Patents

Literature

53results about How to "Does not affect texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood lacquer for purifying formaldehyde and preparation method thereof

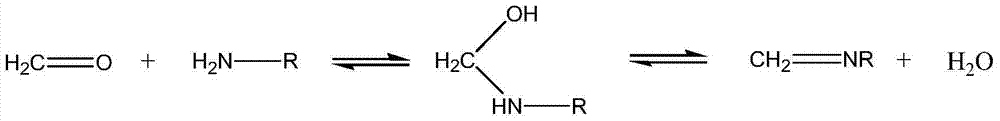

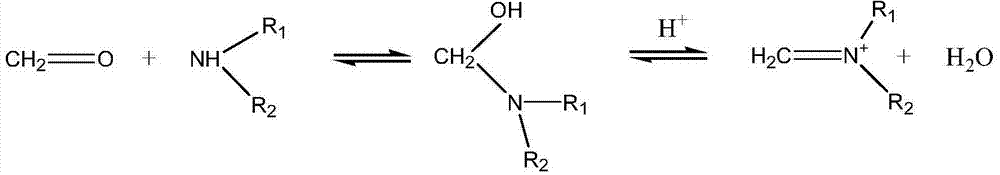

The invention discloses wood lacquer for purifying formaldehyde and a preparation method thereof. The wood lacquer is prepared by mixing a component A with a component B in a mass ratio of (1:0.25)-(1:0.5), and then stirring the mixture uniformly, wherein the component A is prepared by putting alkyd resin and alcohol solvents into a reaction kettle under the protection of nitrogen, stirring the materials uniformly and heating the materials to 50-75 DEG C, adding first diluents, fillers, driers, wax powder, formaldehyde removal agents and an anti-settling agent in sequence, continuing stirring, maintaining the temperature at 40-70 DEG C and reacting for 15-60 minutes, and discharging the material after returning to the room temperature; the component B is prepared by putting second diluents into the reaction kettle under the protection of nitrogen, stirring and insulating the materials, putting curing agents, a levelling agent and a defoaming agent into the reaction kettle, insulating and stirring the materials, and discharging the material after returning to the room temperature. The wood lacquer has high formaldehyde removal efficiency and good durability, dispenses with recoating films, and is convenient to use.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of aqueous two-component super wear-resistant lusterless paint

InactiveCN105713496AImprove high temperature resistanceExcellent super wear resistancePolyurea/polyurethane coatingsMicrosphereWear resistant

The invention relates to a preparation method of aqueous two-component super wear-resistant lusterless paint. The lusterless paint comprises an ingredient A and an ingredient B and a mole ratio of OH to NCO in the ingredients A and B is 1: 1.0-1.5. The ingredient A comprises a hydroxyl-containing aqueous resin, SMA resin, PMMA microspheres, aqueous color paste, auxiliary agents and water. The ingredient B is an aqueous polyurethane curing agent. A film of the aqueous two-component super wear-resistant lusterless paint has excellent high temperature resistance, super wear resistance, water resistance, weatherability and chemical stability. The preparation method improves paint surface texture, fullness, flexibility, smoothness and delustring effects and does not influence paint film texture and a brilliant degree. The aqueous two-component super wear-resistant lusterless paint has low VOC, does not contain heavy metals, is environmentally friendly, can be widely used for surface coating and protection of a base material with high temperature resistance, wear and scratch resistance and lusterless effect requirements and can be used for aqueous floor paint, aqueous high-grade woodenware paint, aqueous plastic cement paint, aqueous mobile phone paint and aqueous industrial paint.

Owner:UNION FOSHAN CHEM +1

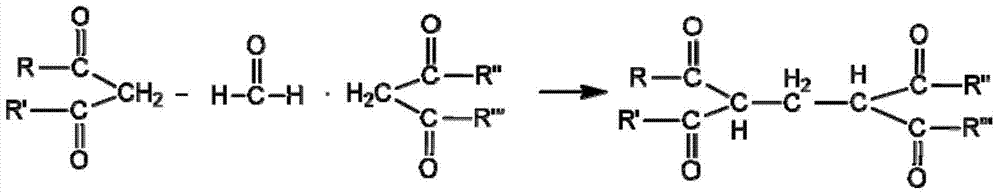

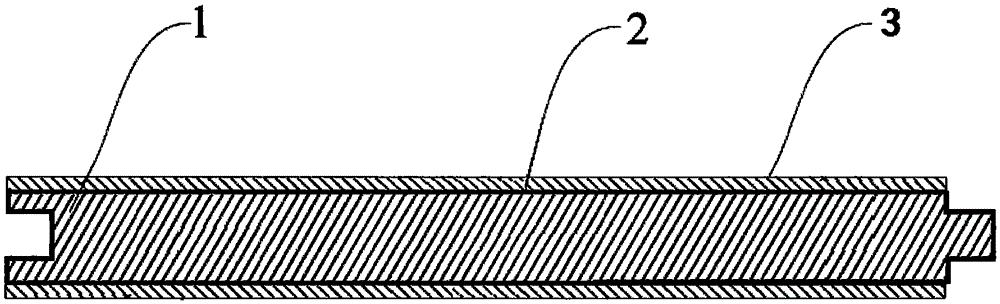

Novel PU printing waterproof and anti-crease fabric and preparation method thereof

InactiveCN101660277AImprove the three-dimensional effectRemove tensionSynthetic resin layered productsDyeing processDisperse dyeAlcohol

The invention discloses a novel PU printing waterproof and anti-crease new fabric, which comprises three layers: the first layer is PU surface layer mainly comprising PU polyurethane; the second layeris printing dyes; the third layer is a PU surface layer mainly comprising PU polyurethane. The printing dyes in the second layer are ink disperse dyes made of disperse dyes and water-soluble carrier,or ink disperse dyes made of the disperse dyes and alcohol-soluble carrier, or ink disperse dyes made of the disperse dyes and oil-soluble resin. The invention also discloses a method for preparing the novel PU printing waterproof and anti-crease fabric, comprising the following steps: firstly, preparing a shell fabric and a backing material; secondly, carrying out coating operation; thirdly, performing the backing lamination; fourthly, drying, rolling and stripping; fifthly, thermally transferring a printing film to base leather; and sixthly, performing the secondary coating on the printingbase leather. The novel PU printing waterproof, anti-crease fabric has advantages of terrific tensile strength and hydrostatic pressure, and is durable in use, fastness to washing, colorfast; and thepreparation method is easy to operate.

Owner:仪征新天地织物面料实业有限公司

Nano material modified fluorocarbon resin stone waterproof coating

The invention discloses a nano material modified fluorocarbon stone stone waterproof coating. The coating includes the following raw material components: resin raw material consisting of vinylidene fluoride resin and acrylic resin, multi-layer graphene oxide, a silane coupling agent, dibutyltin dichloride and solvent oil. The hardness, wear resistance and permeability resistance of the nano material modified fluorocarbon stone stone waterproof coating can be greatly improved by two-dimensional nanomaterial technology on the premise of guaranteeing of the transmittance and glossiness of the stone waterproof coating, and the protection life and the protection effect of the stone waterproof coating are greatly improved.

Owner:云浮华云创新设计有限公司

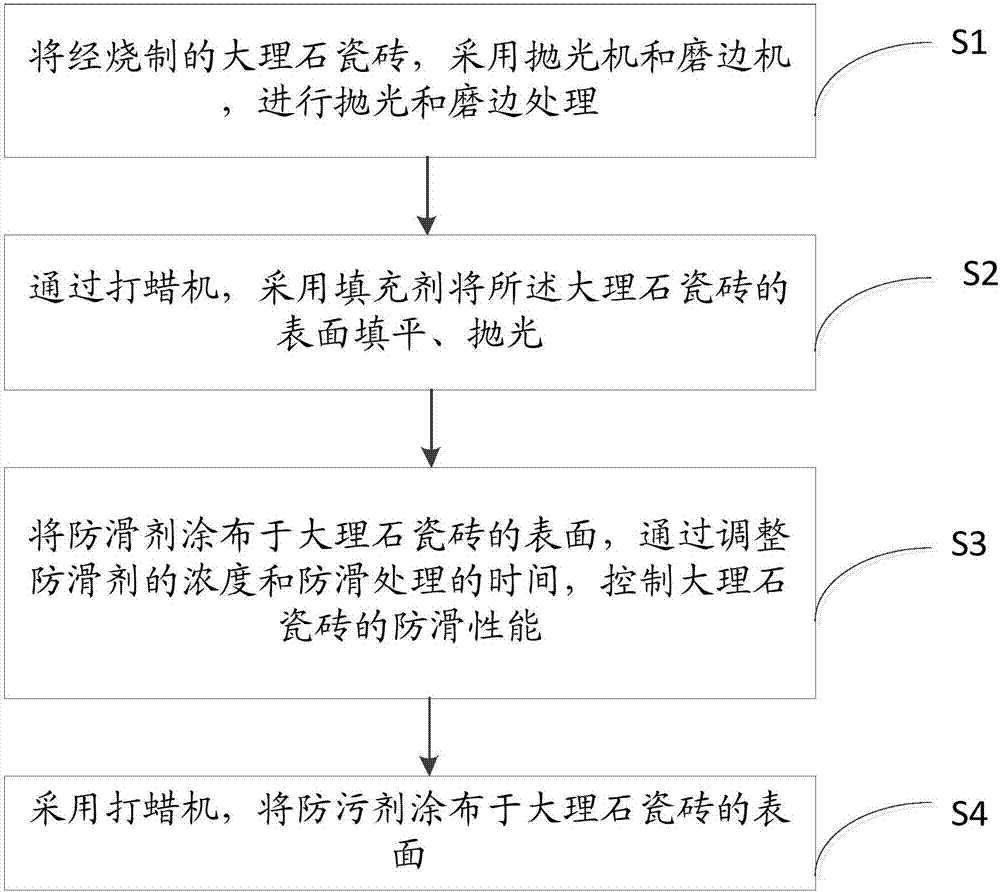

Preparing method for anti-slipping marble tile

InactiveCN107486946ADoes not affect performance indicatorsDoes not affect transparencyCovering/liningsFlooringStainTreatment time

The invention discloses a preparing method for an anti-slipping marble tile. The preparing method includes the following steps that S1, a fired marble tile is polished and subjected to edge grinding with a polisher and a grinder; S2, through a waxing machine, the surface of the marble tile is filled and leveled up with a filling agent and then polished; S3, the surface of the marble tile is coated with an anti-slipping agent, and the anti-slipping performance of the marble tile is controlled by adjusting the concentration of the anti-slipping agent and the anti-slipping treatment time; and S4, the waxing machine is used for coating the surface of the marble tile with a stain-proofing agent. By means of the preparing method for the anti-slipping marble tile, the anti-slipping performance of the marble tile can be improved without affecting the surface decorating effect.

