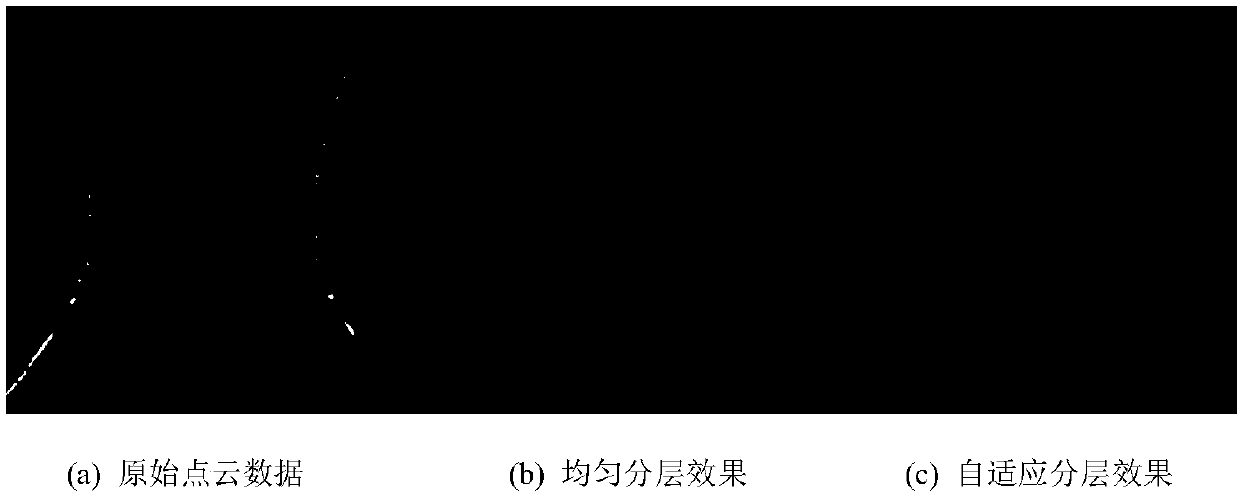

Adaptive plane layering method based on additional material remanufacturing point cloud model

A point cloud model and remanufacturing technology, applied in additive processing, image data processing, instruments, etc., can solve the problems of large error, low efficiency, obvious step effect, etc. Efficiency and precision, achieving clear and clear results in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (Example 1, an adaptive plane layering method based on the additive remanufacturing point cloud model)

[0012] The adaptive plane layering method based on the additive remanufacturing point cloud model of the present embodiment includes the following steps:

[0013] ① Determining the delamination direction: The determination of the delamination direction should not only consider the shape characteristics of the part itself, but also facilitate rapid remanufacturing. The general selection principle is to determine the delamination direction based on the selection principle of minimum stacking height or maximum base area; Priority is set to the Z-axis direction under Base, so before the initial collection of point clouds, the parts should be clamped according to this standard as much as possible. If the Z axis is not the optimal layering direction of the point cloud, the position of the model can be adjusted through human-computer interaction, that is, a series of rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com