Patents

Literature

186 results about "Plane layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prosthesis for reinforcement of tissue structures

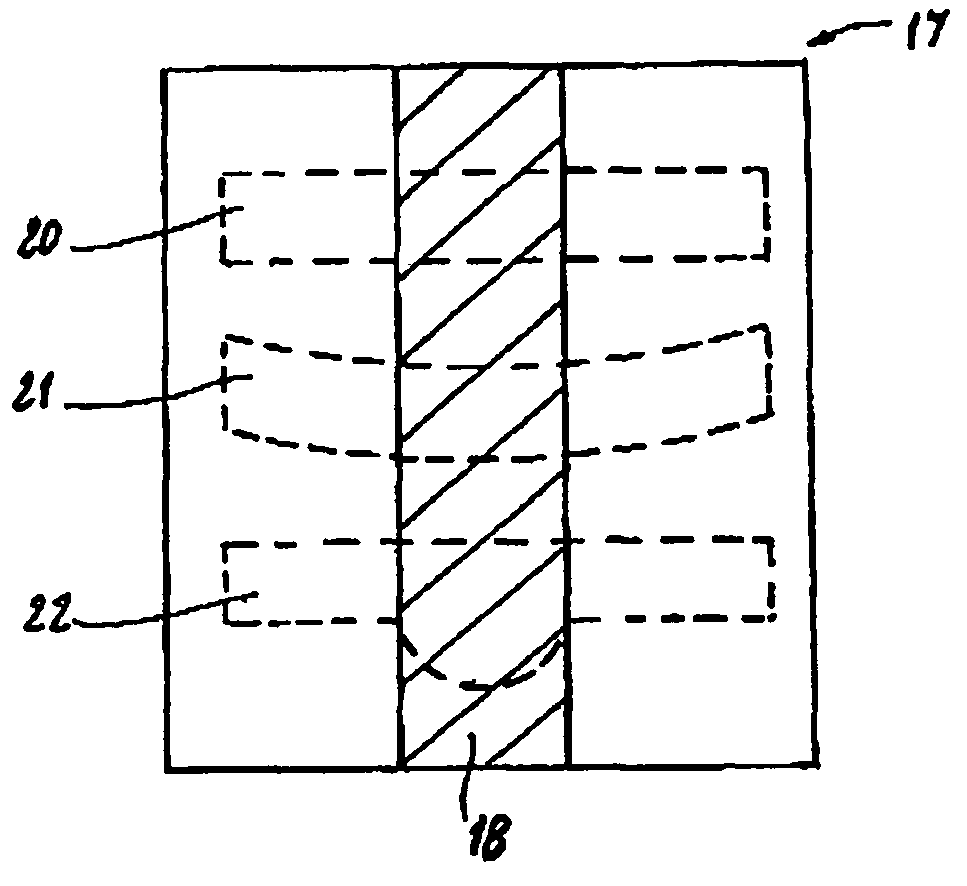

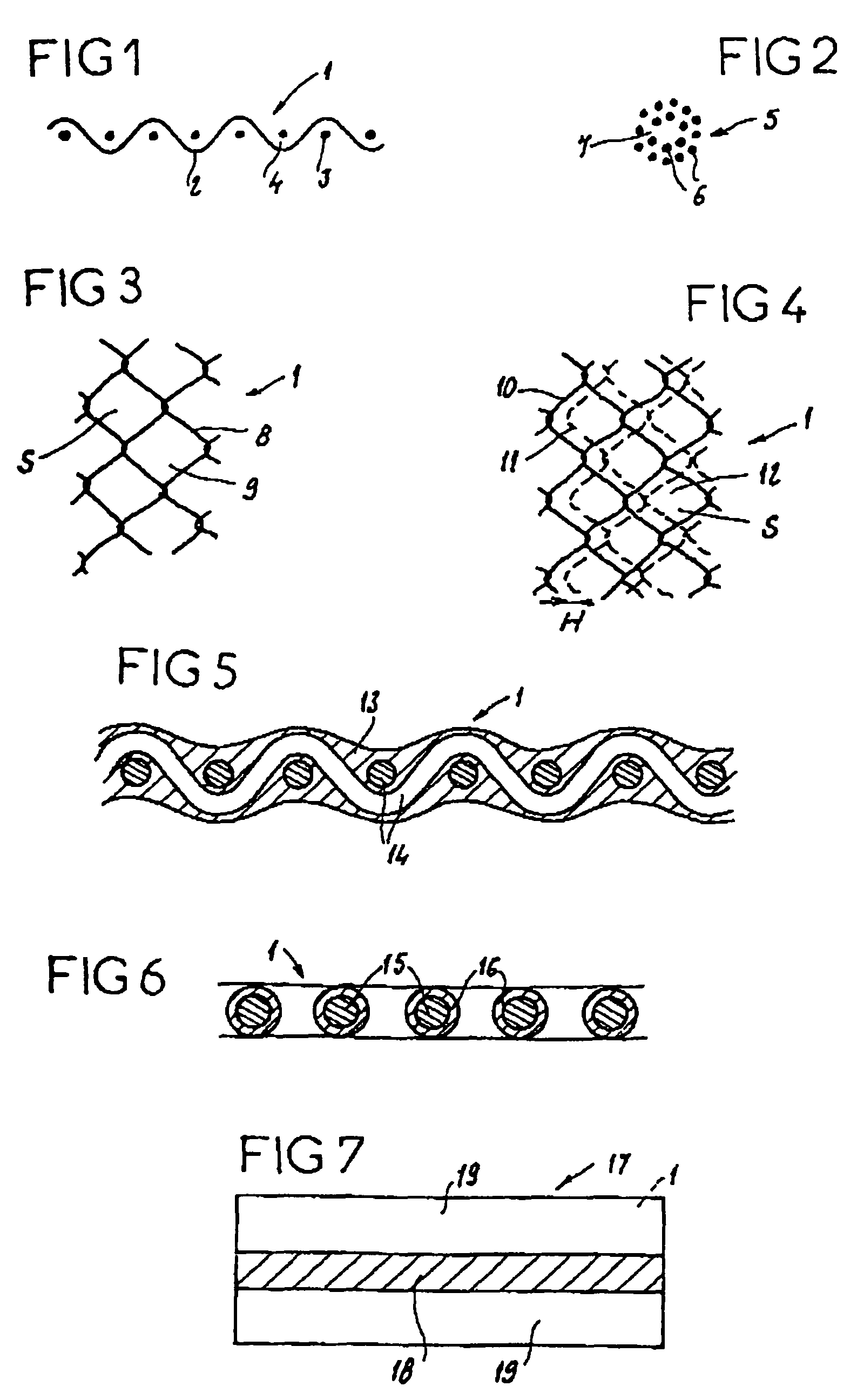

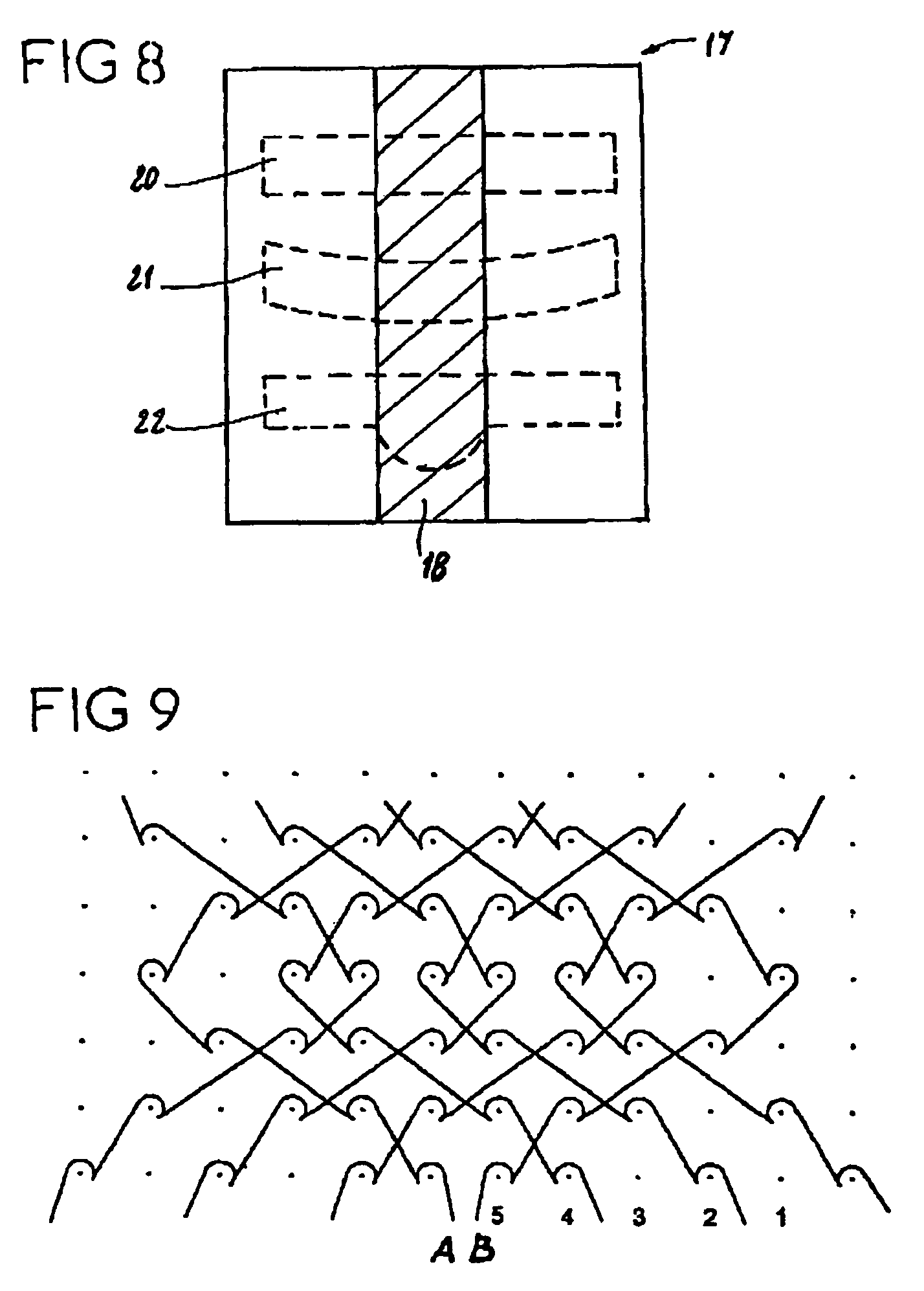

The present invention relates to a composite prosthesis for reinforcement of a tissue structure, including a porous textile support which includes an arrangement of threads each composed of at least one filament of nonabsorbable polymer material, said textile support defining a microporous texture including the interstices located between at least two threads at the sites of contact of one thread with at least one other thread, wherein, in at least one protected zone of the textile support, a hydrophilic absorbable material coats the textile support, forming a film enveloping and penetrating into the arrangement of threads, occluding at least the microporous texture, but without forming a plane layer covering at least one face of the textile support.It also relates to a process for preparing such a composite reinforcement prosthesis.

Owner:SOFRADIM PROD SAS

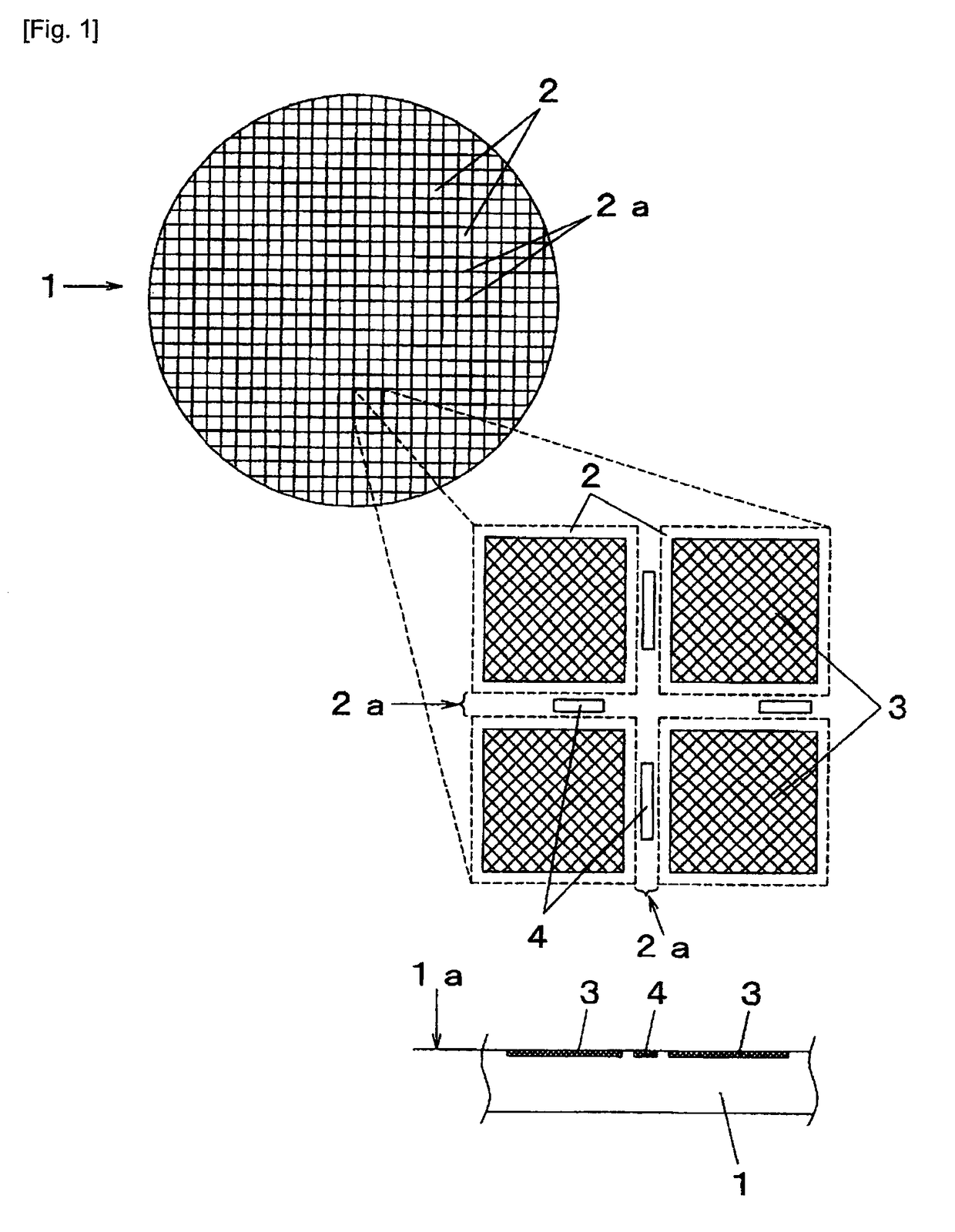

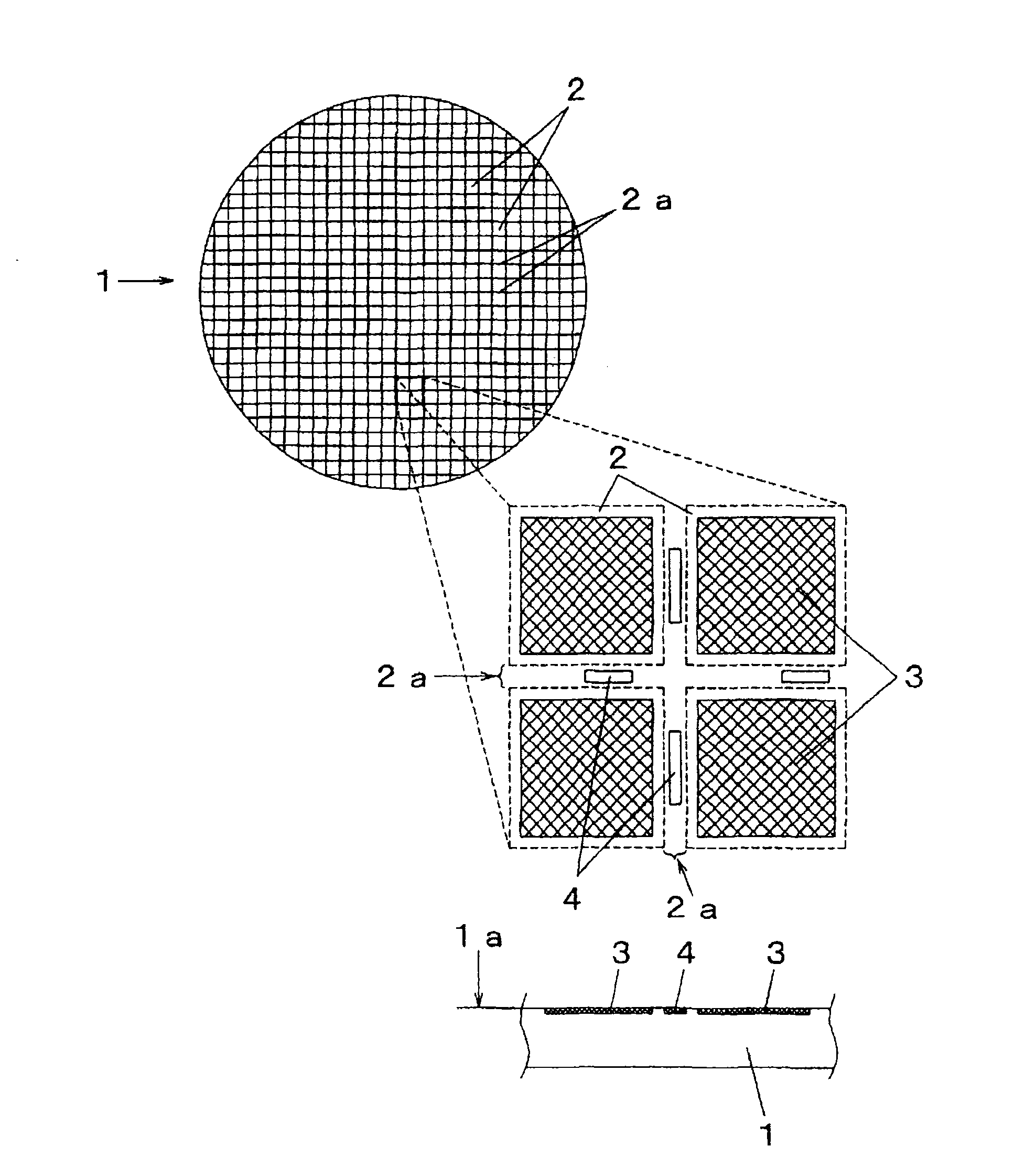

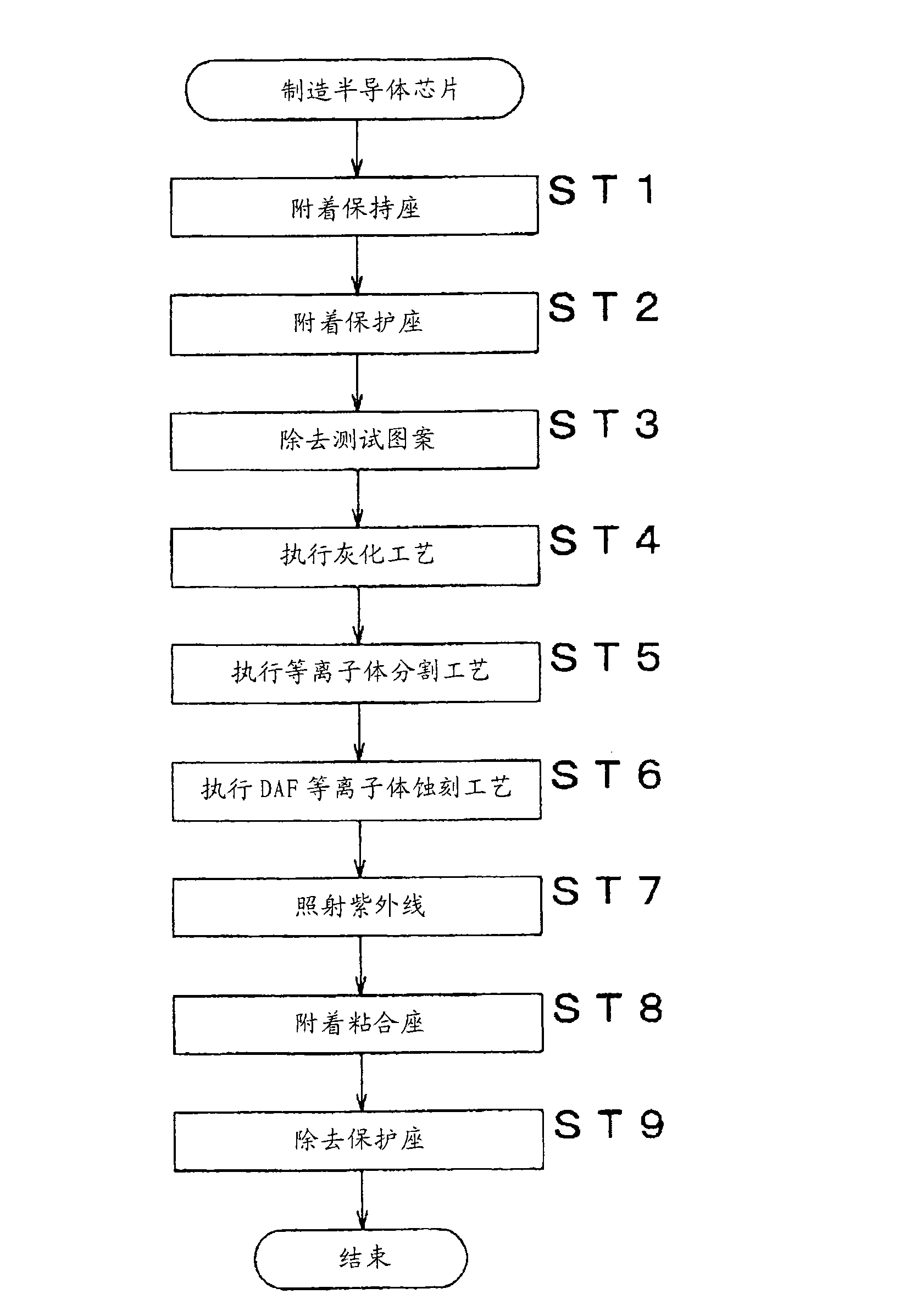

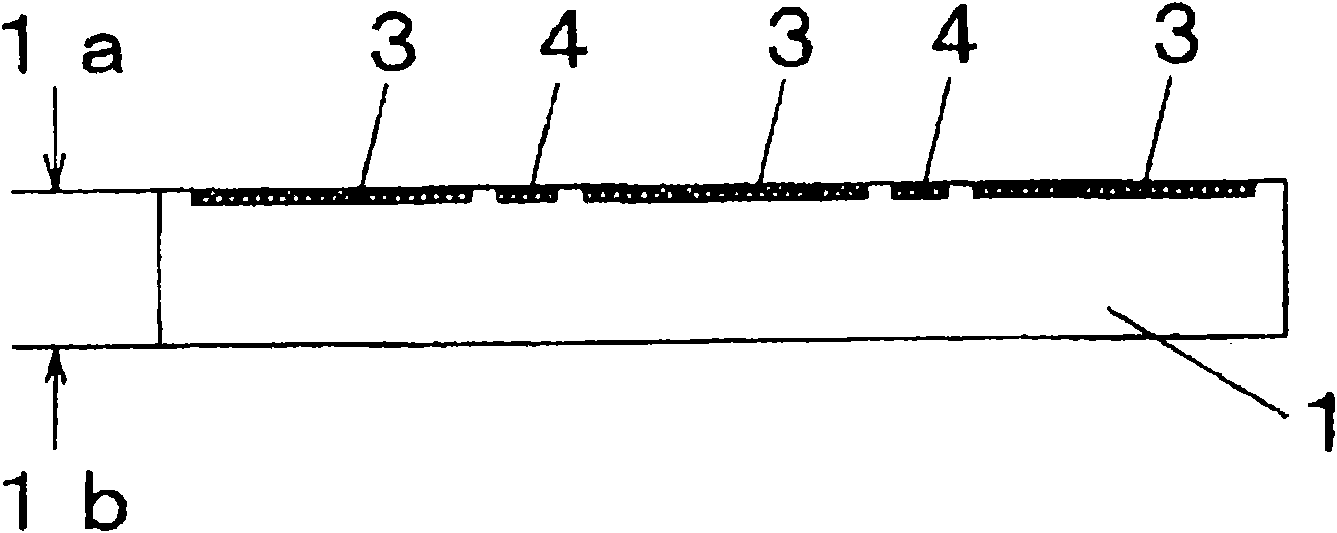

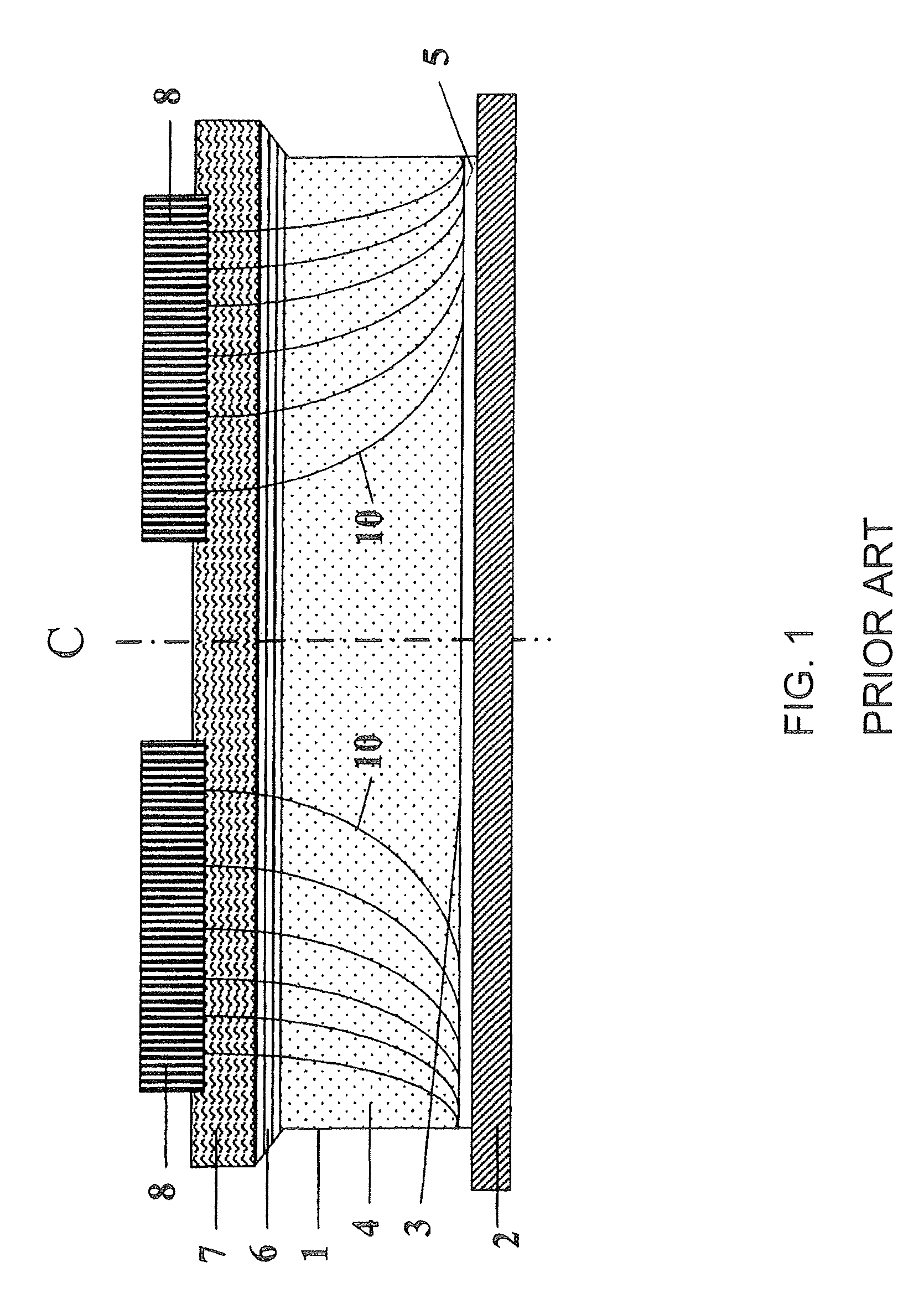

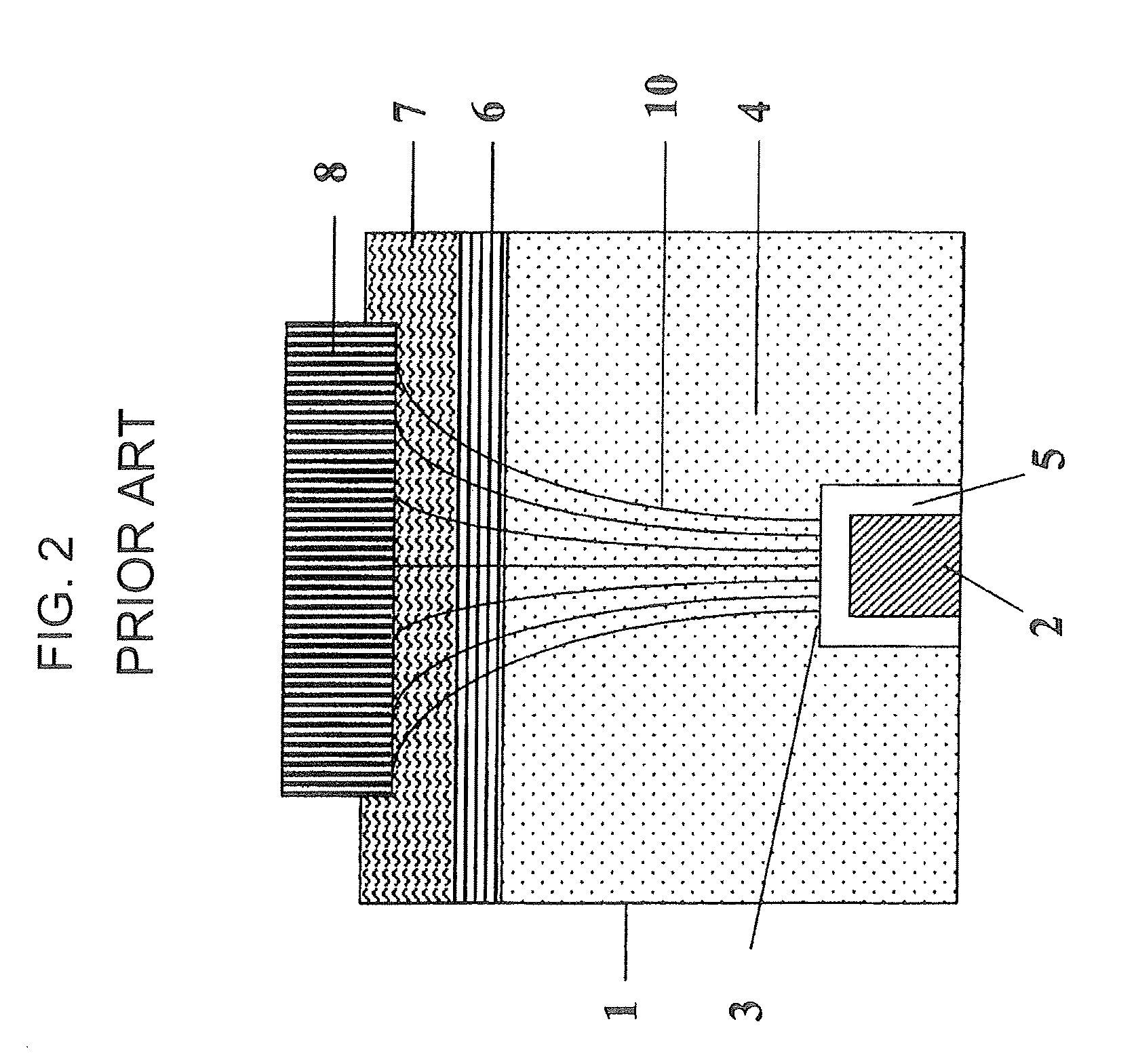

Method of manufacturing semiconductor chip using laser light and plasma dicing

ActiveUS7906410B2Improve efficiencySimple stepsSolid-state devicesSemiconductor/solid-state device manufacturingGeneral purposeSemiconductor chip