Owner:FOSHAN CITY GANI CERAMICS CO LTD +1

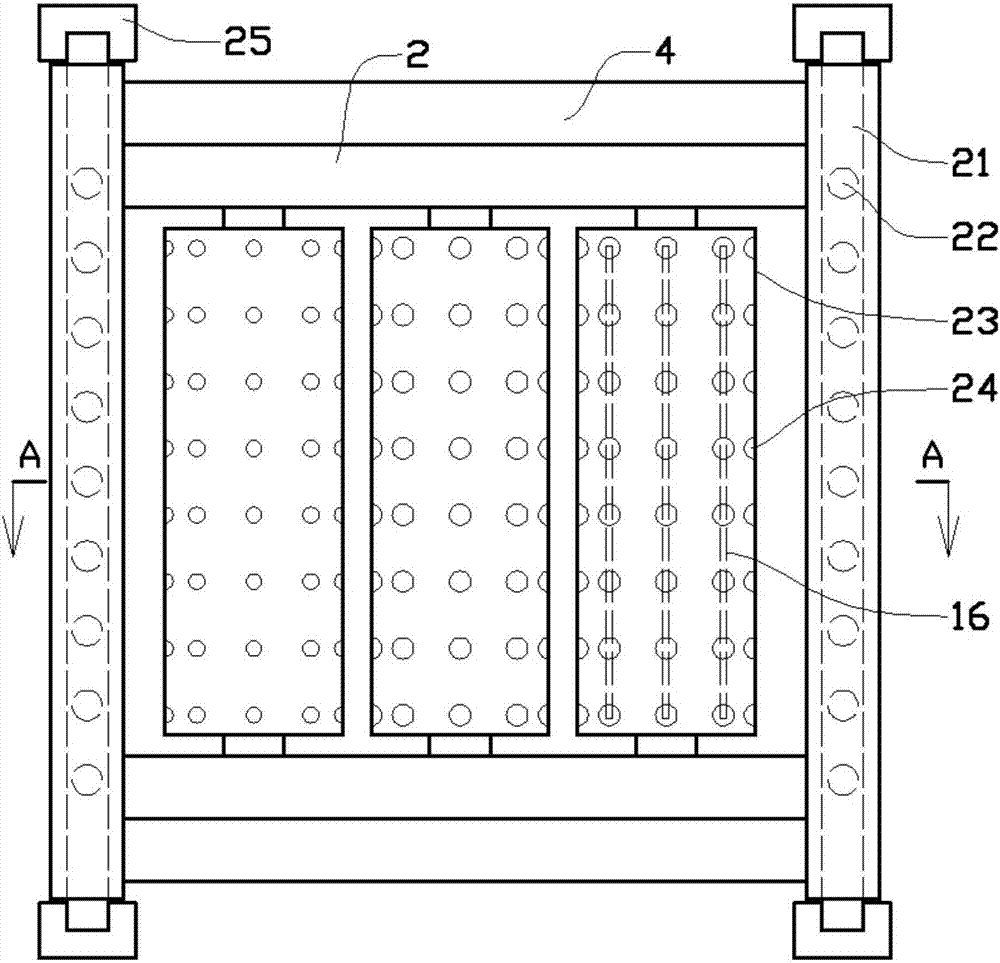

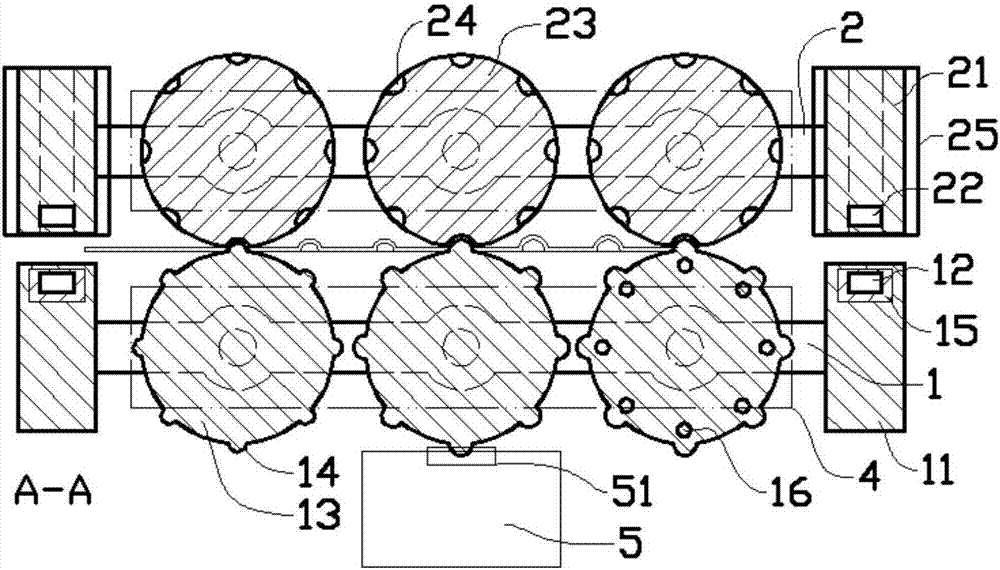

Fabric bump forming multi-roll stretching device

ActiveCN105839330BEasy to stretchUniform transmissionLiquid surface applicatorsPattern makingEngineeringFront and back ends

The invention provides a convex point forming multi-roller stretching device for a cloth. The convex point forming multi-roller stretching device comprises a lower fixed rack and an upper sliding rack, wherein more than two lower feed rollers which are assembled side by side are arranged in the lower fixing rack, and uniformly arranged hemispherical convex points are arranged on the circumferential surfaces of the lower feed rollers; the upper sliding rack is assembled at the upper part of the lower fixing rack, and transversely fixed upper magnetic strips are arranged at the front and back ends of the upper sliding rack; the two sides of the upper magnetic strip are assembled with vertical sliding tracks, and the two sides of the upper magnetic strip are assembled in the sliding tracks; the upper sliding rack is internally assembled with more than two upper feed rollers assembled side by side, and concave points are arranged on the surfaces of the upper feed rollers. The cloth can be conveniently pulled out by the device, so that the cloth is smooth, the convex points can be processed on the surface of cloth, and the texture of cloth can be simultaneously ensured.

Owner:乳山吾星纤维有限公司

Modified and enhanced flame retardant treating agent for wood floor wood

ActiveCN104057506ADoes not affect textureDoes not affect colorWood impregnation detailsUltimate tensile strengthEucalyptol

The invention relates to the field of modified treatment of wood floor wood, and particularly relates to a modified and enhanced flame retardant treating agent for the wood floor wood. The modified agent is prepared from the following raw materials in parts by weight: 1 to 2 parts of eucalyptol, 1 to 3 parts of nekal, 3 to 5 parts of natrium salicylicum, 0.1 to 0.2 part of capsaicine, 2 to 4 parts of iso-tridecanol polyoxyethylene ether, 1 to 2 parts of sodium alginate, 20 to 25 parts of sodium chloride, 28 to 30 parts of water glass, 10 to 12 parts of sodium sulfamate, 380 to 400 parts of water and 6 to 8 parts of auxiliaries. According to the modified agent disclosed by the invention, the effects of corrosion prevention, desinsectization and aroma enhancement of the raw materials including the eucalyptol and the capsaicine are combined, and the raw materials including the water glass and the sodium alginate are added, so as to enhance the wood intensity, improve the heat resistant capability and achieve the flame retardant effect. The modified agent has the advantages of being easy in raw material obtaining, simple in preparation method, good in penetrability, difficult in running off after permeating through the wood, long in modified effect and free from influence on wood textures or color, the modified wood is good in size stability, and manufactured wood floor has the advantage of durability, high safety and high market competitiveness.

Owner:定远县林能木业有限责任公司

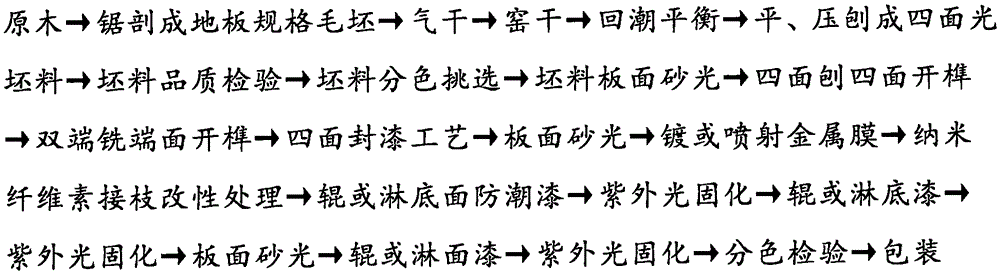

Solid wood floor with metallic luster and manufacturing method for solid wood floor

InactiveCN105415476AWith metallic lusterGood dimensional stabilityWood working apparatusFlooring insulationsSolid woodPulp and paper industry

The invention relates to solid wood floor with metallic luster and a manufacturing method for the solid wood floor. A layer of metal films is arranged between a solid wood floor base material and a paint layer, so that the floor has metallic luster; and the wood has performances of absorbing moisture, desorbing, carrying out dry shrinkage and wet expansion, and the like. According to the solid wood floor with the metallic luster, one layer of metal films is arranged between the solid wood floor base material and the paint layer, so that the contact between the solid wood floor base material and water molecules in air is effectively isolated, and therefore, moisture in the solid wood floor base material is kept constant, and deformation, caused by moisture content, of the solid wood floor can be effectively solved; the thicknesses of the metal films are 20 nanometers to 30 microns, so that the floor surface has the metallic luster, the dimension stability of the solid wood floor is improved, and the wood texture is not affected.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Wood impermeable flame retarding modification treatment agent for wood floor

ActiveCN104057512AImprove penetration resistanceStrong dimensional stabilityWood impregnation detailsSodium acetateCellulose

The invention relates to the field of wood modification treatment for wood floor, and in particular to a wood impermeable flame retarding modification treatment agent for wood floor. The modification agent is prepared from the following raw materials in parts by weight: 0.1-0.2 part of calcium sulfate, 0.01-0.02 parts of naphthalene sodium acetate, 4-5 parts of methylene binaphthalene sulfonic acid, 0.1-0.2 part of guaiacol, 10-12 parts of cellulose ether, 35-38 parts of diammonium hydrogen phosphate, 0.1-0.2 part of methyl sodium silicate, 350-400 parts of water and 6-8 parts of additives. The raw materials of the modification treatment agent are environment-friendly, easy to obtain, simple in production and low in cost; effective components including calcium sulfate, naphthalene sodium acetate, guaiacol and cellulose ether permeate into the wood, then are uniformly dispersed and adhered, and are filled into seams of the wood material, thus the compactness of tissue is improved, the impermeability of the wood material is greatly improved, the withstanding resistance to the ambient environment is relatively high, the size stability is good, the effective components are not easy to lose, and the modification effect is long-lasting; the wood floor made of the modified wood material is long-lasting, durable, waterproof, flame-retarding, good in security and high in market competitiveness.

