A method for detecting the energy distribution in the mill of the intelligent automatic speed regulation system of the mill

A technology of automatic speed regulation and energy distribution, applied in grain processing and other directions, can solve problems such as high labor intensity, achieve strong anti-interference ability, reduce steel consumption and cost, and measure signal characteristics with obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

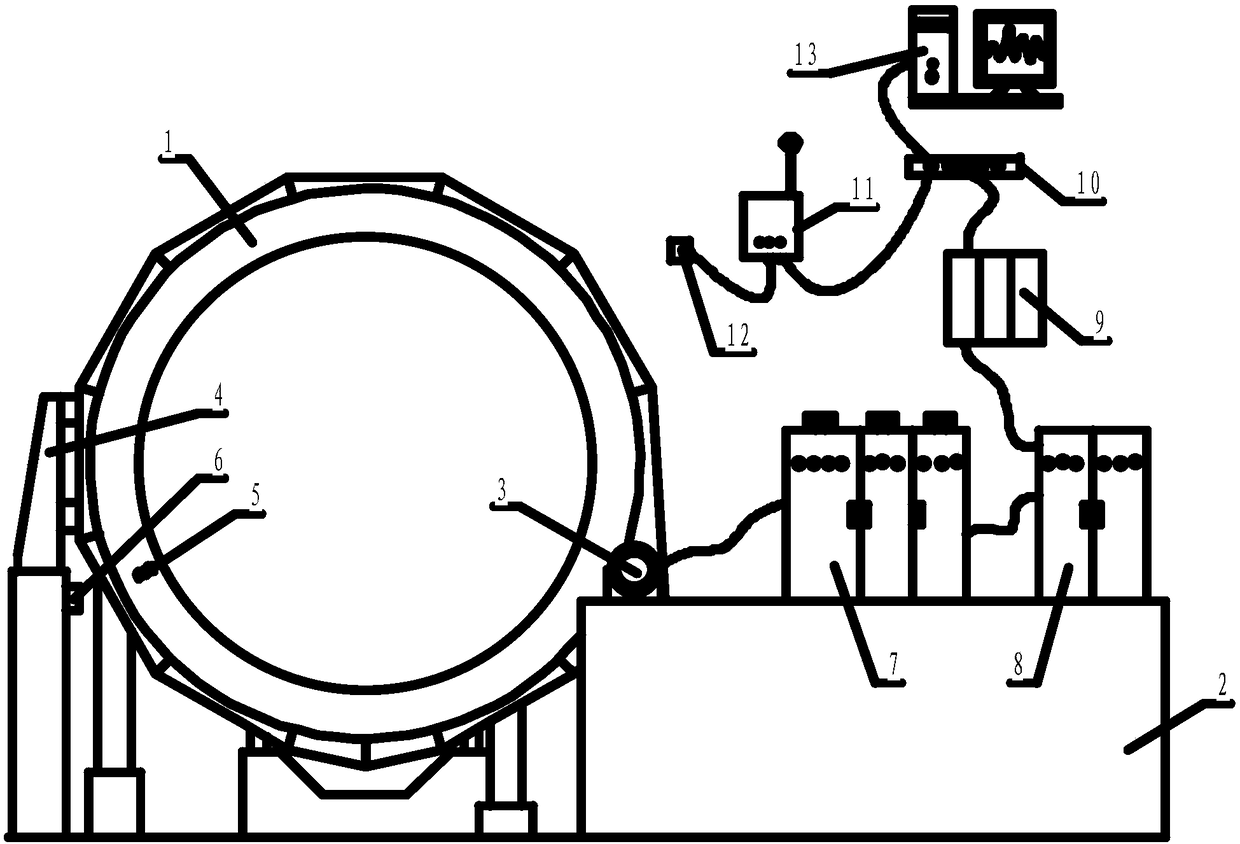

[0035] A mill 1 is arranged on one side of the base 2, a stand 4 is arranged under the mill 1, a motor 3 is arranged on one side above the base 2, the motor 3 drives the mill 1 to rotate, and a wireless vibration sensor 5 is arranged on the mill 1, so A trigger 6 is set on the stand 4, a governor 7 is set between the motor 3 and the low-voltage control cabinet 8, a data acquisition module 9 is set between the low-voltage control cabinet 8 and the switch 10, and the switch 10 is set in the wireless vibration signal processing and intelligent Between the speed regulation strategy system 13 and the wireless vibration signal receiver 11, an AC power supply 12 is arranged on one side of the wireless vibration signal receiver 11, a motor 3, a governor 7, a low-voltage control cabinet 8, a data acquisition module 9, a switch 10, a wireless Vibration signal receiver 11, AC power supply 12, wireless vibration signal processing and intelligent speed regulation strategy system 13 are prov...