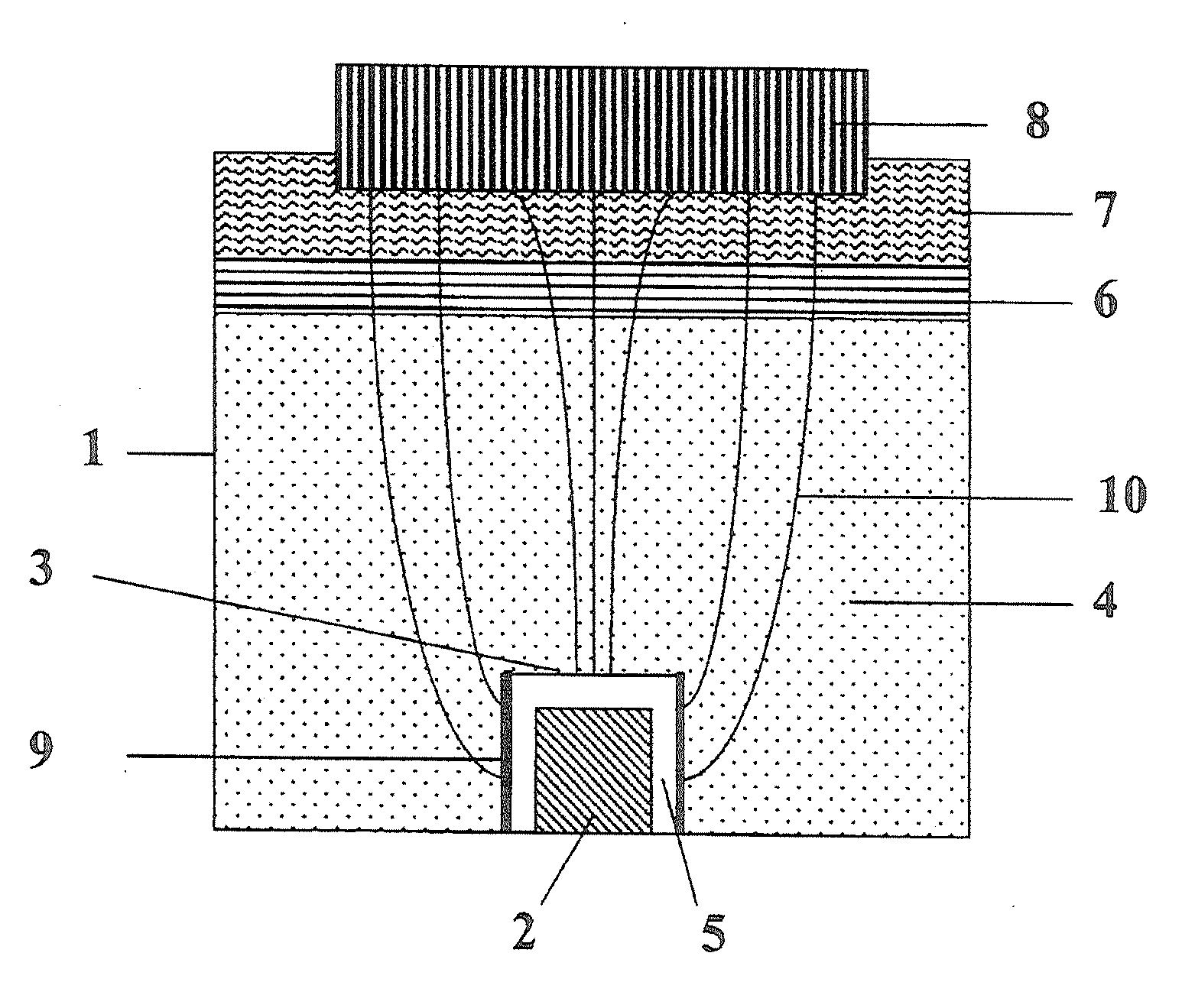

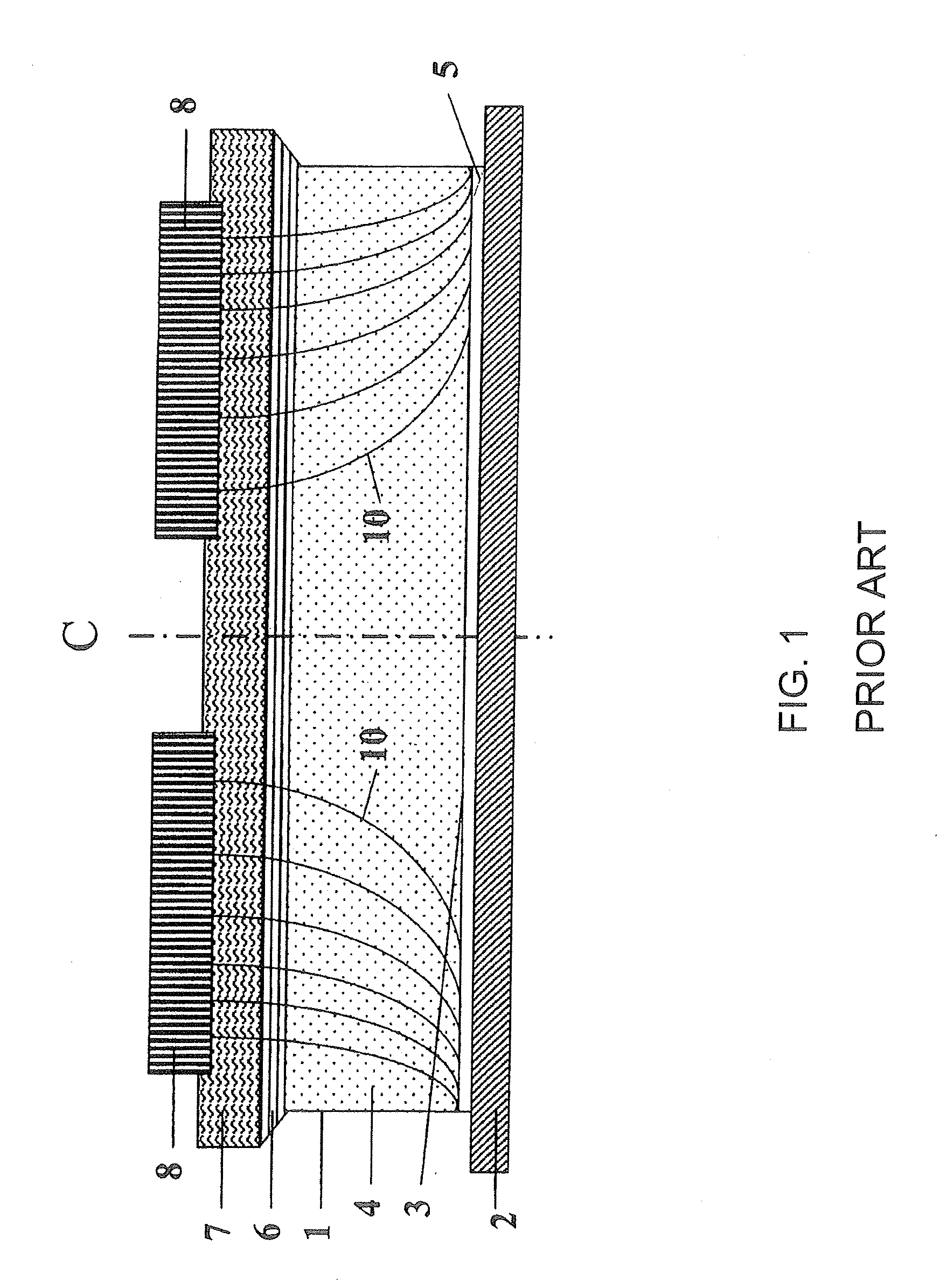

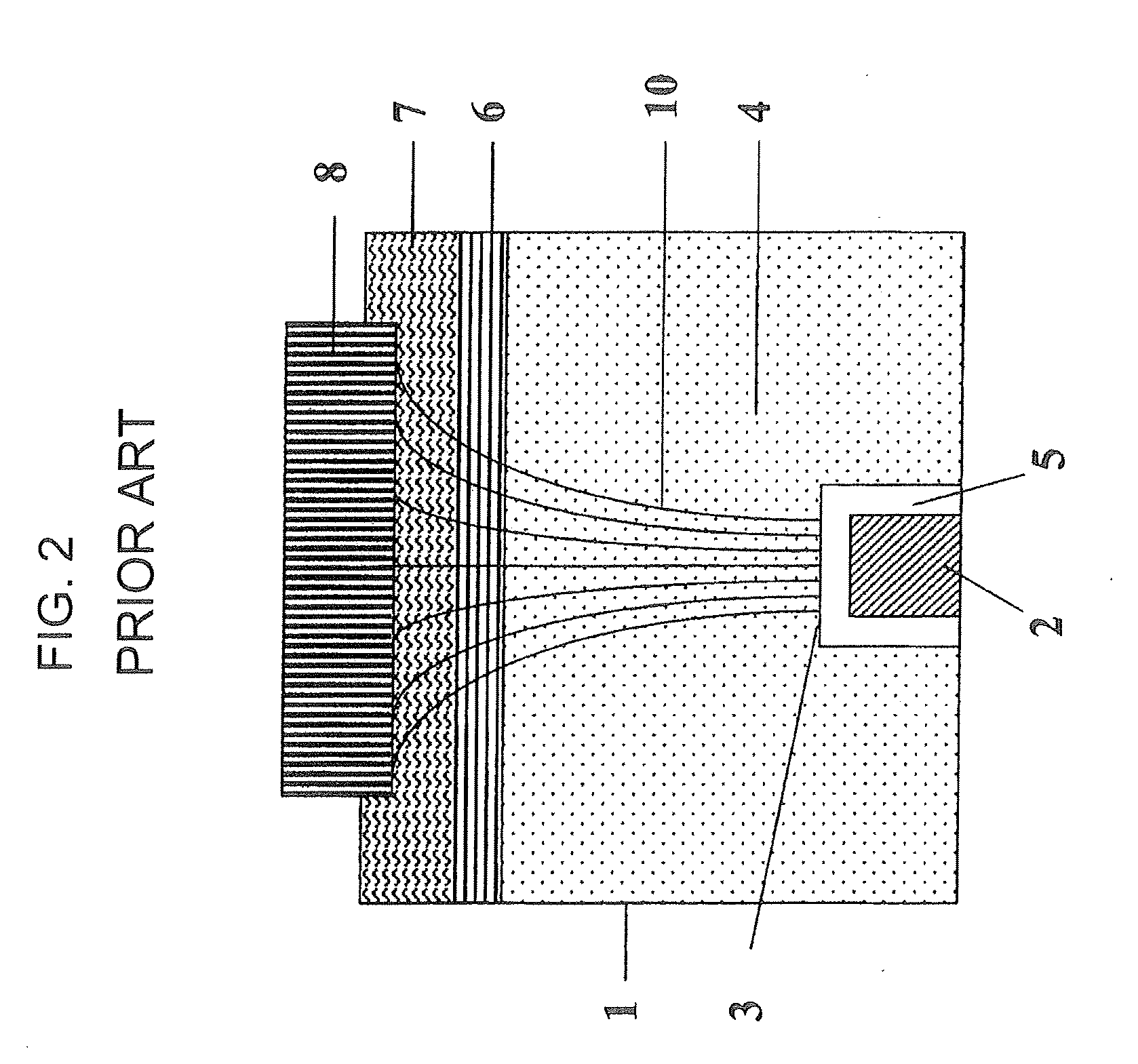

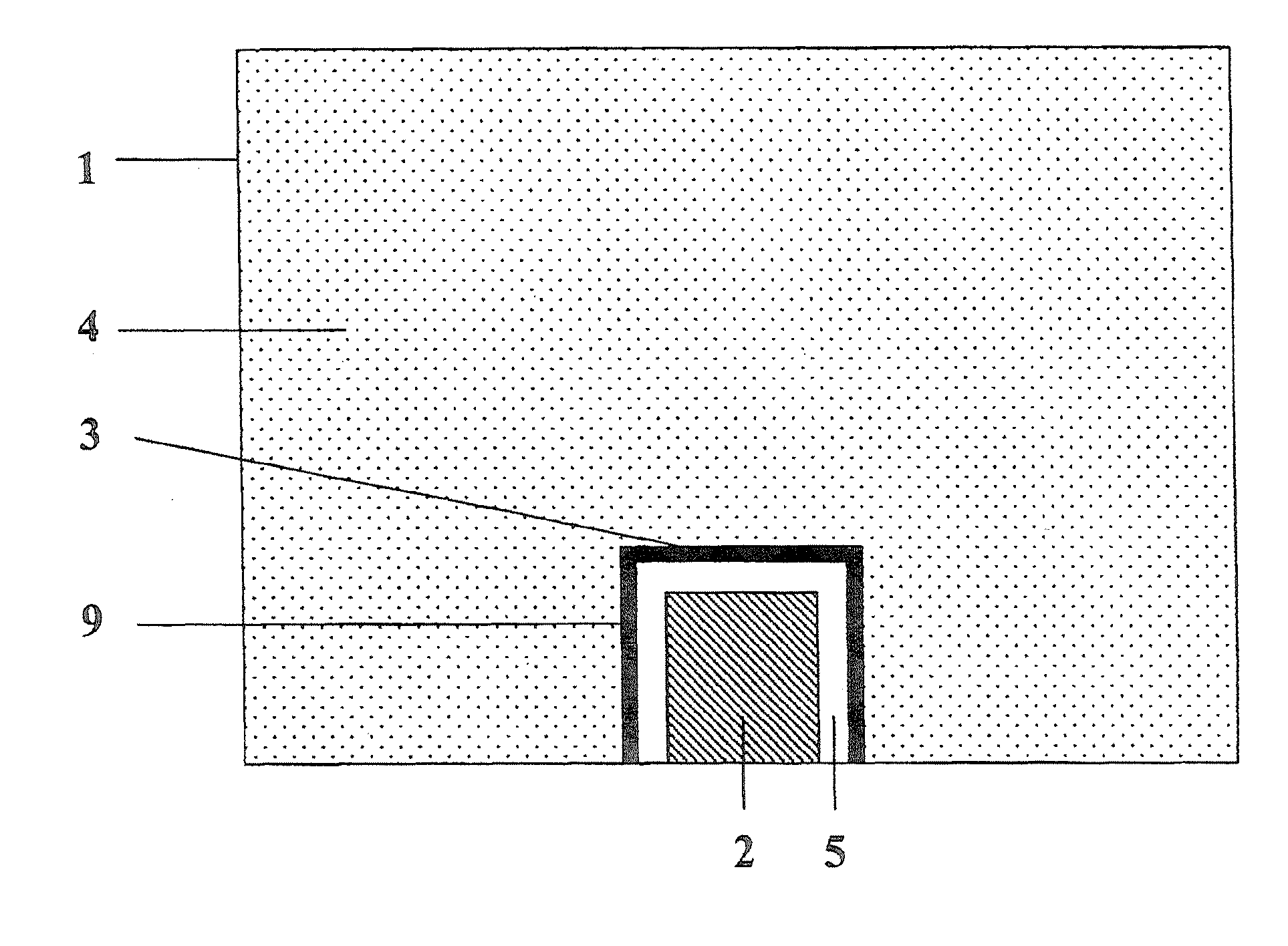

In a method in which a semiconductor wafer 1 having integrated circuits 3 formed in a plurality of chip regions and test patterns 4 formed in scribe lines 2a is divided by a plasma etching process so as to manufacture individual semiconductor chips, in the semiconductor wafer 1, a protection sheet 5 which constitutes a mask in the plasma etching process is adhered onto a front plane 1a thereof where the integrated circuits 3 have been formed; since laser light 9a is irradiated along the scribe lines 2a, only a predetermined width of the protection sheet 5 is removed so as to form a mask having a plasma dicing-purpose opening portion 5b; and also, the test patterns 4 are removed by the laser light 9a in combination with a front plane layer of the semiconductor wafer 1. As a result, the test patterns 4 can be removed in a higher efficiency and in simple steps, while the general purpose characteristic can be secured.

Owner:PANASONIC CORP

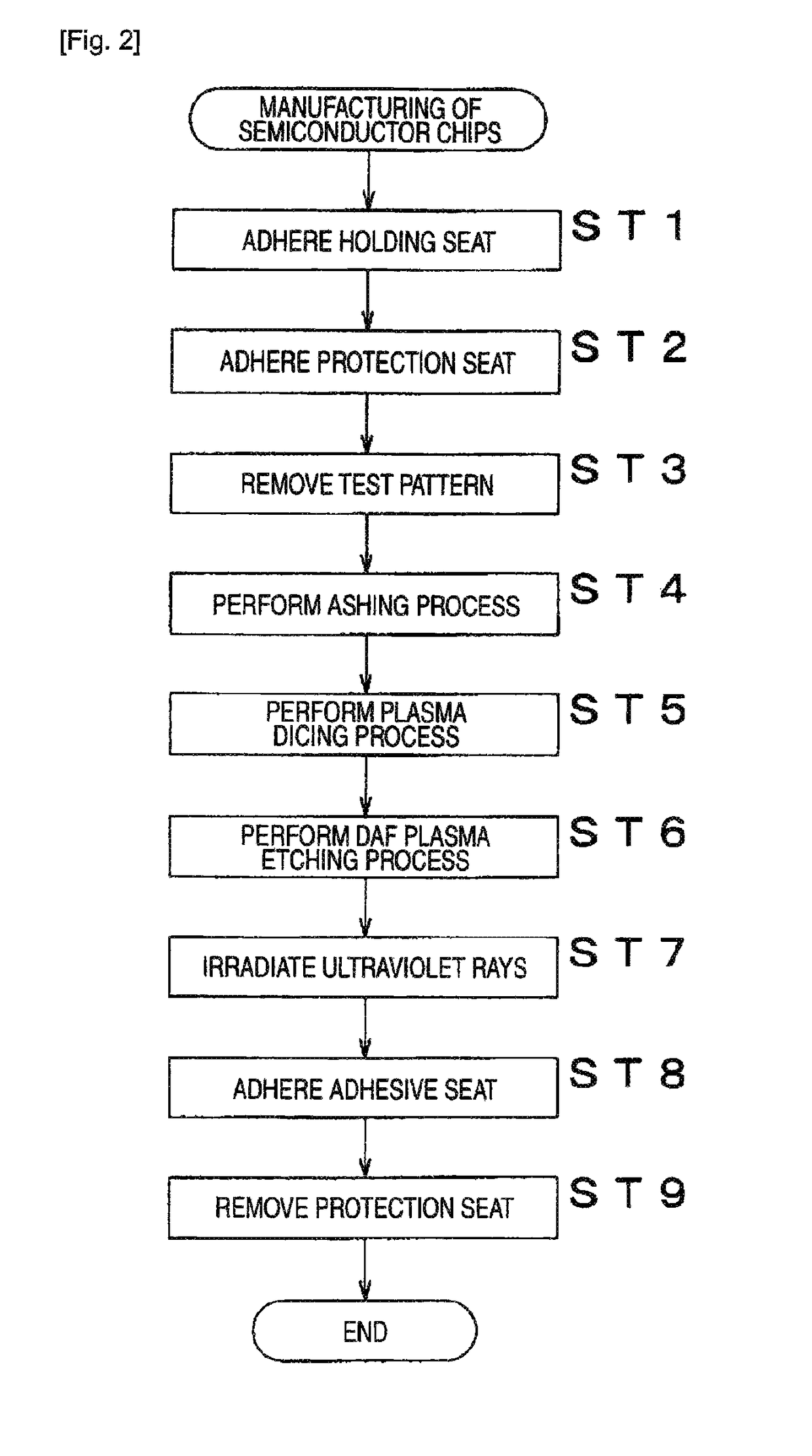

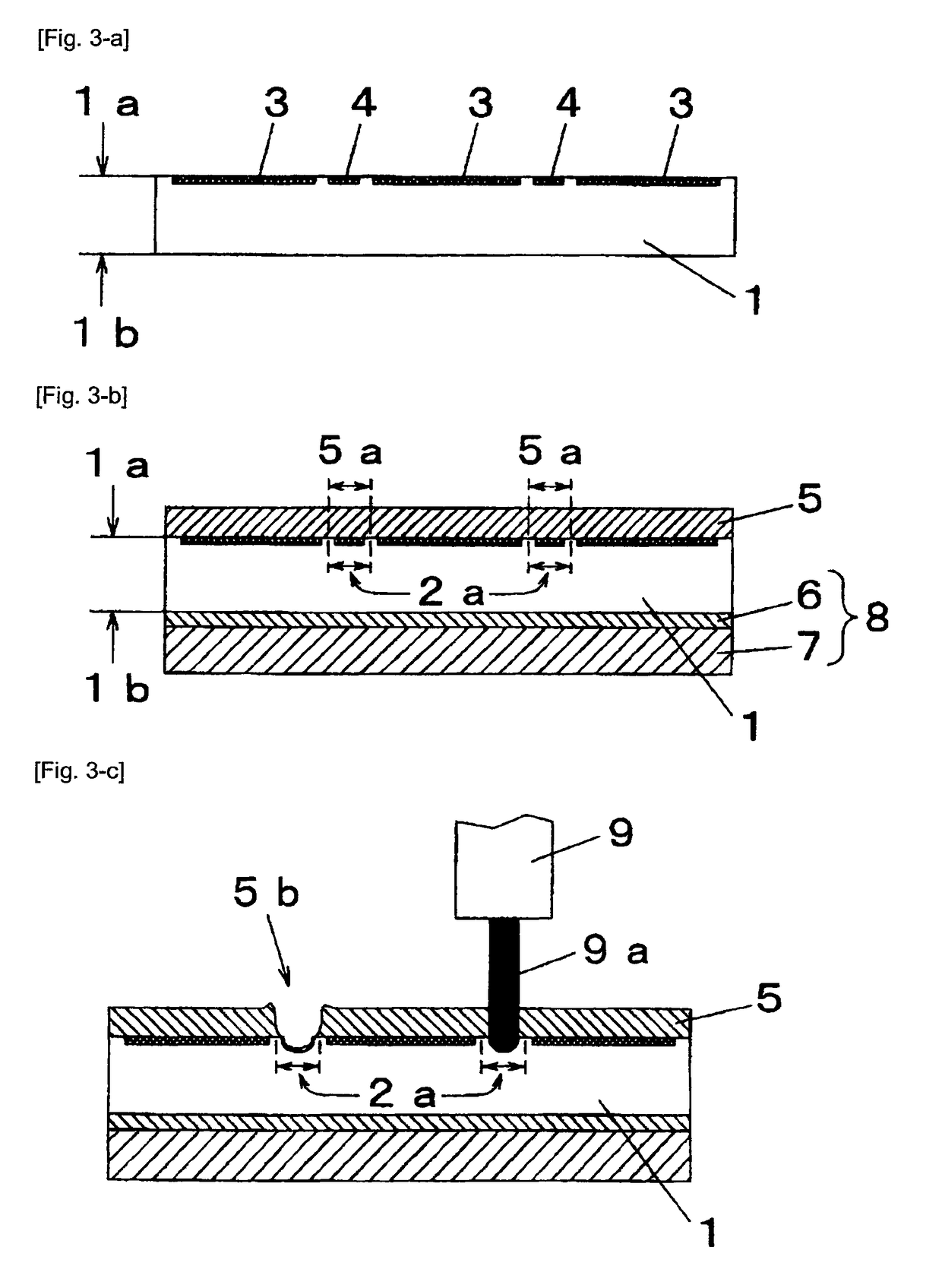

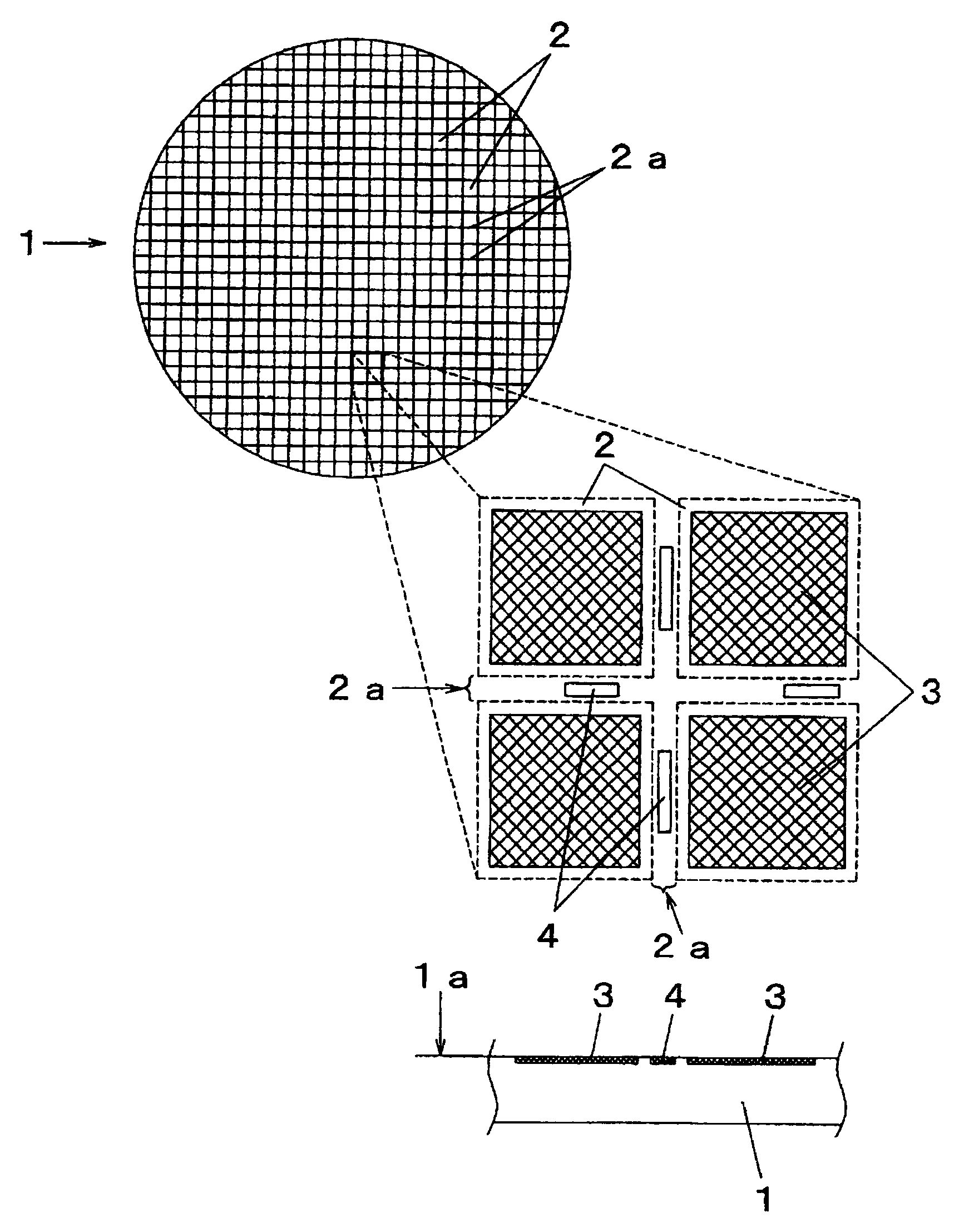

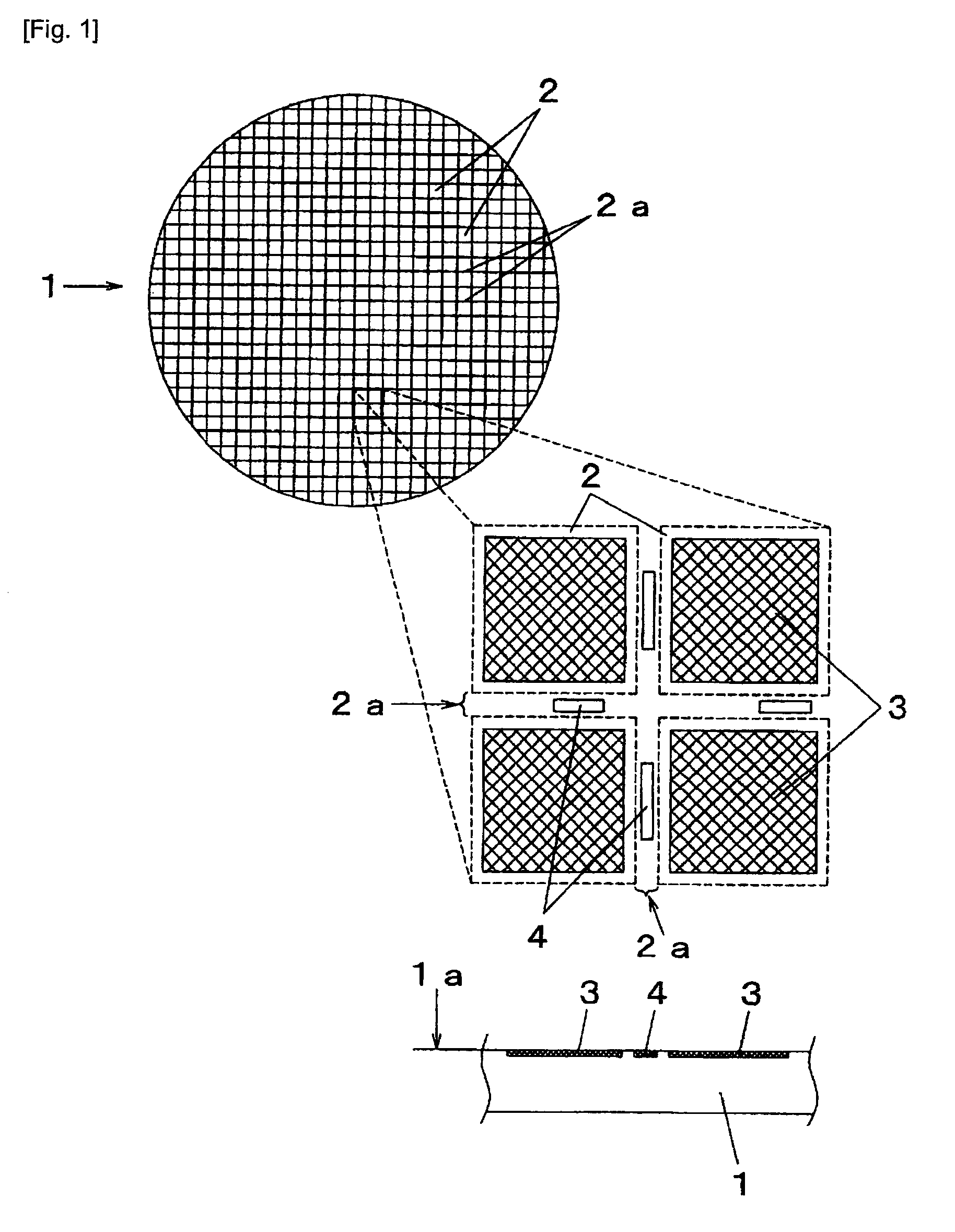

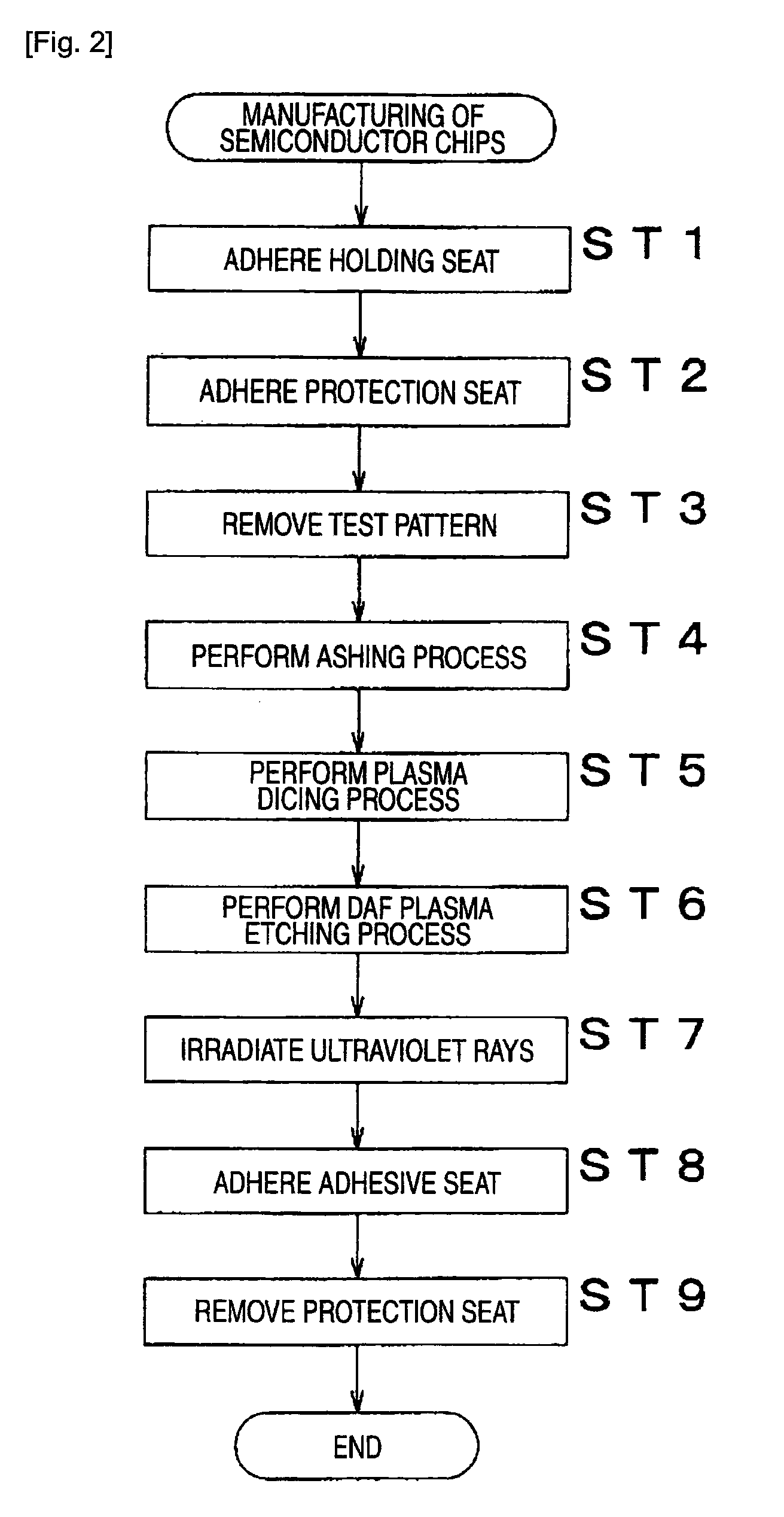

Method of manufacturing semiconductor chip

ActiveUS20100173474A1Improve efficiencySimple stepsSolid-state devicesSemiconductor/solid-state device manufacturingGeneral purposeSemiconductor chip

In a method in which a semiconductor wafer 1 having integrated circuits 3 formed in a plurality of chip regions and test patterns 4 formed in scribe lines 2a is divided by a plasma etching process so as to manufacture individual semiconductor chips, in the semiconductor wafer 1, a protection seat 5 which constitutes a mask in the plasma etching process is adhered onto a front plane 1a thereof where the integrated circuits 3 have been formed; since laser light 9a is irradiated along the scribe lines 2a, only a predetermined width of the protection seat 5 is removed so as to form a mask having a plasma dicing-purpose opening portion 5b; and also, the test patterns 4 are removed by the laser light 9a in combination with a front plane layer of the semiconductor wafer 1. As a result, the test patterns 4 can be removed in a higher efficiency and in simple steps, while the general purpose characteristic can be secured.

