Layering Method of Isometric Surface Based on Additive Remanufacturing Point Cloud Model

A point cloud model and remanufacturing technology, applied in image enhancement, 3D modeling, instruments, etc., can solve the problems of inability to completely eliminate the step effect, complicated operation process, obvious step effect, etc., to eliminate the step effect and reduce errors. source, the effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

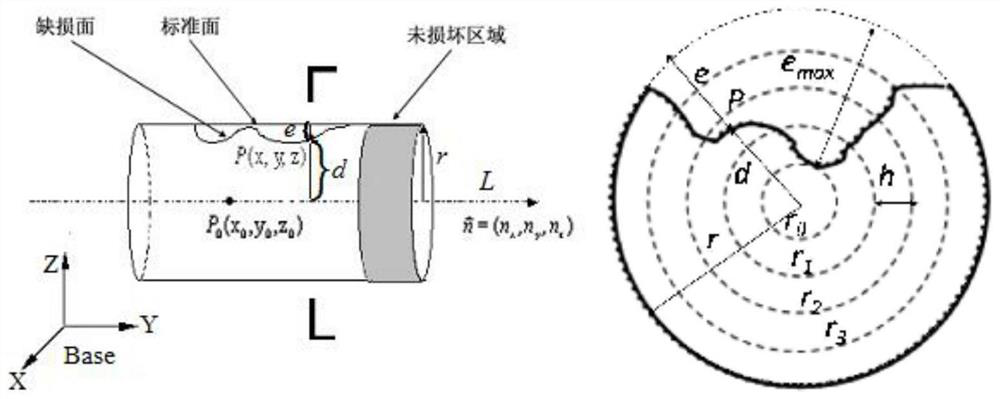

[0031] The traditional layering method adopts plane layering, while curved surface layering can develop the layering method from traditional two-dimensional plane layering to spatial curved surface layering, and the forming method is closer to the intelligent manufacturing mode. Due to the inevitable layered steps in the plane layering, changing the plane layering layer to the surface generated in response to the model will make the forming surface of the part smooth because there are no steps, and improve the forming accuracy.

[0032] The isometric surface layering method based on the additive remanufacturing point cloud model of this embodiment is used for the layering of the additive remanufacturing model of shaft parts. The specific steps are as follows:

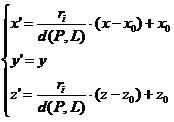

[0033] ① Fitting cylindrical surface: Select the point cloud of the undamaged area of the shaft part to fit the cylindrical surface. The standard model is the standard cylindrical surface. A point on the axis can be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com