Gear pair abrasion loss prediction method based on dynamic meshing force

A forecasting method and a technology of gear pairs, which are applied in the fields of instruments, calculations, electrical digital data processing, etc., can solve the problem that the forecasting method cannot take into account both forecasting efficiency and forecasting accuracy, and achieve the effect of giving consideration to both efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Such as Figure 8 As shown: this embodiment discloses a method for predicting the amount of gear pair wear based on dynamic meshing force, which is characterized in that it includes the following steps:

[0062] S1. Obtain the basic parameters of the gear pair;

[0063] S2. Calculate the time-varying meshing stiffness and static load distribution coefficient of the worn gear pair according to the obtained basic parameters of the gear pair and the tooth bearing contact analysis method;

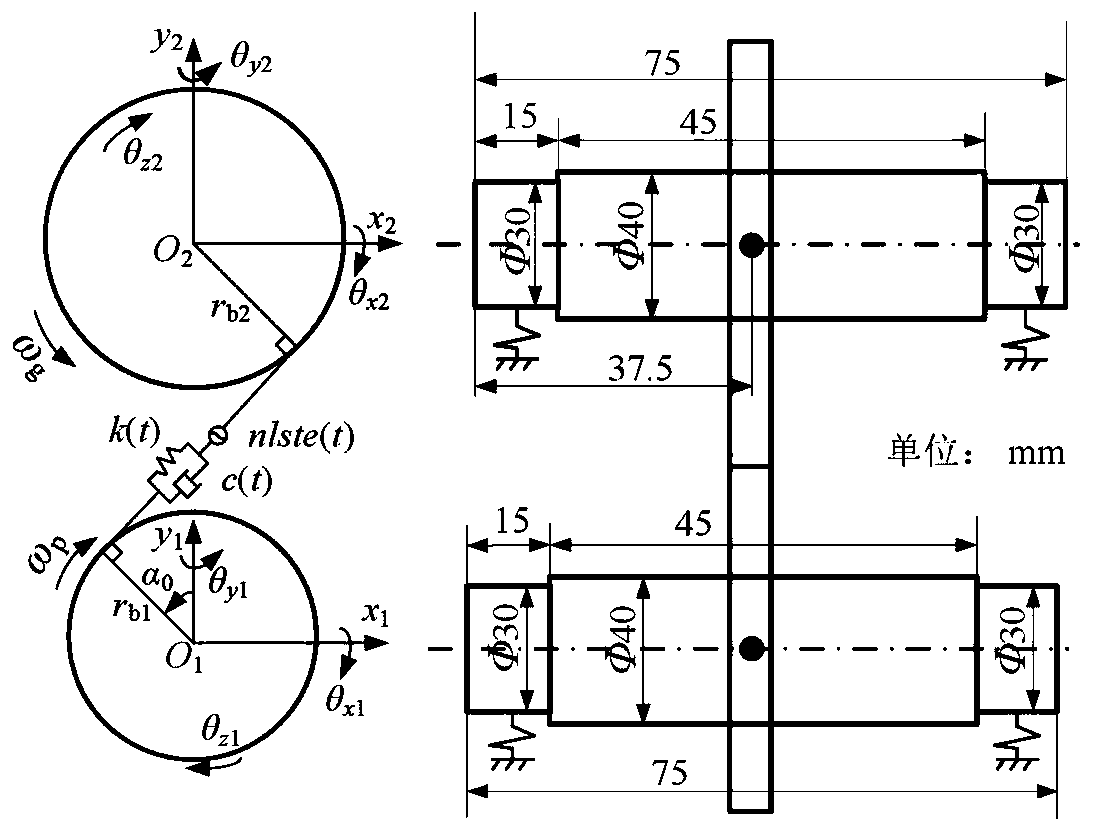

[0064] S3, introducing the calculated time-varying meshing stiffness into the dynamic model of the gear-rotor system to calculate the dynamic meshing force and dynamic load distribution coefficient of the gear pair;

[0065] S4. Using the Archard wear theory, the empirical formula of the wear coefficient, the dynamic meshing force of the gear pair and the dynamic load distribution coefficient to calculate the wear amount of the tooth surface of the gear pair.

[0066] It should be note...