Owner:PANASONIC CORP

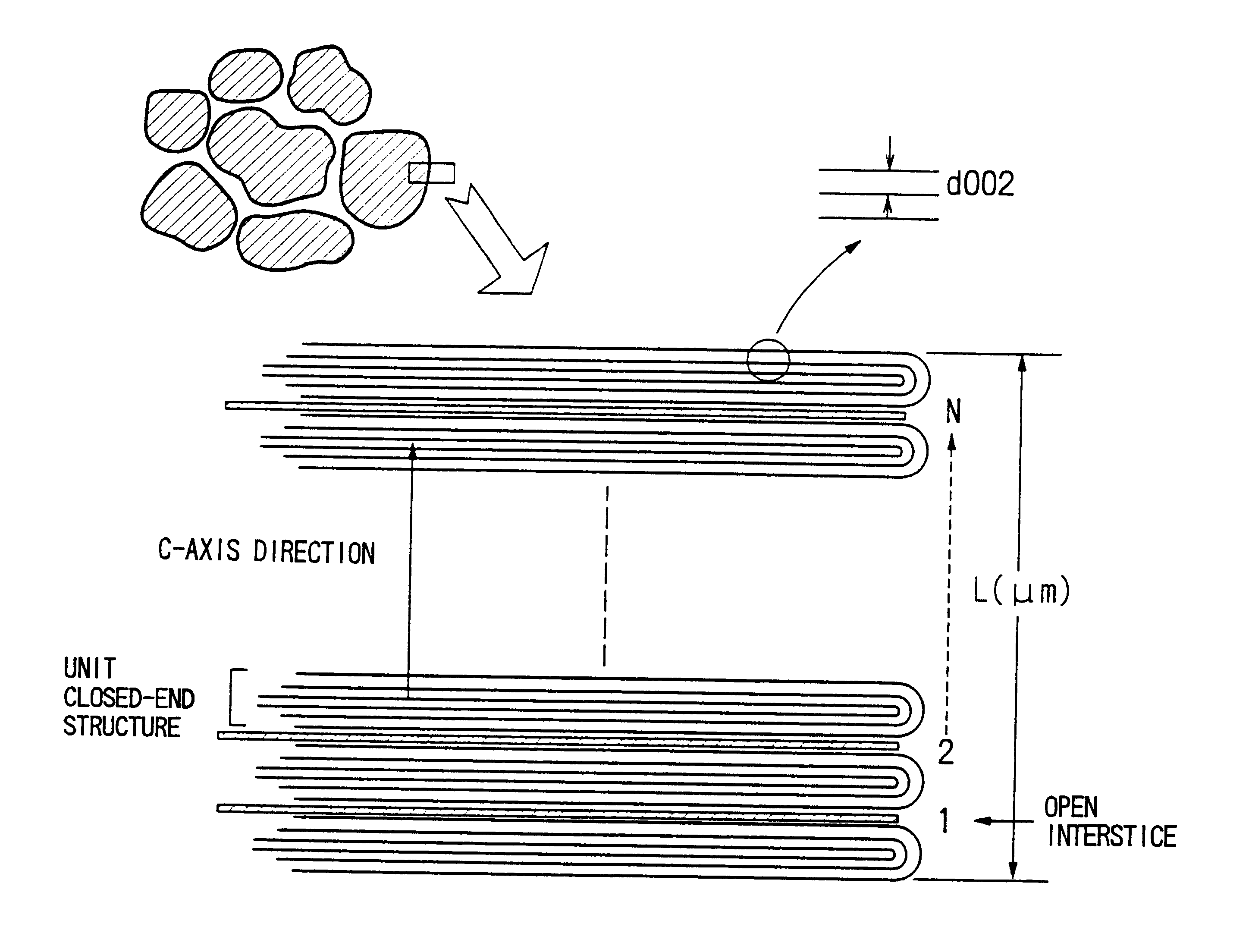

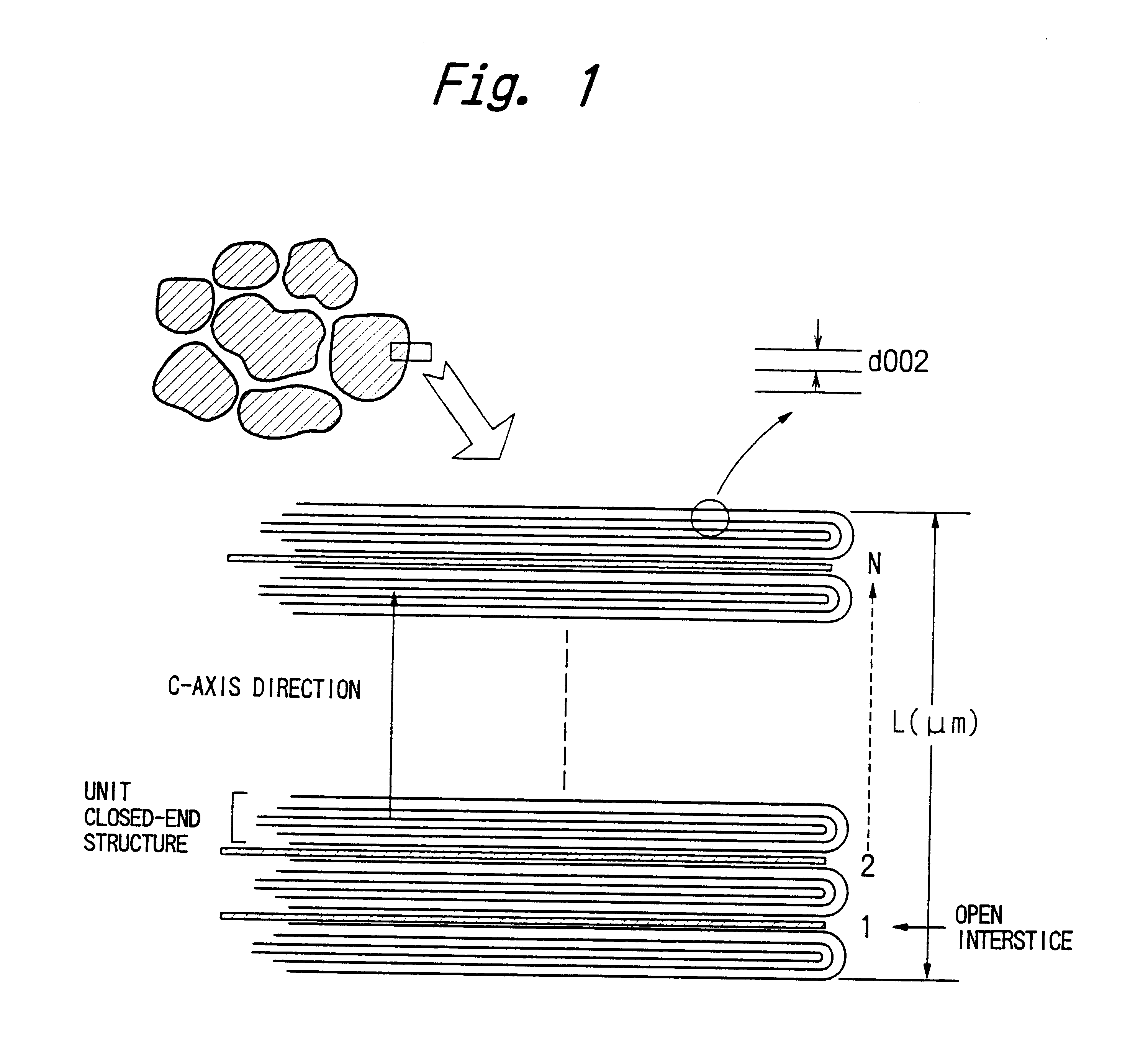

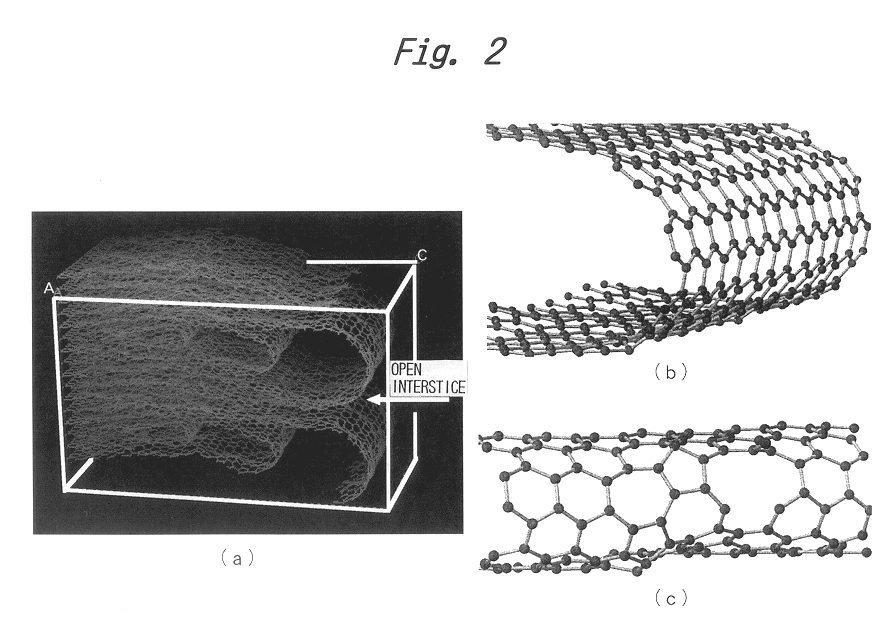

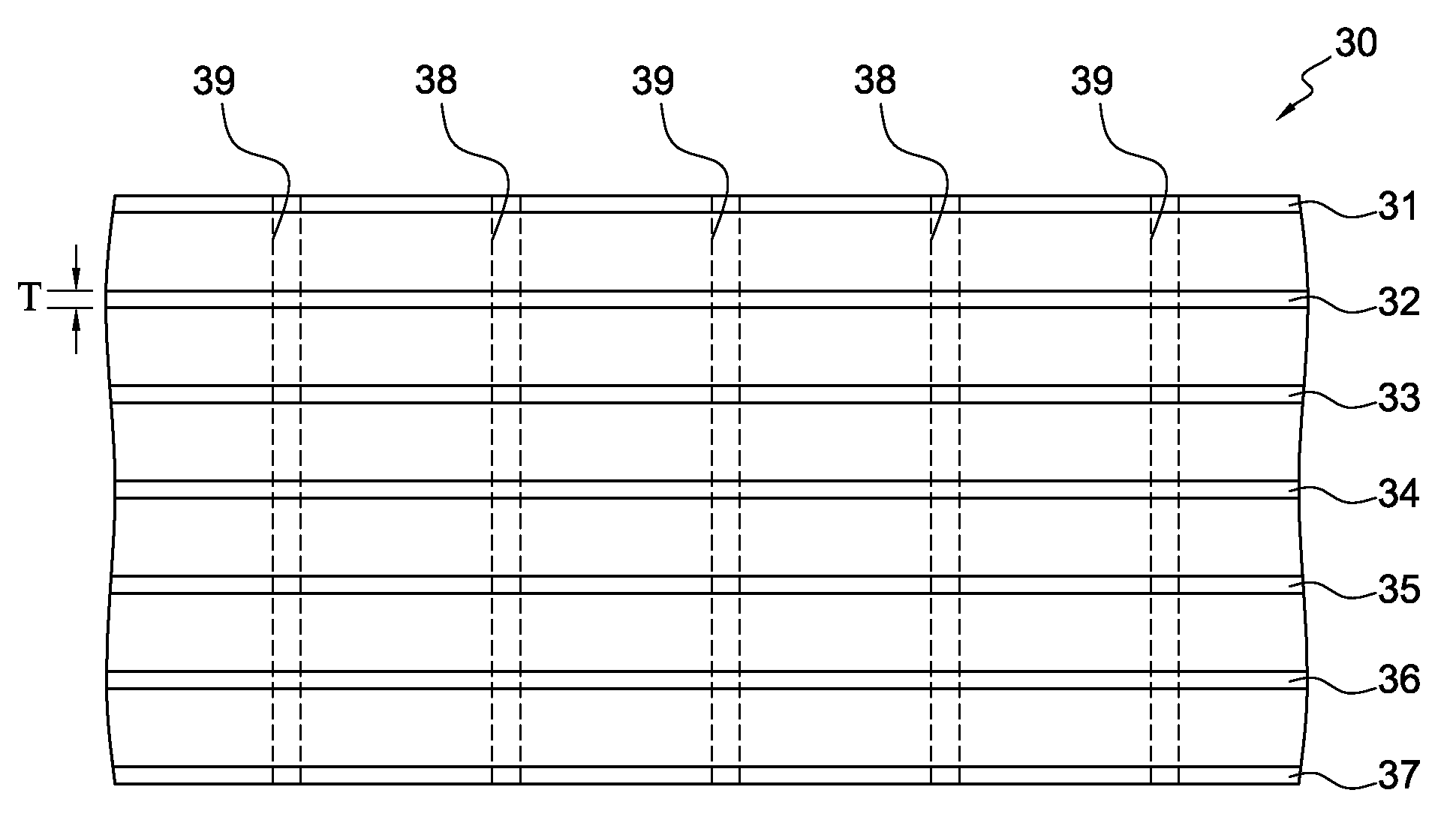

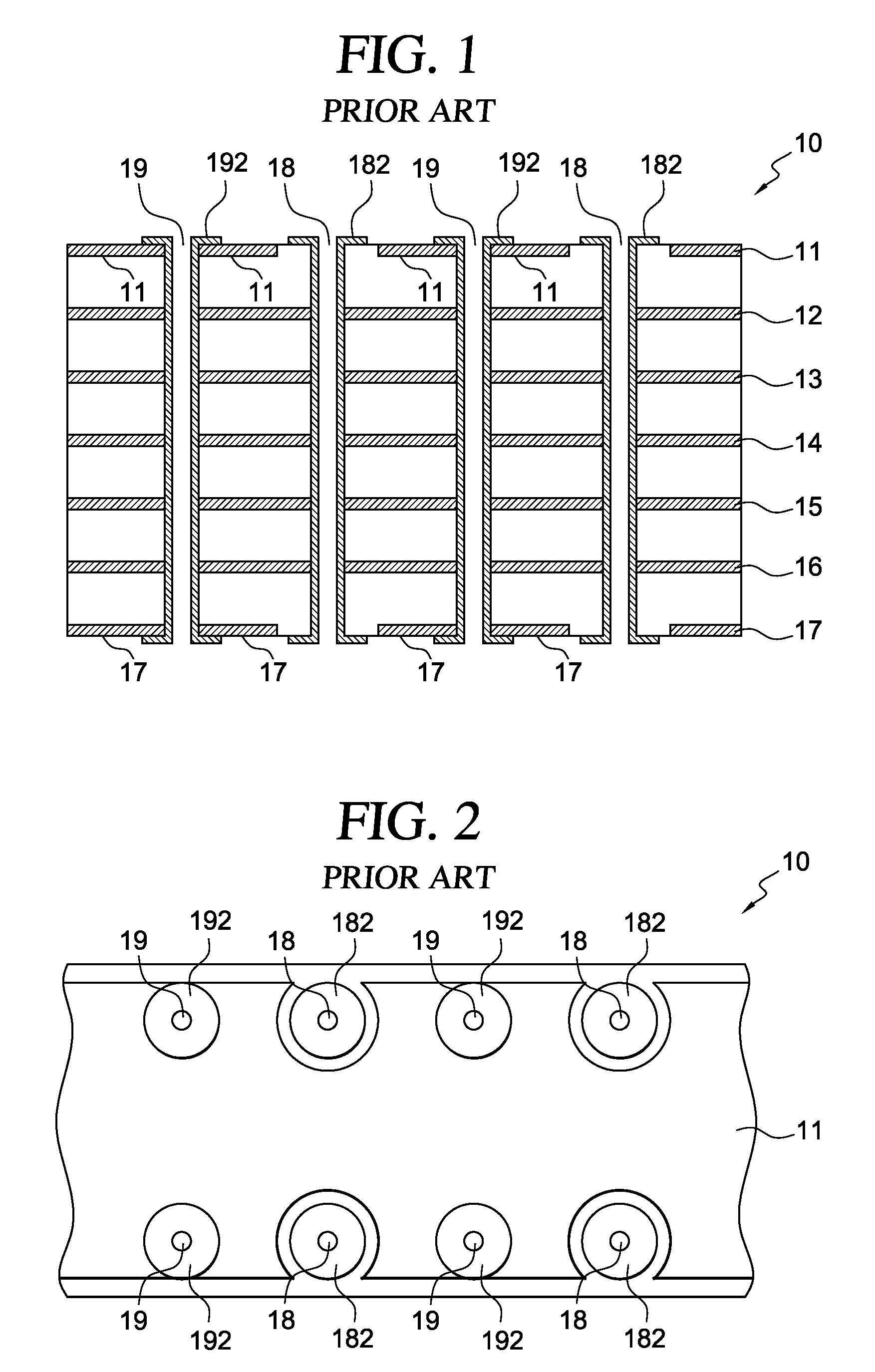

Graphite powder suitable for negative electrode material of lithium ion secondary batteries

InactiveUS6576369B1Improve discharge capacityImprove Coulombic efficiencyNon-aqueous electrolyte accumulatorsGraphiteLithiumMicrometer

A graphite powder has surface closed-end structures in which the graphite c-plane layers of the graphite layer crystal lattices have closed-ends on the surface of the graphite powder by linking the ends of one or more pairs of the c-plane layers, leaving interstices which are open on the surface of the graphite. The number of open interstices is at least 100 and at most 1500 per micrometer in a c-axis direction of the graphite. Preferably, the graphite powder has a specific surface area of 1.0 m2 / g or less. Such a graphite powder can be prepared either by graphitizing a carbon material, which has been pulverized at a high speed under well-controlled conditions before and / or after the carbonization, or by subjecting a carbon material, which has been pulverized under well-controlled conditions before and / or after the carbonization, to graphitization and then to oxidative heat treatment at a temperature of 600-800° C. and finally to heat treatment at a temperature of 800° C. or higher in an inert gas. The graphite powder can be used to produce negative electrodes of lithium ion secondary batteries having a high discharge capacity of at least 320 mAh / g and a high charge / discharge coulombic efficiency of at least 90%.

Owner:NIPPON DENKO CO LTD +1

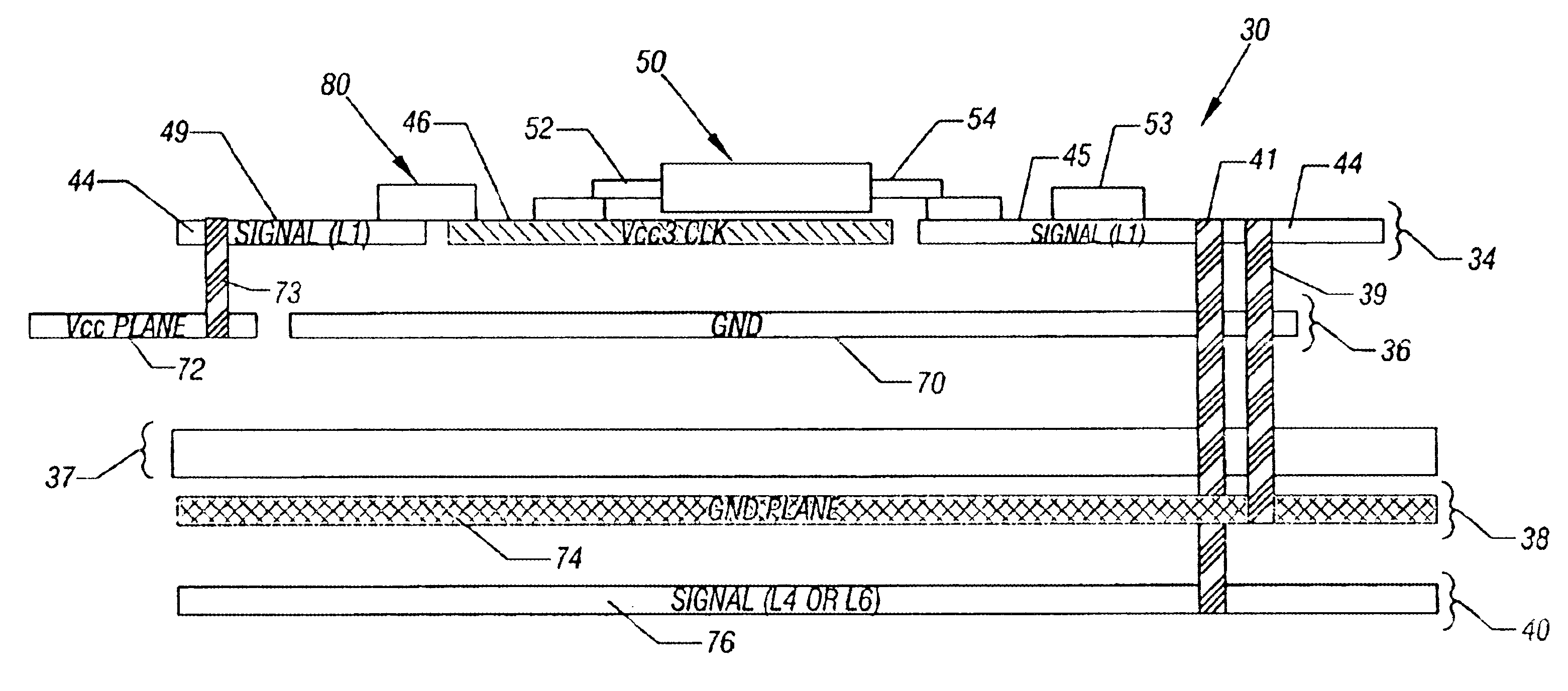

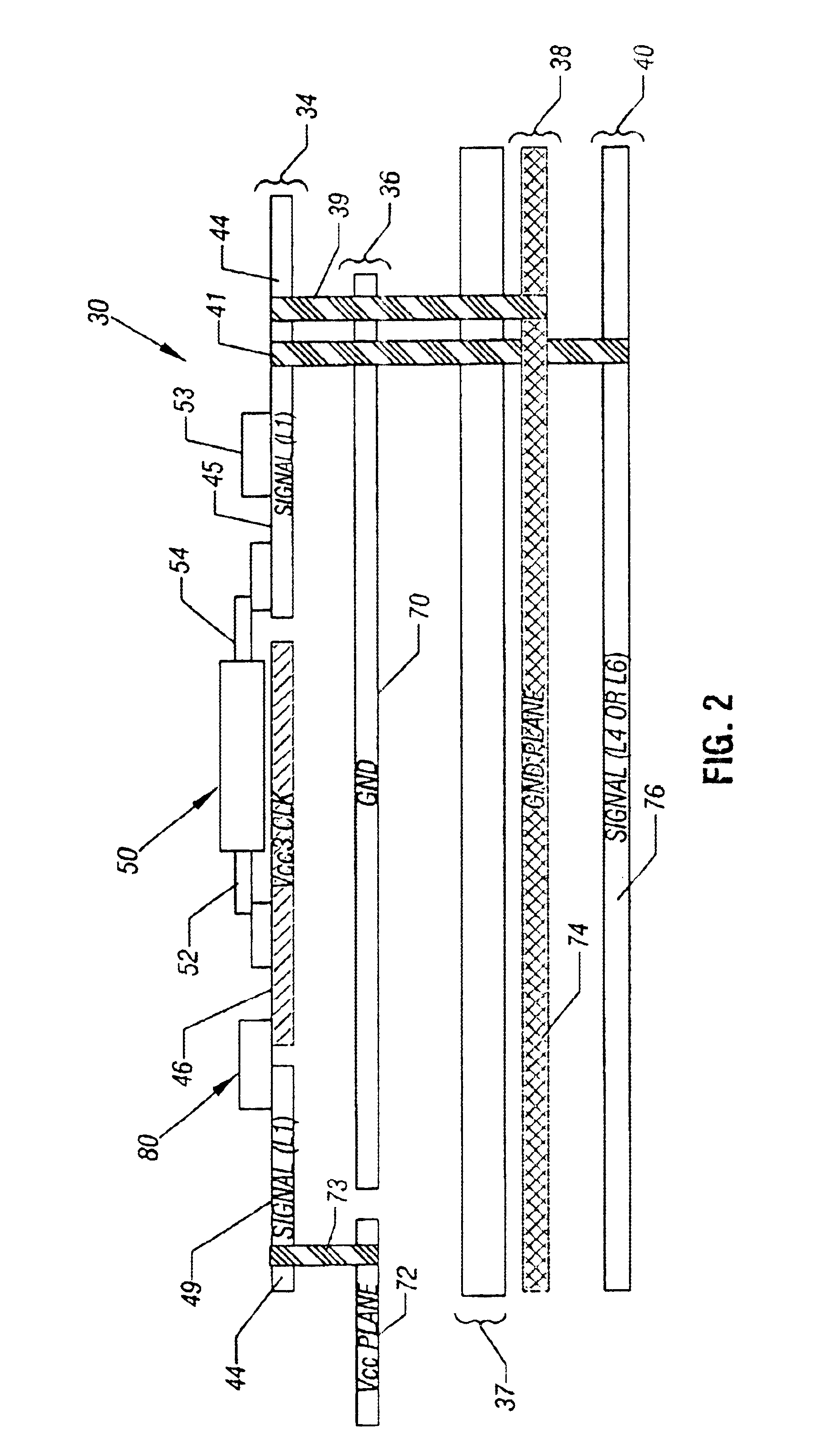

Printed circuit board routing and power delivery for high frequency integrated circuits

InactiveUS6900992B2Cross-talk/noise/interference reductionHigh frequency circuit adaptationsEngineeringGround plane

A printed circuit board includes a signal layer and a supply voltage plane layer. The signal layer includes traces to communicate signals that are not associated with regulated supply voltages. The supply voltage plane is embedded in the signal layer to supply power to multiple supply voltage pins of a component that is mounted to the printed circuit board. The printed circuit board may also include a supply voltage plane layer to communicate a supply voltage. A ground plane may be embedded in the supply voltage plane layer to provide ground connections to multiple pins of the component.

Owner:INTEL CORP

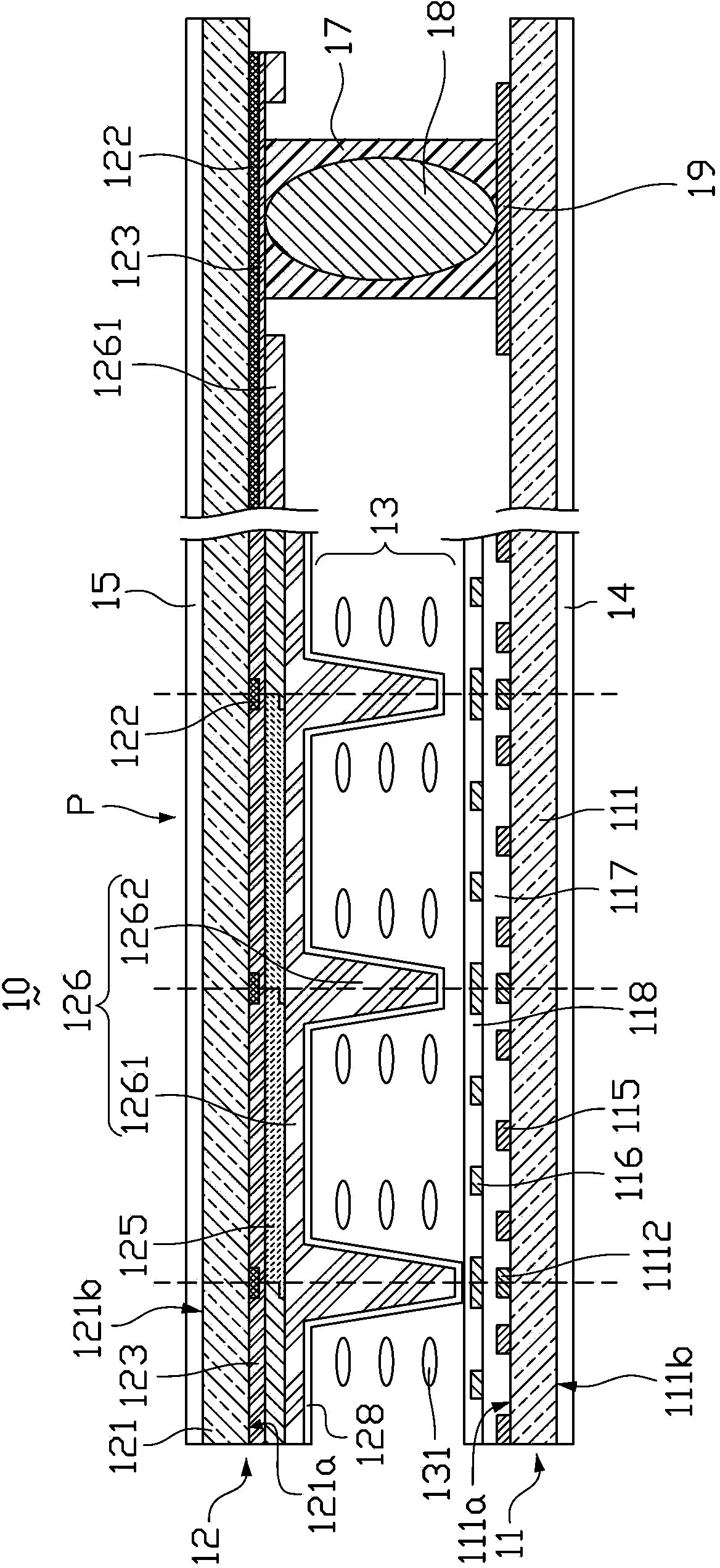

Liquid crystal display device and manufacturing method thereof

ActiveCN103353693AEliminate the effects ofWeaken the vertical electric fieldNon-linear opticsColor filmPhotoresist

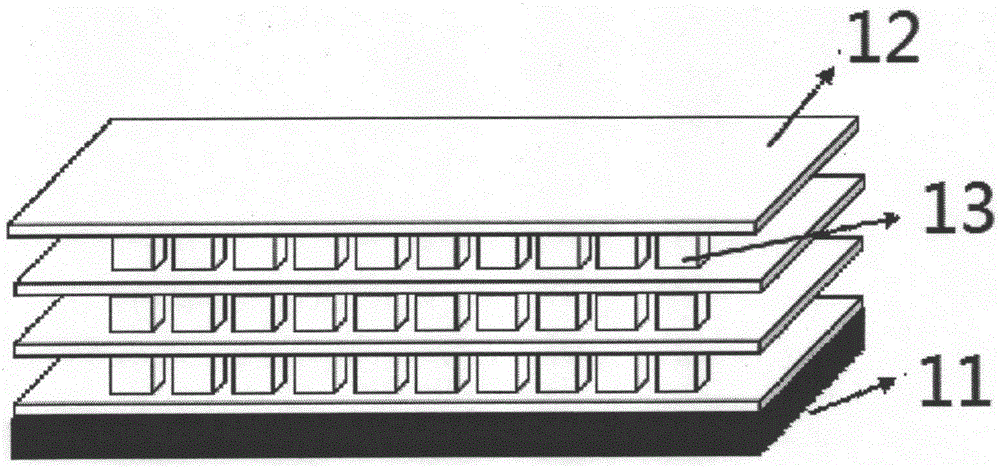

The invention discloses a liquid crystal display device. The liquid crystal display device comprises an array substrate, a color film substrate opposite to the array substrate and a liquid crystal layer sandwiched between the array substrate and the color film substrate, wherein the array substrate comprises a first transparent base as well as first electrodes and second electrodes formed on the first transparent base, the first electrodes and the second electrodes are arranged on different layers, and an insulation layer is arranged therebetween; the color film substrate comprises a second transparent base as well as black matrixs formed on the second transparent base, third electrodes, a photoresist layer and optical clearance objects; the third electrodes cover the black matrix and the surface on which the black matrix is not arranged, of the transparent base, the photoresist layer covers the third electrodes, the optical clearance objects cover the photoresist layer, and the optical clearance objects comprise a plane layer covered with the photoresist layer and optical clearances integrally extending from the plane layer and used for providing interval support for the liquid crystal layer; liquid crystal molecules in the liquid crystal layer are negative.