Owner:定远县林能木业有限责任公司

Noctilucent shell fabric

InactiveCN102342609ADoes not affect textureNo radioactivityProtective garmentSpecial outerwear garmentsEngineeringCotton material

The invention discloses a noctilucent shell fabric which is compounded from a polymer noctilucent material and cloth and is composed of two layers of materials, wherein the two layers of materials are respectively a common material layer and a noctilucent material layer; the common material layer is positioned at the outer side and is woven by pure cotton, pure silk and pure hemp in a blending way and used for realizing the warming function of dress fabrics; and the noctilucent material layer is positioned at the inner side, is made of a polymer material and is provided with a plurality of noctilucent cavity holes. The noctilucent shell fabric has the beneficial effects of good air permeability, good hand feel, low possibility of fading, low possibility of losing color and the like, and can be cleaned. The shell fabrics which are processed and are not processed do not have essential difference without affecting shell fabric texture; the processed shell fabric is nontoxic and harmless, is free of radioactivity, can keep lighting for more than 10 hours, can be reused unlimitedly, and has stable lighting performance.

Owner:CHANGSHU YALAN GARMENTS

Aluminum oxide sol-containing wood modification treatment agent of wood floor

The invention relates to the field of wood modification treatment of wood floors, and particularly relates to an aluminum oxide sol-containing wood modification treatment agent of a wood floor. The aluminum oxide sol-containing wood modification treatment agent is prepared from the following raw materials in parts by weight: 5-8 parts by weight of dimethylacetamide, 1-3 parts by weight of triethanolamine, 8-12 parts by weight of saccharose, 38-40 parts by weight of urea, 1-2 parts by weight of turkey red oil, 25-30 parts by weight of bamboo vinegar, 1-2 parts by weight of cupric acetate, 2-3 parts by weight of didecyl dimethyl ammonium chloride, 8-10 parts by weight of aluminum oxide sol, 350-400 parts by weight of water and 6-8 parts by weight of additive. The aluminum oxide sol-containing wood modification treatment agent provided by the invention is low in price and easy to obtain, simple in preparation and low in cost; effective ingredients of the saccharose, the urea, the aluminum oxide and the like can be uniformly dispersed and adhered in wood after permeating into the wood, the fiber hardness can be improved after the wood is dried, the mechanical property of a tissue structure is improved, and the size stability of the tissue is improved. The aluminum oxide sol-containing wood modification treatment agent permeates into the wood and then is difficult to lose, thus the modification effect is durable, a solution can be reused, waste liquid is easily treated, the wood floor made by adopting the modified wood is durable, corrosion and moisture are prevented, and the market competitiveness is strong.

Owner:定远县林能木业有限责任公司

Cooking method of spicy crabs

ActiveCN107751348AReduce bacteriaDelay quality deteriorationMeat/fish preservation using chemicalsWater bathsSpoilage bacteria

The invention discloses a cooking method of spicy crabs. The cooking method comprises the following steps: (1) immersing crabs in a citric acid water solution and temporarily breeding at room temperature, and washing the crabs with clean water; (2) putting the crabs obtained by step (1) in a boiled water bath and leaching; (3) frying the crabs obtained by step (2) with oil and leaching oil; (4) mixing a fresh-keeping agent, an auxiliary agent and a condiment solution to obtain a pickling solution, wherein the fresh-keeping agent is any one or two of epsilon-polylysine hydrochloride and oreganoessential oil; (5) immersing the crabs obtained by step (3) into the pickling solution obtained by step (4) and pickling at room temperature, and then draining; and (6) putting the crabs obtained bystep (5) into a sterile material and packaging, and sterilizing to obtain the spicy crabs. According to the production method disclosed by the invention, the aim of effectively prolonging the shelf life of spicy crabs is realized by comprehensively utilizing raw material sterilization, the compound fresh-keeping agent and a moderate sterilization manner; and the fresh-keeping agent comprises epsilon-polylysine hydrochloride and the oregano essential oil, which have a cooperatively complementary effect to effectively inhibit spoilage bacteria in spicy crabs.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

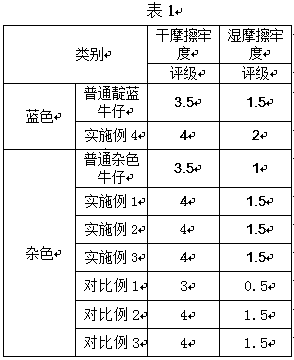

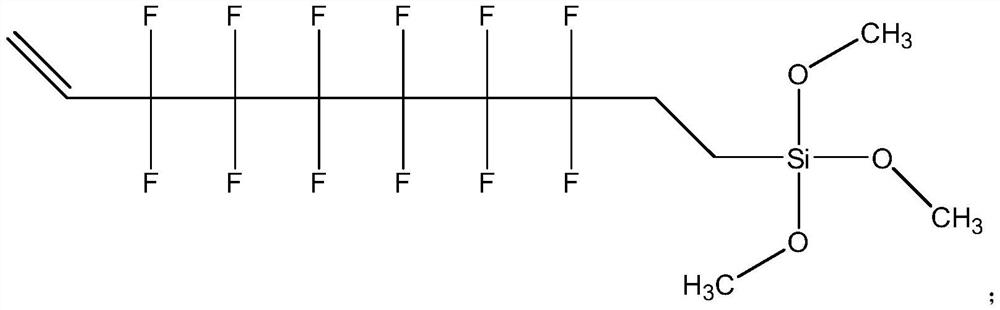

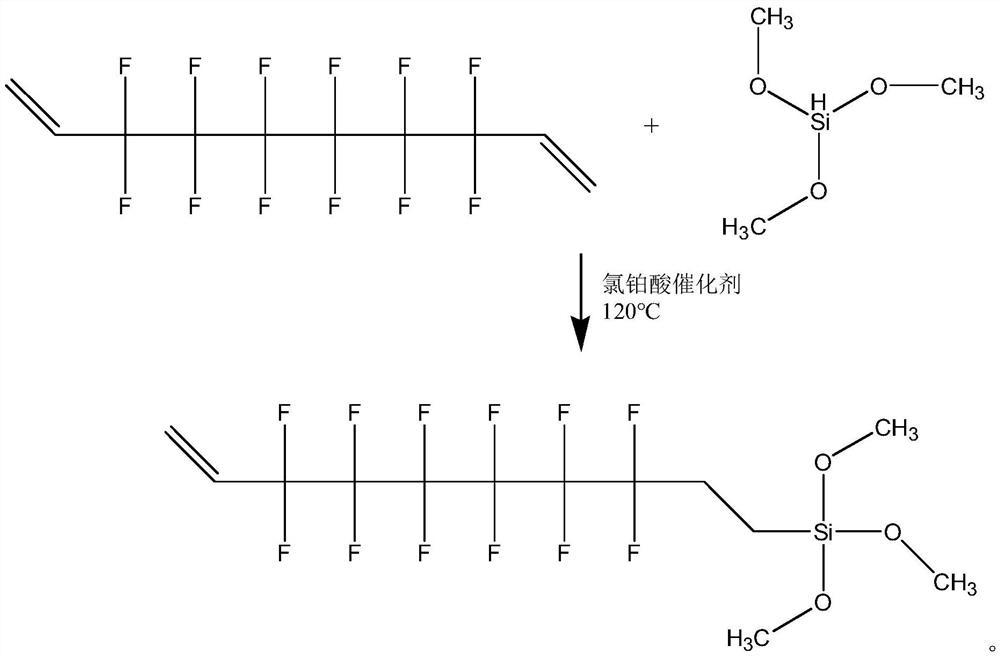

Preparation process of fadeless jean fabric

InactiveCN111364257AHigh color fastnessVariety of colorsDyeing processColour fastnessSubstantive dye

The invention discloses a preparation process of a fadeless jean fabric, and belongs to the technical field of jean fabric preparation. The main technical problems that an existing jean fabric is single in color and not bright in color, or under the condition that the color is bright, the special white core effect of jean is not achieved, pollution emission is high, and color fastness is poor aresolved. The invention provides the preparation method of the jean fabric which not only can be used as high-grade clothes, but also has fashion sense of jean under certain conditions, and is high in color fastness, rich in color and low in pollution emission. The influence of the direct dye on the jean fabric is improved by mainly utilizing the cooperation of a cationic modifier, a penetrant, salt, a color fixing agent, a dry and wet rubbing fastness improver and a washing and dyeing textile process, so that the direct dye can be applied to the preparation of the jean fabric, and the fadelessjean fabric is prepared.

Owner:山东兰雁纺织服装有限公司

Geothermal solid wood composite floor and manufacturing method thereof

The invention relates to a geothermal solid wood composite floor and a manufacturing method thereof. A layer of metal film is arranged between a base material of the solid wood composite floor and a paint layer, and by using excellent heat-conducting property of metal, heat energy of the ground is conducted to the upper surface of the floor by the metal film, so that the heat-conducting property of the wood floor is effectively improved; wood has properties such as humidity absorption, desorption and air shrinkage and humidity expansion, and the metal film is arranged between the base material of the solid wood composite floor and the paint layer; contact between the base material of the solid wood composite floor and air and water molecules is effectively isolated, and water content in the base material of the solid wood composite floor is kept constant; deformation caused by water content of the solid wood floor is effectively solved; the geothermal floor uses the solid wood composite floor as the base material, and the metal film can reduce formaldehyde emission; the thickness of the metal film is set to be 30 nanometers to 50 micrometers; poor heat-conducting property and size stability of the geothermal floor are improved and wood textures are not influenced.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Egg chicken fodder for improving yolk color and luster

InactiveCN107242393AGood colorPromote digestion and absorptionFood processingAnimal feeding stuffYolkChrysanthemum Flower

The invention discloses an egg chicken fodder for improving the yolk color and luster. The egg chicken fodder is prepared from, by weight, 620-680 parts of corn, 215-225 parts of soybean meal, 15-20 parts of bran, 75-80 parts of stone powder, 8-12 parts of composite yolk color ameliorant, 12-17 parts of calcium hydrophosphate, 2-3 parts of edible salt and 8-12 parts of premix. By adding the composite yolk color ameliorant in the fodder according to matching, and through substances, which are naturally rich in carotenoid, like paprika, citrus and chrysanthemum flowers in the composite yolk color ameliorant, the fodder does not contain any toxic substances and harmful residues, the carotenoid can remarkably improve the yolk color and luster, the paprika, the citrus and the chrysanthemum flowers in the composite yolk color ameliorant are all substances rich in cellulose, by adding cellulose, the digestion and absorption of cellulose can be promoted, therefore the absorption and utilization rate of carotenoid is increased, and the aim of improving the yolk color is achieved.

