Patents

Literature

234 results about "Substantive dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

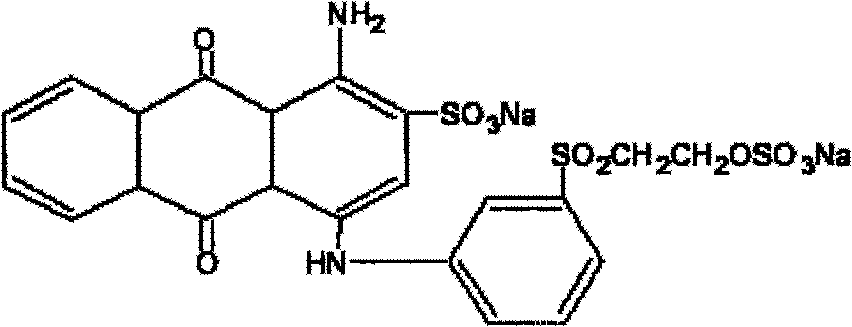

A substantive dye or direct dye is a dye that adheres to its substrate, typically a textile, by non-ionic forces.

Process for altering the appearance of hair using a composition containing direct dyes and non-hydroxide bases

InactiveUS20130167862A1Reducing curl and frizzinessCosmetic preparationsHair removalPolymer scienceSubstantive dye

A process for altering the appearance of hair, the process comprising the steps of (a) providing a composition for dyeing and reducing curl and / or frizziness of hair, said composition comprising, in a cosmetically acceptable carrier: (i) at least one non-hydroxide base; (ii) at least one protein denaturant different from (a)(ii); (iii) at least one direct dye; (iv) at least one thickening agent; (v) optionally, at least one alkoxysilane comprising at least one solubilizing functional group; and (vi) optionally, at least one fatty substance; (b) contacting the hair with the composition in (a) to form treated hair; (c) smoothing the treated hair using a combination of heat and means for physically smoothing hair to form smoothed hair; (d) optionally, shampooing the smoothed hair; and (e) rinsing the smoothed hair.

Owner:LOREAL SA

Laundry Treatment Composition

InactiveUS20080096789A1Detergent dyesOrganic/inorganic per-compounds compounding agentsLaundryAcid dye

Owner:CONOPCO INC D B A UNILEVER

Rare earth mordant dyeing method for kapok fiber and textile thereof

InactiveCN102561063AImprove dyeing effectPromote infectionBleaching apparatusDyeing processState of artKapok fiber

The invention relates to a rare earth mordant dyeing method for kapok fibers and textiles thereof. The method comprises the following steps: pre-treating kapok textile so as to remove some waxy xubstances, impurities and the like on the surface of the kapok fiber and achieve certain whiteness; and then adding a complexing rare earth mordant into a dye bath of the pretreated kapok textile, and mordant dyeing the kapok textile. Compared with the prior art, according to the dyeing method of the invention, the dyeing of the kapok fibers and textiles thereof is not limited to direct dyes and can also be used for other anionic dyes such as reactive dyes and the like, and the problems of low rate of dye-uptake, poor level-dyeing property, poor deep-color dyeing effect, poor dyeing fastness and the like are overcome.

Owner:SHANGHAI UNIV OF ENG SCI

Fabric treatment composition

InactiveUS6726731B2Cationic surface-active compoundsNon-ionic surface-active compoundsMedicineActive agent

The present invention relates to a fabric treatment composition comprising surfactant, fabric substantive dye and dye auxiliary agent. The fabric treatment composition of the invention can be used to change, refresh or maintain the color of fabric.