Owner:KUSN INFOVISION OPTOELECTRONICS

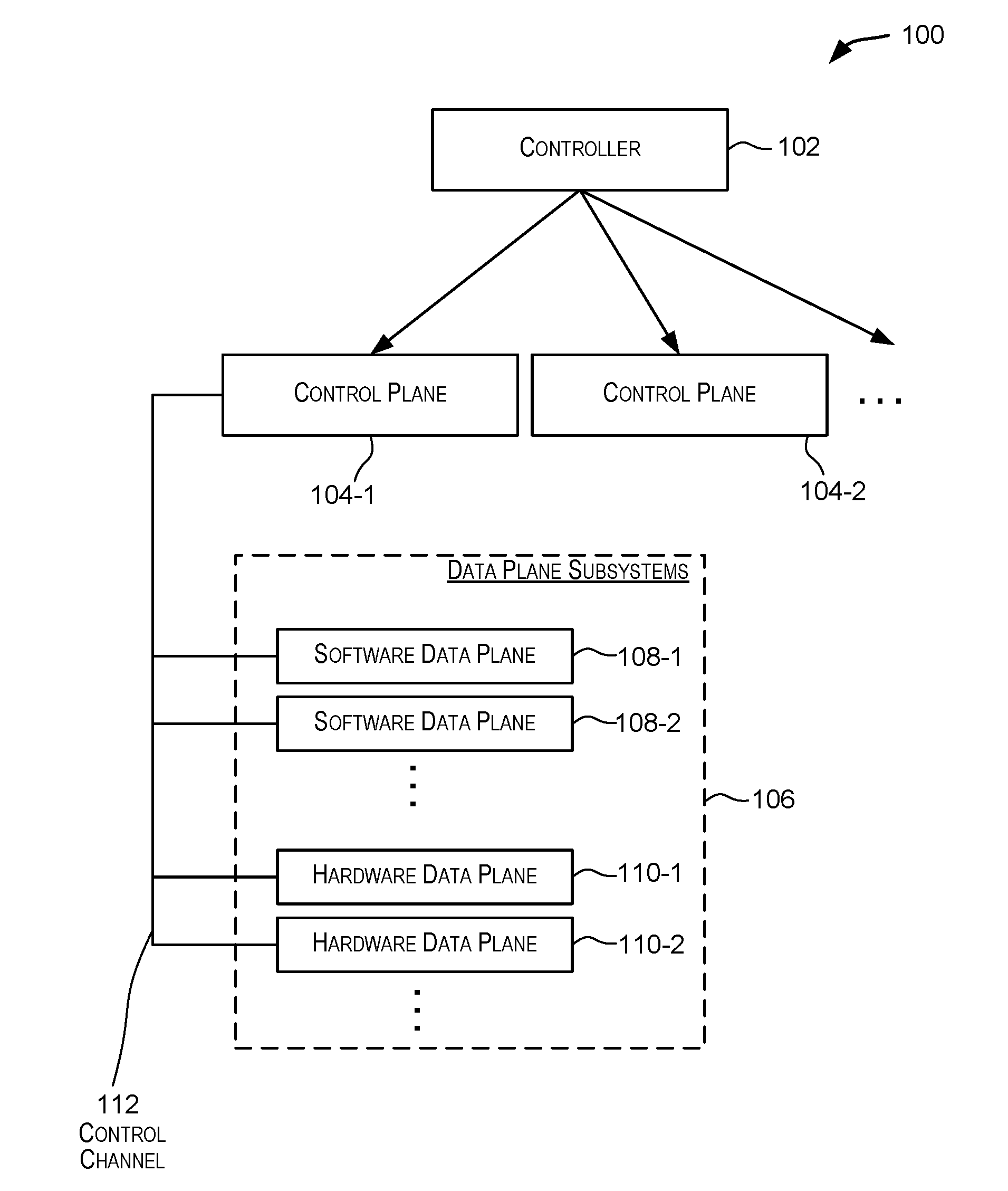

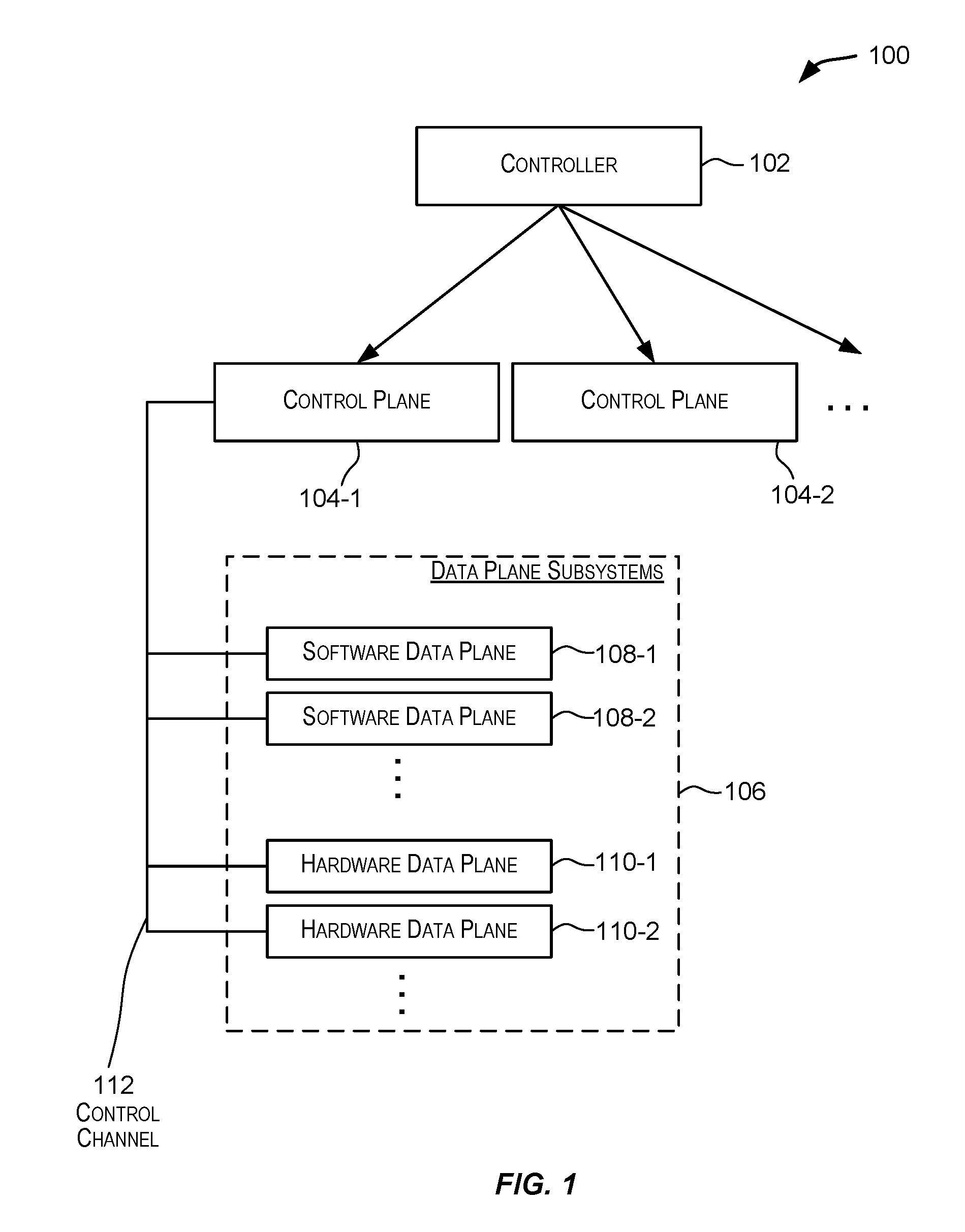

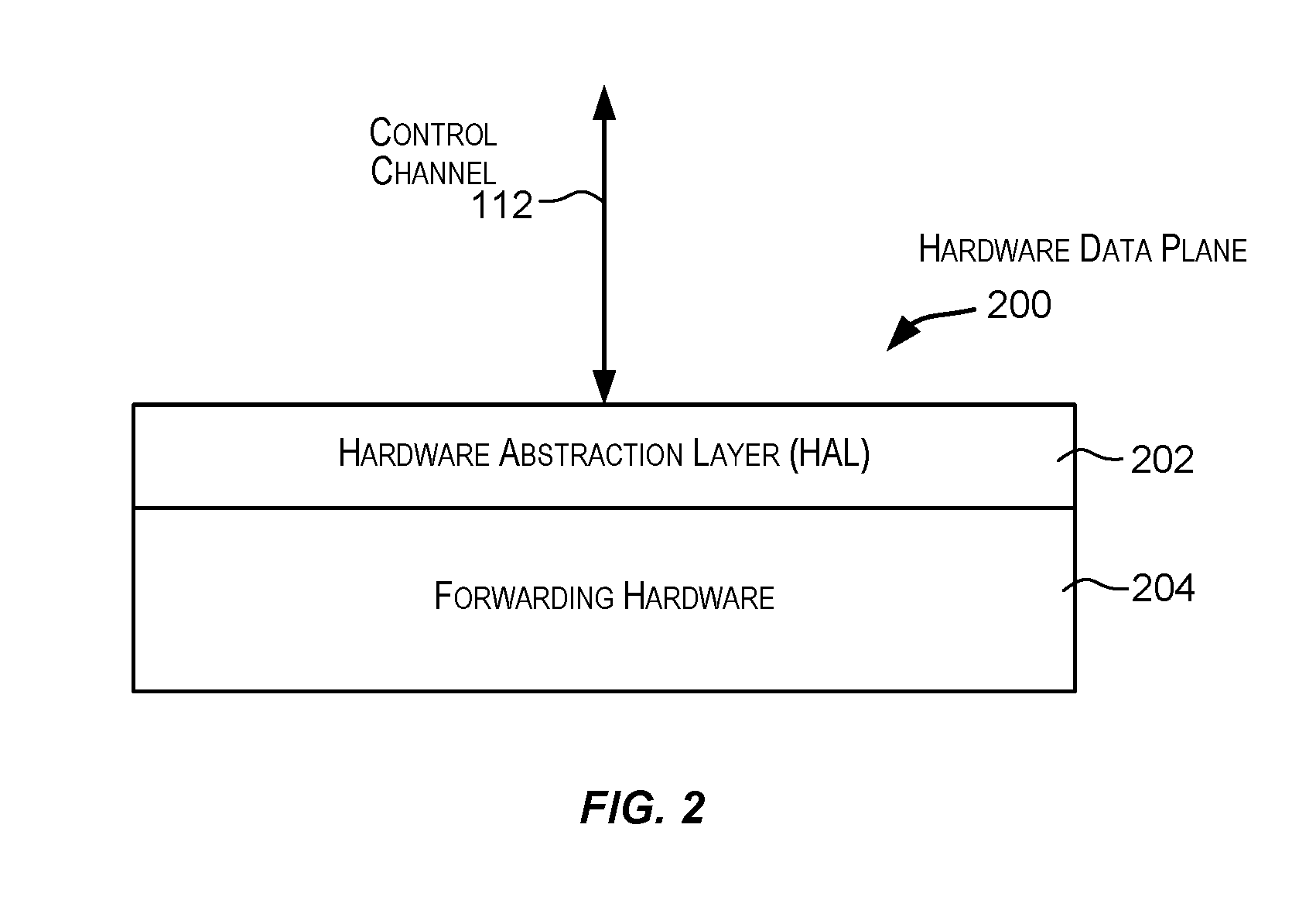

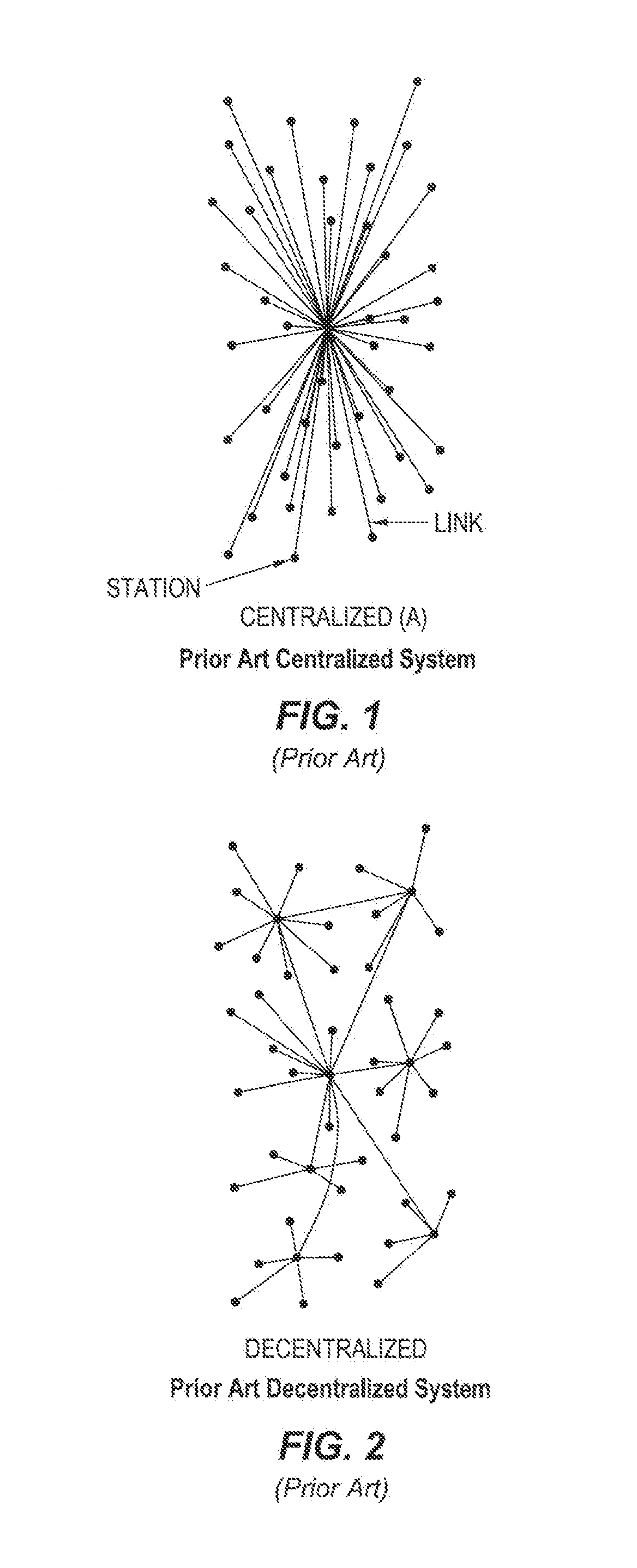

Multilayered distributed router architecture

A distributed multilayered network routing architecture comprises multiple layers including a controller layer comprising a controller, a control plane layer comprising one or more control plane subsystems, and a data plane layer comprising one or more data plane subsystems. A controller may be coupled to one or more control plane subsystems. A control plane subsystem may in turn be coupled to one or more data plane subsystems, which may include one or more software data plane subsystems and / or hardware data plane subsystems. In certain embodiments, the locations of the various subsystems of a distributed router can be distributed among various devices in the network.

Owner:CIENA

Method of manufacturing semiconductor chip

ActiveCN101542714AImprove efficiencyUniversal Feature GuaranteeSolid-state devicesSemiconductor/solid-state device manufacturingGeneral purposeSemiconductor chip

In a method in which a semiconductor wafer 1 having integrated circuits 3 formed in a plurality of chip regions and test patterns 4 formed in scribe lines 2a is divided by a plasma etching process so as to manufacture individual semiconductor chips, in the semiconductor wafer 1, a protection seat 5 which constitutes a mask in the plasma etching process is adhered onto a front plane 1a thereof where the integrated circuits 3 have been formed; since laser light 9a is irradiated along the scribe lines 2a, only a predetermined width of the protection seat 5 is removed so as to form a mask having a plasma dicing-purpose opening portion 5b; and also, the test patterns 4 are removed by the laser light 9a in combination with a front plane layer of the semiconductor wafer 1. As a result, the test patterns 4 can be removed in a higher efficiency and in simple steps, while the general purpose characteristic can be secured.

Owner:PANASONIC CORP

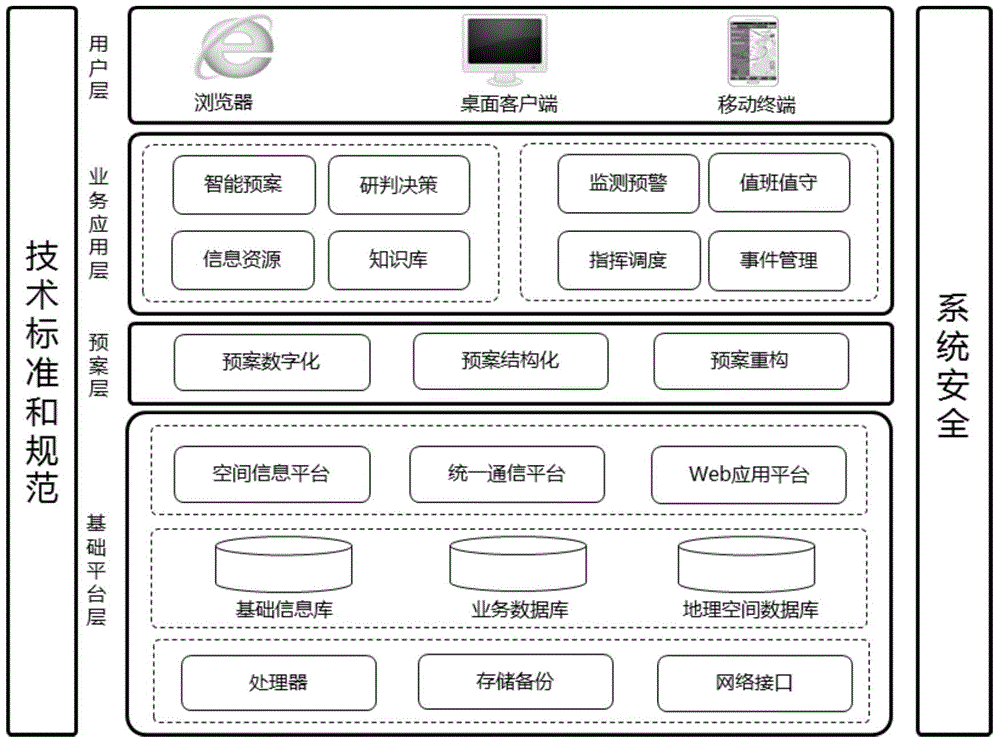

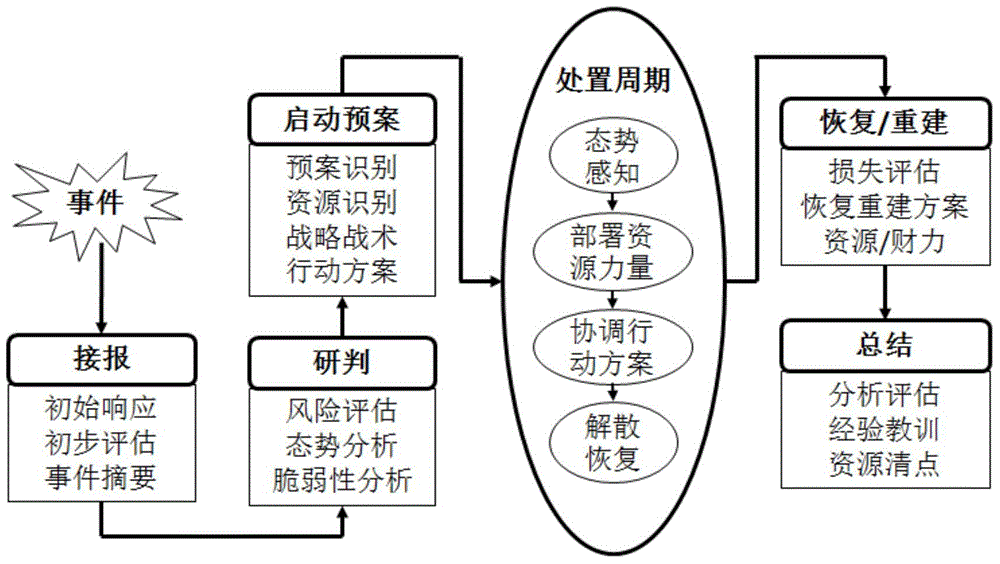

Decision-making and command all-in-one machine based on digital schema and operation method of all-in-one machine

InactiveCN104463759AImprove command efficiencyFully dispatched and commandedData processing applicationsPublic healthUnexpected events

The invention relates to the technical field of comprehensive emergency management, in particular to a decision-making and command all-in-one machine based on a digital predetermined plane and an operation method of the all-in-one machine. The all-in-one machine comprises a basic platform layer, a predetermining plane layer, a service application layer and a user layer in the aspect of architecture and adopts the design combining an application system and a hardware platform as a whole, can cope with natural hazards, accidents, disasters, public security, social security and various emergencies, and meets core requirements for analysis, judgment, decision making, scheduling, commanding and emergency management of public security emergency management. By means of integral design of the decision-making function and the command function and the all-in-one architecture combining practical auxiliary decision making of seven decision-making support technologies, the application system and the hardware platform, investment is little, implementation is easy, effects are fast, and professionalization is achieved. The all-in-one machine can be used for an intelligent emergency decision making and command scheduling system.

Owner:CLOUD COMPUTING CENT CHINESE ACADEMY OF SCI

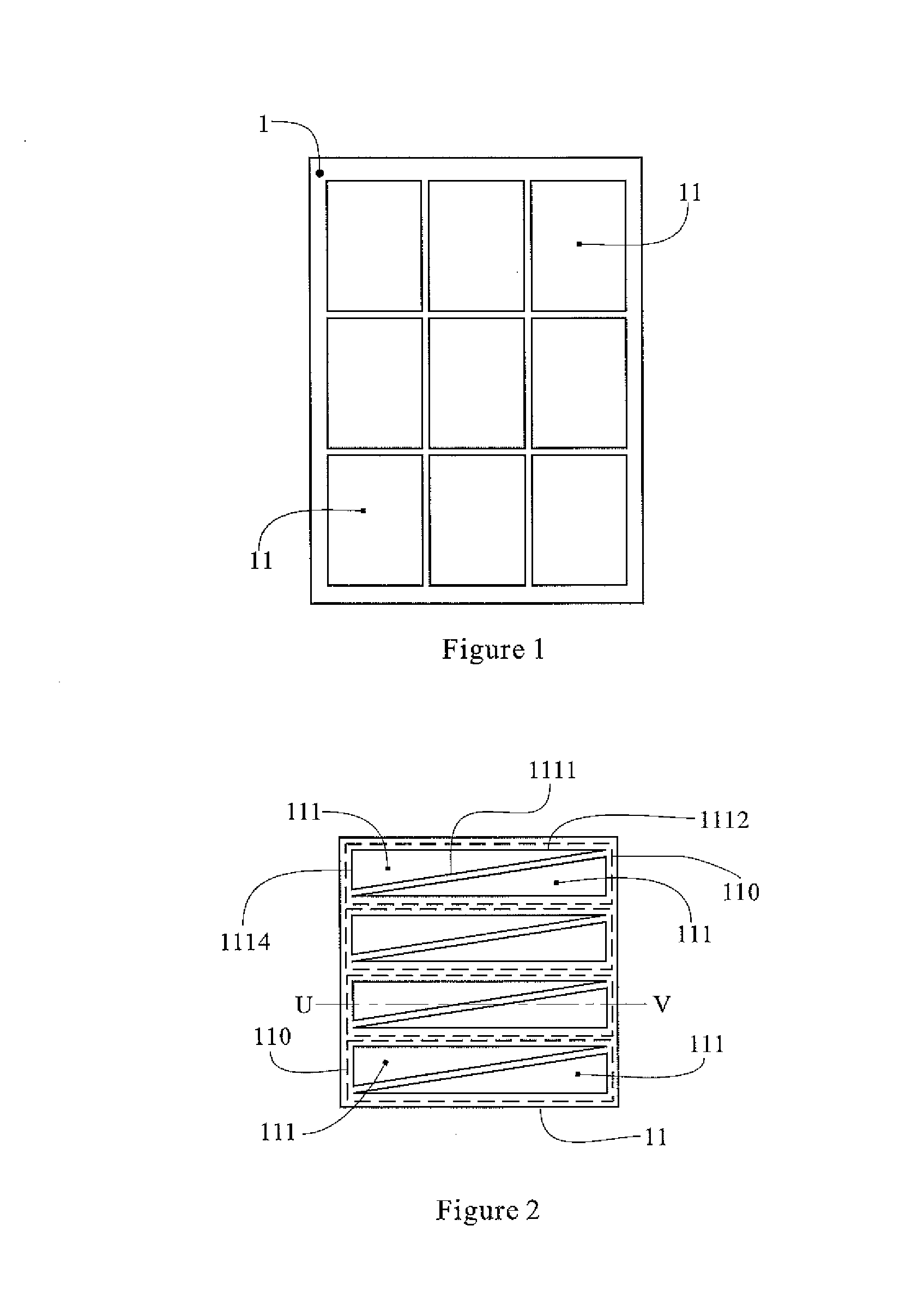

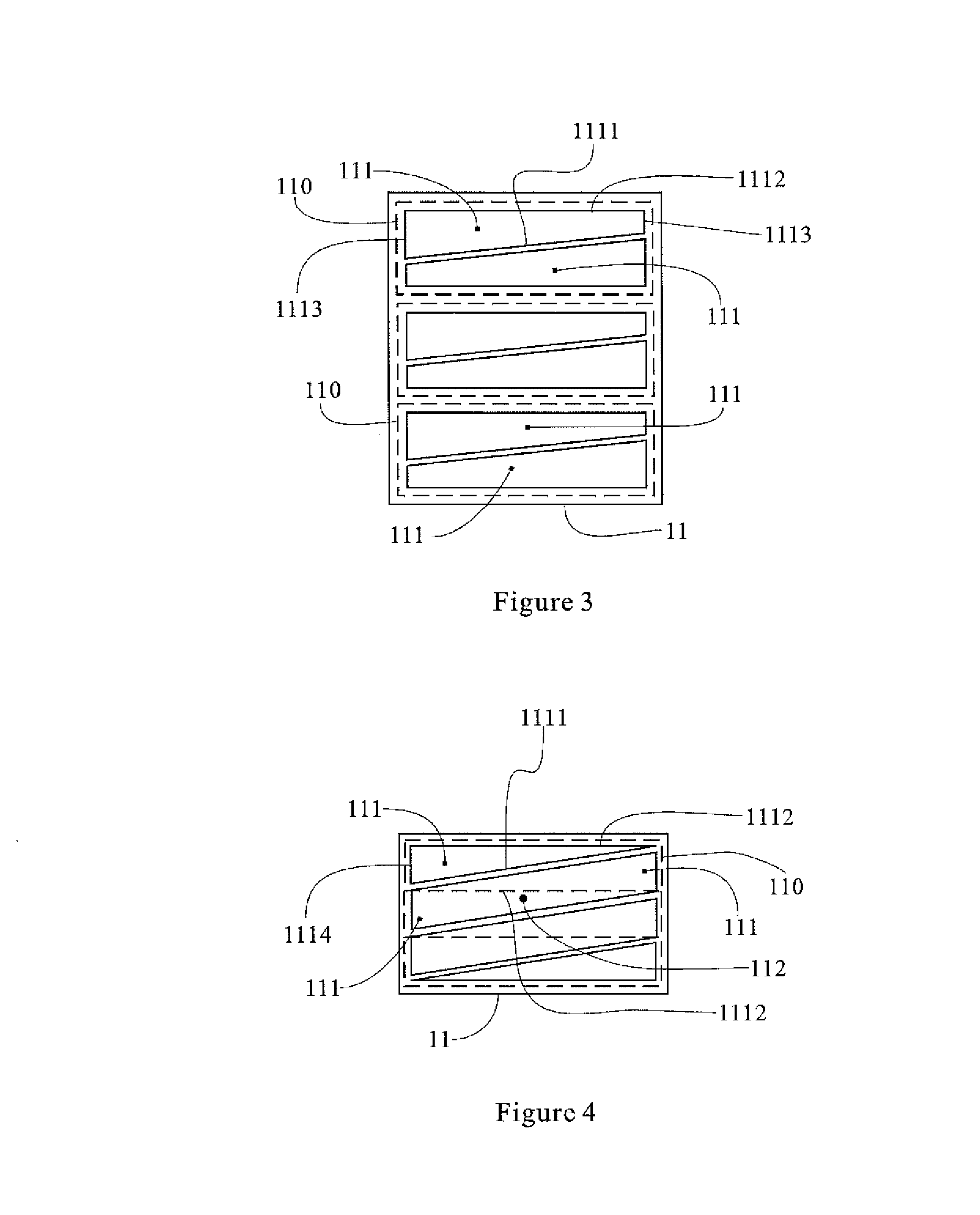

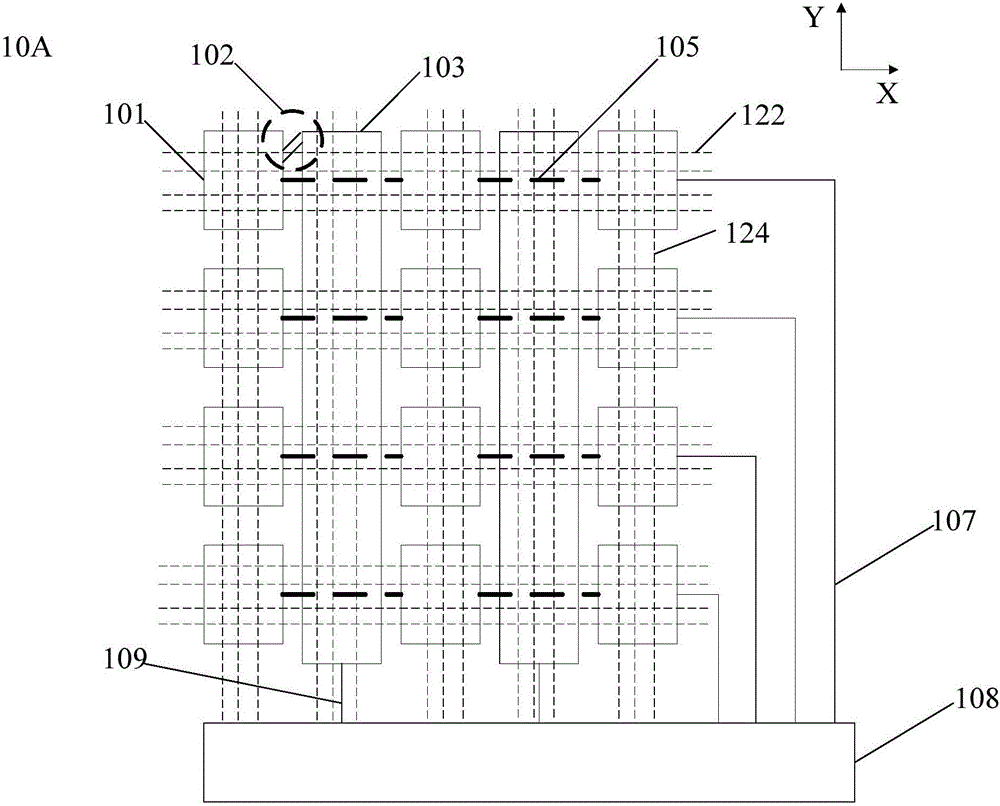

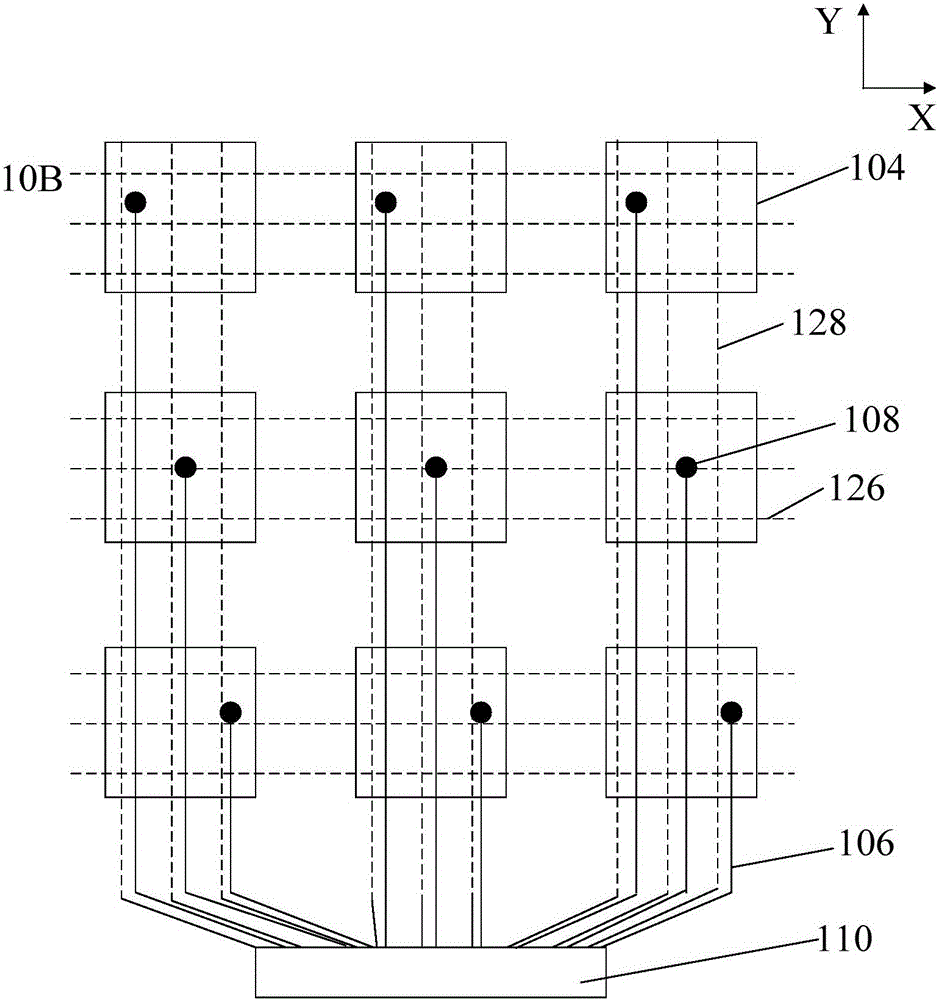

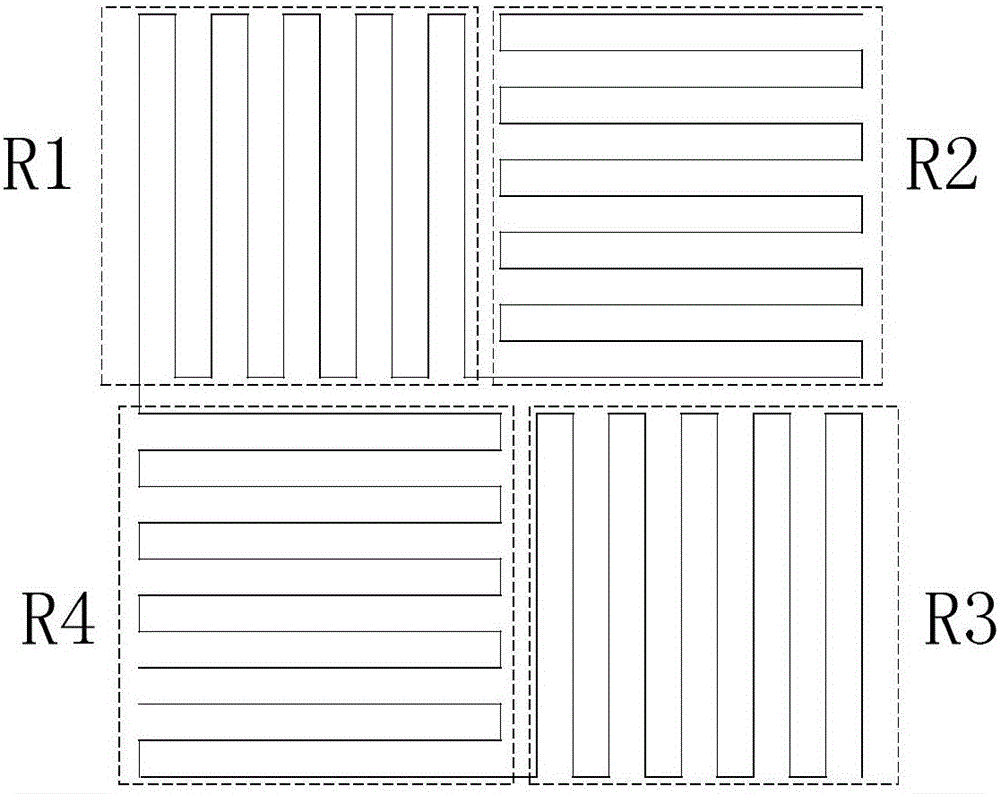

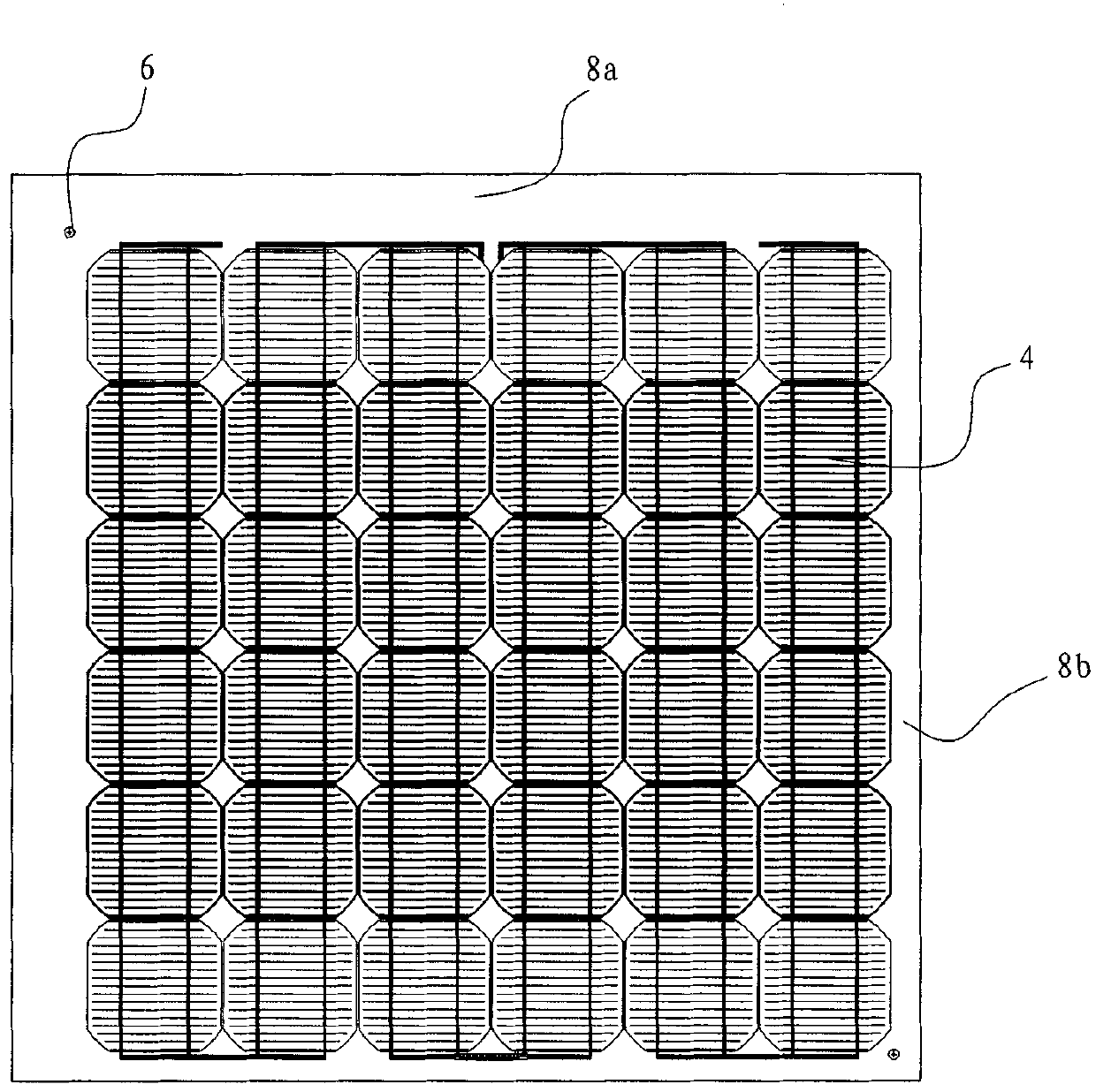

Single layer self-capacitance touch screen realizing multi-touch identification as well as its data processing method

ActiveUS20140009438A1Avoid failureEnhance layeringDigital data processing detailsElectronic switchingCapacitanceAcute angle

A single layer self-capacitance touch screen and its data processing method which can realize multi-touch identification, the said touch screen includes at least two self-capacitance electrode assemblies independent of each other, all of which are located in the same plane layer and fully cover the whole touch zone of the touch screen without overlapping each other; the said self-capacitance electrode assembly includes at least a pair of self-capacitance coupling electrode couples, which include two electrode plates seated in the same plane, and these two electrode plates all include their own straight-line electrode plate coupling side and straight-line electrode plate base, which have included angle of acute angle; in the self-capacitance electrode assembly, the centre lines of the self-capacitance coupling electrode couples are placed parallel to each other, and the centre lines of arbitrarily two self-capacitance coupling electrode couples are also placed parallel to each other. This invention fully utilizes simple technological structure feature of single layer self-capacitance touch screen and realizes multi-point touch control function at possible lowest manufacturing cost.

