Test beam long-term loading system and method

A loading system and test beam technology, applied in the direction of elasticity testing, machine/structural component testing, measuring devices, etc., can solve the problems of a large number of high-density loading blocks, difficult to meet the loading level, inconvenient loading and unloading, etc. and unloading, saving time and effort, convenient processing, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

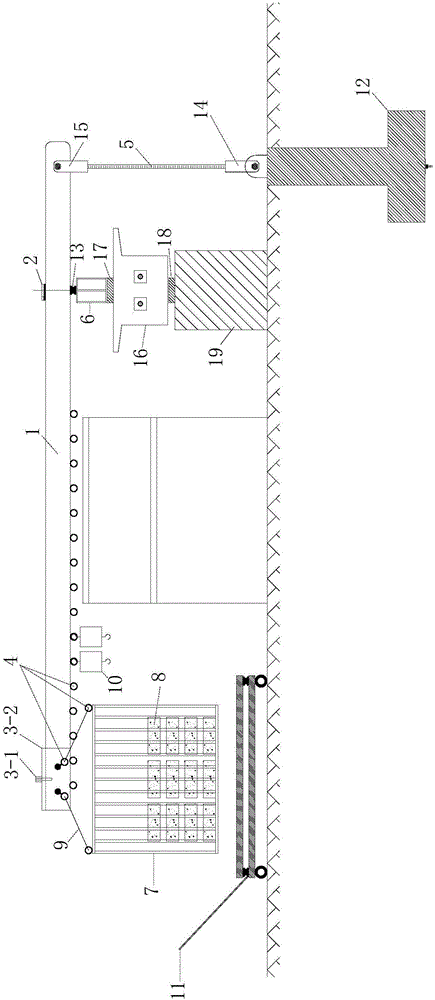

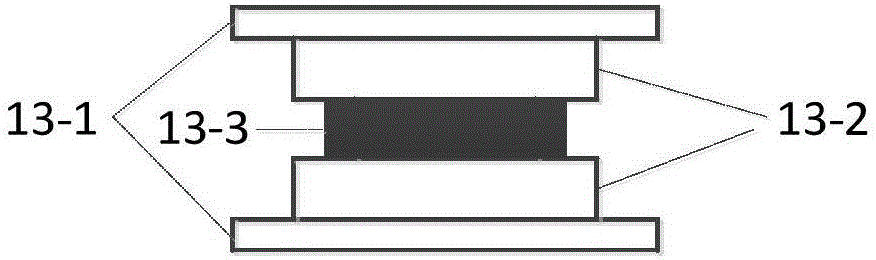

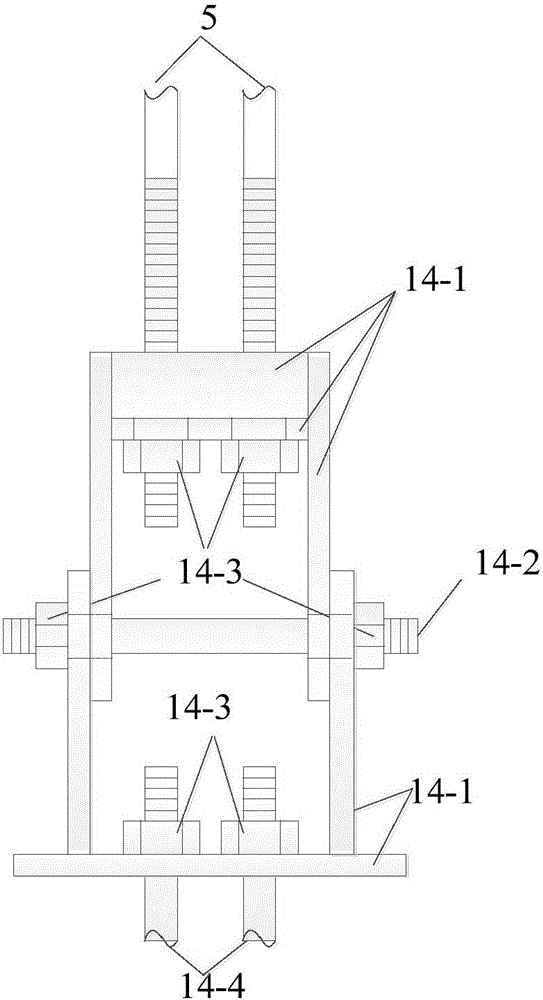

[0054] The long-term loading system of the test beam as figure 1 , 2 , 3, and 4, including lever 1, level pipe 2, free sliding device 3 (locating bolt 3-1, sliding steel channel 3-2), lifting ring 4, tension rod 5, distribution beam 6, hanging basket 7, and accessories Weight 8, lifting rope 9, manual hydraulic weight adjustment device 11, ground anchor 12, force transmission and testing device 13 (13-1 is the upper and lower backing plate, 13-2 is the customized steel ring, 13-3 is the pressure sensor), Connector 14 (14-1 is a welded steel plate, 14-2 is a high-strength screw, 14-3 is a high-strength bolt nut, and 14-4 is a ground anchor screw) for connecting the tension rod and the ground anchor. Lever connection regulator 15 (15-1 is welded steel plate, 15-2 is high-strength screw rod, 15-3 is high-strength bolt and nut), test beam 16, force distribution loading point backing plate 17, test beam support 18, test beam Pedestal 19. The specific assembly is mainly completed...

Embodiment 2

[0069] The long-term loading system of the test beam as figure 1 , 2 , shown in 3 and 4, including lever 1, level pipe 2, suspension ring 4, tension rod 5, distribution beam 6, weight 10, ground anchor 12, force transmission and testing device 13 (13-1 is backing plate up and down, 13 -2 is a customized steel ring, 13-3 is a pressure sensor), a connector 14 for connecting the tension rod and the ground anchor (14-1 is a welded steel plate, 14-2 is a high-strength screw rod, 14-3 is a high-strength bolt and nut, 14-4 is the ground anchor screw), the connection regulator 15 (15-1 is the welded steel plate, 15-2 is the high-strength screw, 15-3 is the high-strength bolt and nut) used to connect the tension bar and the lever, the test beam 16, the force Distribute the loading point backing plate 17, the test beam support 18, and the test beam pedestal 19. The specific assembly is mainly completed by the following steps:

[0070] (1) First, according to the design drawing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com