Owner:西安格润牧业股份有限公司

EB curing copper-clad aluminum substrate heat dissipation coating

ActiveCN112961600ADoes not affect transparencyDoes not affect texturePolyurea/polyurethane coatingsEpoxy resin coatingsCoated surfaceAcrylic resin

The invention belongs to the technical field of aluminum-based copper-clad plates, and particularly relates to an EB curing copper-clad aluminum-based plate heat dissipation coating which comprises the following components in parts by weight: 20-30 parts of acrylic resin, 10-20 parts of active monomers, 30-60 parts of phase change capsules, 0.1-0.5 part of a flatting agent, 0.1-0.5 part of a dispersing agent, 0.1-0.5 part of a defoaming agent, 5-10 parts of absolute ethyl alcohol and 10-20 parts of modified inorganic powder. According to the EB curing copper-clad aluminum substrate heat dissipation coating, the phase change capsule is added, heat dissipated by an aluminum-based copper-clad plate can be rapidly absorbed and further dissipated through the surface of the coating, and the phase change capsule is obtained by coating an organic phase change material with an organic matter and has good compatibility with a coating system; and the transparency of the coating and the original texture and texture of the material are not influenced while the heat dissipation effect is improved, excessive solvents do not need to be added, and the method is more environment-friendly.

Owner:GUANGDONG HEYGEY LIGHT CURING MATERIALS

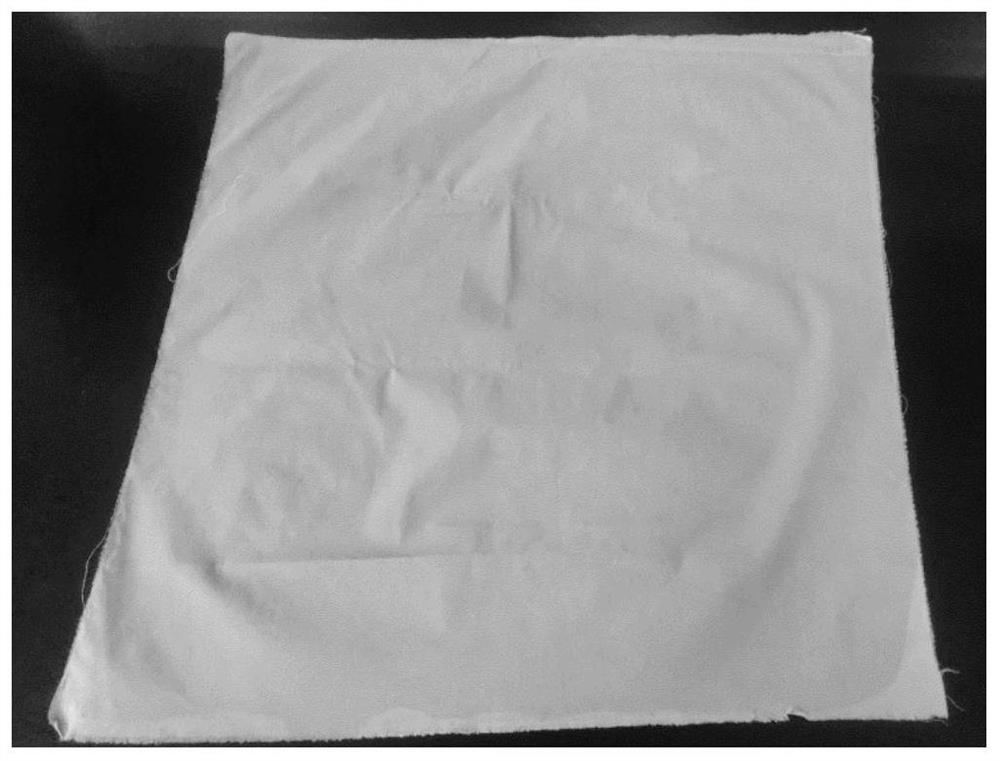

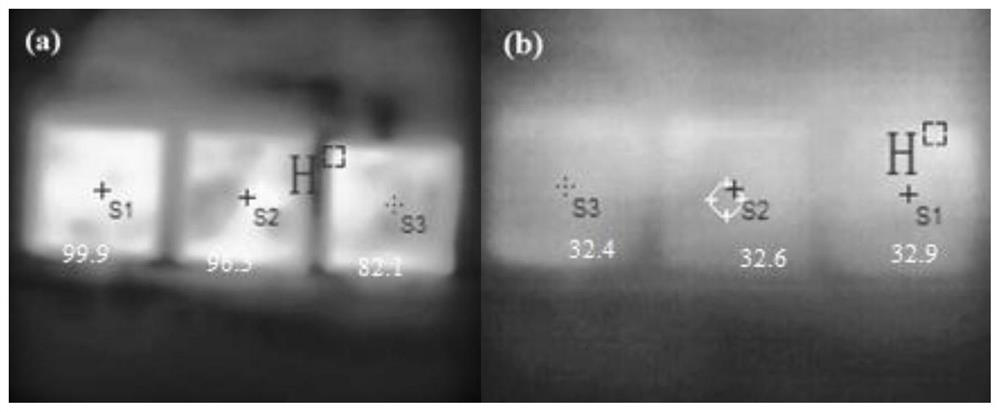

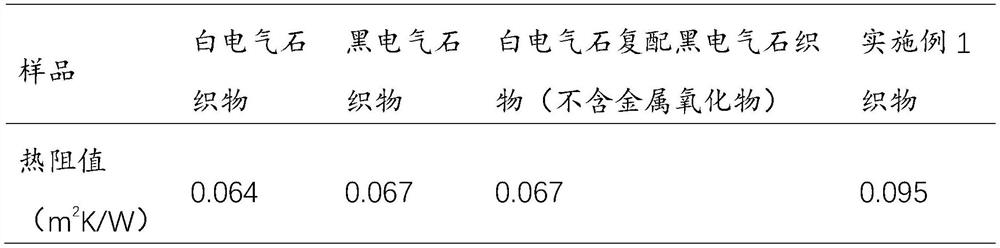

White tourmaline mineral compounded quick-heating warm-feeling textile and preparation method thereof

PendingCN113818263AReduce energy consumptionWide range of mineral sourcesDyeing processSustainable buildingsWoven fabricDyeing

The invention generally relates to the technical field of functional textiles, in particular to a white tourmaline mineral compounded quick-heating warm-feeling textile and a preparation method of the industrially produced quick-heating warm-feeling textile. According to the white tourmaline mineral compounded quick-heating warm-feeling textile, white tourmaline and schorlite which can increase the surface temperature after absorbing light energy and have a far infrared ray emission function are used as main components, a metal oxide is used as an auxiliary agent, and a dispersing agent and a conditioning agent are added to prepare water-based slurry; then, an adhesive and a printing thickening agent are added for preparing printing paste; and finally, printing and dyeing are carried out, so that the textile is obtained. The whole preparation method is simple and suitable for large-scale industrial production and preparation, large-scale continuous production can be achieved, and the prepared white tourmaline mineral compounded quick-heating warm-feeling textile is white gray and can be directly converted into an actual commercial product by simply spraying patterns in the later period.

Owner:YUYUE HOME TEXTILE +1

Assembly method of high-weather-resistant transparent self-cleaning film

InactiveCN103524961AHigh transparencyExcellent peelabilitySolid woodMethyl methacrylate-butyl acrylate copolymer

An assembly method of a high-weather-resistant transparent self-cleaning film. The film comprises 30-80 wt% of polyvinylidene fluoride and 20%-70% of a methyl methacrylate-butyl acrylate copolymer; and a total amount of the above components is 100 wt%. The film has good self-cleaning performance, thin thickness, good transparency and good releasability with metal, and can be produced through a rolling mode; and the film can be used as a protective film on the surface of solid wood furniture without influence on the texture of the solid wood furniture, so as to well protect the surface of the solid wood furniture and solve the long-time difficult technical problem in the solid wood furniture industry.

