Luminous coating fabric and processing method thereof

A technology of luminous coating and processing method, applied in dyeing method, textile and papermaking, etc., can solve the problems of high manufacturing cost and pollution, and achieve the effect of stable luminous performance, good air permeability and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

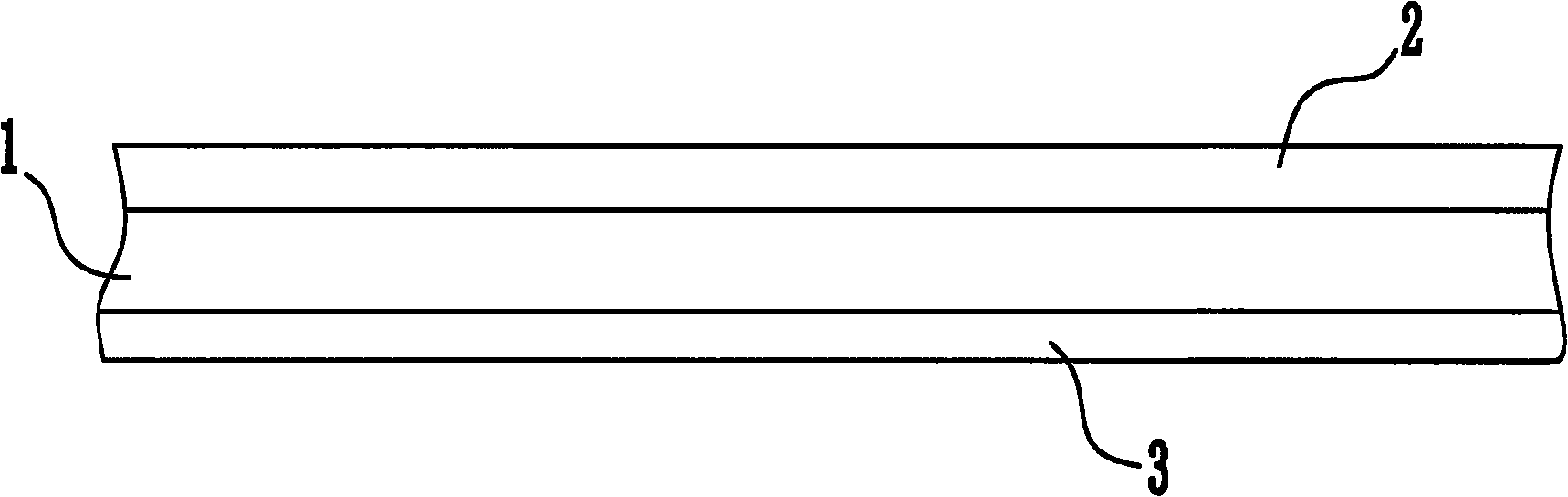

[0028] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the luminous coating fabric of the present invention. The present invention provides a luminous coating fabric, comprising: a fabric 1, the fabric 1 includes at least one plane layer, wherein the plane layer is provided with a luminous coating 2, and the other side 3 of the fabric 1 can be a plane layer It can also be a non-planar layer, and the fabric 1 described here must be a light-transmitting fabric.

[0029] Wherein the fabric 1 here can be a fabric fabric or a plush fabric, and the luminous coating is composed of inorganic pigment hydrosol, luminous powder, color fixing agent, stabilizer, thickener and softener.

[0030] The above is a description of the structure of the luminous coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com