Wear life calculation method for aviation hydraulic sliding valve

A technology for hydraulic slide valves and wear life, which is applied in the testing of slide valves, valve devices, and mechanical components, and can solve problems such as increased frictional resistance between the valve core and valve sleeve, wear, and increased internal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

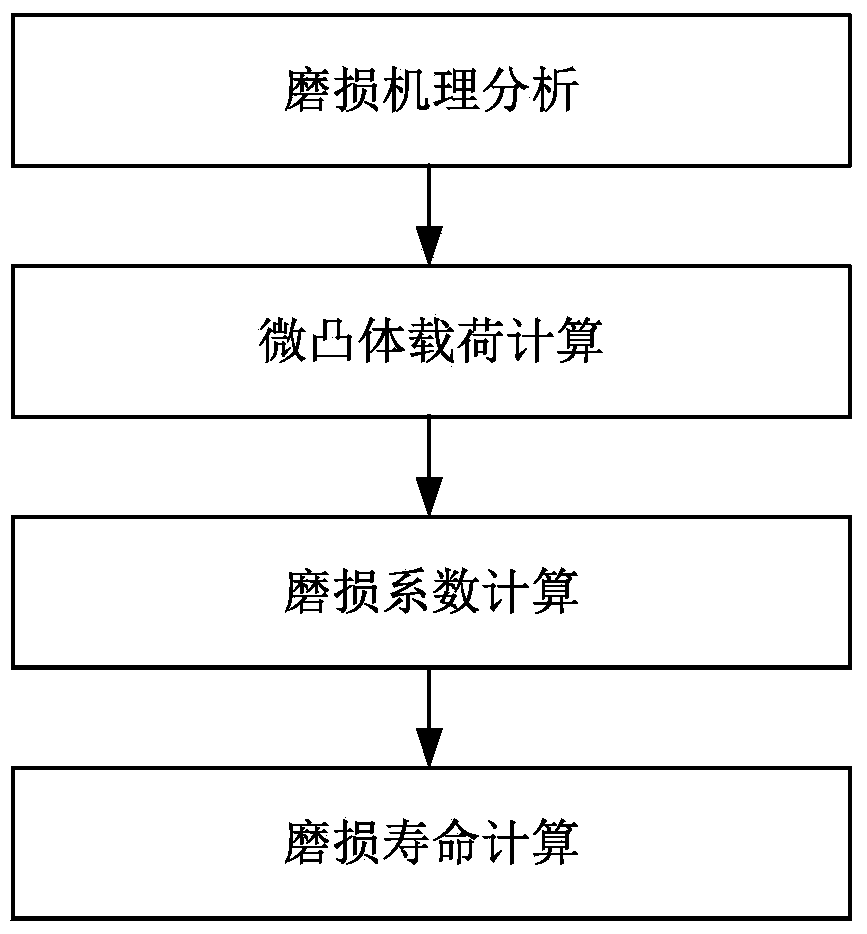

[0063] A method for calculating the wear life of an aviation hydraulic spool valve according to the present invention, see figure 1 As shown, the specific steps of the method are as follows:

[0064] Step 1: Wear mechanism analysis. Adhesive wear usually occurs when the contacting objects have the same or similar hardness. Since the material of the spool and sleeve of the aviation hydraulic spool valve is the same, the wear mechanism is determined to be adhesive wear.

[0065] Step 2: Asperity load calculation. Since the spool and sleeve of the aviation hydraulic spool valve are clearance fit, the normal contact load is the asperity load W a . And the asperity load is the load W borne by the asperity in the state of elastic deformation e and the load W on the plastically deformed asperities p Sum. mainly include:

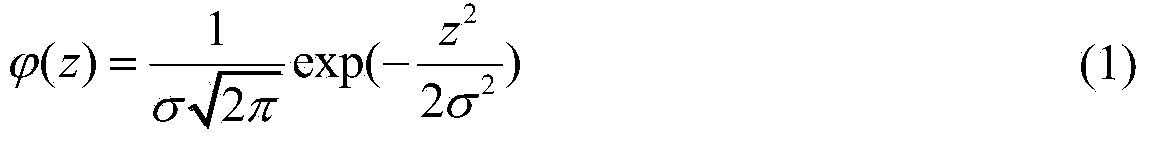

[0066] a. Profile he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com