Owner:张李忠

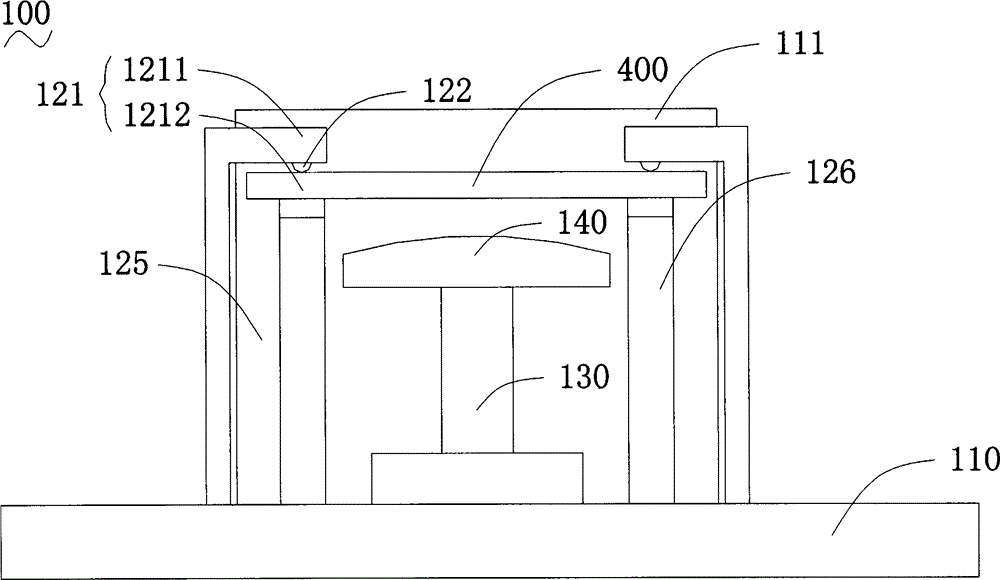

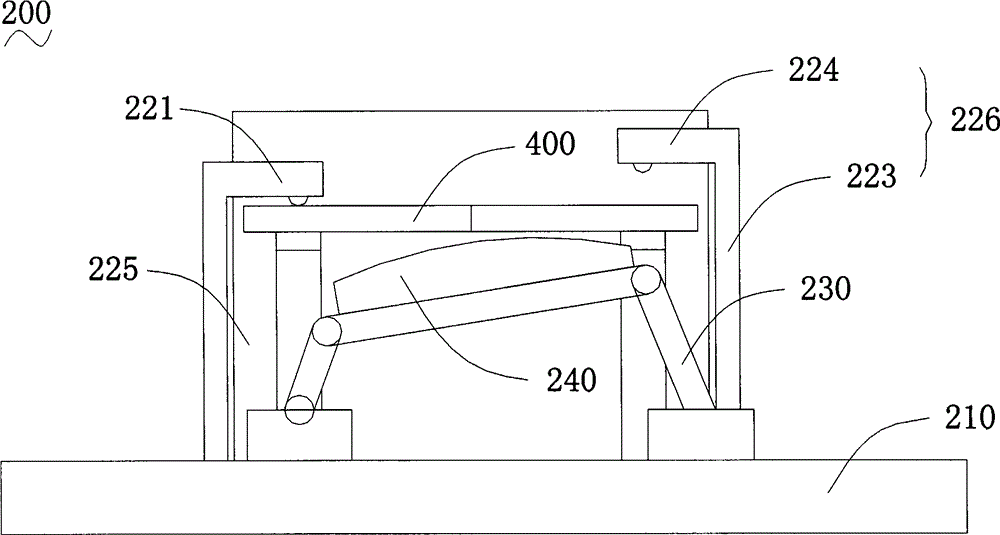

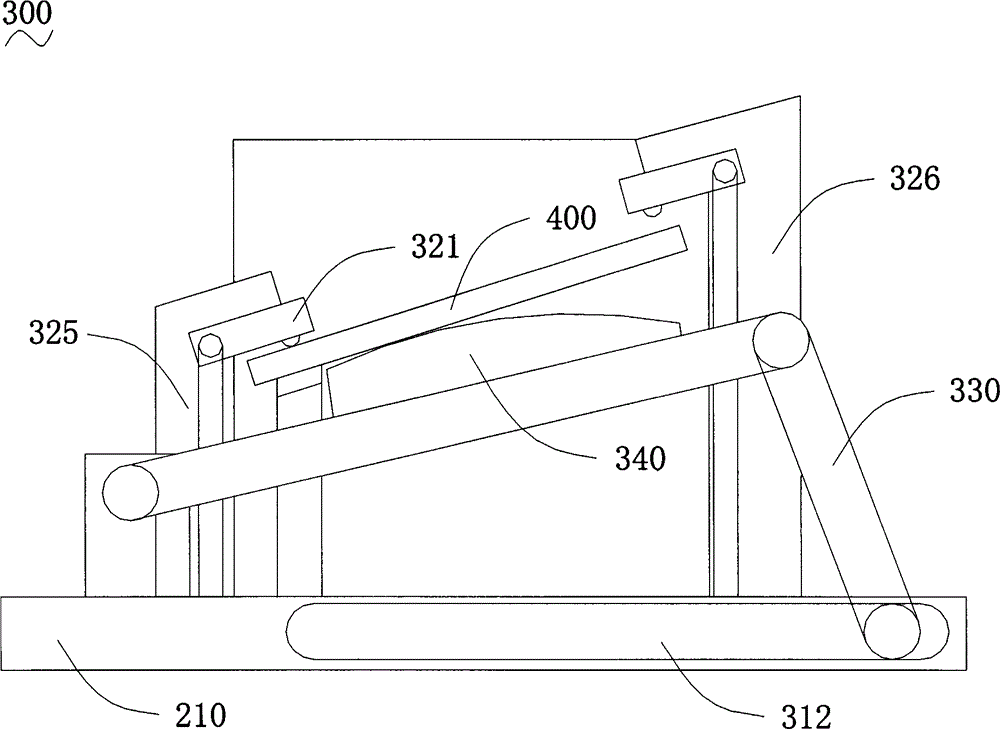

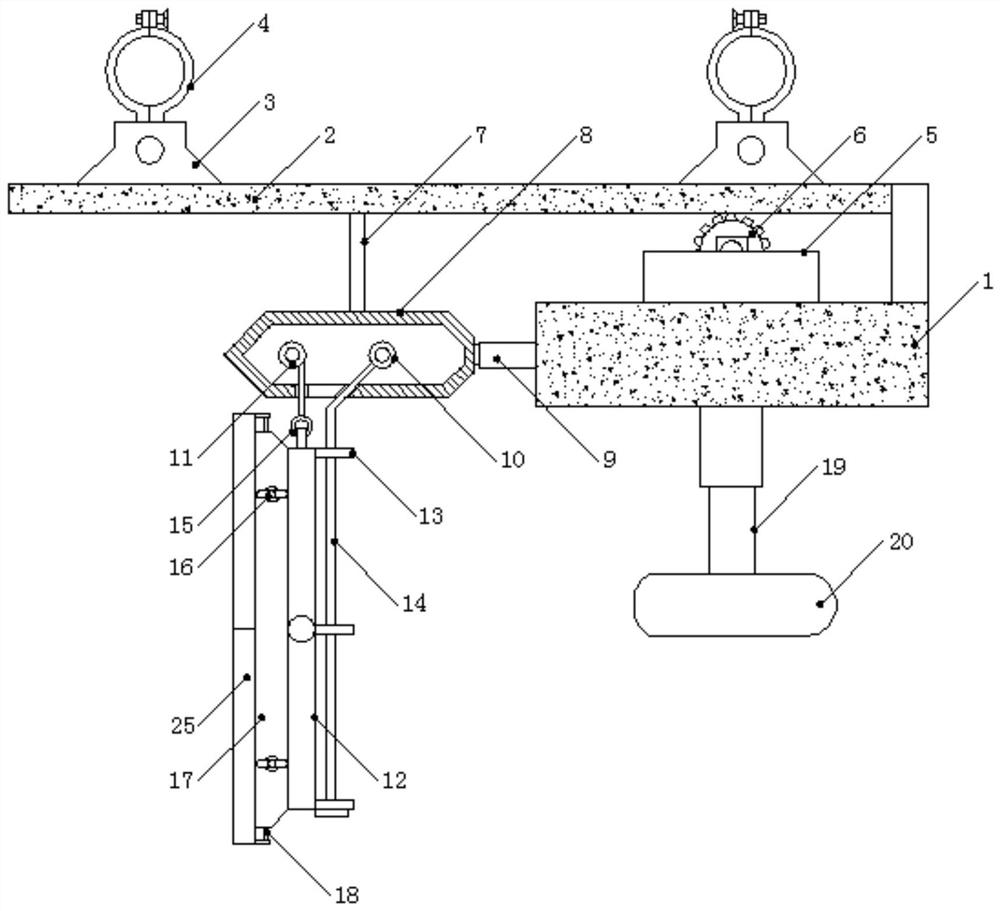

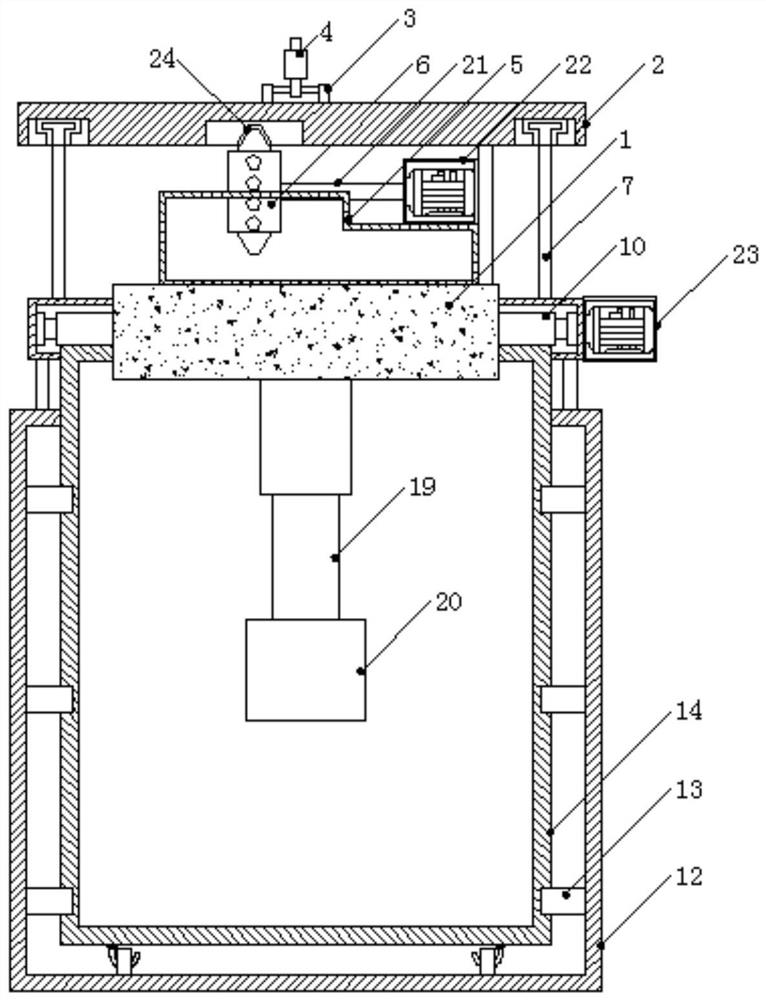

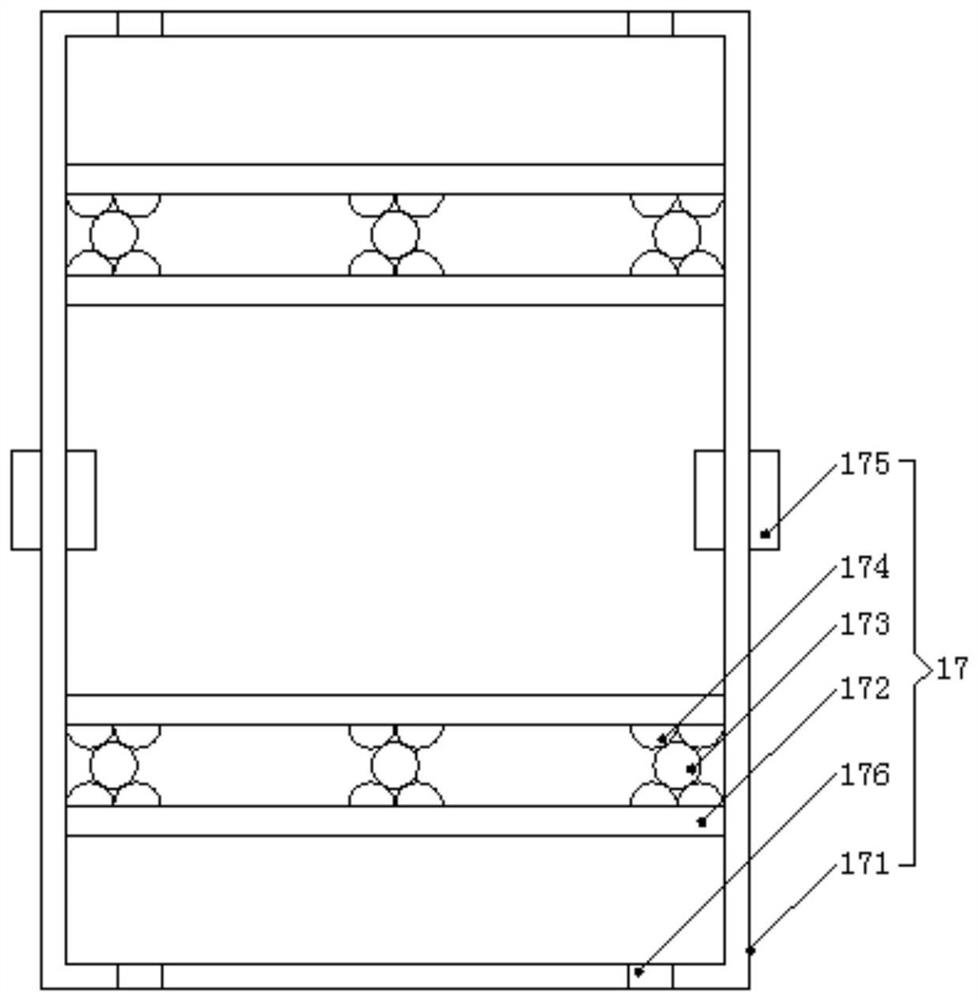

Bending tester

InactiveCN105891008ADoes not affect textureMaterial strength using steady bending forcesForce factorTester device

The invention relates to a bending tester. The bending tester comprises a testing platform, two load supporting mechanisms, an operation shaft rod arranged on the testing platform, a bending testing mold arranged on the upper portion of the operation shaft rod, and a driving mechanism connected with the operation shaft rod and used for driving the operation shaft rod. At least one load supporting mechanism is provided with a clamping structure used for clamping one end of a testing sample, when the driving device drives the bending testing mold to move, the two ends of the testing sample tightly abut against the two load supporting mechanisms respectively, and the testing sample has bending deformation under the action of the bending testing mold. According to the bending tester, no additional external force factor is introduced in the whole testing process, the texture of the surface of the sample cannot be influenced after a bending resistance test, and a true result after the test can be restored.

Owner:HILONG ANTI CORROSION TECH ENG TAICANG

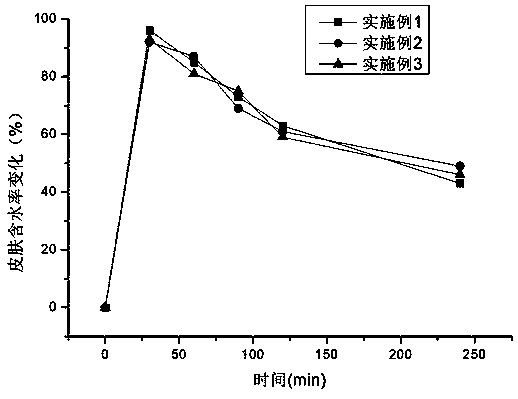

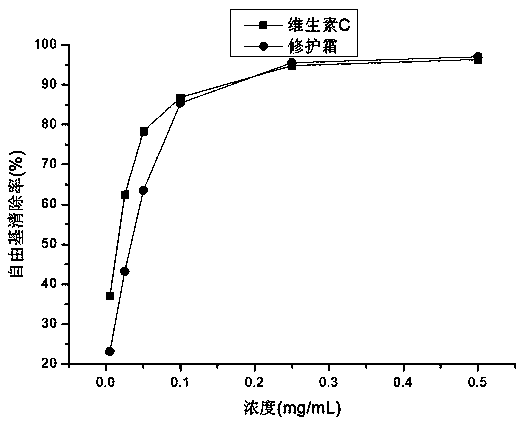

Soothing repair cream and preparation method thereof

PendingCN110840760ADoes not affect textureDoes not affect stabilityCosmetic preparationsToilet preparationsSodium hyaluronateLavandula

