Combined type stainless steel water tank side wall corner

A stainless steel, combined technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of easy damage to the weld, uneven force on the water tank plate, and limited height of the water tank, so as to increase the occupied area, The effect of increased load level and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

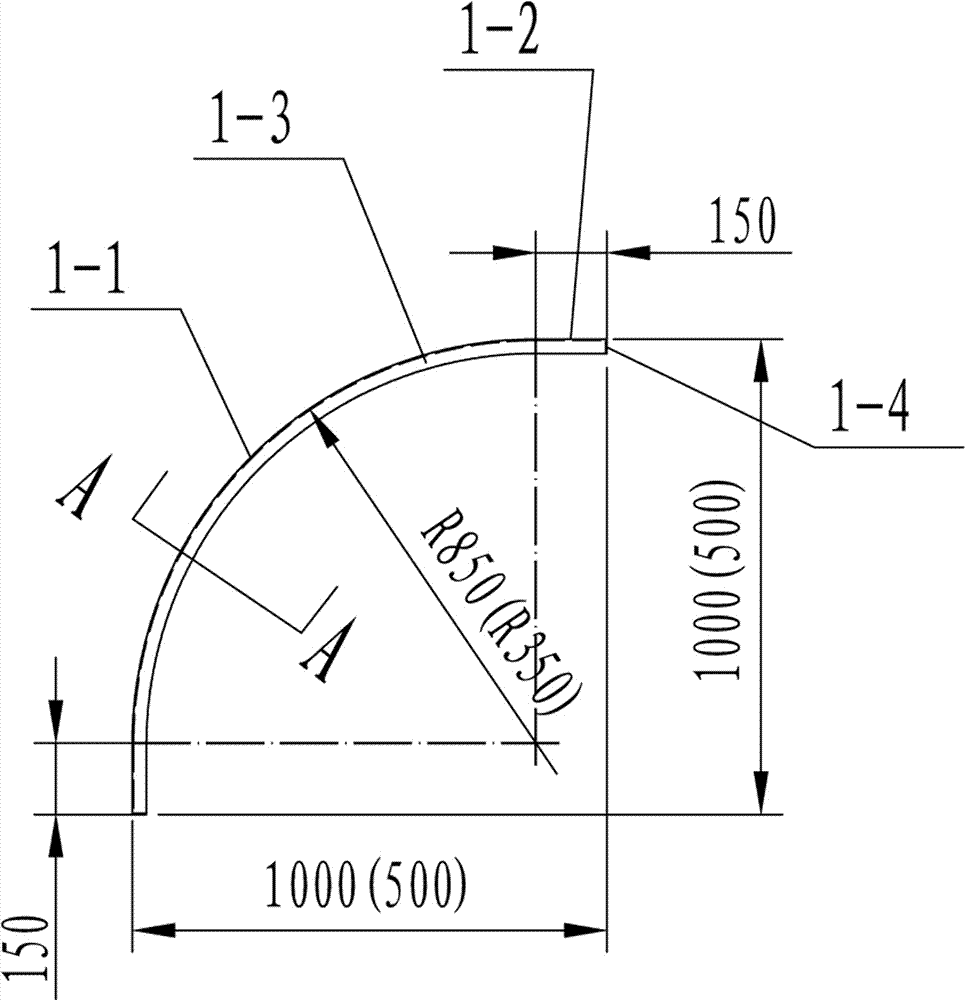

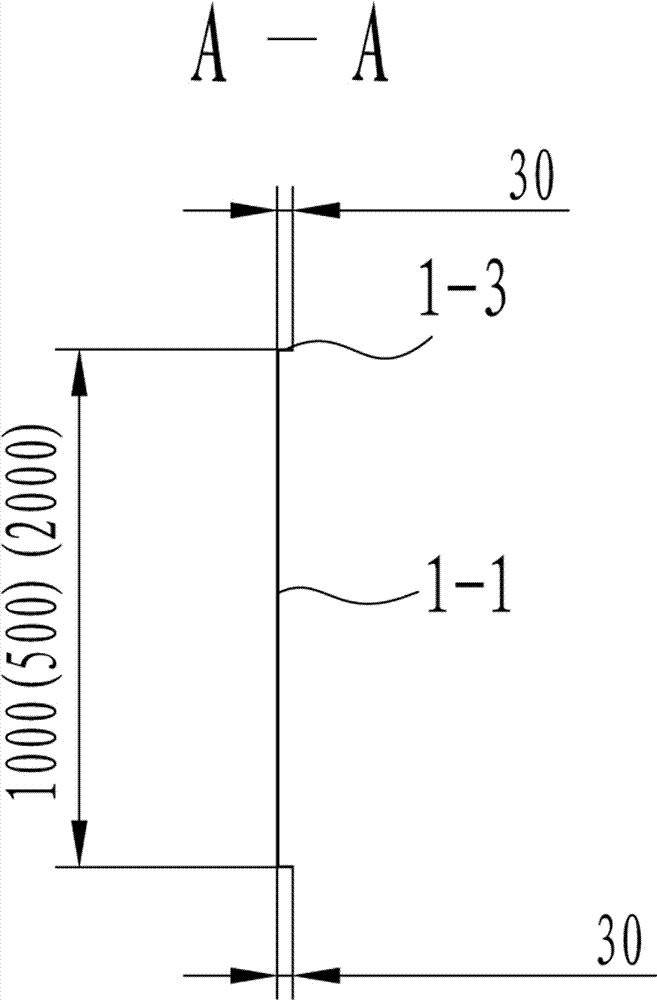

[0017] refer to Figure 1 to Figure 5 , the present invention is made of a whole board. In the middle of the plate is a section of arc surface 1-1, and the two sides of the arc surface 1-1 respectively extend outward to form a straight surface 1-2. The straight face 1-2 is tangential to the arc face 1-1 and is excessively smooth, without structural mutation, which can eliminate stress concentration, so that the force on the wall plate is only the film stress, and its strength is calculated according to the third strength theory, and its bearing capacity is greatly improved. improve.

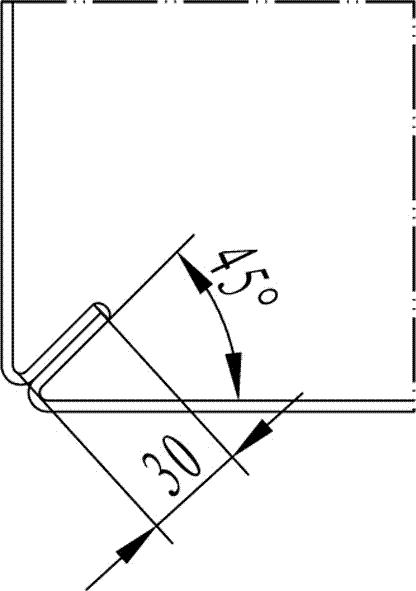

[0018] The top and the bottom of the board are respectively provided with inward horizontal folds 1-3, and the two sides of the straight surface 1-2 are provided with inward vertical folds 1-4. Both the horizontal flanging 1-3 and the vertical flanging 1-4 of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com