Owner:FOCALTECH SYST LTD

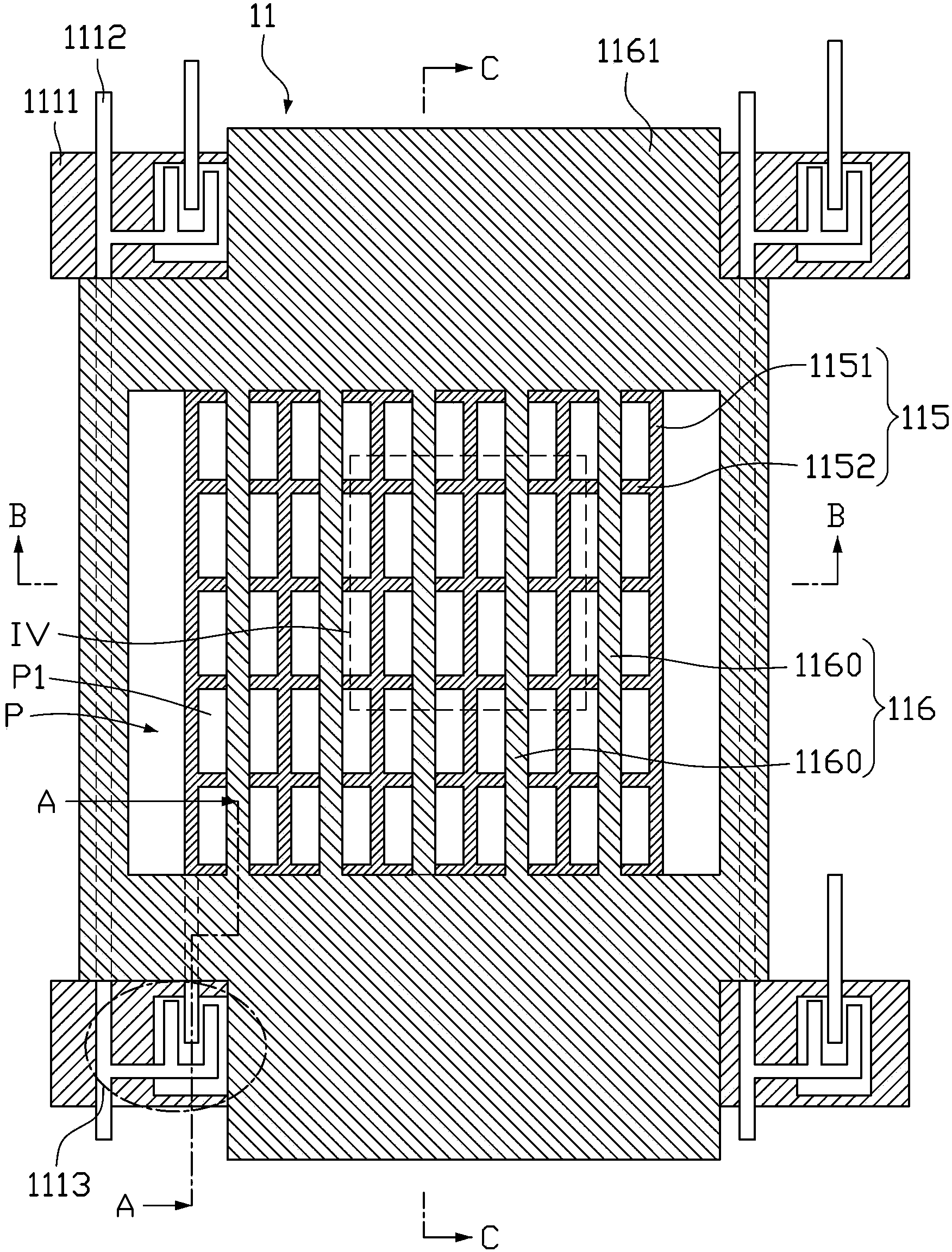

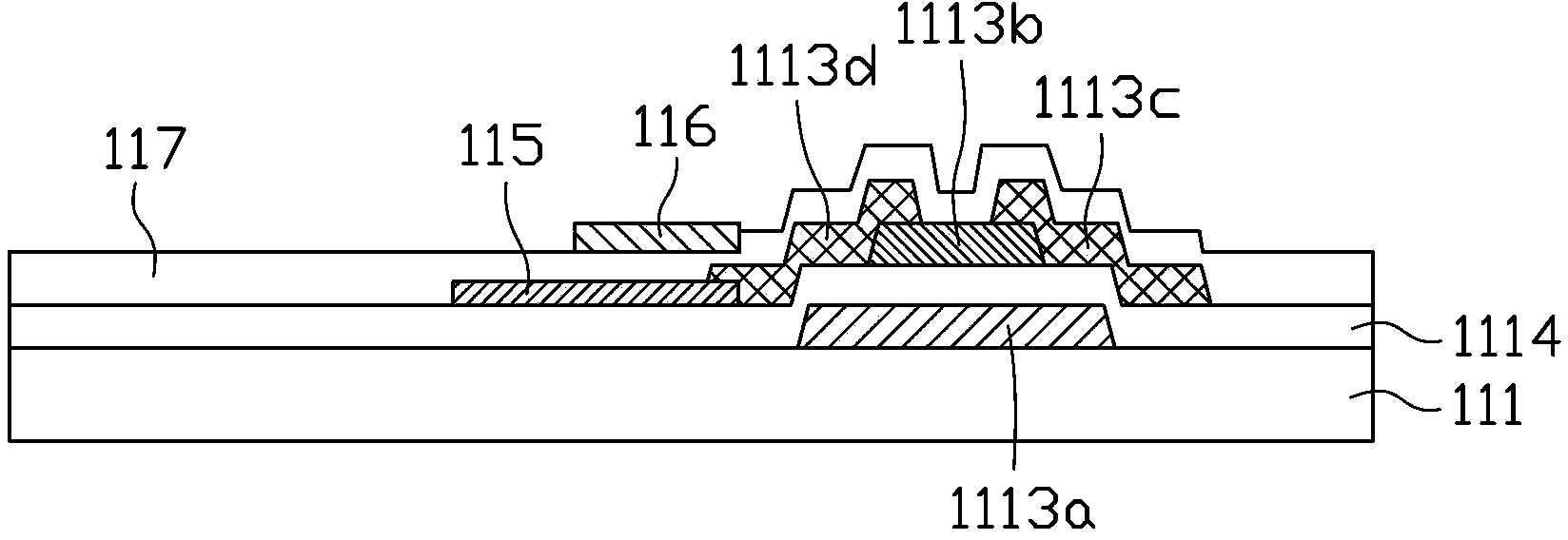

Display panel

ActiveCN105955535ASmall sizeInput/output processes for data processingElectrical resistance and conductanceComputer module

The invention provides a display panel. The display panel comprises a first substrate; a second substrate, which is opposite to the first substrate; and at least one group of pressure sensing modules, wherein the pressure sensing modules comprise a plurality of pressure sensing units, and the pressure sensing units comprise at least two pressure-sensitive resistors located at different plane layers. The display panel provided by the invention can detect the pressing strength when realizing detection of a touch position, that is, the display panel provided by the invention can be integrated with display, touch and pressure touch, and can effectively reduce the bridge size and avoid the influence on a detection result due to the uneven temperature between the pressure sensing units.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Cathodes for Aluminum Electrolysis Cell with Expanded Graphite Lining

ActiveUS20080308415A1Excellent ElectricalImprove thermal conductivityMachining electrodesLine/current collector detailsProduction rateElectrical battery

Cathodes for aluminum electrolysis cells are formed of cathode blocks and current collector bars attached to those blocks. The cathode slots receiving the collector bar are lined with expanded graphite lining thus providing longer useful lifetime of such cathodes and increased cell productivity. The expanded graphite provides a good electrical and thermal conductivity especially with its plane layer.

Owner:TOKAI COBEX GMBH

Cathodes for aluminum electrolysis cell with expanded graphite lining

ActiveUS7776190B2Increase resistanceReduce the overall heightMachining electrodesCellsProduction rateElectrical battery

Owner:TOKAI COBEX GMBH

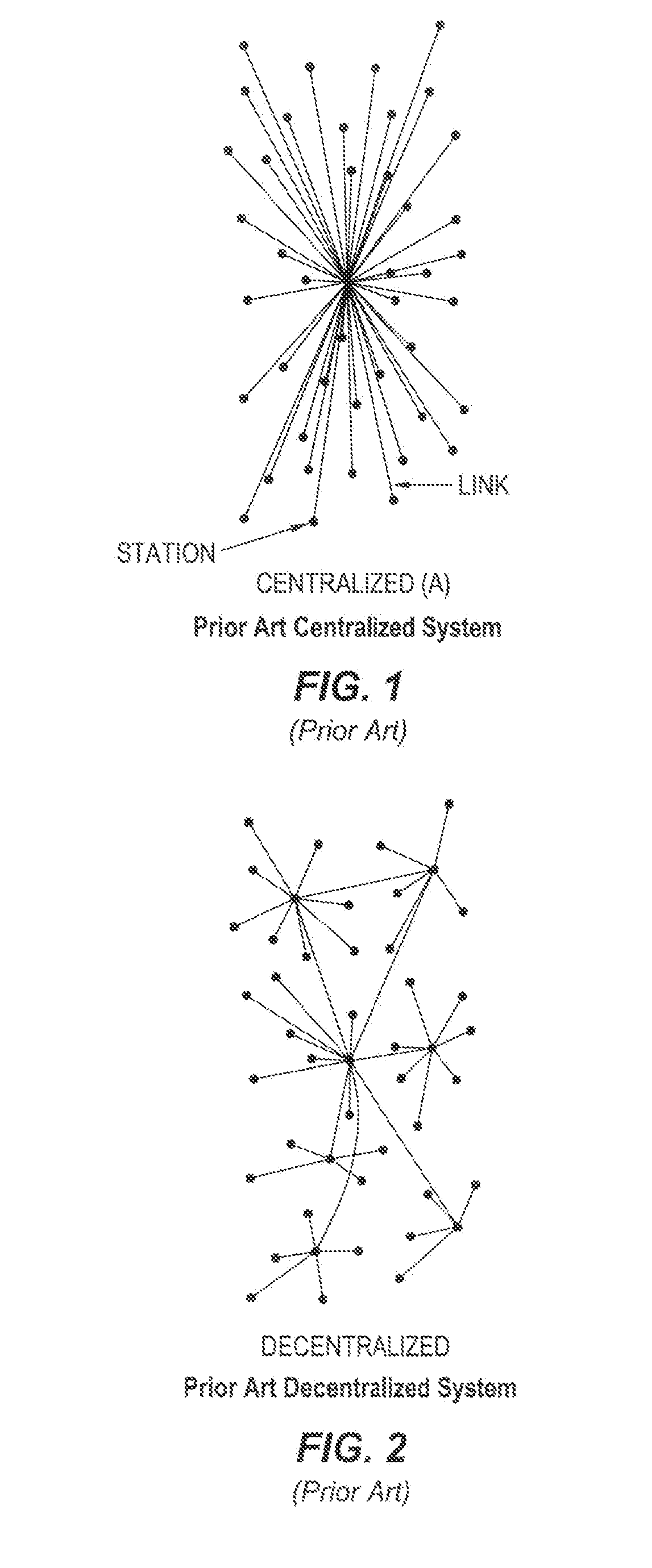

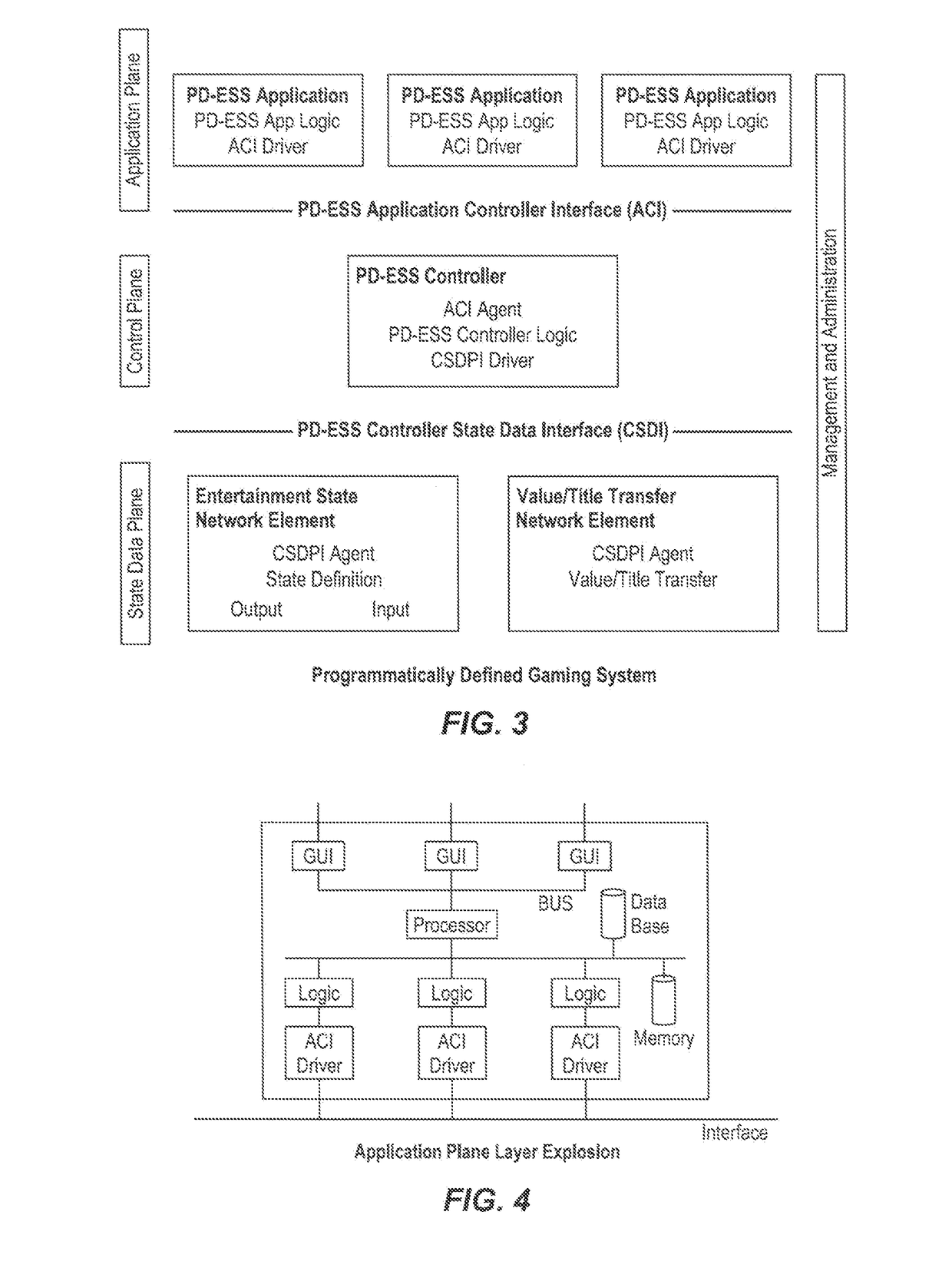

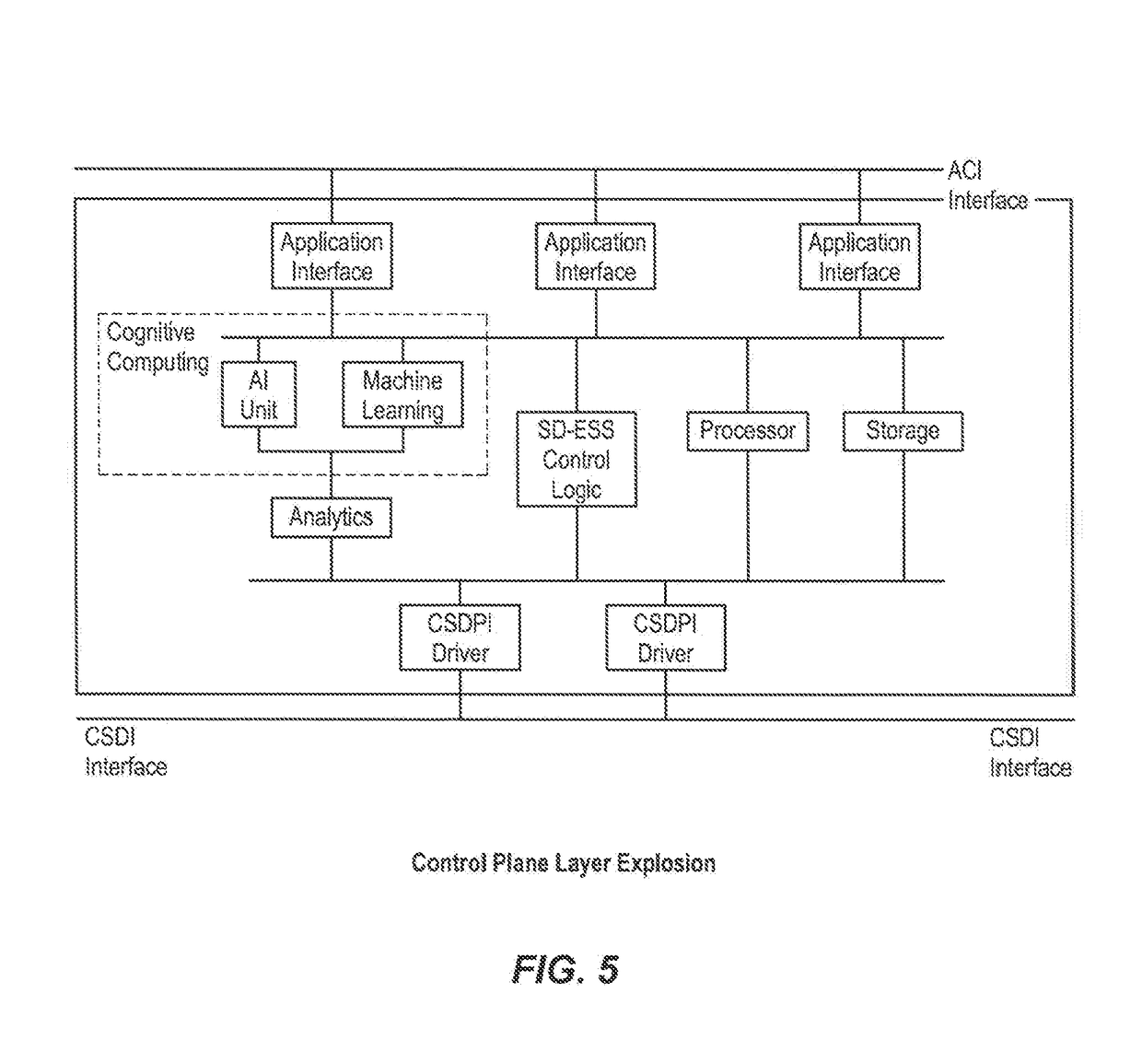

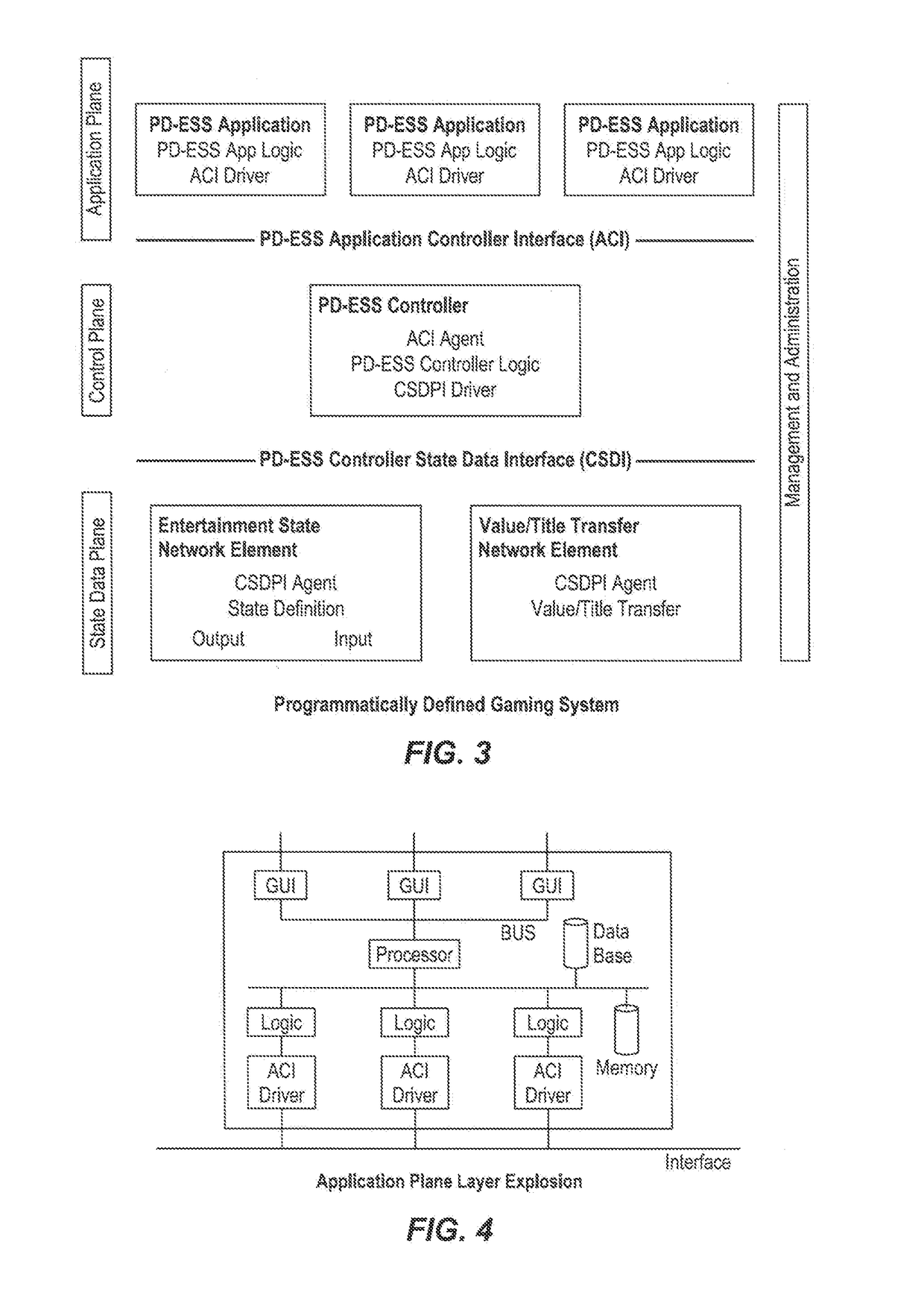

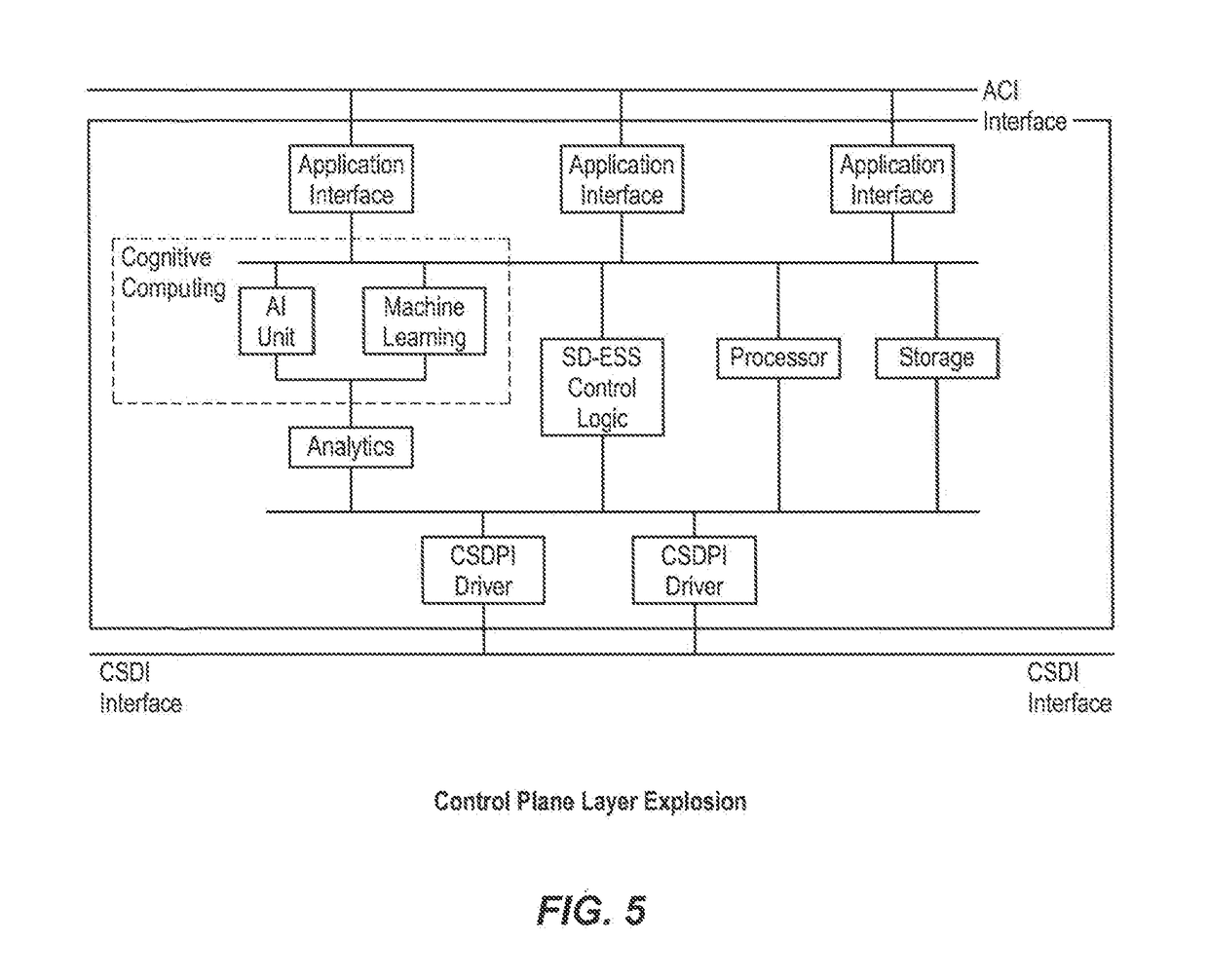

Architectures, systems and methods for program defined transaction system and decentralized cryptocurrency system

ActiveUS20180373983A1Cryptography processingInterprogram communicationLearning unitCognitive computing

In one aspect, the invention comprises a system for control of a transaction state system utilizing a distributed ledger. First, the system includes an application plane layer adapted to receive instructions regarding operation of the transaction state system. Preferably, the application plane layer is coupled to the application plane layer interface. Second, a control plane layer is provided, the control plane layer including an adaptive control unit, such as a cognitive computing unit, artificial intelligence unit or machine-learning unit. Third, a data plane layer includes an input interface to receive data input from one or more data sources and to provide output coupled to a decentralized distributed ledger, the data plane layer is coupled to the control plane layer. Optionally the decentralized distributed ledger stores data on cryptocurrency.

Owner:MILESTONE ENTERTAINMENT LLC

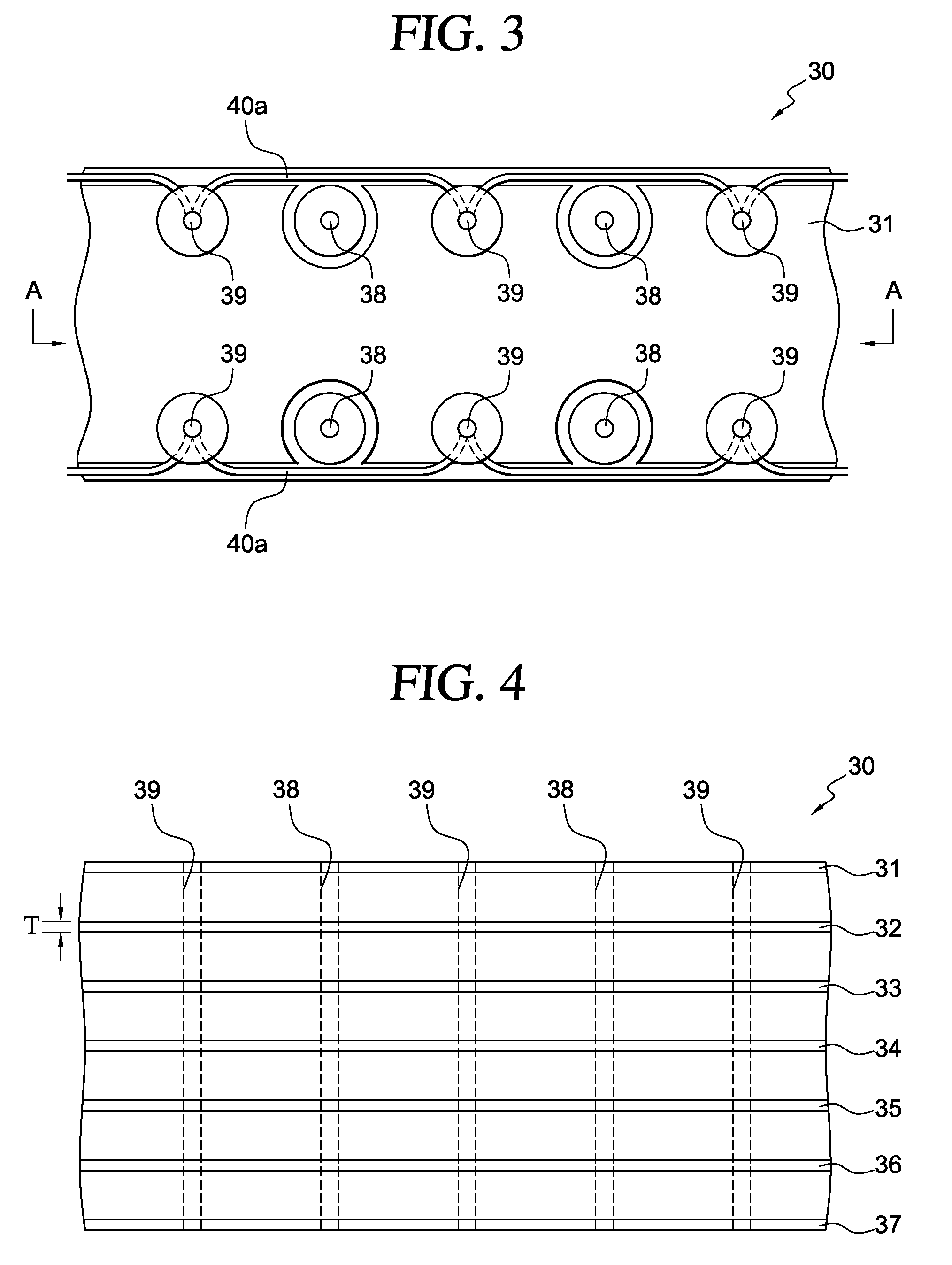

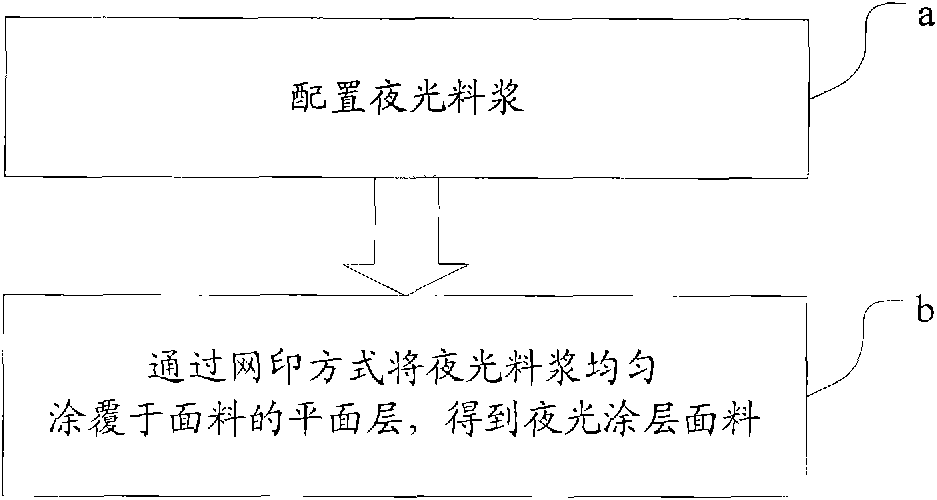

Cotton elastic tubular shirt fabric and textile process thereof

The invention discloses a cotton elastic tubular shirt fabric which is woven from warp and weft, wherein tubular convex layers are arranged on the fabric along the warp direction at intervals; each tubular convex layer is woven by a passive type twin-shaft weaving method; the warp comprises cotton yarns and polyester yarns; and the weft comprises cotton yarns and Lycra core-spun yarns, wherein the Lycra core-spun yarns are formed by wrapping the cotton yarns and / or the polyester yarns outside Lycra yarns. The textile process comprises: a processing technique comprising the steps of yarn cutting, warping and drafting; a simultaneously-performed dampening process which comprises the steps of weft straightening and weft winding; a weaving process; a grey fabric inspecting process; an after finishing process; a finished fabric inspecting process and the like, wherein in the weaving process, the tubular convex layers are arranged in the warp at intervals; the Lycra yarns are woven in the weft at intervals; a plane layer part of the fabric is woven by a plain weaving method; and the tubular convex layer part of the fabric is woven by a twill weaving method. The fabric can enable a textile to have better elasticity in the transverse direction and be comfortable, fit, natural and dynamic in wear, and wrinkles can easily and automatically recover.

Owner:JIANGYIN LONGMA TEXTILE

Architectures, systems and methods for program defined state system

ActiveUS20180341861A1Cryptography processingInterprogram communicationCognitive computingLearning unit

In one aspect, the inventions include a system for control of an entertainment state system. First, an application plane layer is adapted to receive instructions regarding operation of the entertainment state system. Preferably, the application plane layer is coupled to an application plane layer interface. Second, a control plane layer includes an adaptive control unit, such as a cognitive computing unit, an artificial intelligence unit or a machine-learning unit. Third, a data plane layer includes an input interface to receive data input from one or more data sources.

Owner:MILESTONE ENTERTAINMENT LLC

Flexible Multilayer Printed Circuit Assembly with Reduced EMI Emissions

InactiveUS20090188712A1Magnetic/electric field screeningCross-talk/noise/interference reductionGround planeEngineering

A flexible multilayer printed circuit assembly with shield fences. The flexible multilayer printed circuit assembly with multiple conductive layers includes logic ground vias that connect logic ground plane layers together, and shield vias that connect a top and a bottom shield plane layer together. Each of the shield fences is formed between the shield vias on an outside perimeter of each of the conductive layers. Each of the shield fences contains the logic ground vias inside, and also contains each corresponding conductive layer in the horizontal direction to which each layer extends.

