Structure for detecting post-grouted inserting type sleeve and steel bar connector through endoscope method and method applying structure

An endoscopic and plug-in technology, which is applied to the structural field of post-grouting plug-in sleeve steel bar joints by the endoscopic method, can solve problems that affect the quality of on-site connection nodes of prefabricated components and hidden safety hazards of prefabricated buildings, and achieve Good engineering practical prospects, intuitive and reliable results, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

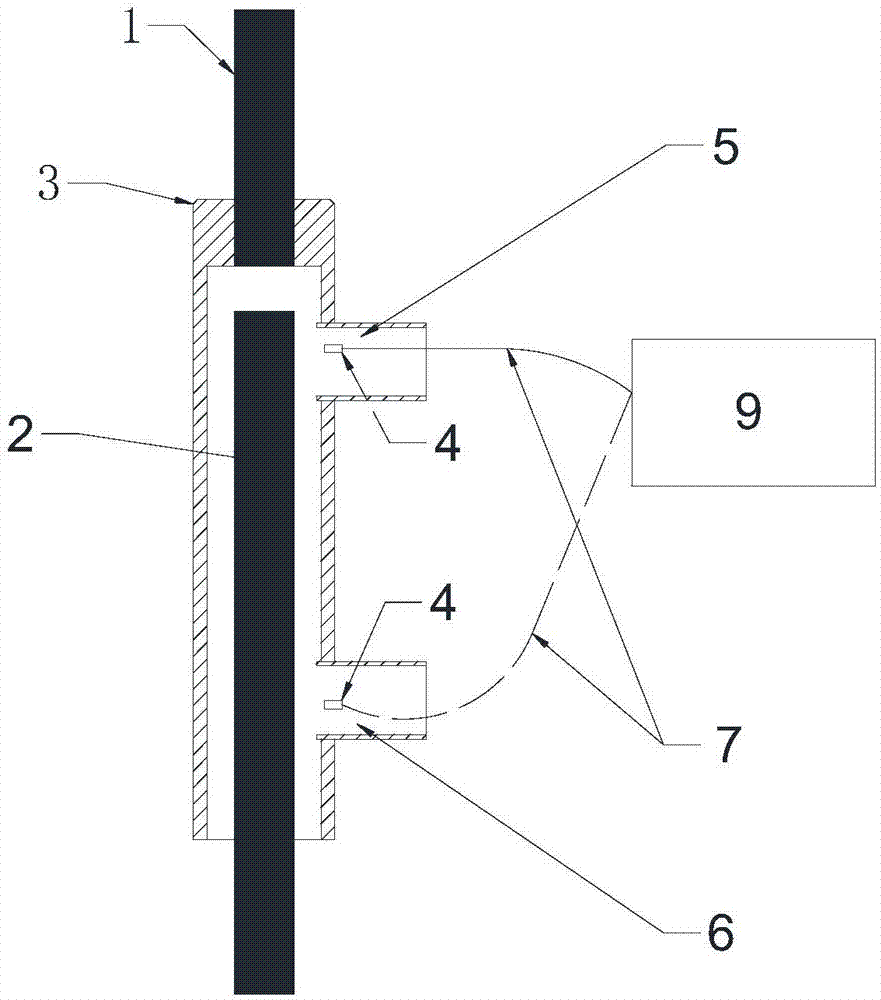

[0024] like figure 1 As shown, it is a schematic diagram of the grouting sleeve-type steel bar joint method after endoscopic detection in this embodiment, which is applicable to the case where the overflow channel 5 and the grouting channel 6 of the sleeve steel bar joint protrude from the outside of the wall. The structure of the post-grouting plug-in sleeve steel bar joint is detected by endoscopy, including the embedded steel bar 1 of the upper member, the embedded steel bar 2 of the lower member, the grouting sleeve 3 and the industrial endoscope, and the top of the grouting sleeve 3 is provided with threads The hole has a groove in the inner cavity, and the pre-embedded steel bar 2 of the lower member is preferably ribbed steel bar to increase the grouting strength. The end of the pre-embedded steel bar 1 of the upper member is threaded and screwed and fixed in the threaded hole on the top of the grouting sleeve 3 . The upper and lower parts of the grouting sleeve 3 are ...