Owner:PROCTER & GAMBLE CO

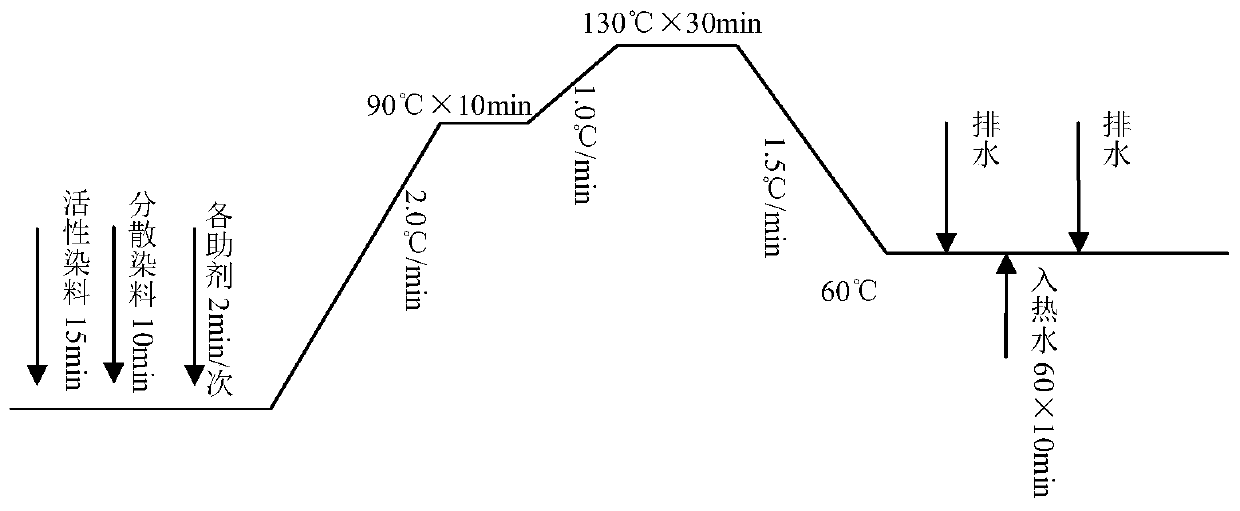

Polyester fiber cospinning textile used dispersion and direct dye alkali bath dyeing method

The invention, belonging to printing and dyeing area for silk cloth, relates to a dyestuff alkali-washing dyeing method for polyester mixed textile dispersedly and directly. Said method is that under the condition of 7<PH<9 alkali, direct and dispersal dye of alkali resistivity are use as dyeing for polyester textile. Under the lower alkali condition, polyester fibre after dyeing can avoid shortcoming of a mass of flaw generated by lixiviation of slurry, oils and other catabolite in acidic bath. It can conquer damnification of dyeing and fibre under the circumstance of high temperature, pressure and alkali. The invention can conserve energy, decrease cost and improve production efficiency.

Owner:FUJIAN CHARME TEXTILE

Fabric treatment composition

InactiveUS20020108184A1Cationic surface-active compoundsNon-ionic surface-active compoundsMedicineActive agent

The present invention relates to a fabric treatment composition comprising surfactant, fabric substantive dye and dye auxiliary agent. The fabric treatment composition of the invention can be used to change, refresh or maintain the color of fabric.