The invention discloses soothing repair cream. The soothing repair cream is prepared from 7% of glycerin, 7% of 1,3-butanediol, 0.3% of carbomer, 0.3% of sodium hyaluronate, 1-2% of caprylic capric triglyceride, 1-2% of white beeswax, 1-2% of butyrospermum parktt, 2% of behenyl alcohol, 6-10% of glyceryl monostearate, 2% of 1,2-pentanediol, 0.5-0.7% of triethanolamine, 3-8% of a semen coicis extract, 2-4% of herba portulacae extract, 0.04-0.06% of lavender essential oil and the balance deionized water, wherein the total percentage is 100%. The soothing repair cream with high contents of the semen coicis extract and the herba portulacae extract is capable of effectively scavenging free radicals in human bodies and has a great repair effect on damaged skin.

Owner:JILIN AGRI SCI & TECH COLLEGE

Simulation stone for replacing dry-hang stone

InactiveCN107338927AImprove securityDoes not affect textureCovering/liningsAntifouling/underwater paintsSurface layerStone dust

The invention discloses a simulation stone for replacing a dry-hang stone. The simulation stone comprises a stone surpassing stone system. The stone surpassing stone system comprises a levelling layer, a curing layer, an alkali-resistant layer, a natural stone powder flat layer, a natural stone powder texture layer, a stone color bottom layer, a stone figure middle layer and a waterproof and dustproof surface layer. By arranging the simulation stone for replacing the original dry-hang stone, then the simulation stone is formed through the multiple layers, all the layers of materials are common materials, the construction cost is reduced, the safety of a veneer manufactured through the simulation stone is improved, the texture, attractiveness and durability of the manufactured veneer are not influenced, the simulation stone is suitable for being used for high floors, the using application is enlarged, meanwhile, the simulation stone is also suitable for household usage, is widely applied to public building materials and has a long guarantee period.