Owner:GLOBALFOUNDRIES INC

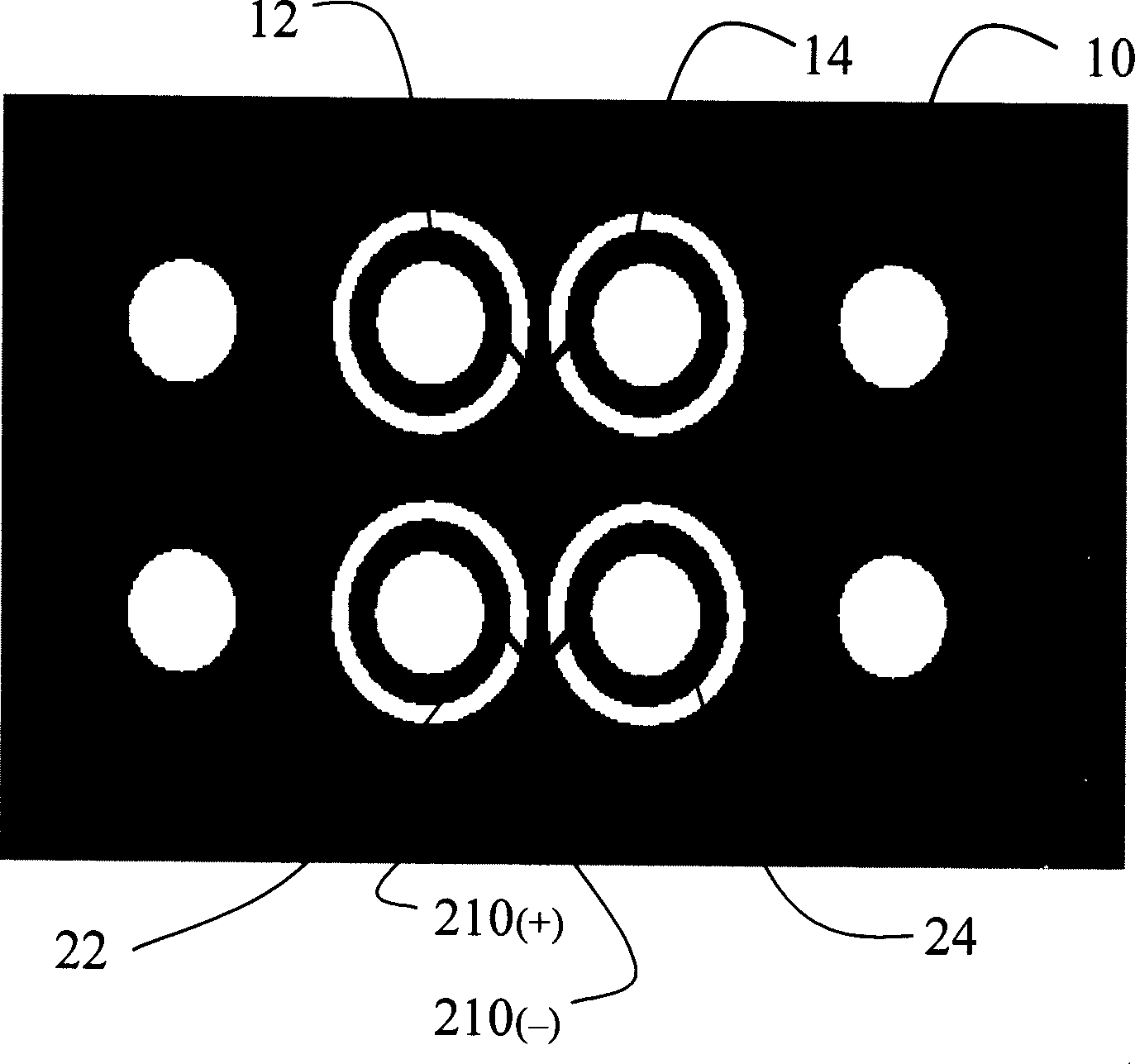

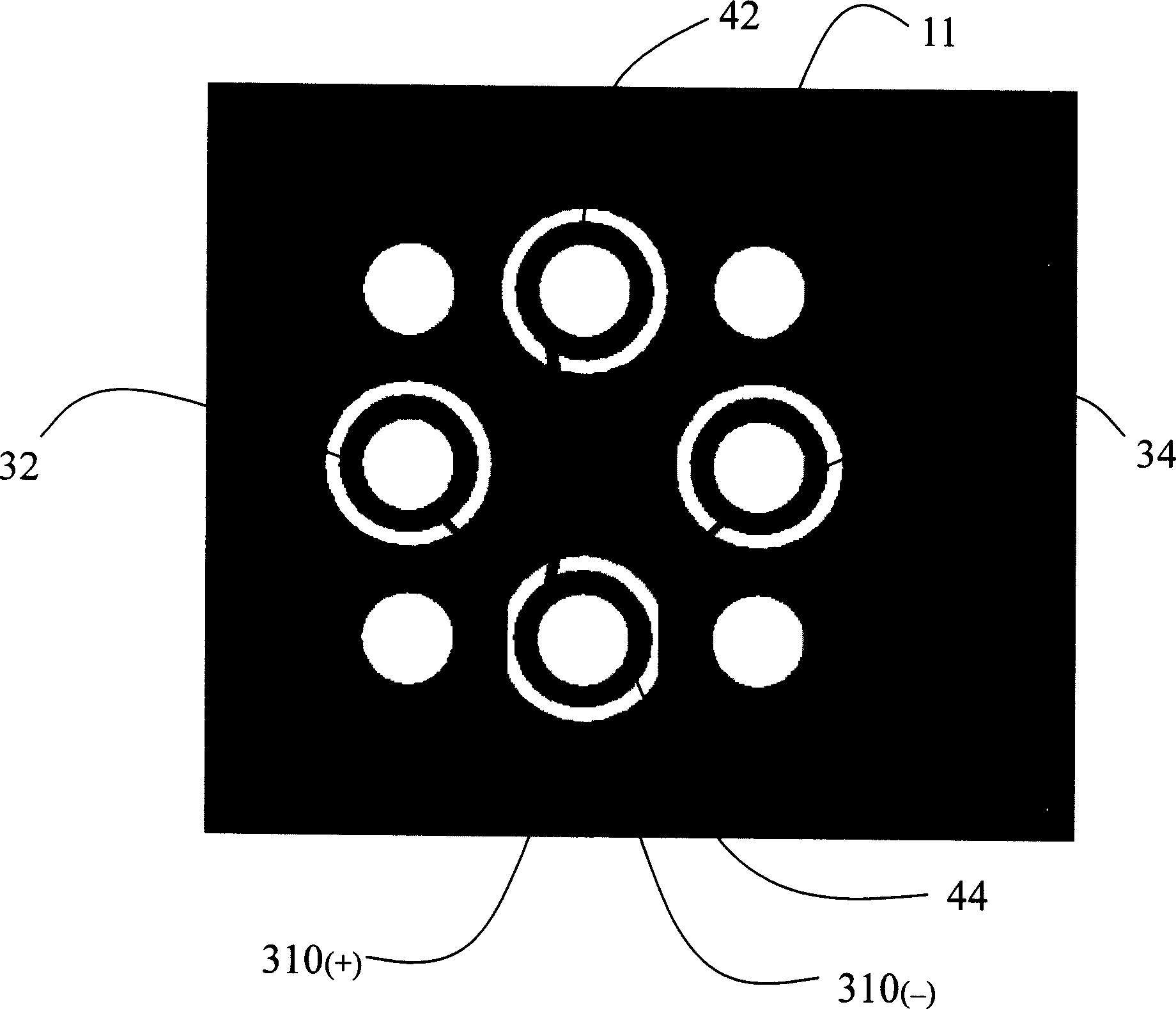

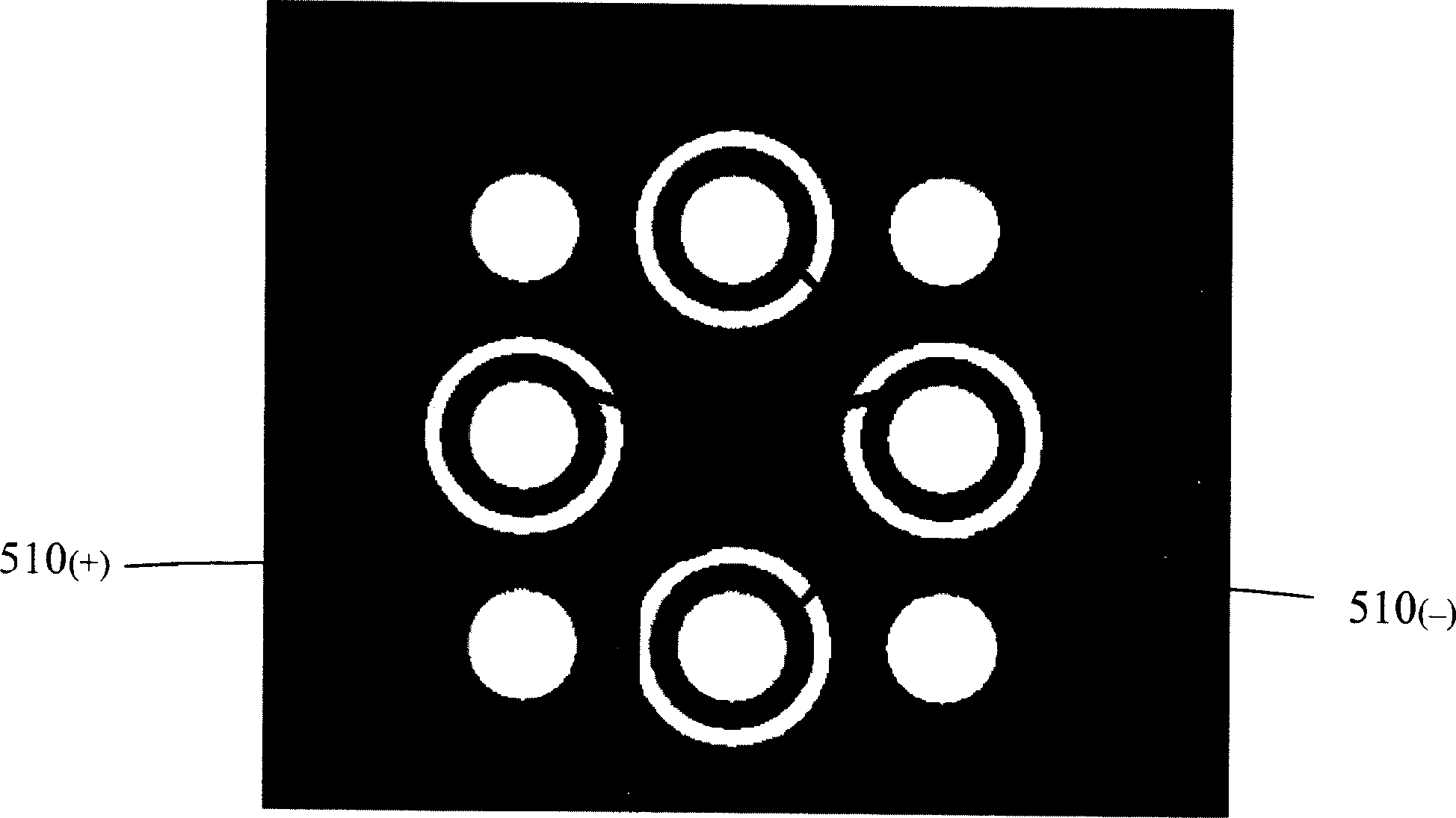

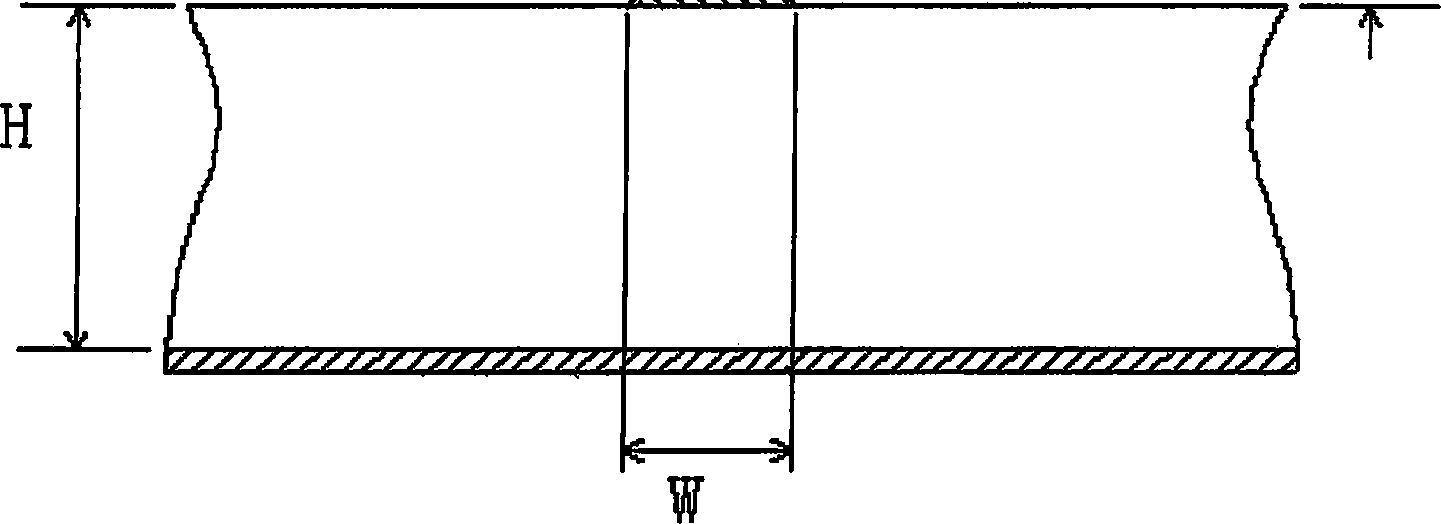

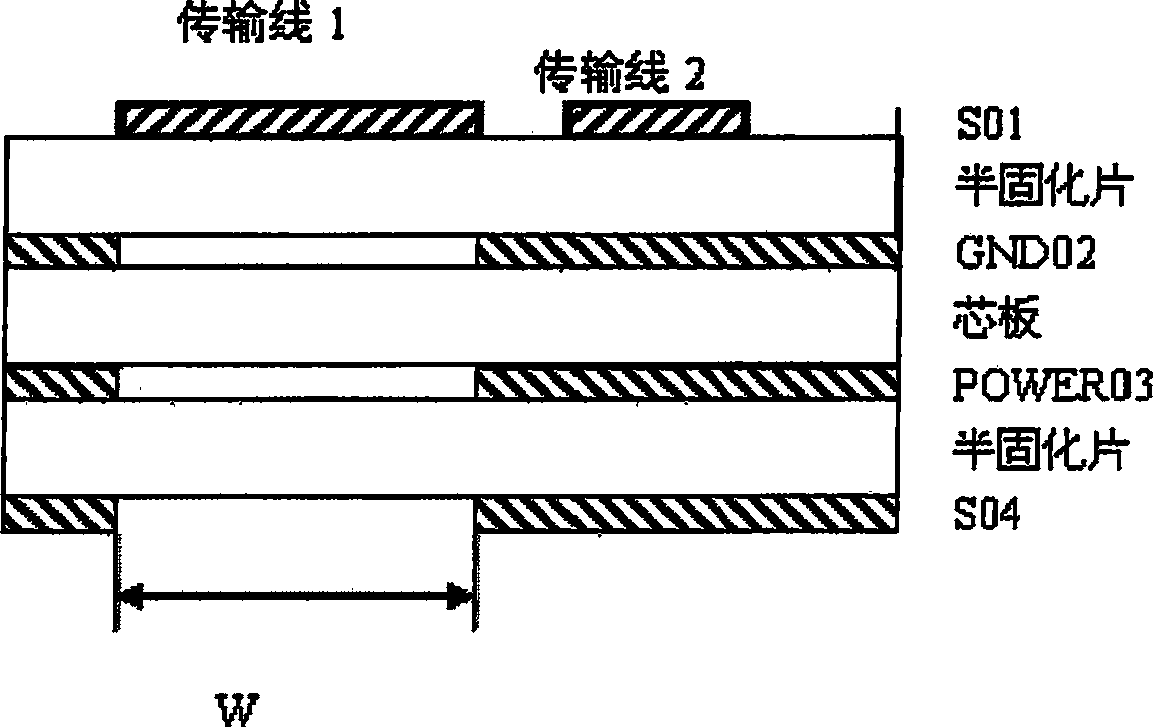

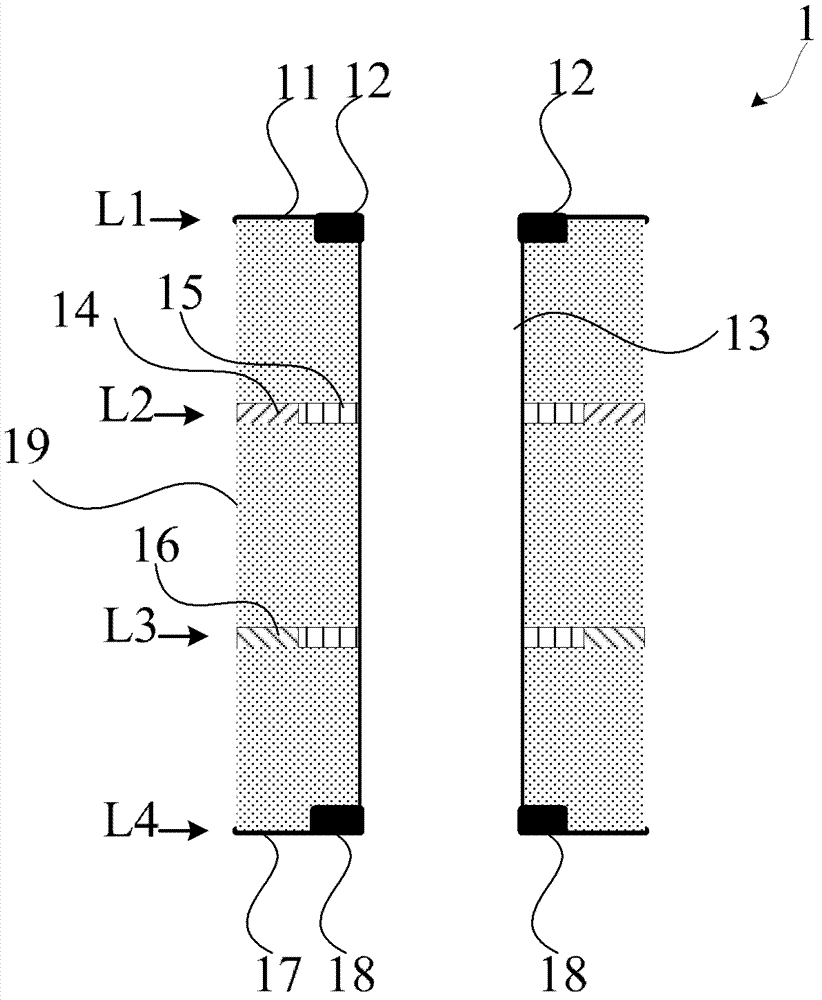

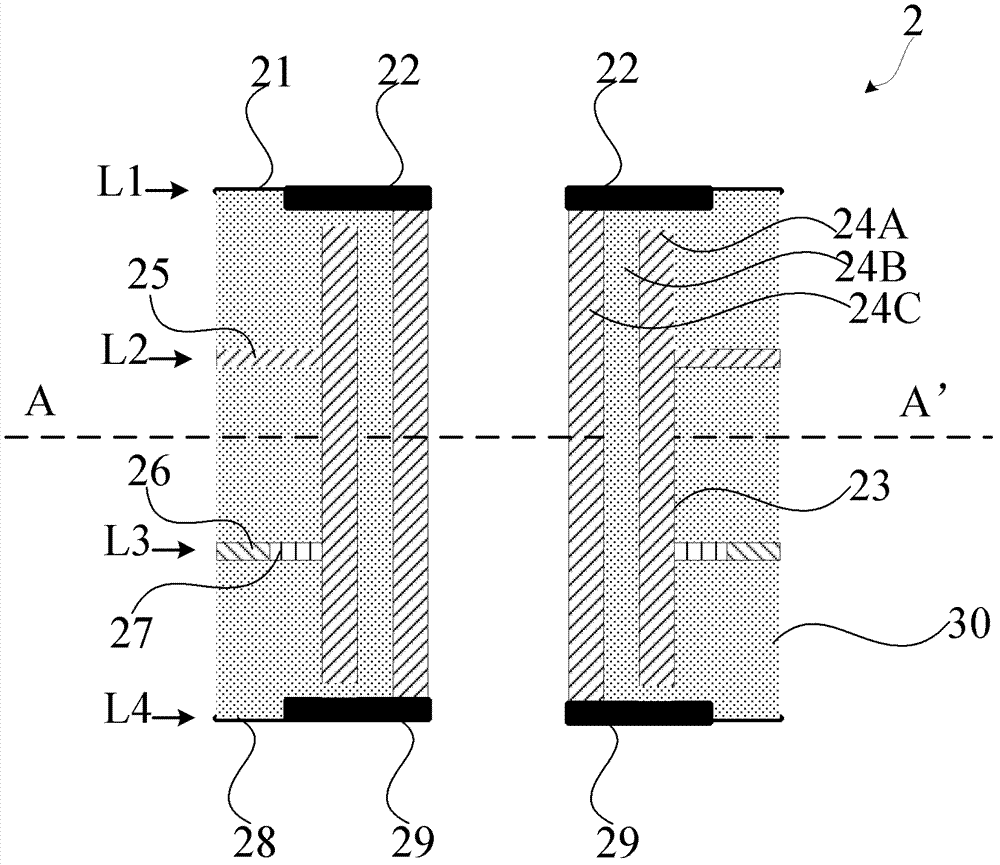

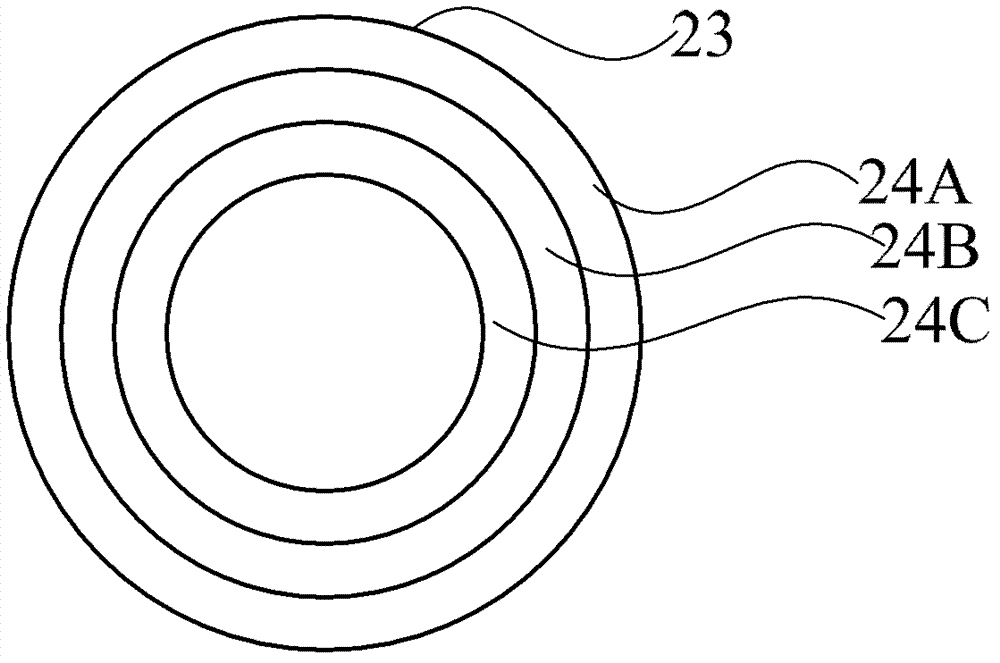

Printed circuit board with improved differential via

InactiveCN1870852AImprove transmission characteristicsCross-talk/noise/interference reductionPrinted circuit aspectsEngineeringPrinted circuit board

This invention provides a PCB with improved differential via including a number of groups of differential via, differentia transmission lines corresponding to said differential via and some plane layers of electric connecting ensured by the adoption of the above transmission line. Every group of differential via includes two pairs, and one pair is located on the plumb bisector to the centerline of the other pair. Through this design, interference between the differential via on the PCB can be offset and the quality of signal transmission is increased.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Filtering material with antibacterial function and preparation method thereof

ActiveCN106621590AImprove filtration efficiencyThe biggest advantage can fully make the air filter material maintain high filtration efficiencyGas treatmentDispersed particle filtrationFiberNanofiber

The invention provides a filtering material with an antibacterial function and a preparation method thereof. The filtering material is characterized by comprising a base material and a nanofiber membrane arranged on the base material. The nanofiber membrane comprises at least one hierarchy unit, wherein each hierarchy unit comprises a plane layer disorderly aggregated by nanofibers and a cavity structure piled by directionally-arranged nanofibers, part of or all the cavity structure is filled with antibacterial substances, and the nano fibers are doped with antibacterial substances. The filtering material is high in filtering efficiency, large in resistance pressure drop, good in antibacterial performance, promising in application prospect in aspect of filtering materials for air purifiers, window screens and masks, and the like.

Owner:DONGHUA UNIV

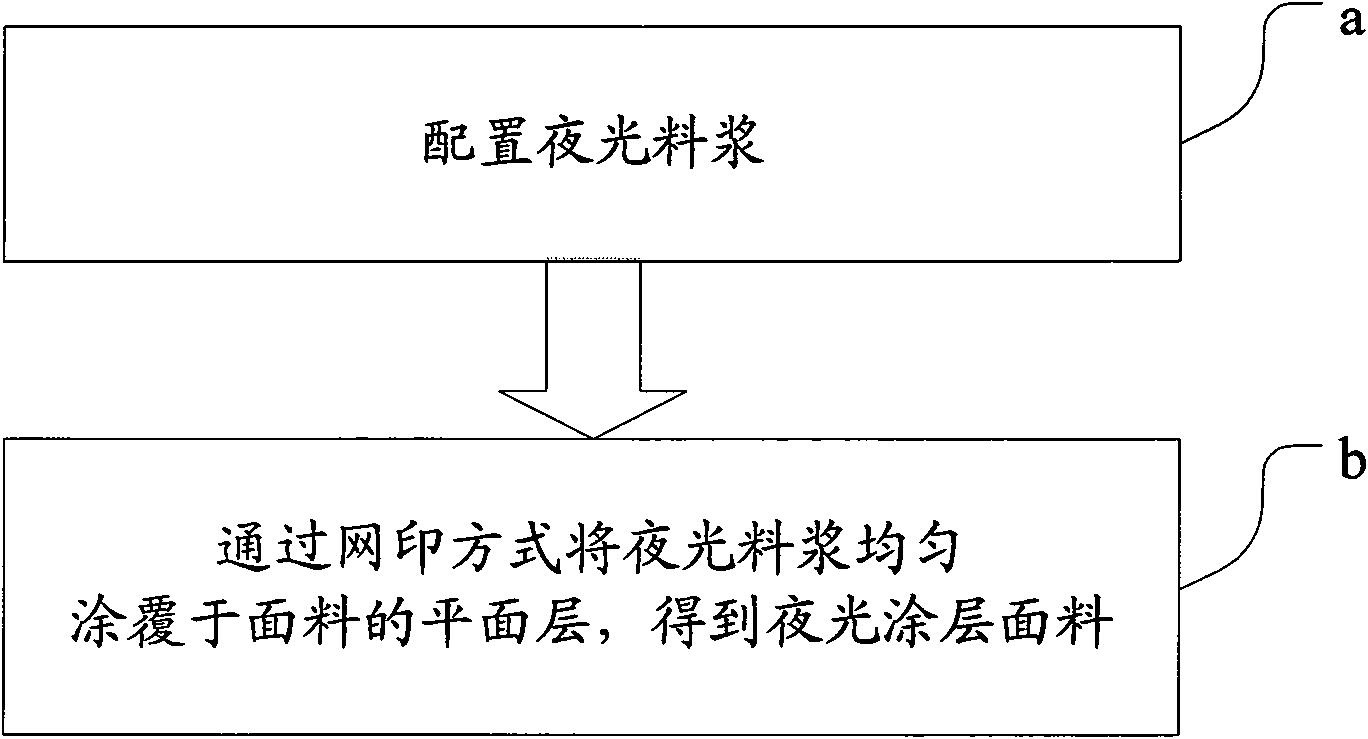

Luminous coating fabric and processing method thereof

The invention discloses luminous coating fabric and a processing method thereof. The method comprises the following steps of: a, preparing luminous slurry: adding 30 to 40 percent luminous powder solvent into 60 to 70 percent inorganic pigment hydrosol, stirring the mixture uniformly, then adding 50 percent color fixing agent, 10 percent stabilizing agent, 15 percent thickening agent and 15 percent softening agent into the mixture in turn for harmonious blending, and stirring the mixture for 1 to 2 hours; and b, uniformly coating the luminous slurry on the plane layer of fabric in a screen printing mode, and then thermally baking the fabric at the temperature of between 130 and 150 DEG C and the row speed of 35 to 40 meters per minute to obtain the luminous coating fabric. Compared with the prior art, because the luminous powder is dyed on the fabric in the screen printing mode, the luminous coating fabric provided by the invention has the advantages of good air permeability, good handfeel, fading resistance, color loss resistance, cleaning property and the like; the processed fabric has no essential difference compared with the fabric before processing, so the texture of the fabric is not affected; and the processed fabric has no toxicity, harm or radioactivity, can be continuously luminous for over 10 hours in dark, can be infinitely recycled, and has stable luminous performance.

Owner:顾军

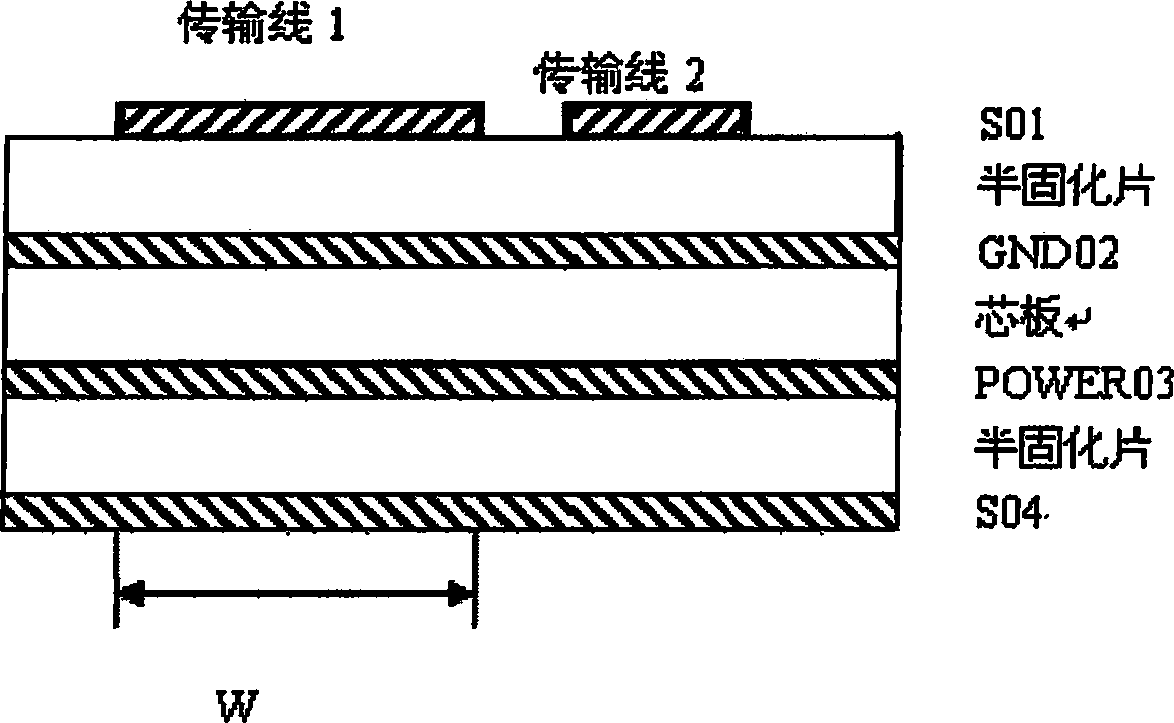

Method for controlling impedance

ActiveCN1874652AImprove transmission qualityGuaranteed Impedance MatchingTransmission control/equlisationPrinted circuit detailsImpedance matchingEngineering

The method comprises: a) hollowing out all signaling layers and plane-layers corresponding to the vertical direction of the controlled transmission line; b) the hollowed widths of all signaling layers and plane-layers can be set into a variable; with adjusting and setting the hollowed width, controlling the impedance of transmission line at any required values.

