Gradient curved-surface layering method based on additive remanufacturing point cloud model

A point cloud model and remanufacturing technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not completely eliminating the step effect, complicated operation process, obvious step effect, etc., to eliminate the step effect. , reduce the source of errors, and ensure the effect of rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

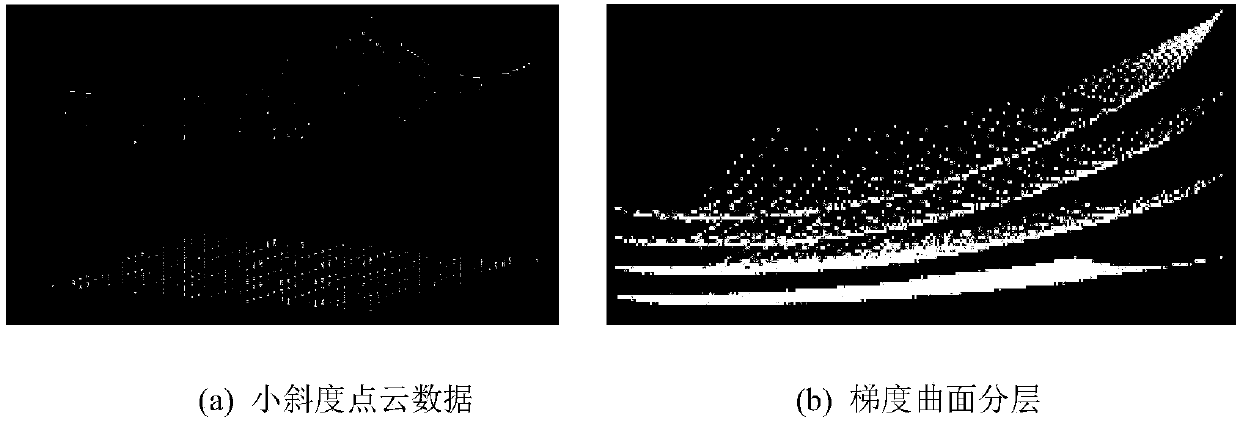

[0039] In order to solve the problem of forming accuracy of the surface with a small inclination, this embodiment proposes a layered gradient curved surface method. This method refers to the construction of several intermediate sub-layers with gradient changes within the range of forming height, so as to realize the transition from the remanufacturing base to the forming surface. Determining the layered surface according to the model features is the key to gradient layering.

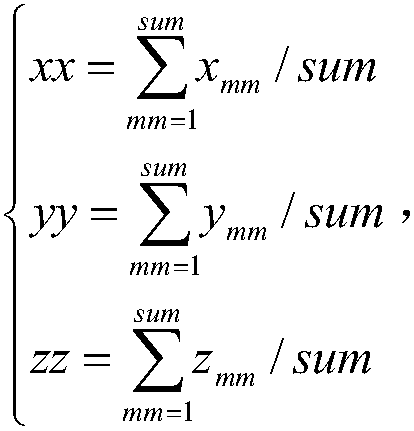

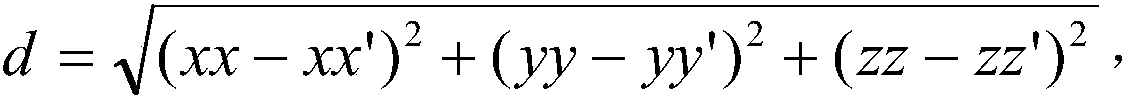

[0040] for a typical presentation type or For the remanufacturing model of the remanufacturing model, for the convenience of research, the layering direction is generally set as the Z-axis direction under the Base. At this time, the model has strict convexity preservation. If the point cloud of the remanufacturing base surface is layer-by-layer Growth forms a series of transitional layers. At the same time, the growth value of the point cloud also constitutes the forming points on the layered surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com