Valve rod leak-proof structure

A sealing structure and valve stem technology, applied in shaft seals, valve details, valve devices, etc., can solve the problems of not widely used, not easy to popularize, easy to age, etc., and achieve the effects of long service life, easy operation and low wear coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

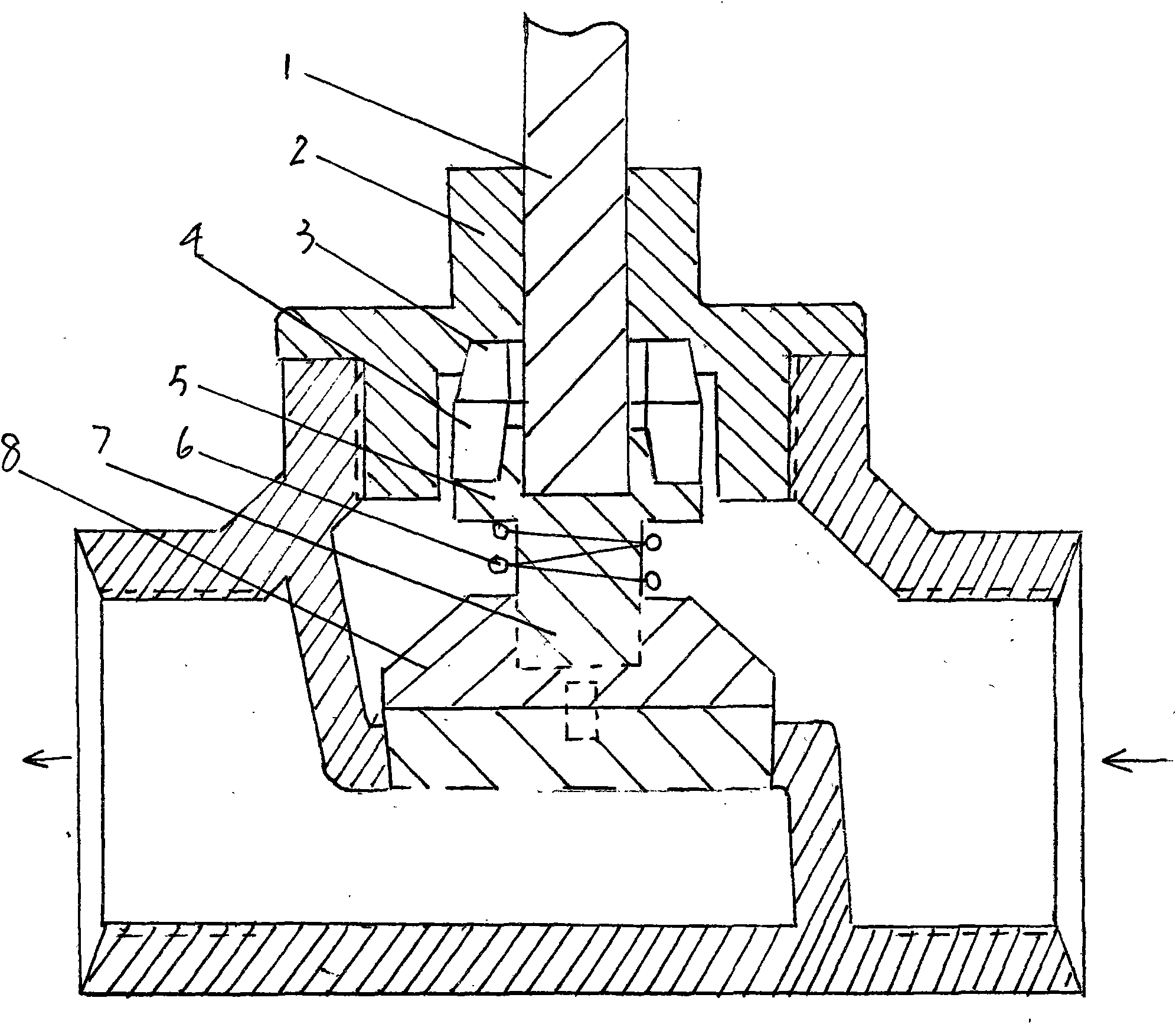

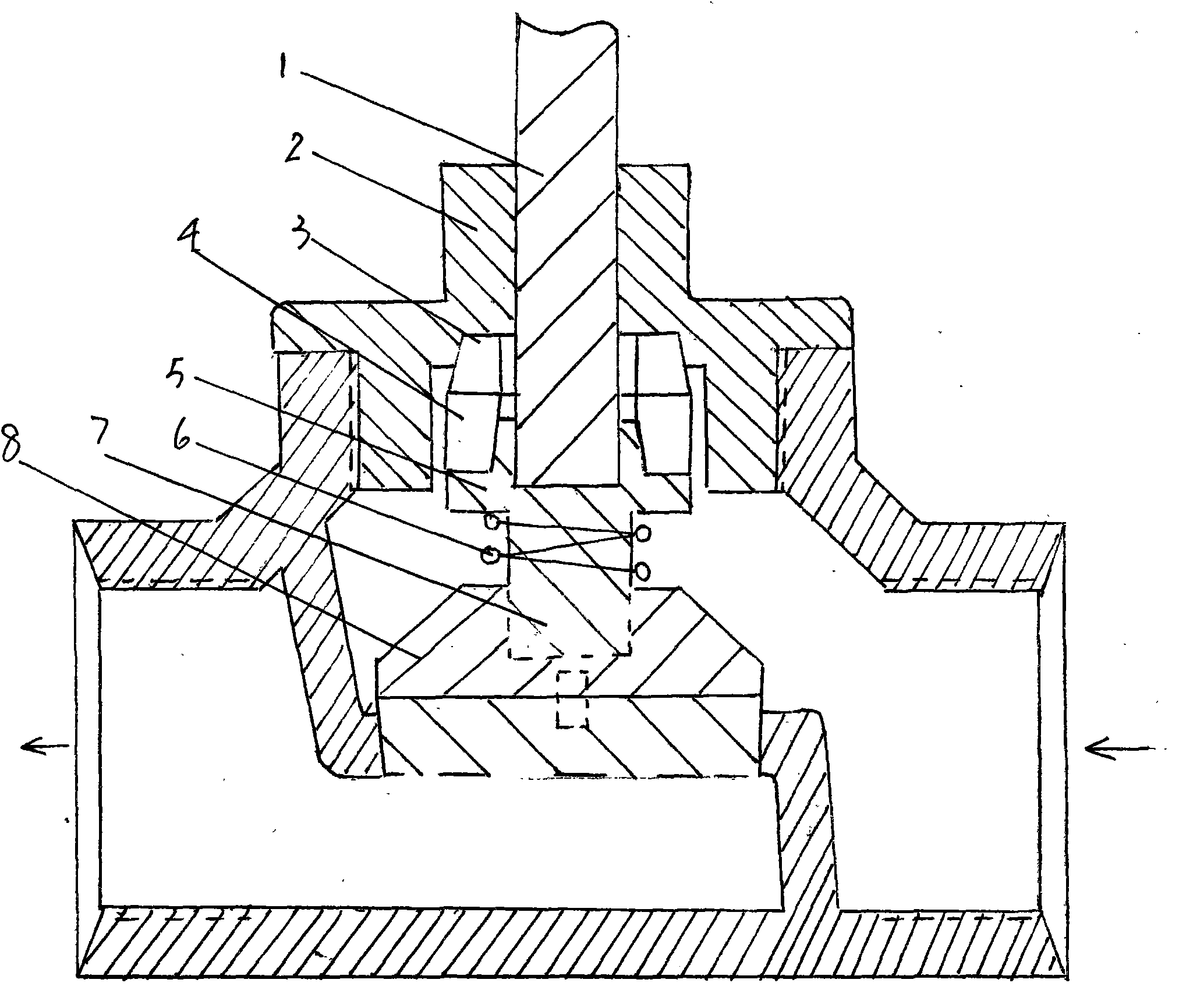

[0013] The structure of the present invention is shown in the accompanying drawings. The valve stem is designed into two parts, namely the upper valve stem 1 and the lower valve stem; the lower valve stem is composed of the lower ceramic ring 4 and the ceramic ring seat 5, and the lower ceramic ring 4 is embedded in the On the upper end of the seat 5, there is a square groove in the middle of the ceramic ring seat 5, which is used to connect with the upper valve stem 1; The spool 8 rotates; an upper ceramic ring 3 corresponding to the lower ceramic ring 4 is inlaid on the inner side of the valve cover 2, and the surfaces corresponding to the two ceramic rings 3 and 4 are polished surfaces; the upper end of the upper stem 1 passes through the upper The ceramic ring 3 and the valve cover 2 are connected to the valve handle, and the lower end passes through the groove in the middle of the lower ceramic ring 4 connecting the ceramic ring seat 5; the valve spring 6 is installed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com