Owner:THE PROCTER & GAMBLE COMPANY

Hair dye composition

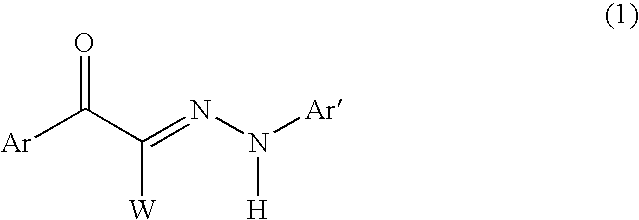

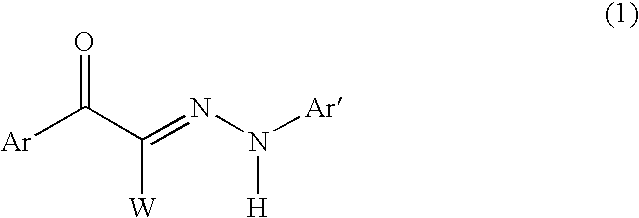

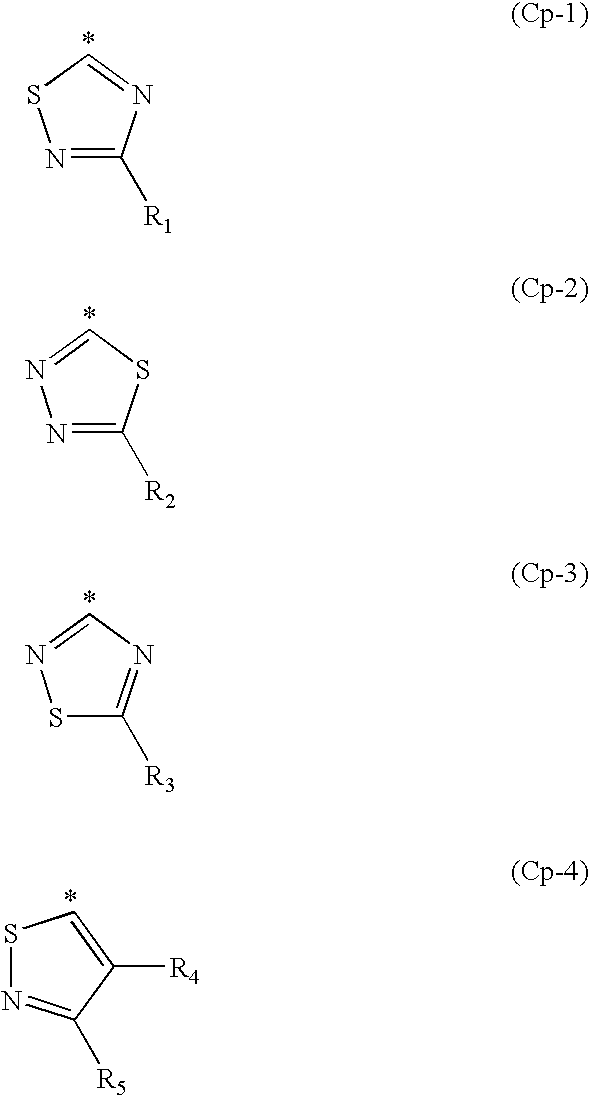

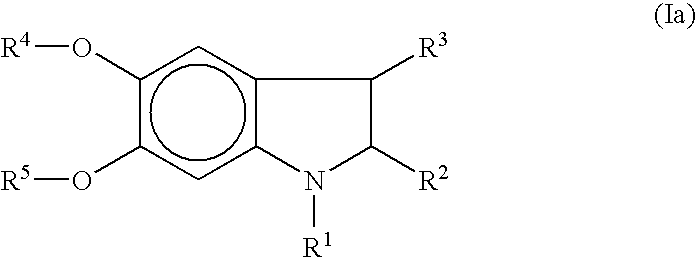

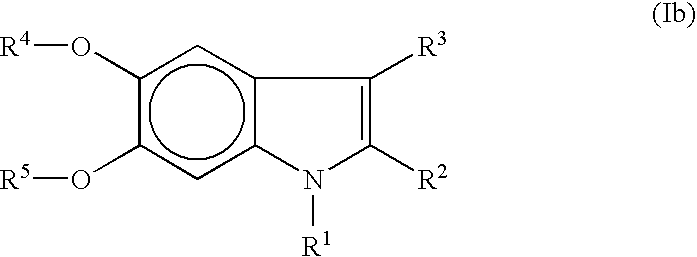

Provided is a hair dye composition containing a dissociative direct dye (1):(wherein Ar represents an aromatic group or heterocyclic aromatic group which may have a substituent, Ar′ represents an aromatic group which may be substituted by an alkyl group or an electron drawing group, or a specific heterocyclic aromatic group, and W represents an electron drawing group); or salt thereof.

Owner:KAO CORP +1

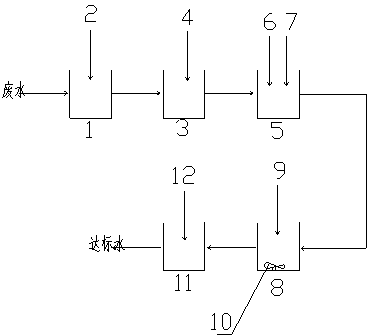

Printing and dyeing wastewater treatment process

InactiveCN104071920ARapid responseHigh decolorization rateMultistage water/sewage treatmentFiltrationDyeing wastewater