Embodiment 2

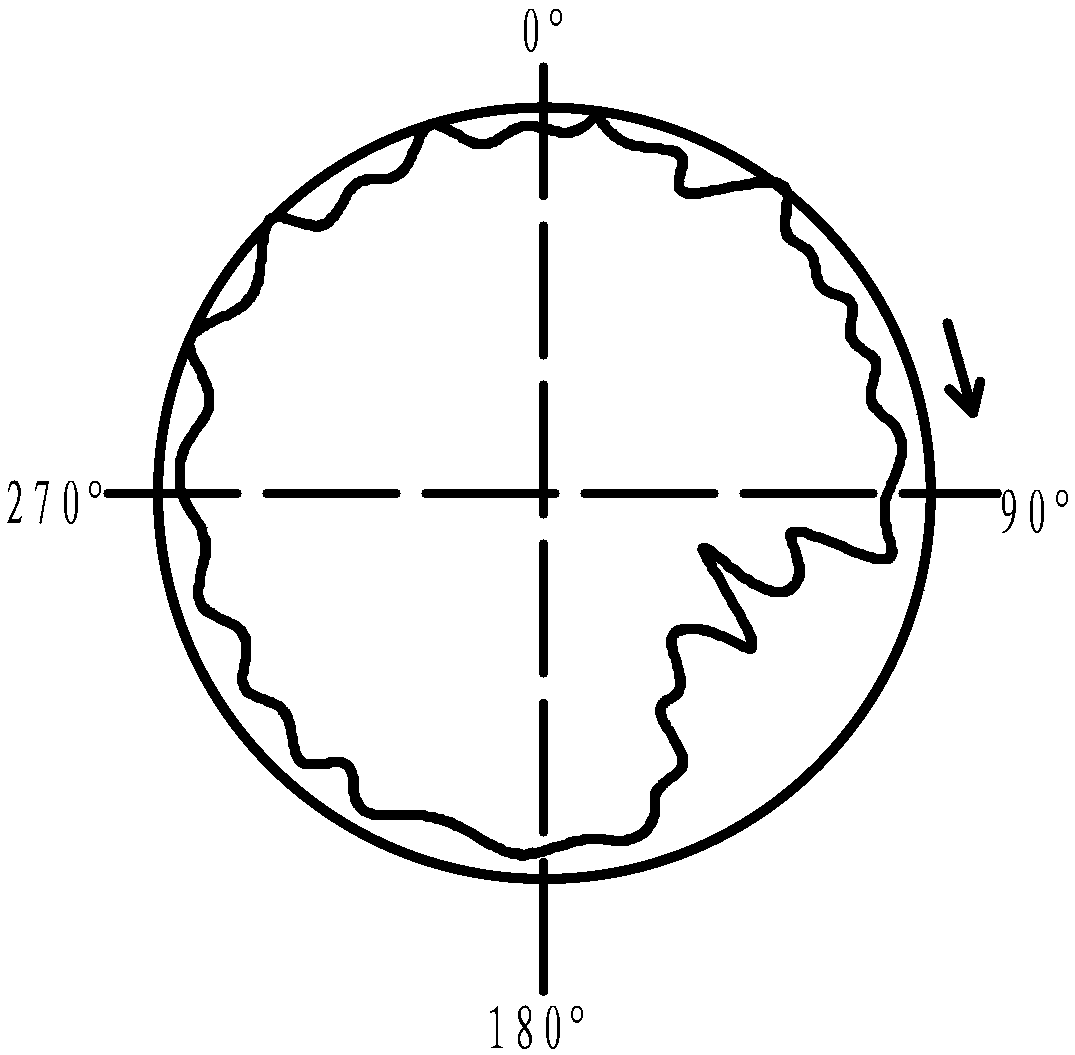

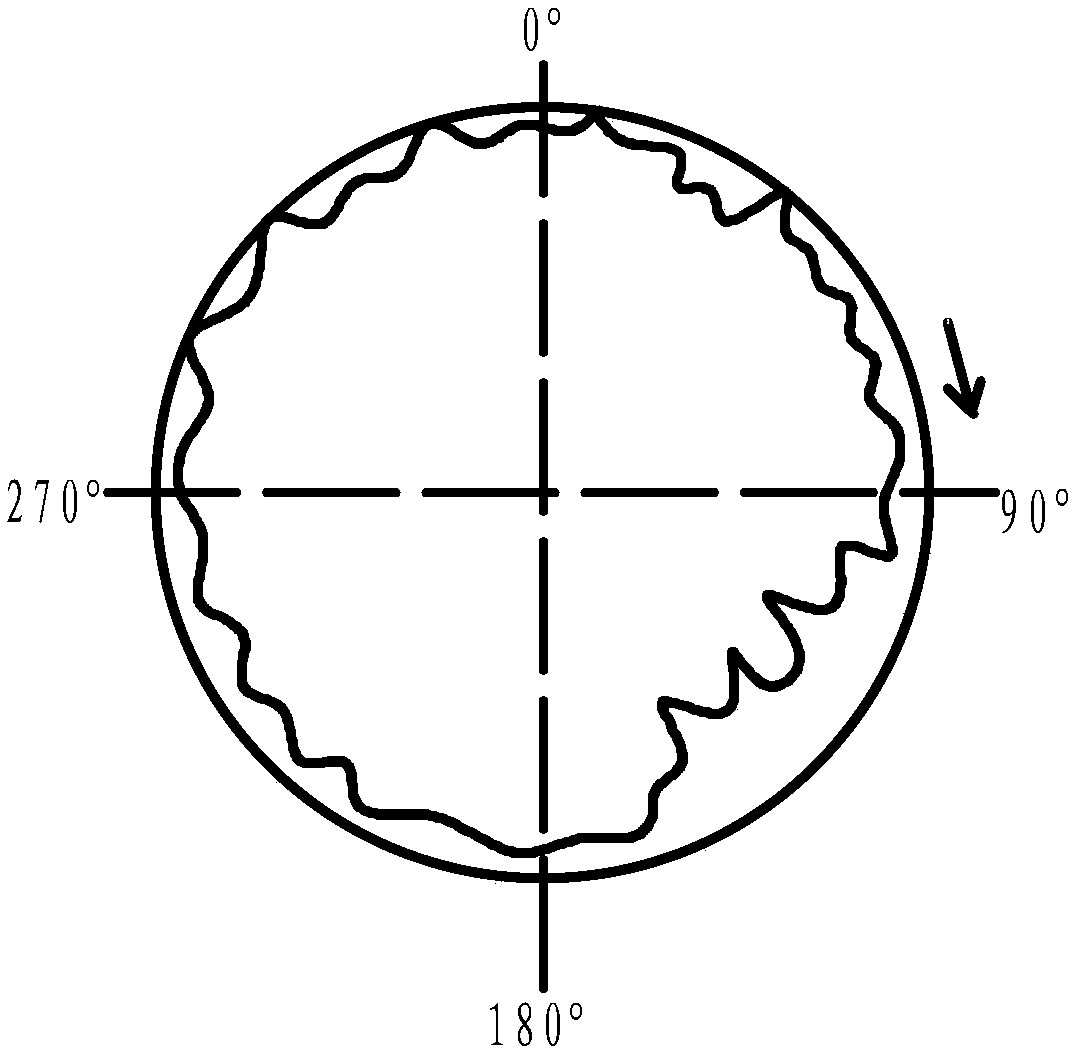

[0043] The method for collecting the vibration signal of the cylinder wall of the mill 1 is as follows: the inner end of the wireless vibration sensor 5 is fixedly arranged on the lining plate of the inner surface of the mill 1, the outer end is exposed on the outer surface of the mill 1, and the wireless vibration sensor 5 directly detects the vibration signal of the mill 1. The energy of the medium in the machine 1 impacting the wall of the mill 1. During the normal operation of the mill 1, the wireless vibration sensor 5 rotates synchronously with the mill 1. When the wireless vibration sensor 5 is close to the trigger 6 on the stand 4, it triggers The sensor 6 sends a start signal, and the wireless vibration sensor 5 starts to detect the vibration data of the medium in the mill 1 impacting the wall of the mill 1. When the wireless vibration sensor 5 follows the synchronous rotation of the mill 1 and approaches the trigger 6 again, the trigger 6 sends a stop signal. signal, ...

Embodiment 3

[0045] The data acquisition, processing, communication and storage methods are as follows: the wireless vibration signal receiver 11 receives the vibration data collected by the wireless vibration sensor 5, and the vibration data is carried out using the TCP / IP protocol between the wireless vibration signal receiver 11 and the switch 10. communication, the exchange 10 transmits the processed vibration data to the wireless vibration signal processing and intelligent speed regulation strategy system 13, and the wireless vibration signal processing and intelligent speed regulation strategy system 13 is provided with a man-machine interface for the vibration data collection part, which is used to Set the sampling frequency and sampling wavelength of vibration data, and determine the best acquisition parameters by analyzing the vibration characteristic values at different sampling frequencies and sampling wavelengths;

[0046] The wireless vibration signal processing and intellige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com