Owner:重庆益净贸易有限公司

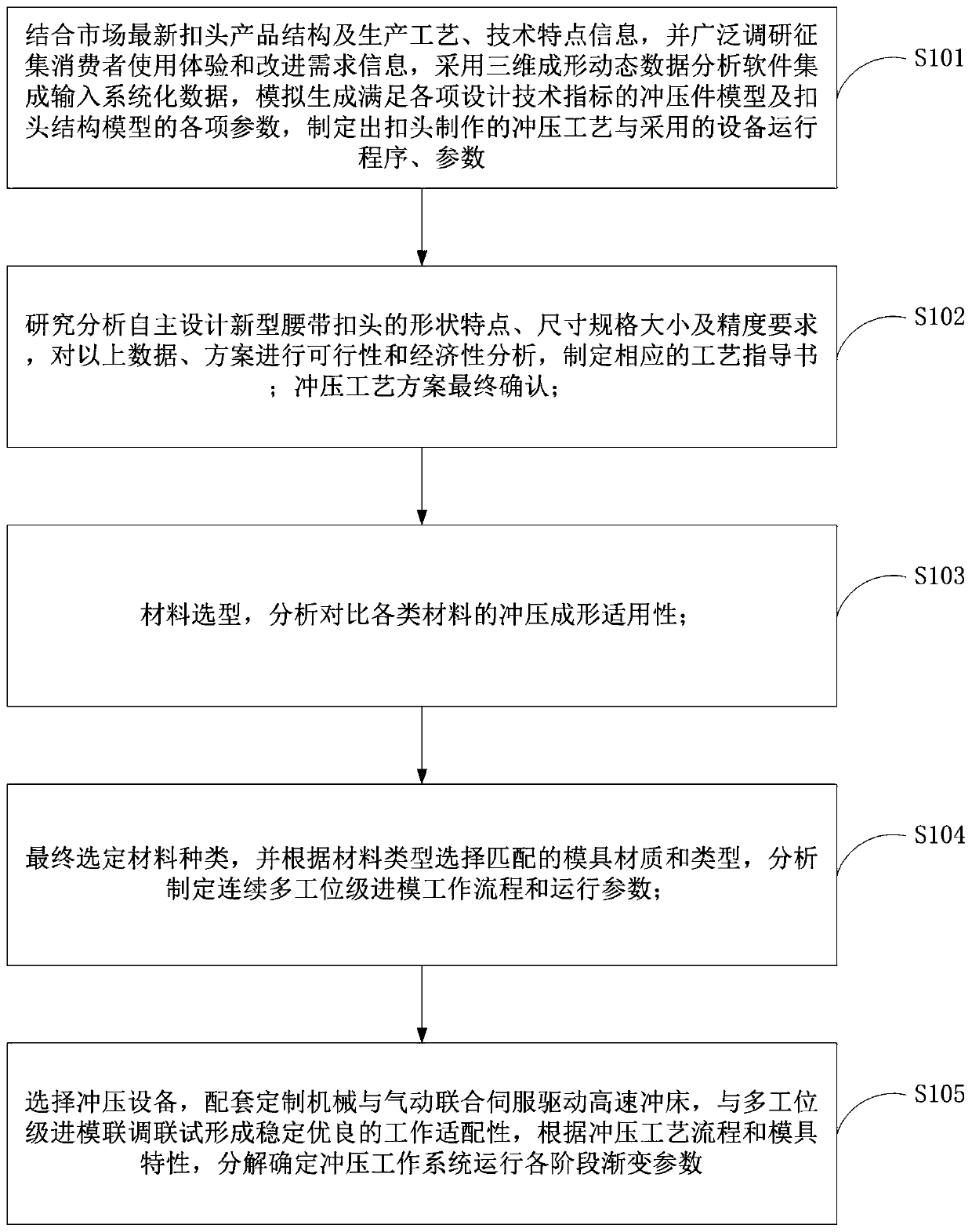

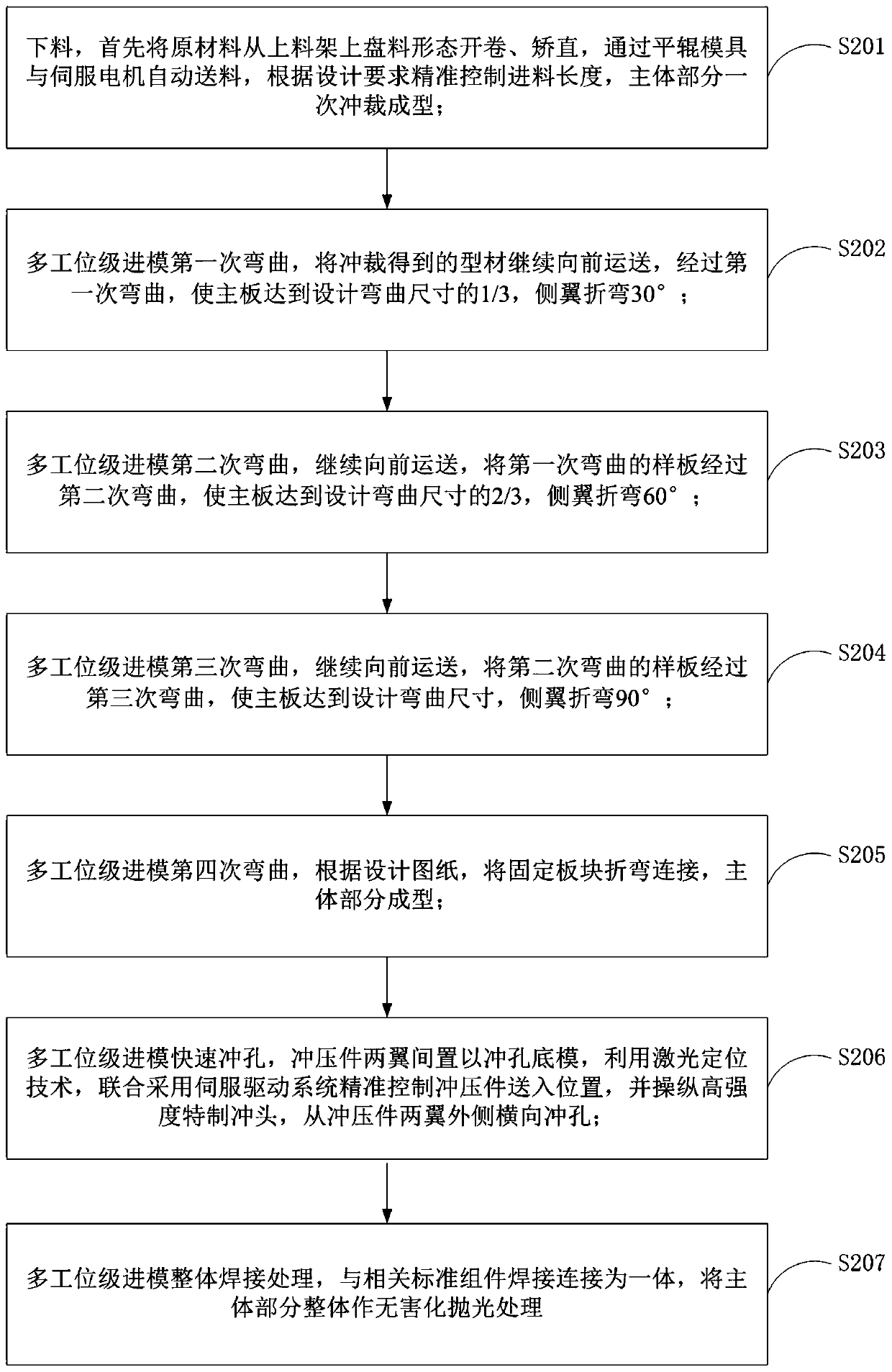

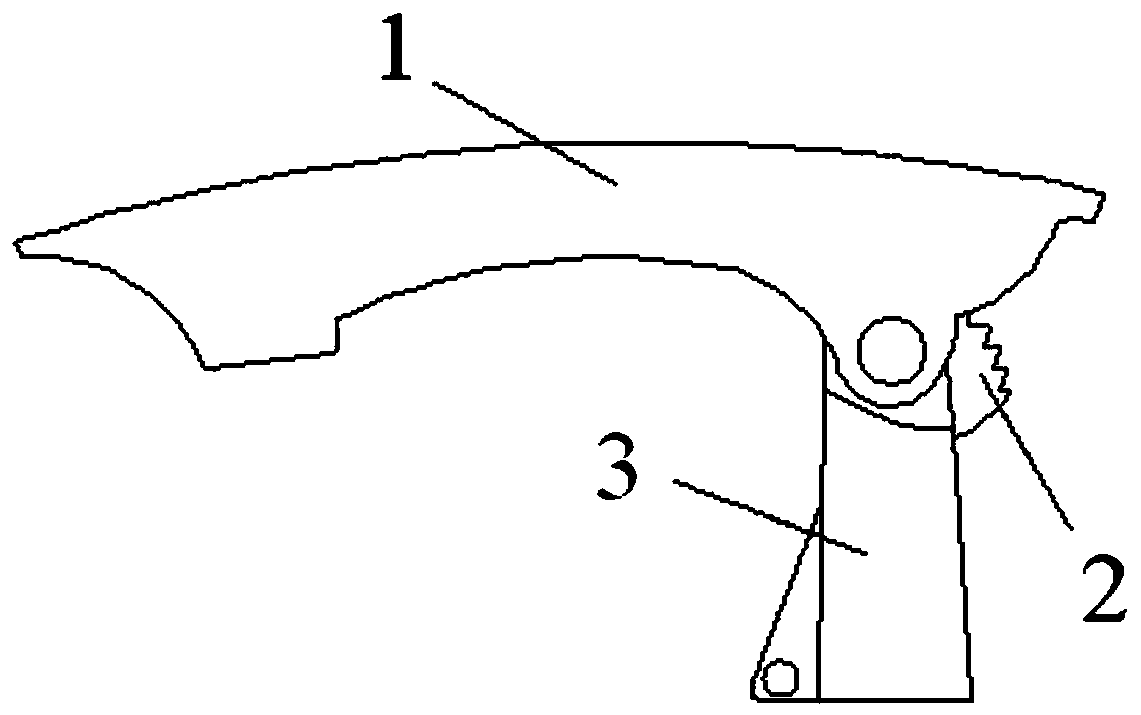

Processing technology and material of rotary asymmetrical self-retractable spring belt buckle

InactiveCN109719198AThe processing technology is reasonable and scientificStamping production is easy to realizeMetal-working feeding devicesPositioning devicesDynamic dataElectroplating

The invention belongs to the technical field of mechanical manufacturing, and discloses a processing technology and material of a rotary asymmetrical self-retractable spring belt buckle. By combiningwith a newest buckle head product structure and production technology on the market and technical characteristic information, and widely researching and collecting using experience and improvement demand information of consumers, three-dimensional forming dynamic data are adopted to analyze software integration input systematic data, all parameters of a stamping part model and a buckle head structure model meeting all design technical indexes are generated by simulation, and a stamping technology of buckle head manufacturing and operating procedures and parameters of adopted equipment are made. According to the processing technology of the rotary asymmetrical self-retractable spring belt buckle, the process is reasonable and scientific, the operating process is simple and controllable, thus stamping production of a belt buckle head is easier to realize, and the elegant appearance is achieved; and technologies such as electroplating of traditional schemes are omitted, the product quality is guaranteed, the product yield is increased, the stamping efficiency can be improved greatly, and the production cost is saved.

Owner:祁同刚

Multimedia projection device with assembled projection plate and use method of multimedia projection device

The invention discloses a multimedia projection device with an assembled projection plate, which belongs to the technical field of multimedia projection. The device comprises a case; a fixed bracket is arranged at the top of the case; a bearing seat is arranged at the top of the fixed bracket; a clamping lantern ring is movably arranged on the inner wall of the bearing seat through a connecting shaft; an outer protective shell is movably arranged on the inner wall of the case; a servo motor is arranged on the outer wall of the rear end of the outer protective shell; the output end of the servomotor is connected with a rotating shaft through a speed reducer; the other end of the rotating shaft extends to the inner side of the outer protective shell and is connected with a driving gear; a sliding rod is movably arranged at the bottom of the fixed bracket; the bottom of the sliding rod is connected with a winding drum. The projection device has the advantages that the projection device is integrated, the installation and the debugging are convenient, the use of the projection device is faster, a projection screen or a projection plate is selectively used, different requirements of users are met, the texture of projected images is not influenced, the integral structure is convenient to operate, and the use is more convenient.

Owner:广西轻舟信息科技有限公司

Method for manufacturing mothproof antistatic pure cashmere fabric and obtained fabric product

InactiveCN110670357AImprove stabilityDoes not affect textureBiochemical treatment with enzymes/microorganismsAnimal fibresCelluloseFiber

The invention relates to a method for manufacturing a mothproof antistatic pure cashmere fabric and an obtained fabric product. The method comprises the steps of S1, selecting pure cashmere fibers; S2, performing mothproof treatment on the cashmere fibers, to be specific, preparing a treatment liquid with methyl cellulose, oxidized sodium alginate with dialdehyde groups, Bacillus thuringiensis andwater; adding the pure cashmere fibers into the treatment solution for impregnation, and carrying out microencapsulation by ultrasound; adding ethanol, mixing well, and allowing to stands and precipitate; centrifugally spin-drying, taking out, and drying the cashmere to obtain mothproof cashmere fibers loaded with Bacillus thuringiensis microcapsules; S3, spinning and twisting; S4, weaving; S5, post-finishing, to be specific, finishing the fabric in a finishing liquid containing an antistatic agent; and S6, drying for setting. Compared with the prior art, the method has the advantages that abiological preparation is introduced into the pure cashmere fabric, so that the pure cashmere fabric has excellent and lasting mothproof effect and is environmentally friendly and harmless to human bodies, has improved quality of the fabric and unaffected texture as the antistatic agent is added for cooperation.

Owner:江苏烨天羊绒科技有限公司

DuiJin artware making method

PendingCN111421995ARich in detailsRich three-dimensional senseDecorative surface effectsOrnamental structuresFiberStructural engineering

The invention relates to a DuiJin artware making method, which solves a problem that a conventional handcraft of DuiJin is poor in stereo perception and texture and is not easy to produce in large scale. A technical scheme comprises steps of blank making, sheet making and shaping of a whole artware; and specifically comprises the following steps: making a blank master mask and a female die according to a pattern, and forming each local blank through injection molding and blank stripping; wrapping the local blank with a fiber material to form a sheet; and adhering the different made sheets on corresponding position of a drawing board according to the pattern to complete the artware. The sheet made according to the invention has a concave and convex curved surface, so that the whole DuiJin artware has more abundant detail and stereo perception; product consistency is excellent, quality is controllable, the artware is more approximate to a designed pattern, and massive and efficient high-quality making of the DuiJin artware is facilitated.