Owner:XFUSION DIGITAL TECH CO LTD

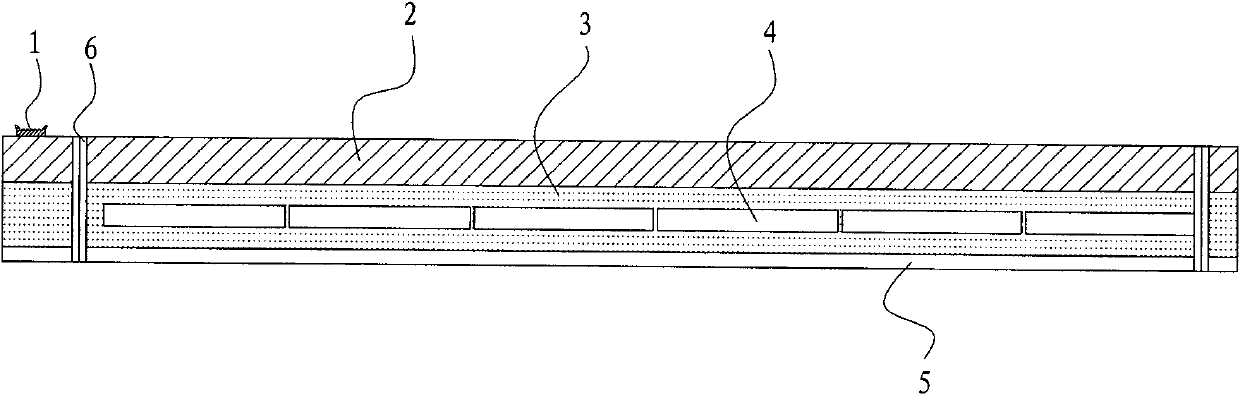

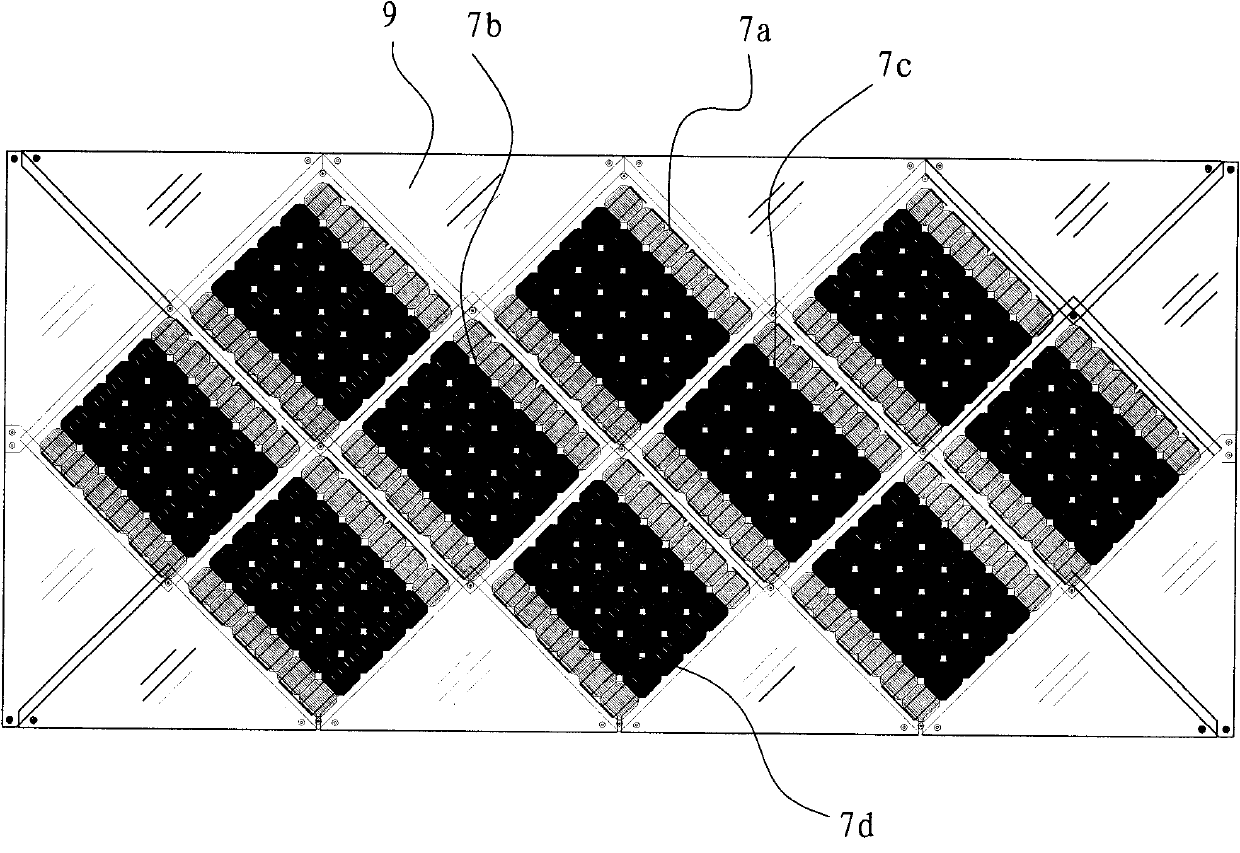

Diamond-shaped solar tile and installation structure thereof

InactiveCN101793082AGood solidification effect between layersStrong bonding between layersPhotovoltaic supportsRoof covering using slabs/sheetsSurface layerPv generation

The invention discloses a diamond-shaped solar tile and an installation structure thereof, which are characterized in that: the solar tile is made of diamond-shaped plates, wherein the bottom layer of each diamond-shaped plate is a water-proof back-plane layer, the intermediate layer of each diamond-shaped plate is an EVA coating layer, and the surface layer of each diamond-shaped plate is a light-transmitting toughened glass plate layer; four edges of each diamond-shaped plate are mounting edges, and two diagonal positions of each diamond-shaped plate are provided with mounting holes passing through the diamond-shaped plate; solar cells connected in series in a solar panel shape is sealed in the EVA coating layer to form an integral structure; the diamond-shaped plates are arranged in a vertical direction by one diagonal line of the mounting hole and in a transverse direction by the other diagonal line; and the four diamond-shaped plates, namely an upper plate, a lower plate, a left plate and a right plate, are positioned on the same plane and formed into a diamond-shaped unit. The solar tile and the installation structure thereof ensure that a solar cell assembly can be directly used for laying and installing on roofs or walls after the solar cell assembly is packaged. The solar tile not only plays a role in photovoltaic generation, but also becomes a building material so as to realize integration of photovoltaic and construction.

Owner:安徽超群电力科技有限公司

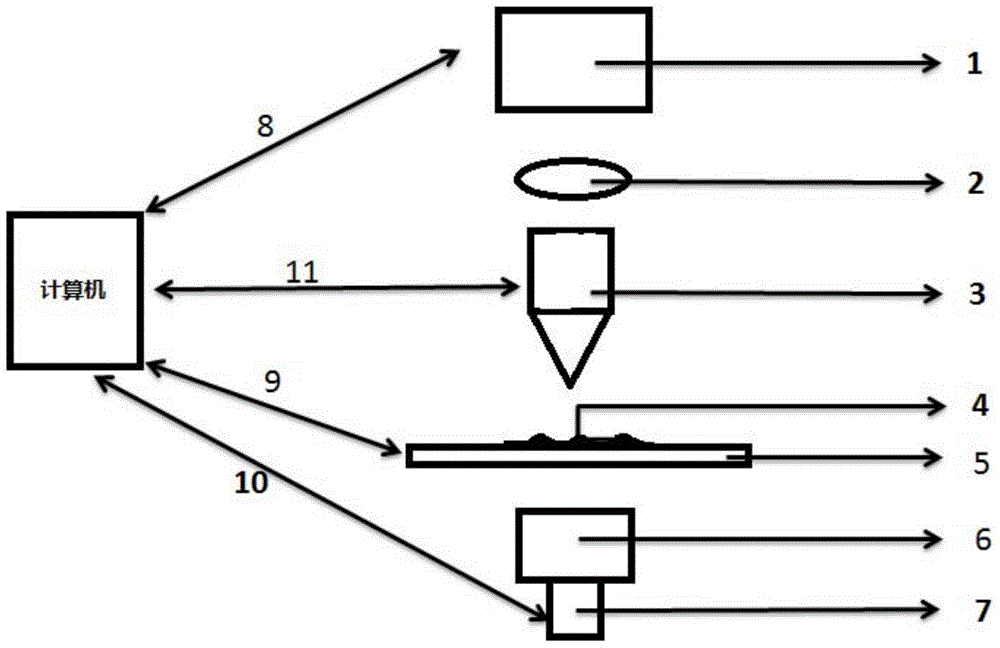

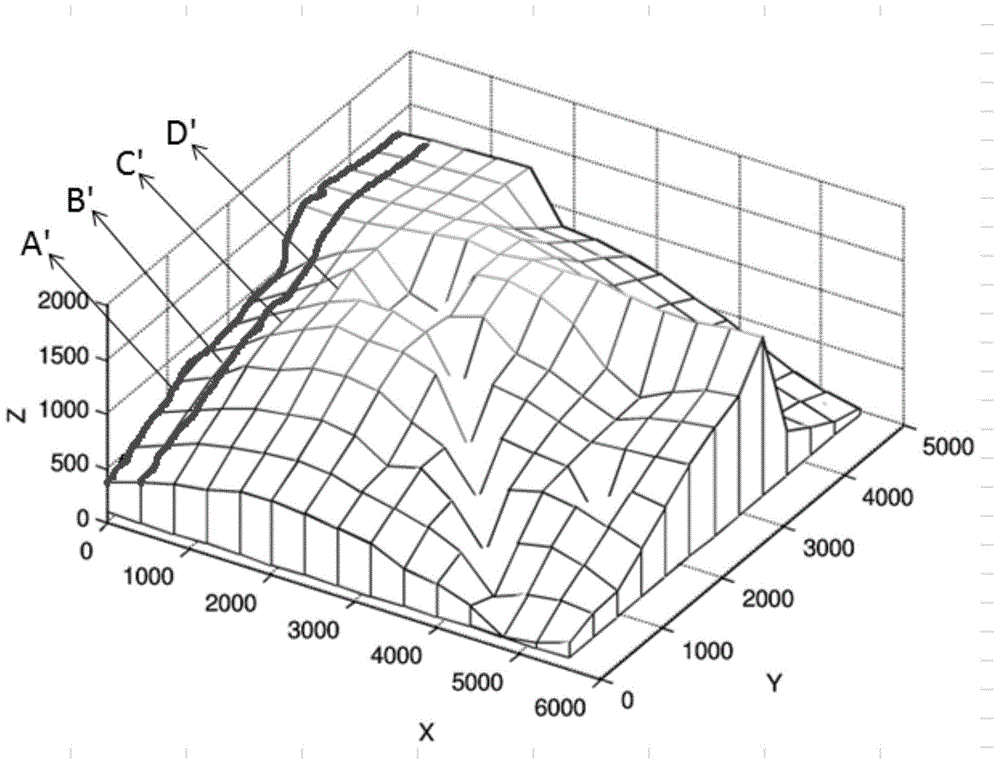

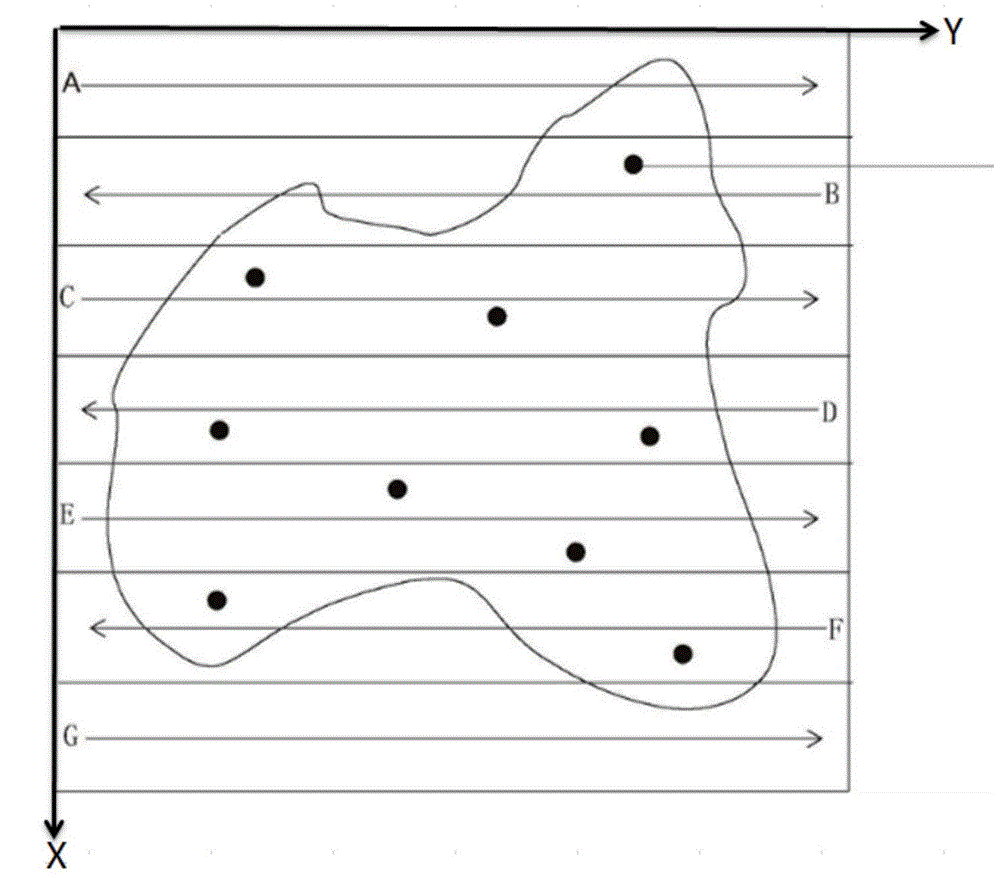

3D imaging and fusion method based on pathological slice scanning device

InactiveCN105118088ASolve the problem of losing the details of its own imageFusion complete and clearImage enhancementGeometric image transformation3d imagePlane layer

The invention provides a 3D imaging and fusion method based on a pathological slice scanning device and belongs to the biomedicine field. Through the pathological slice scanning device, a 3D image of each focal plane is simulated. Through the fusion method, the 3D images on the different focal planes are fused on one image. Finally, data of each focal plane layer and data of a fusion layer are combined into one 3D image. By using the method of the invention, a problem that the scanned image losses details of the image itself during a scanning process of the pathological slice scanning device is solved; a 3D effect can be conveniently and concisely watched without a microscope and the above situation is simulated effectively through the pathological slice scanning device; and through a fusion function, distinct tissues on the different focal planes are fused on one image so that images of all the cells and tissues on a slice can be completely and clearly checked.

Owner:曲阜裕隆生物科技有限公司

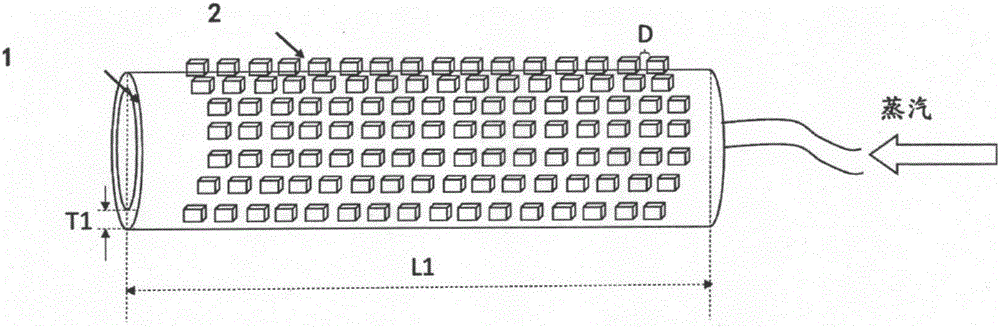

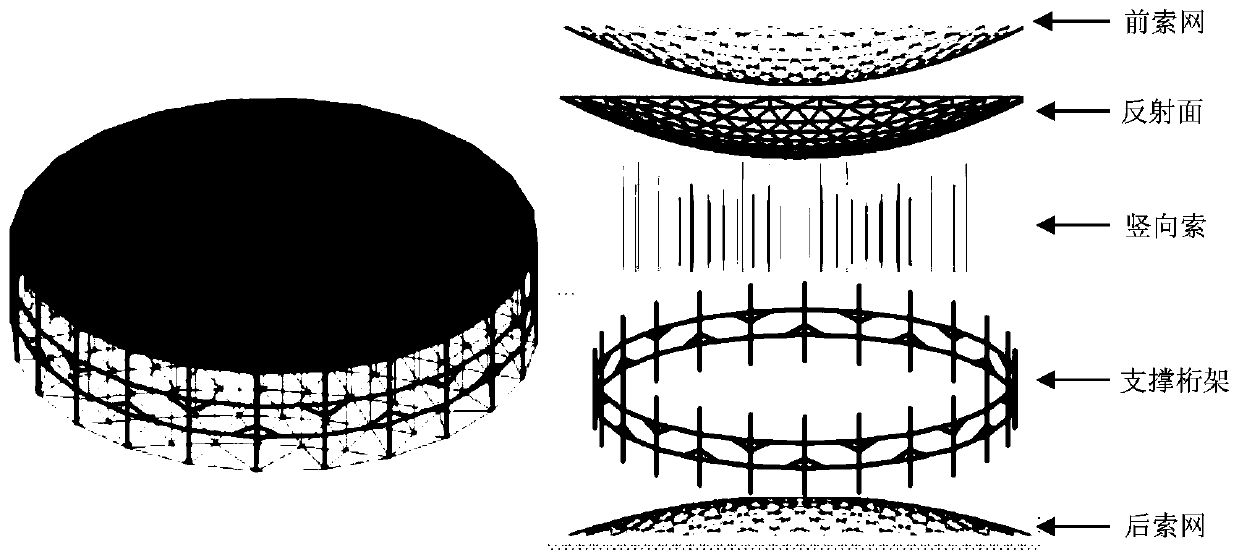

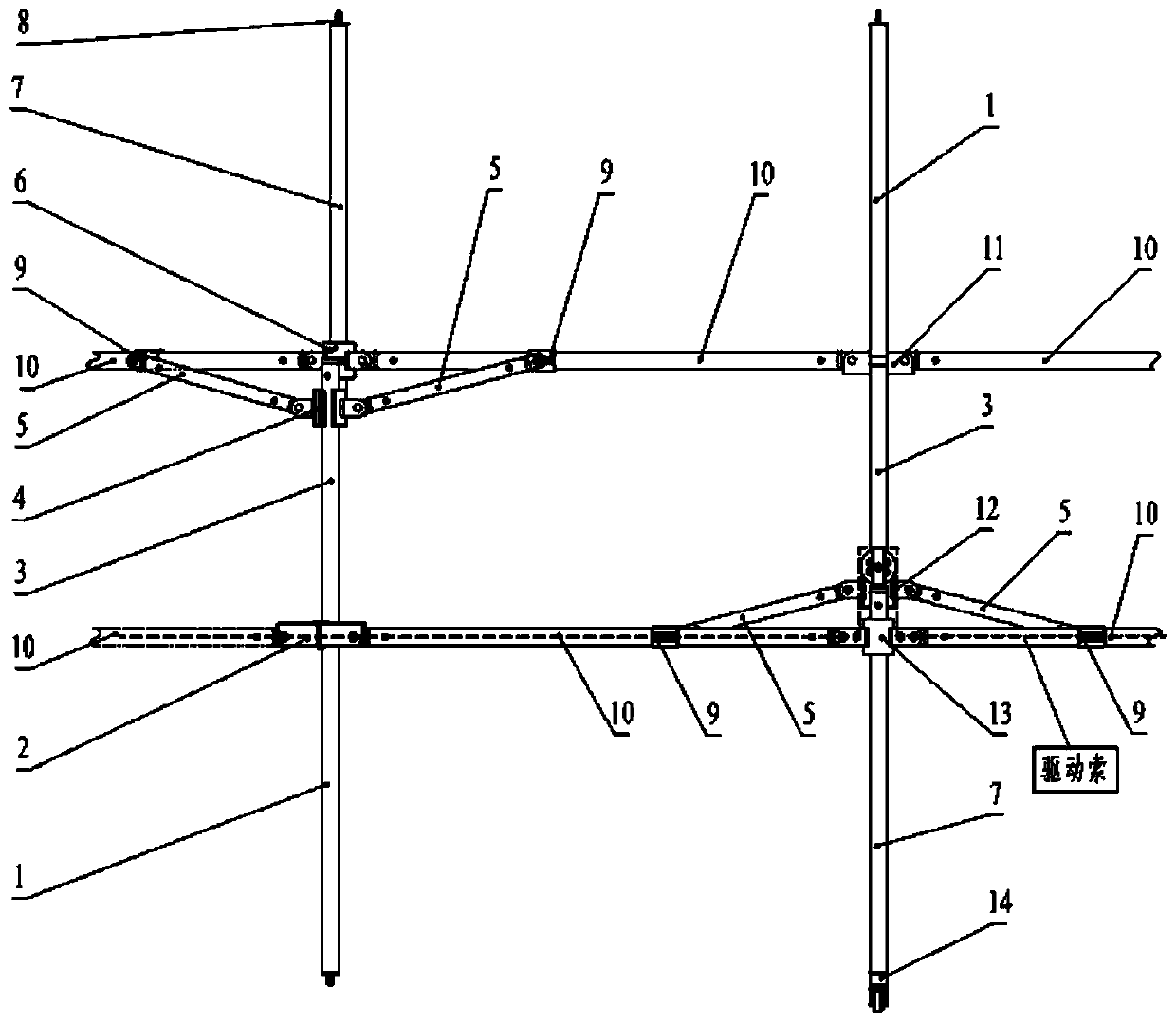

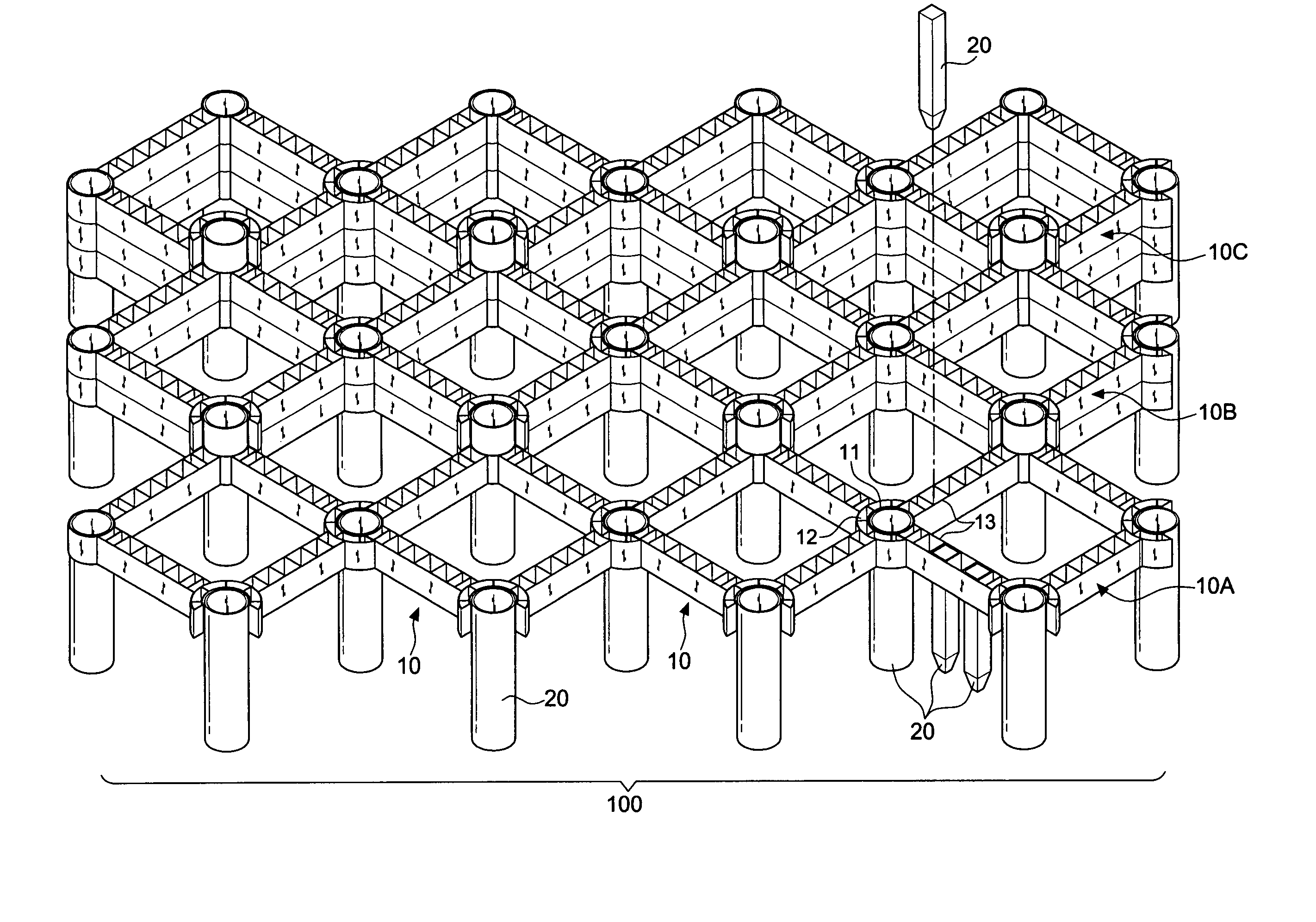

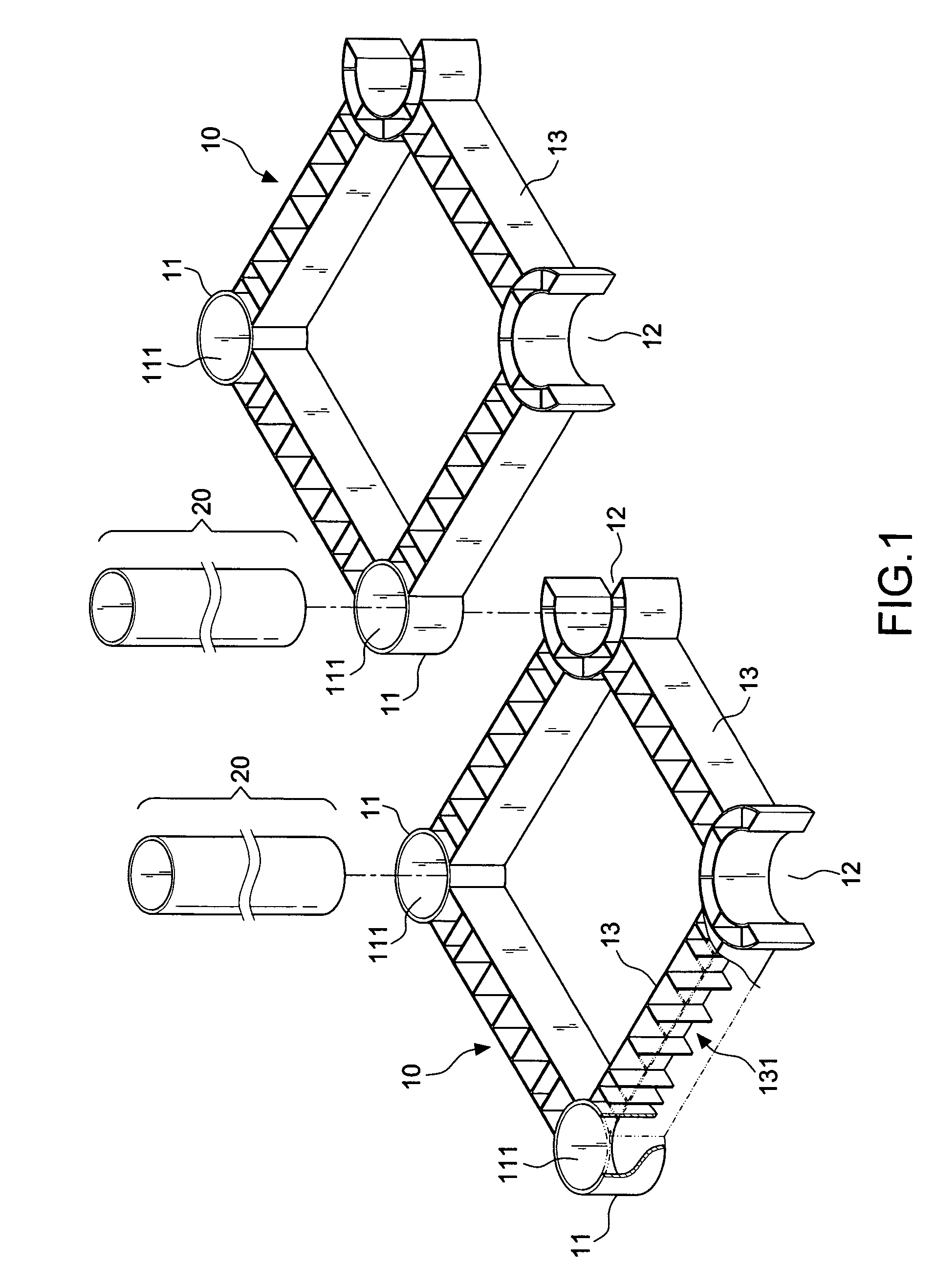

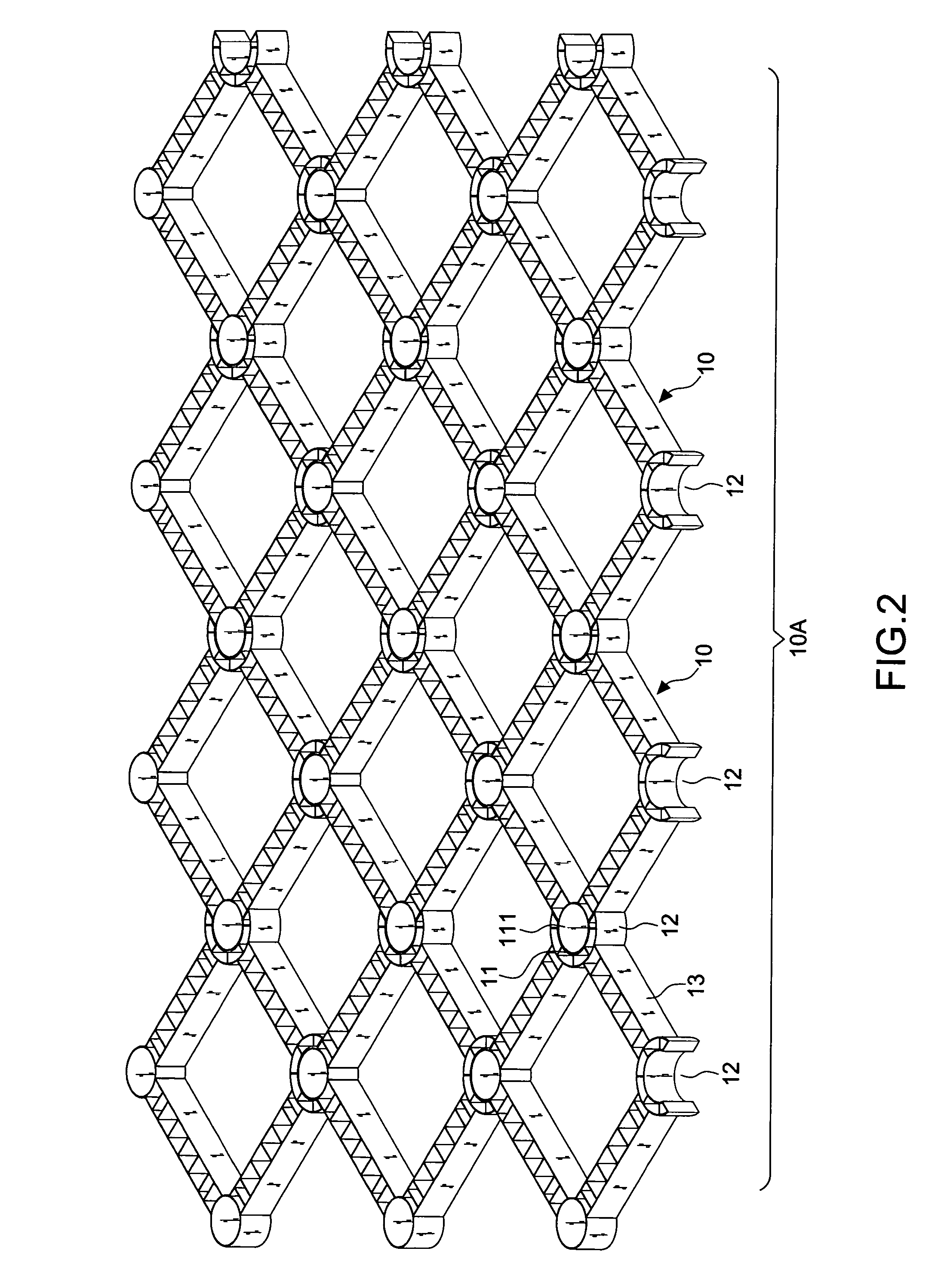

Reticulated annular deployable antenna and antenna truss

ActiveCN110085964AIncrease the opening diameterIncrease heightTelescopic elementsVertical barEngineering

The invention discloses a reticulated annular deployable antenna and an antenna truss. The antenna truss comprises an annular structure formed by connecting a plurality of structural units end to end,and the structural units constitute a closed annular structure through sharing cross bars; and one of the structural unit includes four cross bars, two sliding vertical bars, two main vertical bars,two extended vertical bars, four connecting bars, a lower cross bar fixed joint, an upper connecting rod sliding joint, an upper cross bar sliding joint, an upper cross bar fixed joint, a lower connecting bar sliding joint, a lower cross bar sliding joint and four articulation joints. The bars of the structure are distributed on three plane layers along the radial direction, thereby effectively reducing the folding diameter, making full use of the folding space, and greatly reducing the folding height. Compared with similar reticulated deployable antennas, the antenna provided with the invention is significantly improved in height and diameter storage ratio, and thus increases the deployable aperture of the antenna under the condition of realizing the same folding requirements.

