A Construction Method of Filling on the Arch of Double Curved Arch Bridge

A construction method and technology for double-curved arch bridges, which are applied in the construction of arch bridges, bridges, bridges, etc., can solve the problems affecting structural safety, structural durability and driving comfort, the driving comfort of bridge deck cannot be improved, and the steel bar of main arch ring is rusted. Expansion concrete spalling and other problems, to achieve the effect of improving formwork support work efficiency, improving driving comfort, and improving load level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

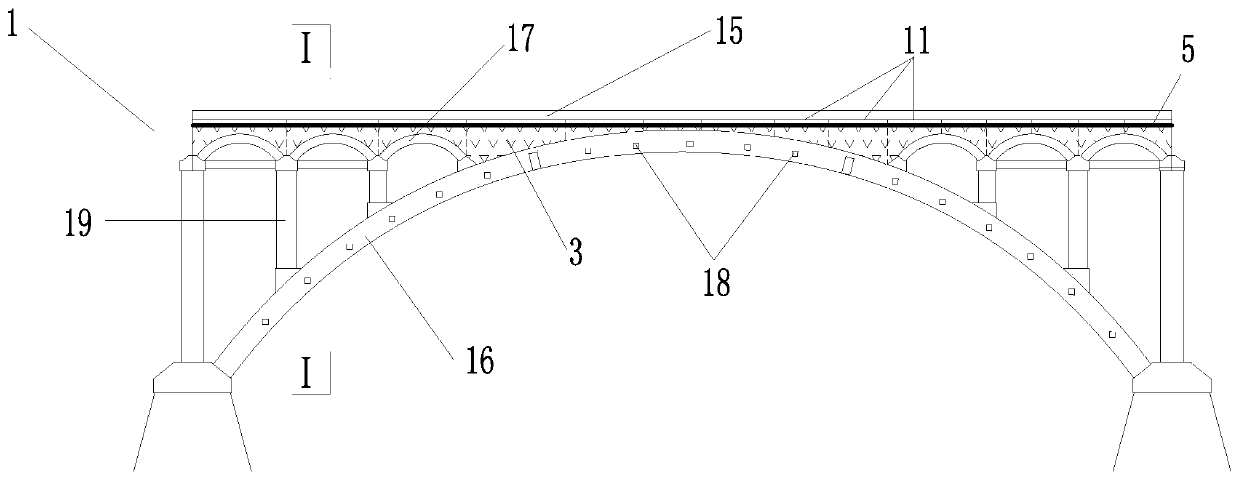

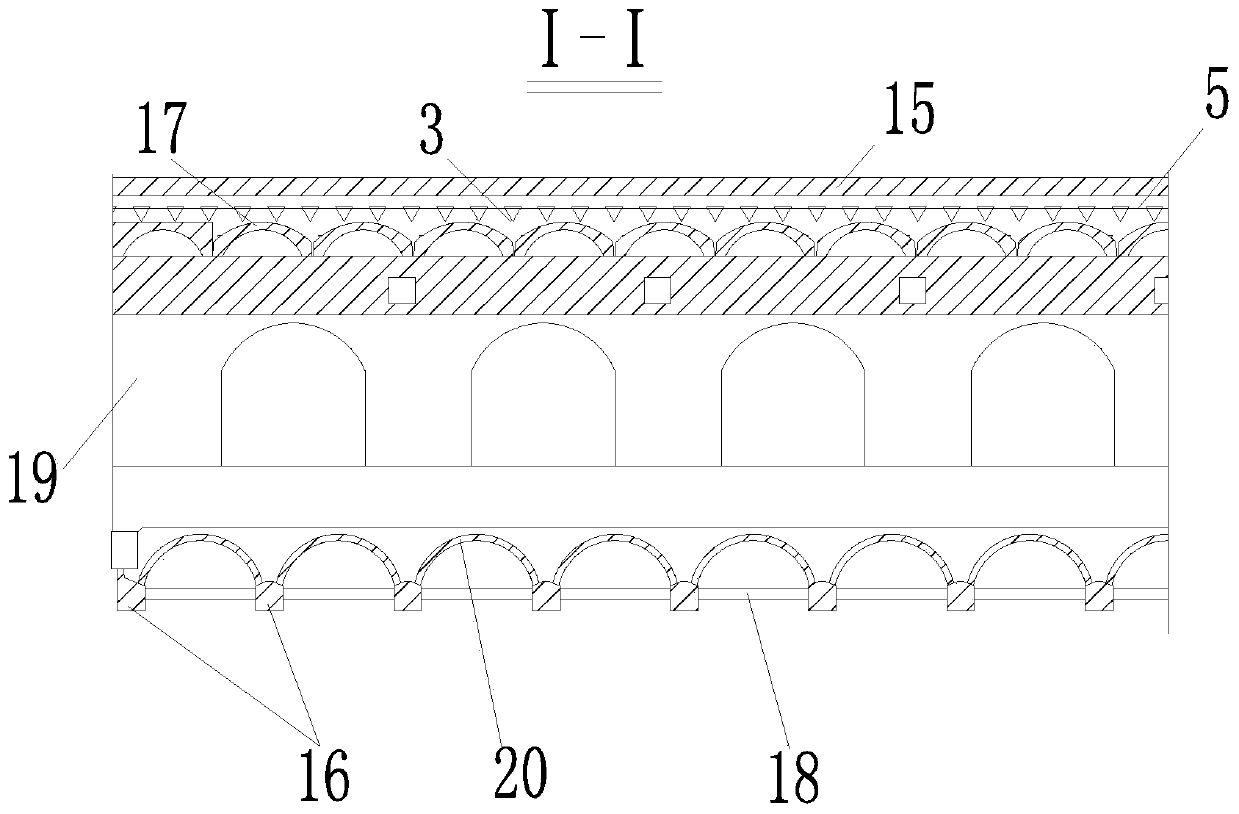

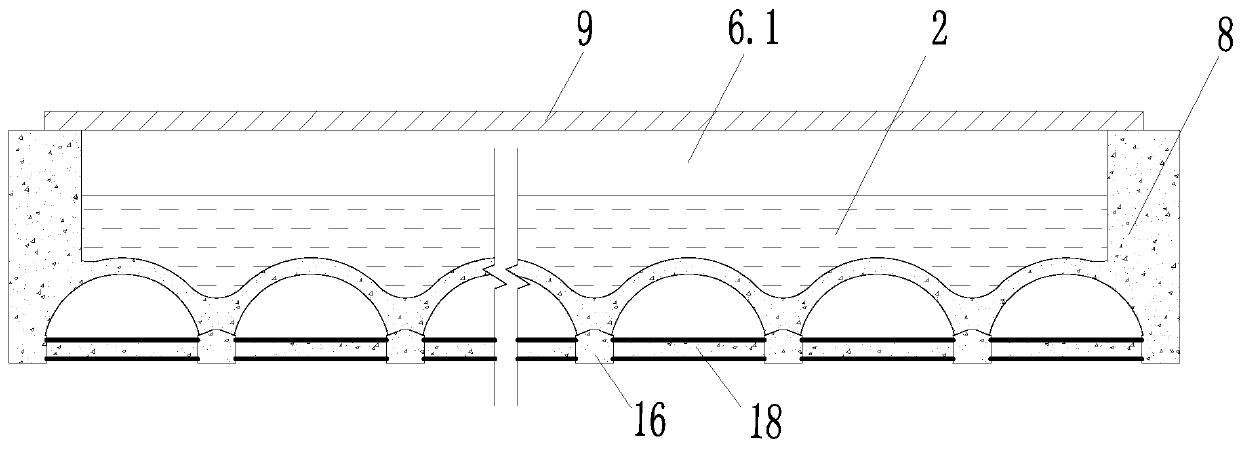

[0034] Such as figure 1 The construction method of filler on the double-curvature arch bridge arch shown in -6 comprises the following steps:

[0035] 1), along the longitudinal direction of the bridge 1, the filler on the arch is divided into a plurality of pouring sections 11, and the support formwork is installed at the end of the pouring section 11. If the end of the pouring section 11 is located at the expansion joint, the rigid formwork 7 is installed. If pouring The end of the section 11 is located at the non-expansion joint, then the rigid frame 4 is installed, and the flexible template 6 is fixed on the rigid frame 4 based on the rigid frame 4;

[0036] The installation method of the rigid formwork 7 is: adopt the rigid formwork 7 composed of horizontal struts 7.1, vertical struts 7.2, diagonal struts 7.3, planting bars 7.4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com