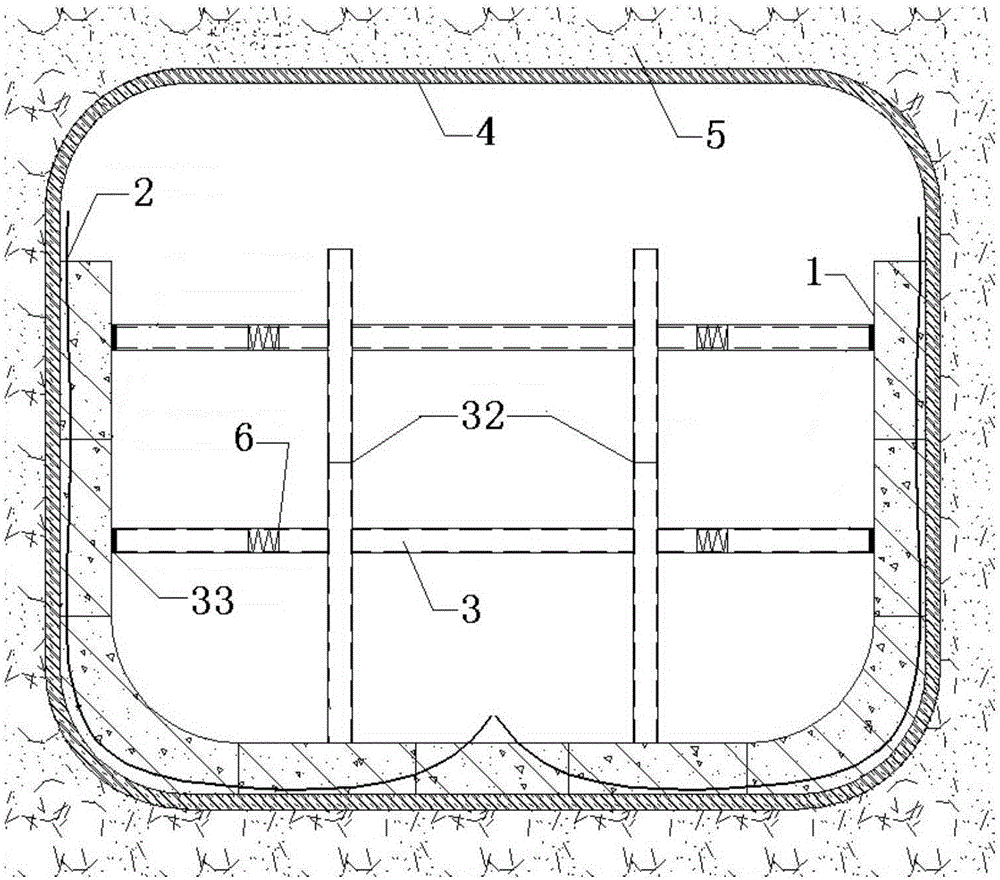

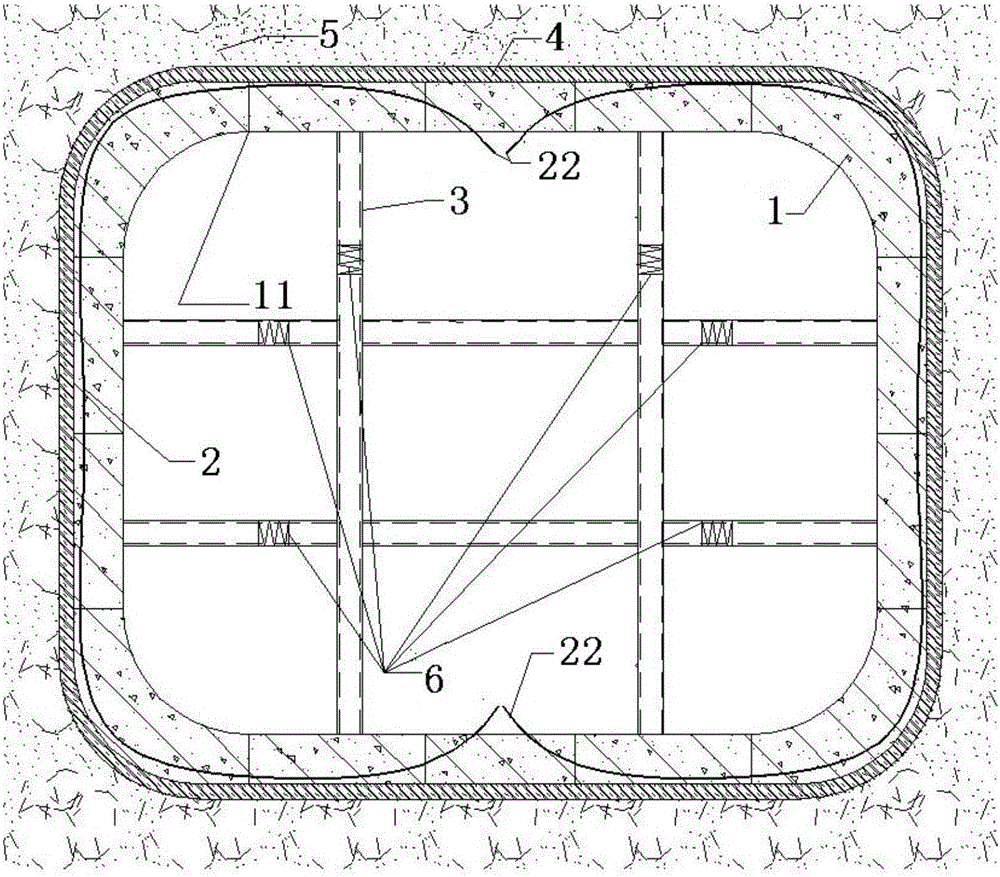

[0039] Such as Figure 1 to Figure 12 The construction method of the prestressed combined well tunnel module structure includes the following steps: a. Firstly, according to the design and construction needs, carry out standardized design and production in the module factory, and determine according to the section size, embedding depth, soil layer characteristics and project characteristics. The total number of modules; b, secondly, build a vertical shaft at the beginning of the tunnel, and use a shield to build support at the horizontal starting point to form a shield support ring 4; c, in the above shield support ring 4, along the shield support ring 4 The prefabricated lining segment 1 is gradually assembled from the bottom to the top of the wall, and the prestressed cable 2 is threaded in the prefabricated lining segment 1, and the position of the threaded prestres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com