Embodiment 2

[0103] This embodiment discloses a method for predicting the amount of gear pair wear based on dynamic meshing force, which includes the following steps:

[0104] Step 1: Determine the basic parameters of the gear pair;

[0105] Step 2: Calculate the time-varying mesh stiffness and static load distribution coefficient of the gear pair;

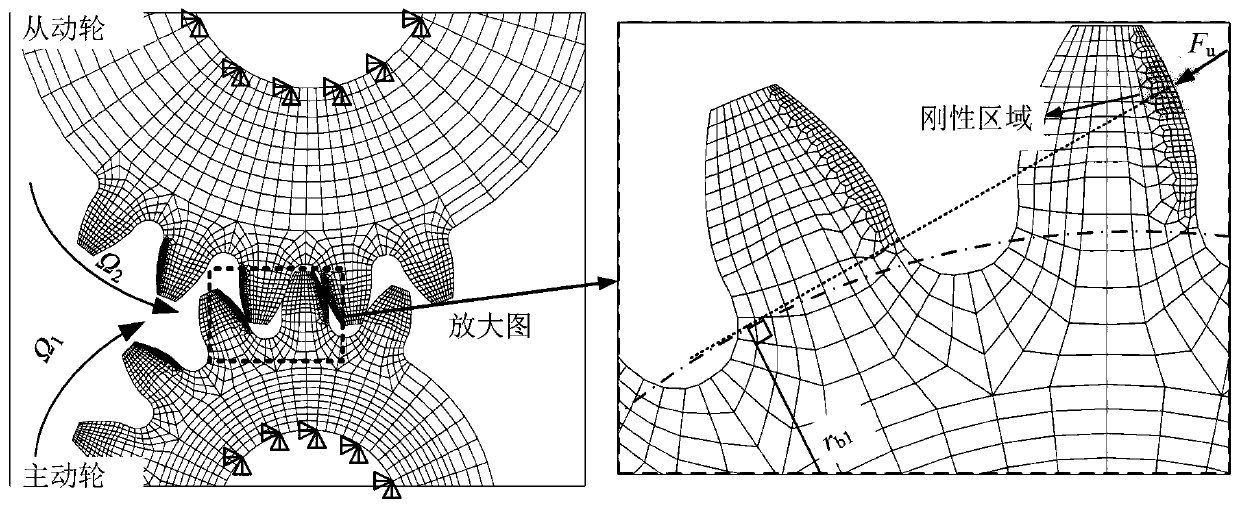

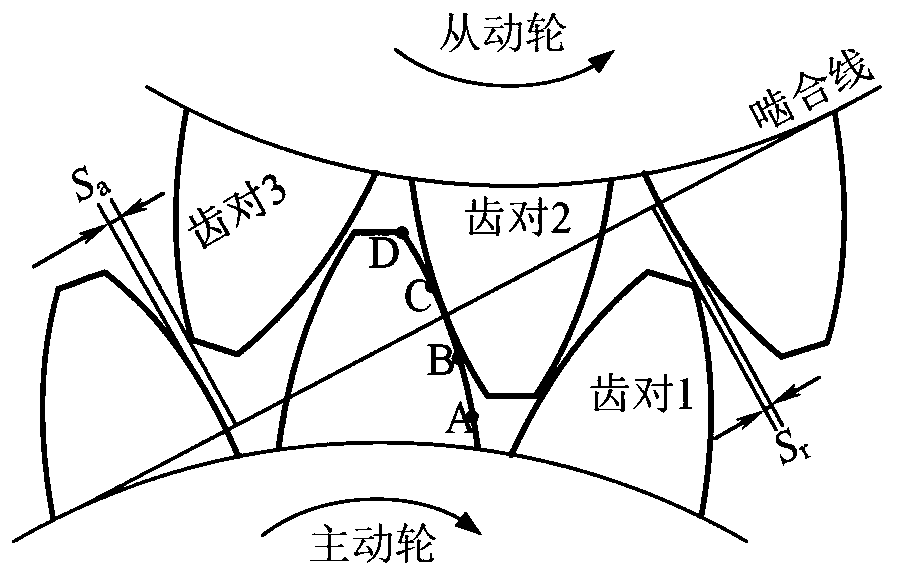

[0106] In this embodiment, the tooth-loaded contact analysis method is used to calculate the time-varying meshing stiffness and load distribution coefficient of the gear pair. The main idea of the tooth load-bearing contact analysis method is to separate the overall deformation of the gear pair from the local deformation, use the finite element method to calculate the rigid body compliance of the gear, and use the analytical formula to calculate the local contact compliance. Here, the MATLAB platform is used to write the finite element program, such as figure 1 is the overall finite element mesh displayed in the MATLAB environment.

[010...

Embodiment 3

[0166] The parameters of the gear pair in the literature [5] are adopted. The torque is 302Nm, and the output speed is 100r / min.

[0167] Table 1 Main parameters of gear pair

[0168]

[0169] The time-varying mesh stiffness of a worn gear pair is Figure 4 Shown (N represents the number of wear cycles). The present invention matches well with the contact finite element method, and the maximum error is 8.68%. This proves that the tooth-loaded contact analysis method used in the present invention can accurately wear the time-varying mesh stiffness of the gear pair. However, the computational efficiency of this method is much higher than that of the finite element method. Taking the calculation of a meshing cycle as an example, this method and the finite element method take 4 seconds and 2 hours respectively.

[0170] Most of the literature on wear curve prediction assumes that the wear coefficient is constant during the meshing cycle, while the wear coefficient obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com