Embodiment 2

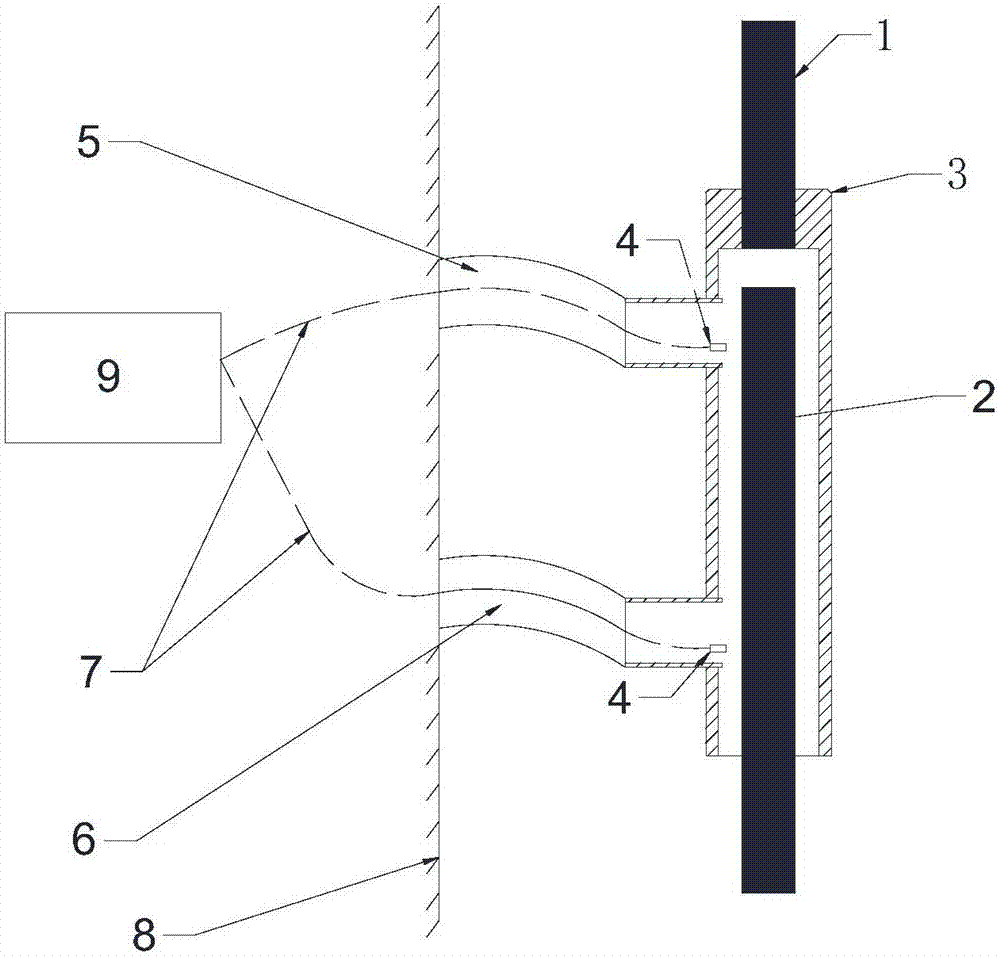

[0030] The difference from the previous embodiment is only that the grouting channel 5 and the grouting channel 6 of the sleeve steel joint to be detected in this embodiment are located inside the wall 8, and the grouting channel 6 and the grouting channel 5 are far away from the grouting operation. The face wall 8 is far away, so it is necessary to use a connecting hose to connect the surface of the wall in advance to form an extended grouting channel 6 and a grouting channel 5 . Then the industrial endoscopic probe 4 is sent into the extended channel to carry out the above-mentioned detection work.

[0031] One of the main problems that may arise when using the post-grouting sleeve insertion type steel bar connection method to connect prefabricated building components is whether the steel bar is really completely inserted into the sleeve (whether it may be intercepted for various reasons). The invention uses an industrial endoscope to observe whether the position of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com