Owner:XIDIAN UNIV

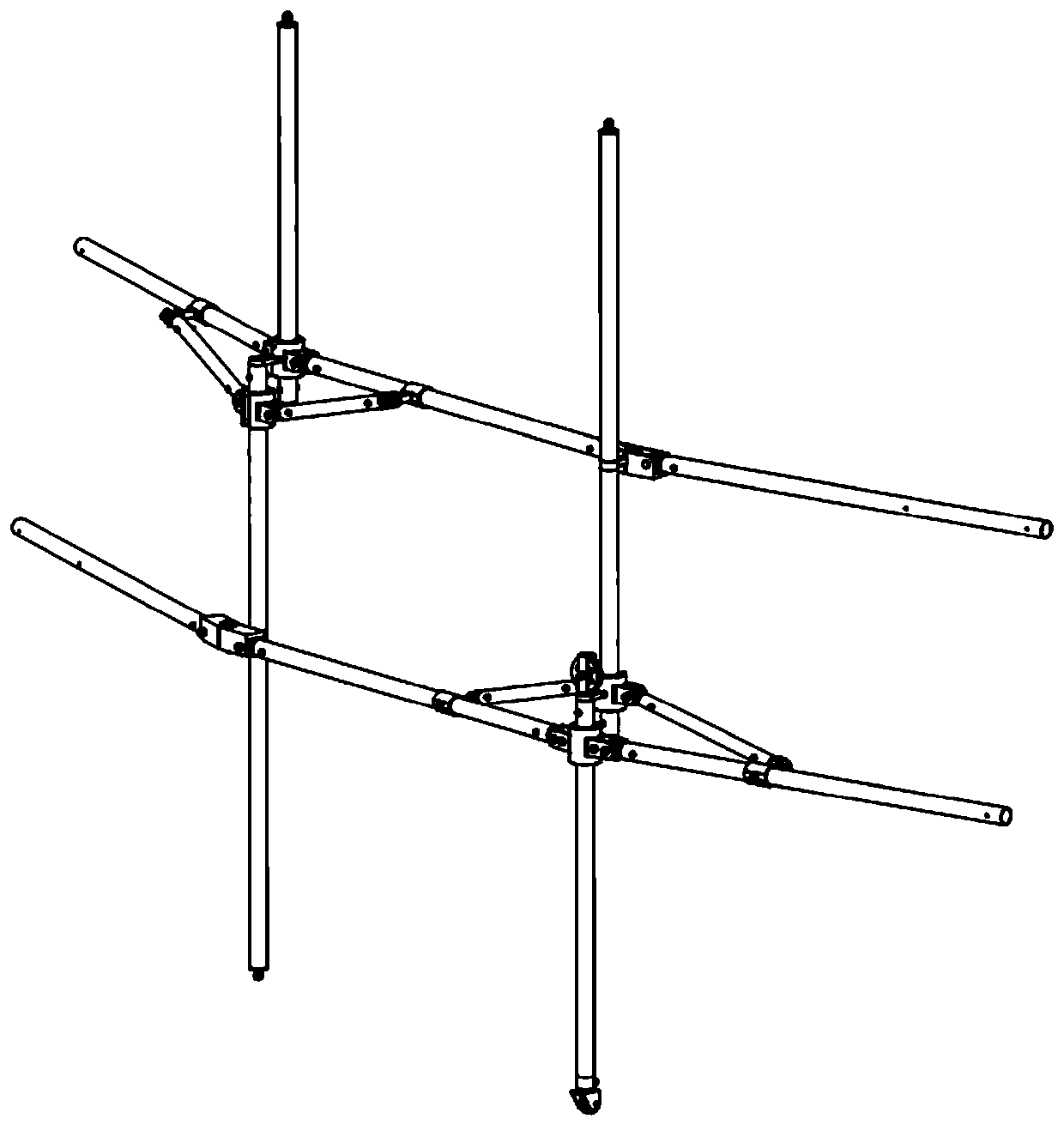

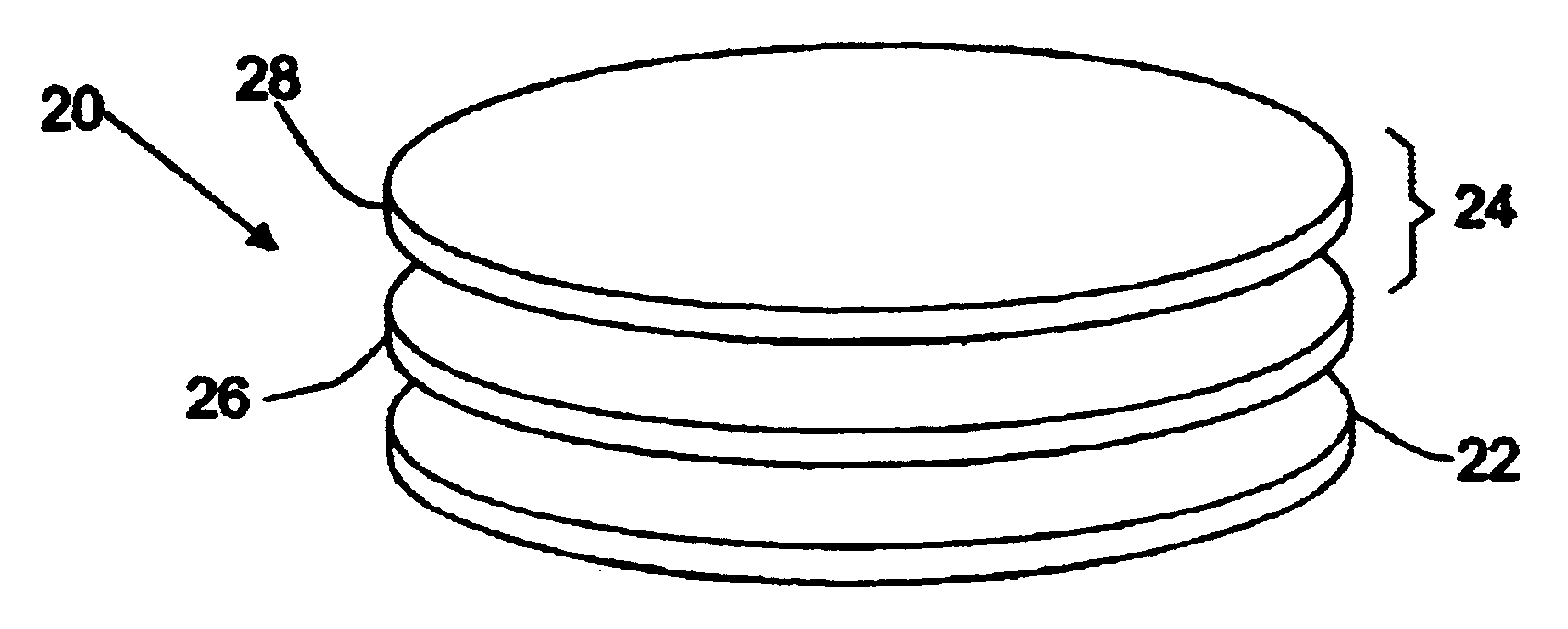

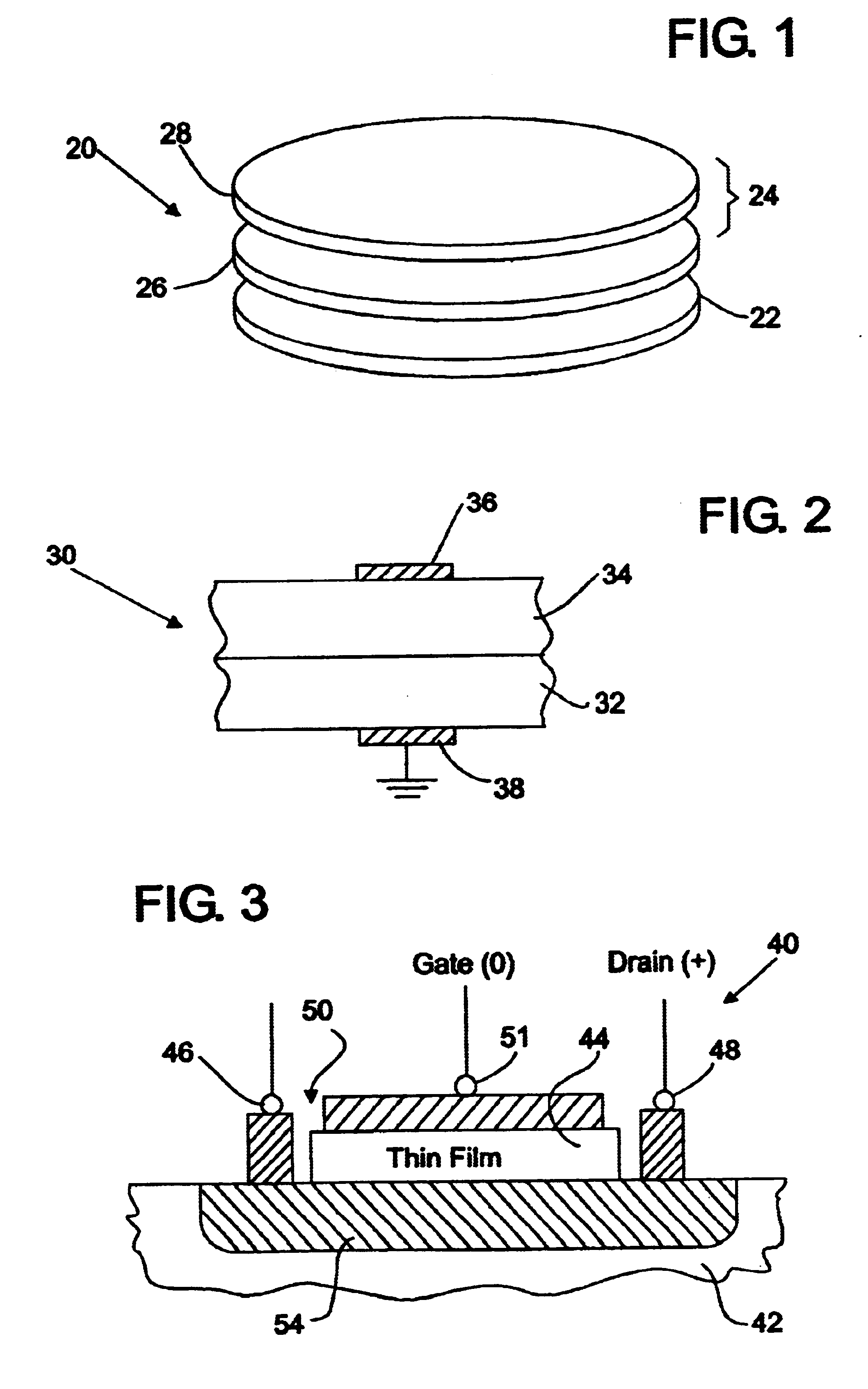

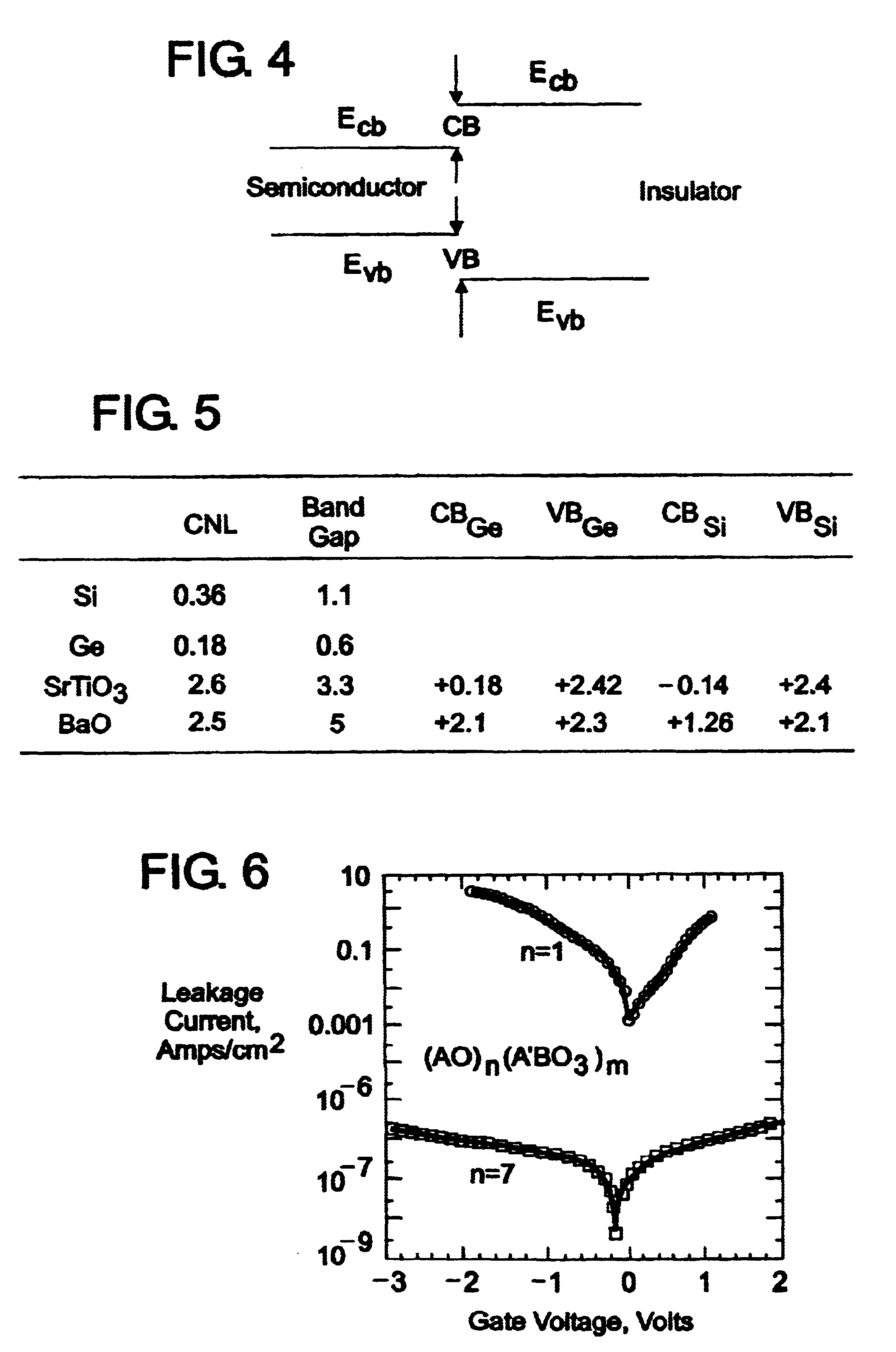

Structure and method for controlling band offset and alignment at a crystalline oxide-on-semiconductor interface

InactiveUS6652989B2Polycrystalline material growthSemiconductor/solid-state device manufacturingCrystalline oxideCell layer

A crystalline oxide-on-semiconductor structure and a process for constructing the structure involves a substrate of silicon, germanium or a silicon-germanium alloy and an epitaxial thin film overlying the surface of the substrate wherein the thin film consists of a first epitaxial stratum of single atomic plane layers of an alkaline earth oxide designated generally as (AO)n and a second stratum of single unit cell layers of an oxide material designated as (A'BO3)m so that the multilayer film arranged upon the substrate surface is designated (AO)n(A'BO3)m wherein n is an integer repeat of single atomic plane layers of the alkaline earth oxide AO and m is an integer repeat of single unit cell layers of the A'BO3 oxide material. Within the multilayer film, the values of n and m have been selected to provide the structure with a desired electrical structure at the substrate / thin film interface that can be optimized to control band offset and alignment.

Owner:UT BATTELLE LLC

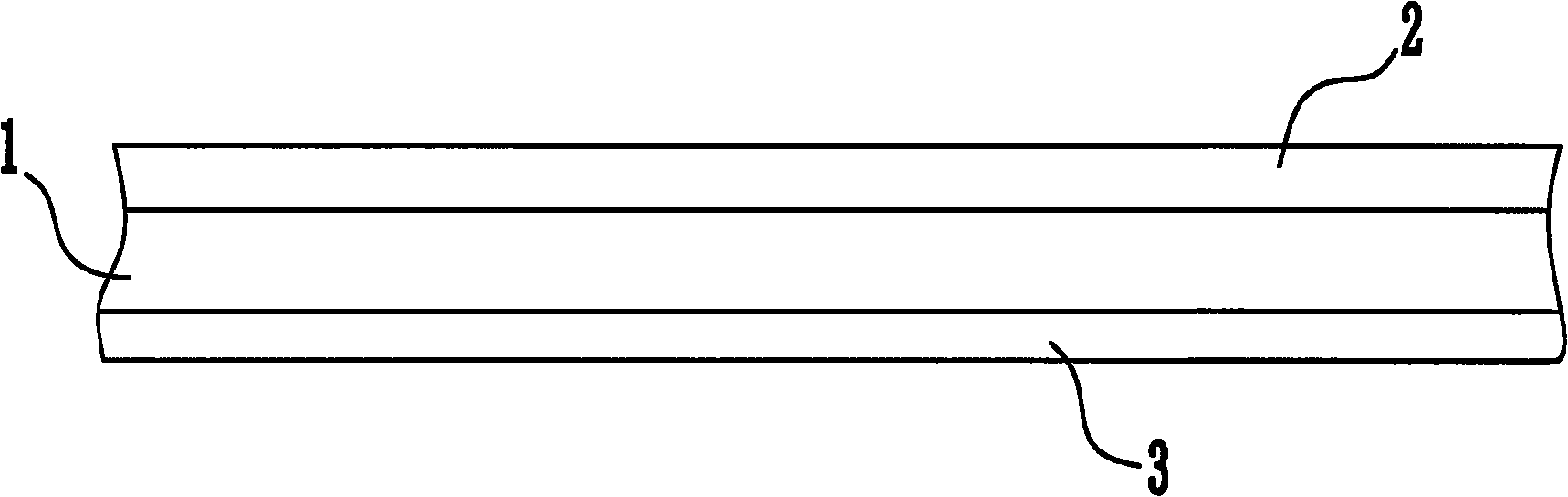

Tenon joint type space lattice structure

InactiveUS7857552B2Improve adjustment flexibilityCostArtificial islandsNoise reduction constructionFilling materialsThree-dimensional space

A tenon joint type space lattice structure having a plurality of lattice units and combining pillar is provided. The lattice unit includes a convex tenon and a concave tenon groove disposed at ends of the lattice to form a tenon-and-groove structure. The tenon of one lattice unit may be embedded within an adjacent tenon groove for connecting the lattice units in series to form a continuously extended layer of lattice units. The continuous structure of lattice units forms a plane layer of a space lattice structure. The combining pillar may be passed perpendicularly through a hollow portion of a lattice unit for connecting plane layers of lattice units stacked one over the other to form a three-dimensional space lattice structure. A heavy filling material may fill the hollow portion of the structure to form a gravity structure.

Owner:LI PIAO CHIN

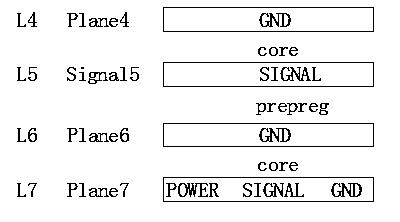

Printed circuit board and manufacture method thereof

InactiveCN103096613AContinuous Via ImpedanceImprove signal integrityElectrical connection printed elementsPrinted element electric connection formationElectrical conductorEngineering

Owner:INVENTEC PUDONG TECH CORPOARTION +1

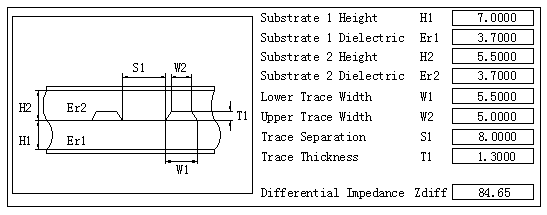

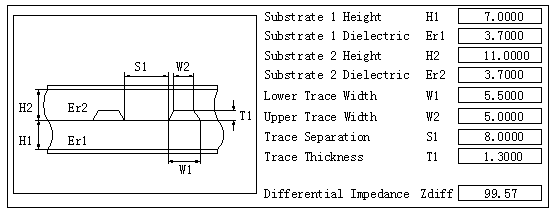

Design method for control transmission lines on same layer and with different impedance

InactiveCN103970956AImprove integrityGuaranteed impedance continuitySpecial data processing applicationsElectrical conductorLine width

The invention discloses a design method for control transmission lines on the same layer and with different impedance. According to different Plane layers arranged on the control transmission lines with different impedance on a calculation mainboard of a server together, different design is performed on the line width and the line distance of the control transmission lines, and optimization design is performed on the high-impedance transmission lines on the premise that optimality of the low-impedance transmission lines is guaranteed; according to the optimization design, a reference plane below the high-impedance transmission lines is hollowed, so that the high-impedance transmission lines refer to a second plane below the high-impedance transmission lines, and the distance between the high-impedance transmission lines and the reference plane is increased. By means of the design method of the transmission lines, the requirement of impedance is met to guarantee impedance continuity of signals, loss of conductors is reduced, and signal integrity is optimized.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

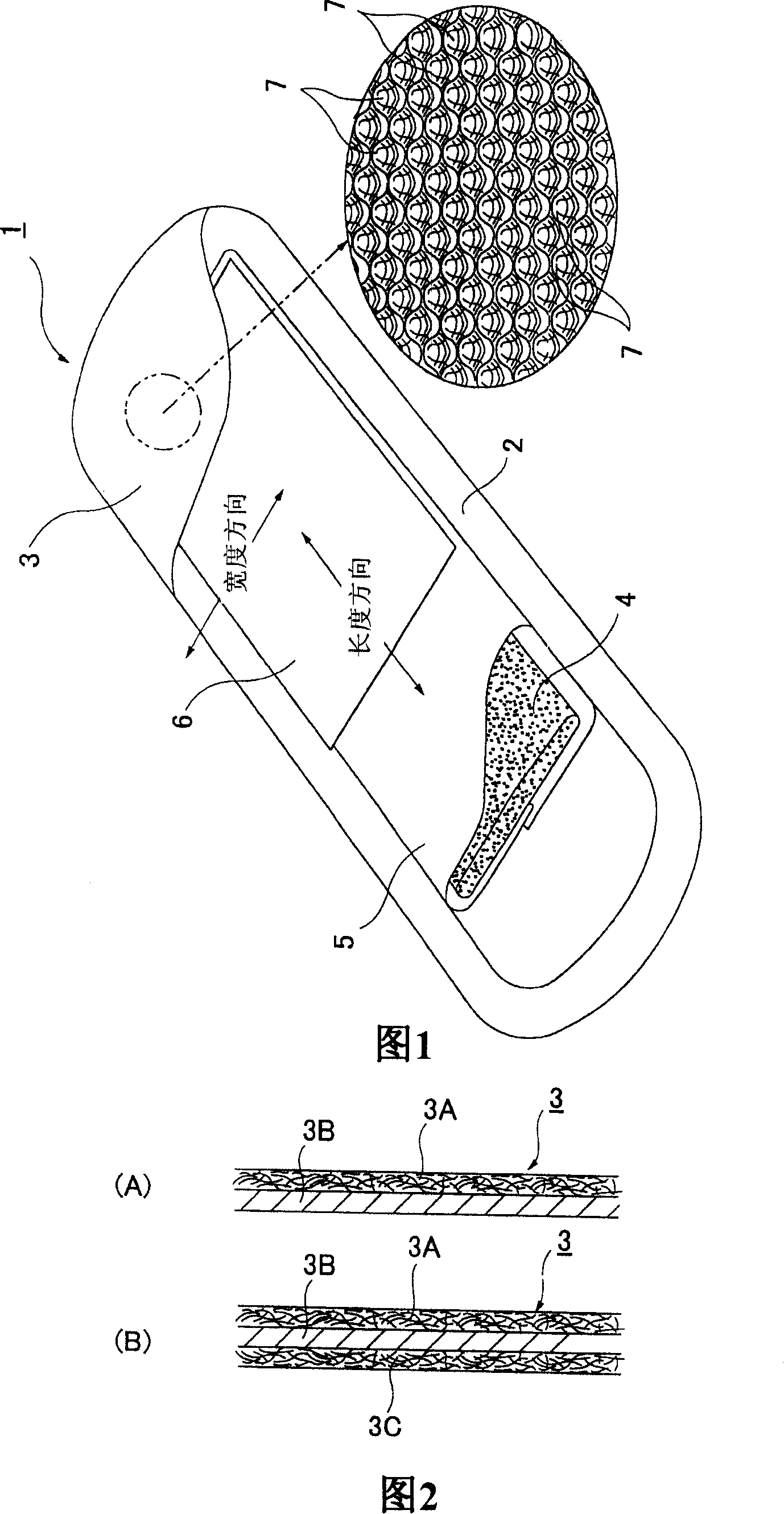

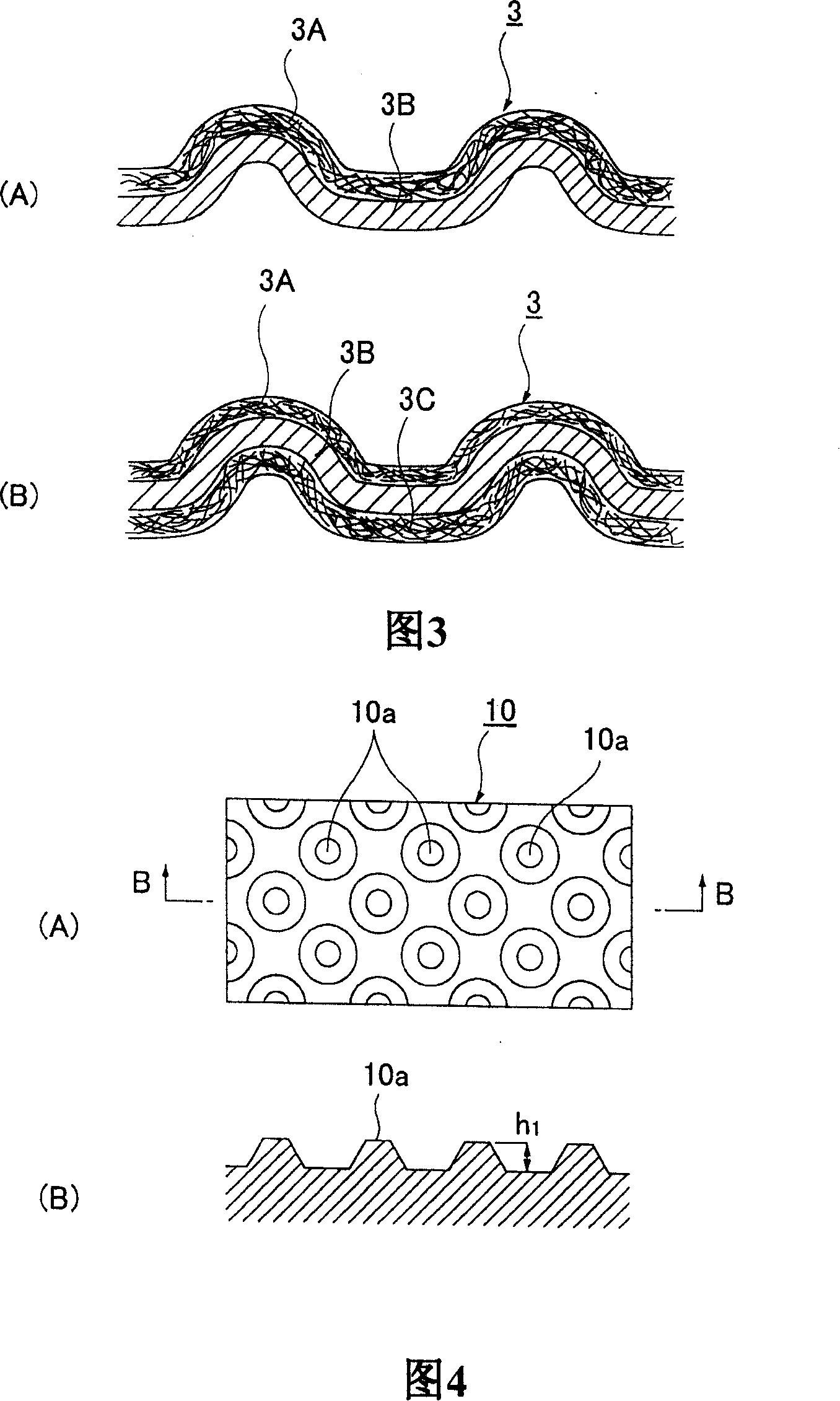

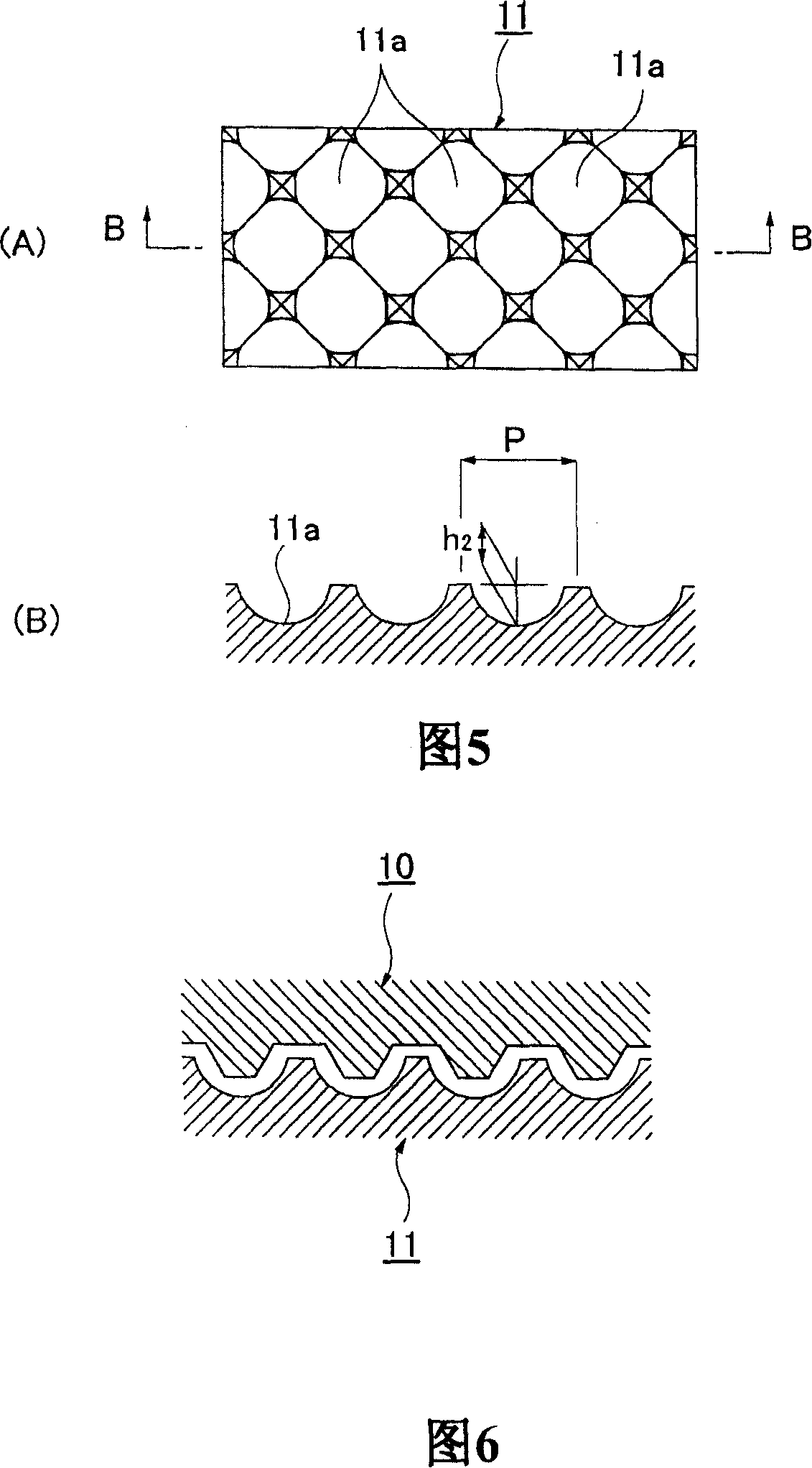

Absorbent article and surface sheet thereof

ActiveCN101151005AGuaranteed cushioning effectGuaranteed feelAbsorbent padsBaby linensCushioningSkin contact

To provide an absorbent article that has not only a highly spatial appearance but also a high cushioning effect, minimizing a contact area with the skin, and that enhances the shape retention of uneven embossing to thereby enable continual maintenance of uneven configuration not only in the dry state but also at body fluid absorption. There is provided absorbent article (1) comprising absorbent member (4) interposed between liquid-permeable surface sheet (3) and backside sheet (2), wherein the surface sheet (3) is a multilayer sheet having at least nonwoven fabric layer (3A) constituting a skin contact plane layer and, superimposed on the skin noncontact plane side remote from the nonwoven fabric layer (3A), plastic film layer (3B), the plastic film layer (3B) constituted of a material of melting point lower than that of the nonwoven fabric layer, and wherein the surface sheet (3) is one having undergone not only multihole making treatment but also rugged embossing forming a multiplicity of outward protruding elevated portions (7,7...) under such heating conditions that the temperature is not lower than the melting point of the plastic film layer (3B) but lower than the melting point of the nonwoven fabric layer (3A).

Owner:DAIO PAPER CORP

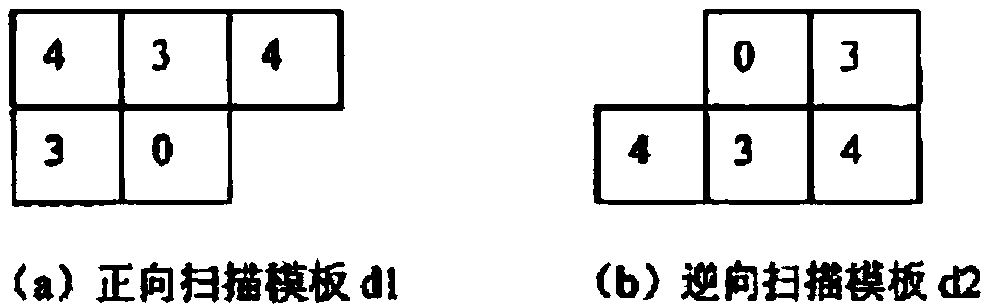

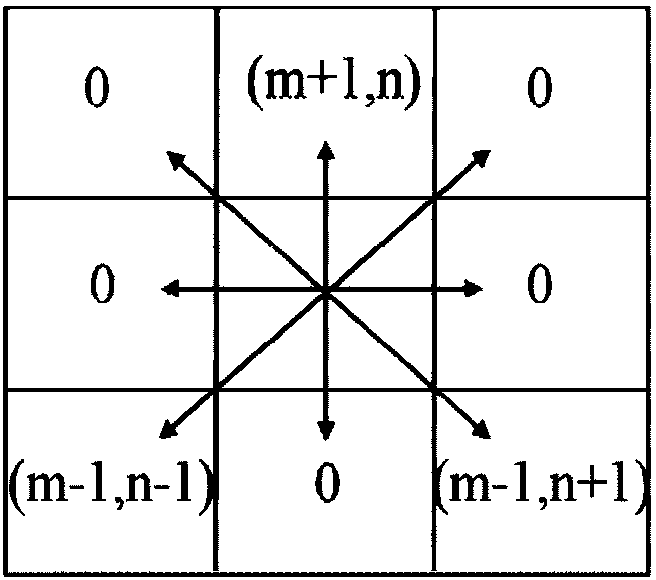

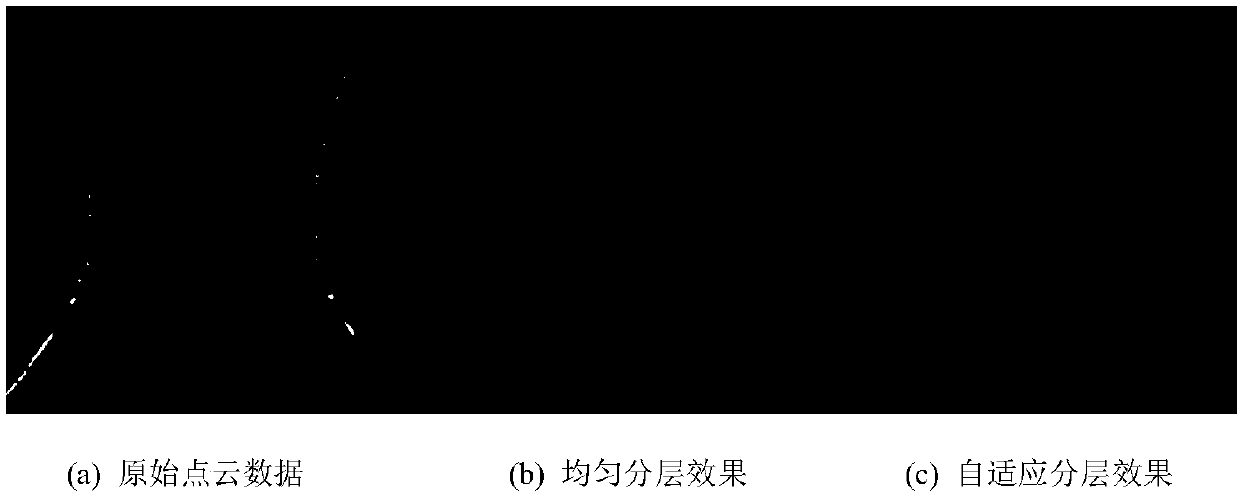

Adaptive plane layering method based on additional material remanufacturing point cloud model

ActiveCN108022307ASkip the resurfacing processImprove efficiencyAdditive manufacturing apparatusImage data processingPoint cloudInter layer

The invention relates to an adaptive plane layering method based on an additional material remanufacturing point cloud model. The method comprises: step one, a layering direction is determined; step two, a layering height is determined; to be specific, traverse of point cloud coordinates is carried out to obtain a zmin and a zmax, difference processing is carried out on the zmin and the zmax to obtain a layering height; step three, an inter-layer point cloud mapping relationship is constructed; step four, a surface error is defined; to be specific, a surface error P is defined to express a surface difference degree between two slices, wherein sigma is equal to Rmax and the Rmax expresses a maximum value a radial width R of a projection point cloud; and step five, a layering thickness is determined. According to the adaptive plane layering method, the maximum value of the radial width R of the projection point cloud is used as a surface error and thus an adaptive layering height is determined by iteration; the algorithm implementation process is clear; and both efficiency and precision are considered.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com