Owner:长治市类通堆锦工艺有限公司

Drawing board with frame

InactiveCN103862995ADoes not affect texturePainting comfortablyOther artistic work equipmentsAdhesiveIndustrial engineering

The invention relates to a drawing board with a frame. Existing drawing boards stick and mount painting paper through paste or other adhesives, and due to the water-solubility of the adhesives, the painting paper loses intrinsic smoothness and permeation performance with quality and texture of a painting being affected, and during the processing process, the painting needs natural air drying and is long in processing time and low in processing efficiency. According to the drawing board with the frame, painting paper is embedded and adhered to a bottom board with the frame, so that the processing period can be greatly shortened, application of production capital can be facilitated, and the cost can be reduced; meanwhile, the drawing board with the frame does not affect the texture of the painting paper and enables a painter to paint comfortably and obtain good painting effects.

Owner:张尹卓

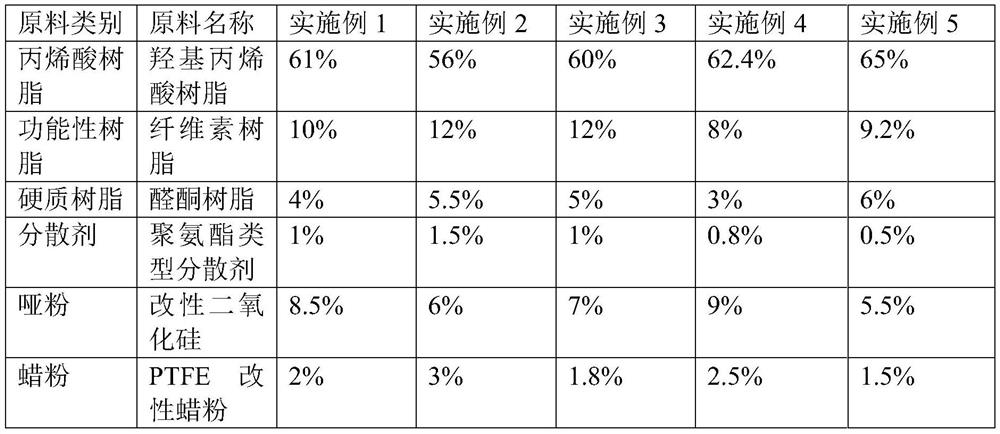

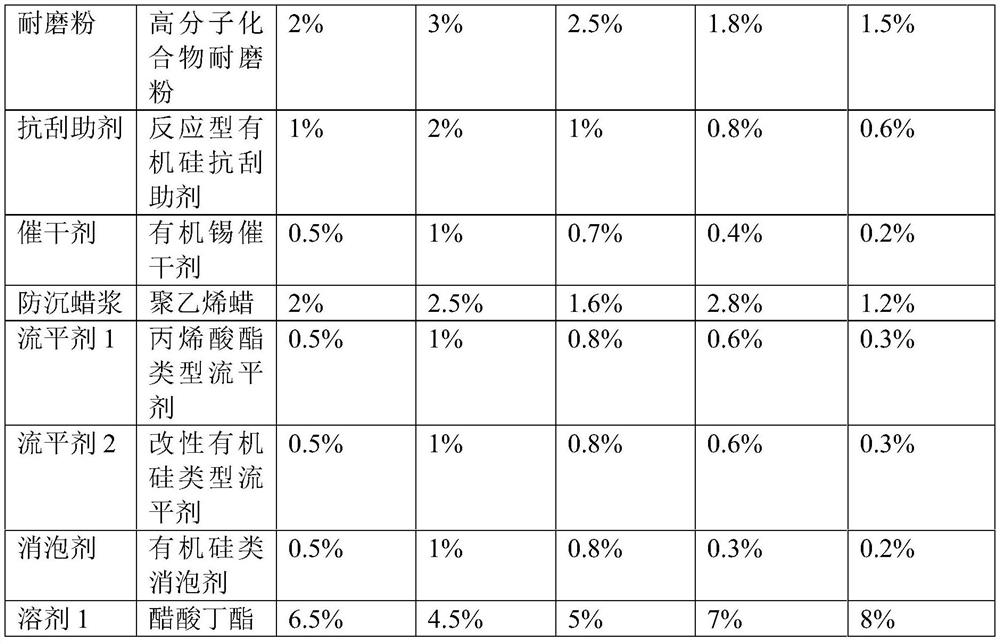

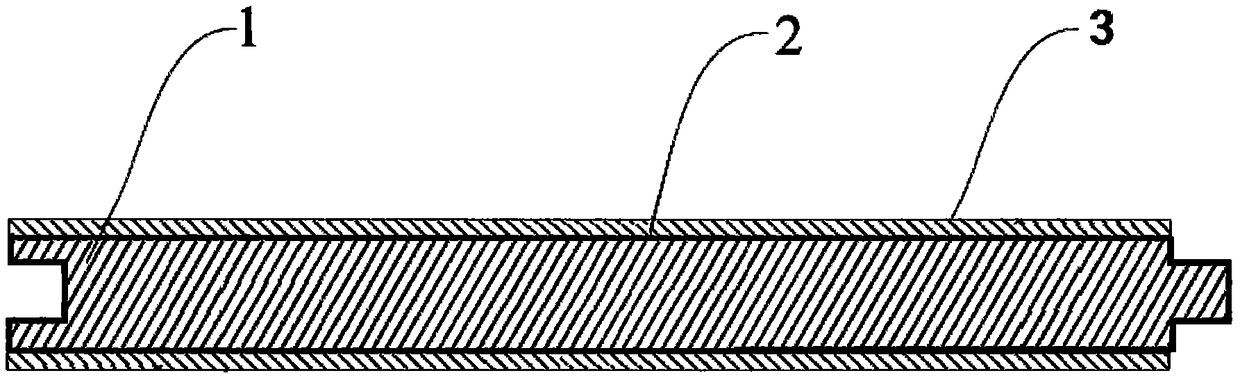

Scratch-resistant wear-resistant matt finish paint for automobile real wood interiors

InactiveCN112812672AReasonable ratioIncrease crosslink densityCellulose coatingsPolyurea/polyurethane coatingsDefoaming AgentsFirming agent

The invention discloses a scratch-resistant wear-resistant matt finish paint for automobile real wood interiors. The scratch-resistant wear-resistant matt finish paint is composed of a main agent and a curing agent according to a ratio of 4: 1. The main agent comprises the following raw materials: 55-65% of acrylic resin, 7-15% of functional resin, 2-6% of hard resin, 0.5-2% of a dispersant, 5-10% of matt powder, 1-3% of wax powder, 1-3% of wear-resistant powder, 0.5-2% of a scratch-resistant auxiliary agent, 0.2-1% of a drier, 1-3% of an anti-settling wax slurry, 0.5-2% of a leveling agent, 0.2-1% of a defoaming agent and 4-8% of a solvent. The curing agent comprises the following raw materials: 39-55% of a solvent, 0.2-1% of a water absorbent and 44-60% of curing agent resin. According to the invention, a material ratio is reasonable, artificial wood grain effect can be achieved on an automobile interior plastic part, good scratch resistance and good wear resistance are provided, and the problems of poor scratch resistance and poor wear resistance of existing finish paint are solved.

Owner:广东安捷伦新材料科技有限公司

Treatment agent with lasting jasmine fragrance for coating surfaces of bamboo weaving handicrafts, and preparation method of treatment agent with lasting jasmine fragrance

The invention relates to the technical field of surface treatment of bamboo weaving handicrafts, in particular to a treatment agent with lasting jasmine fragrance for coating surfaces of bamboo weaving handicrafts, and a preparation method of the treatment agent with lasting jasmine fragrance. The treatment agent is prepared from the following raw materials in parts by weight: 0.001-0.002 part of alanine, 20-30 parts of polyurethane water solution, 4-5 parts of ultra fine powder of diatomaceous earth, 0.001-0.002 part of boric acid, 1-2 part of jasmine essence, 6-10 parts of ethyl alcohol, 1-2 parts of polyethylene glycol 400, and 0.1-0.2 parts of hydrophilic silicone oil. According to the treatment agent disclosed by the invention, the non-toxic transparent polyurethane water solution is used as main coating materials; the jasmine essence solution and the ultra fine powder of diatomaceous earth are mixed and treated by ball milling, so that the jasmine essence which is liable to volatilize is absorbed on the diatomaceous earth; the diatomaceous earth with the jasmine essence uniformly scatters in the polyurethane solution, so that a product has uniform and lasting fragrance; after the surface of the product is coated with the treatment agent, the surface is high in transparency, the color and the texture of the weaved product are not influenced, and the product is non-toxic and harmless; the treatment agent reaches the efficacies of lastingly keeping fragrance, protection and the like.

Owner:ANHUI SHUCHENG HUAZHU IND

Compound bactericide for aquatic products

The invention discloses a compound bactericide for aquatic products. The compound bactericide comprises Chinese pulsatilla root, garlic, folium artemisiae argyi, propolis, bamboo leaf extract, sodiumtripolyphosphate and salt. The compound bactericide for the aquatic products has the advantages that an aquatic product preservative has a simple process and contains traditional Chinese medicine components and antioxidant components, can effectively prolong the preservation time of the aquatic products, does not affect flavors and textures of the aquatic products, and keeps the flavors of the aquatic products to the largest extent.

Owner:太仓苏浏水产有限公司

Solid wood composite floor for geothermal and manufacturing method thereof

The invention relates to a geothermal solid wood composite floor and a manufacturing method thereof. A layer of metal film is arranged between a base material of the solid wood composite floor and a paint layer, and by using excellent heat-conducting property of metal, heat energy of the ground is conducted to the upper surface of the floor by the metal film, so that the heat-conducting property of the wood floor is effectively improved; wood has properties such as humidity absorption, desorption and air shrinkage and humidity expansion, and the metal film is arranged between the base material of the solid wood composite floor and the paint layer; contact between the base material of the solid wood composite floor and air and water molecules is effectively isolated, and water content in the base material of the solid wood composite floor is kept constant; deformation caused by water content of the solid wood floor is effectively solved; the geothermal floor uses the solid wood composite floor as the base material, and the metal film can reduce formaldehyde emission; the thickness of the metal film is set to be 30 nanometers to 50 micrometers; poor heat-conducting property and size stability of the geothermal floor are improved and wood textures are not influenced.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com