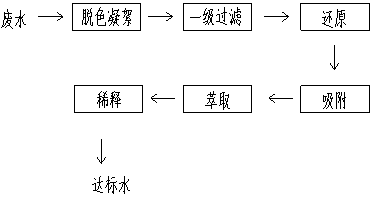

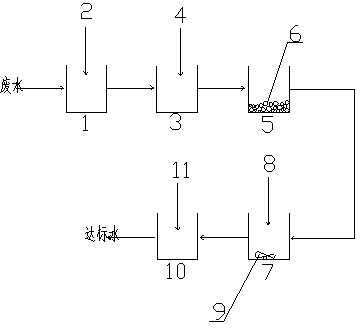

The invention discloses a printing and dyeing wastewater treatment process which comprises the following steps: adding a filter aid into wastewater, flocculating the wastewater, filtering to remove suspended matters from the wastewater, and reserving small suspended matters with colors and dissolved matters; adding a reducing decolorizer into the wastewater subjected to primary filtration for treating dyeing wastewater of direct dyes, so that dye molecules in the wastewater form a reductive degradation product; enabling the wastewater containing the reductive degradation product to pass through an adsorption material for adsorbing the reductive degradation product or other materials in the wastewater to the solid surface due to the adsorption effect; pouring a non-water-soluble organic solvent into the wastewater subjected to adsorption, and vibrating the solvent and the wastewater together, wherein the water phase is colorless when two phases are separated, and the dyes are accumulated on the upper-layer organic phase; and pouring a certain quantity of clean water into the wastewater subjected to extraction for diluting the wastewater. The process has the advantages that the pH value of the wastewater does not need to be adjusted, the effect is good, and the cost is low.

Owner:HUBEI CHUANDONG ENVIRONMENTAL ENERGY DEV CO LTD

Two-part oxidative hair dye composition

Provided is a two-part oxidative hair dye composition having a first agent containing an alkali agent and an oxidation dye intermediate or a direct dye and a second agent containing an oxidizing agent, wherein at least one of the first and second agents contains both of Components (A) and (B):(A) an iso-fatty acid or an anteiso-fatty acid having from 19 to 30 carbon atoms, or a salt thereof, and(B) a quaternary cationic surfactant.

Owner:KAO CORP

Agent and method for oxidative hair coloring which are gentle on keratin fibers

Coloring agents for keratin fibers, in particular for human hair, include—based on their weight—at least one compound selected from the group of oxidation dye precursors, substantive dyes and mixtures thereof, 0.1 to 5% by weight dicarboxylic acid(s) having 2 to 10 carbon atoms and / or salt(s) of said acid(s), 20 to 95% by weight water and less than 0.1% by weight peroxide compound(s), result in oxidative coloring agents with improved fiber protection.

Owner:HENKEL KGAA

Soluble solid hair coloring article

A soluble solid hair coloring article having zwitterionic direct dye and one or more soluble porous solids containing nonionic surfactant, cationic surfactant, or a mixture thereof, such that the one or more soluble porous solids have a density of from about 0.03 g / cm3 to about 0.15 g / cm3; and methods of applying the soluble solid hair coloring article to hair.

Owner:THE PROCTER & GAMBLE COMPANY

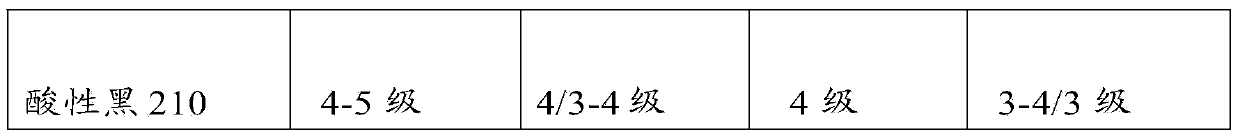

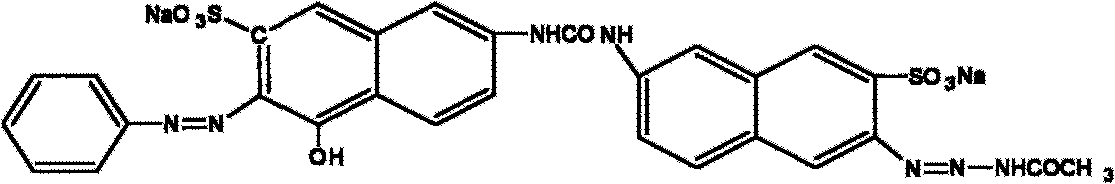

Leather dye and preparing method thereof

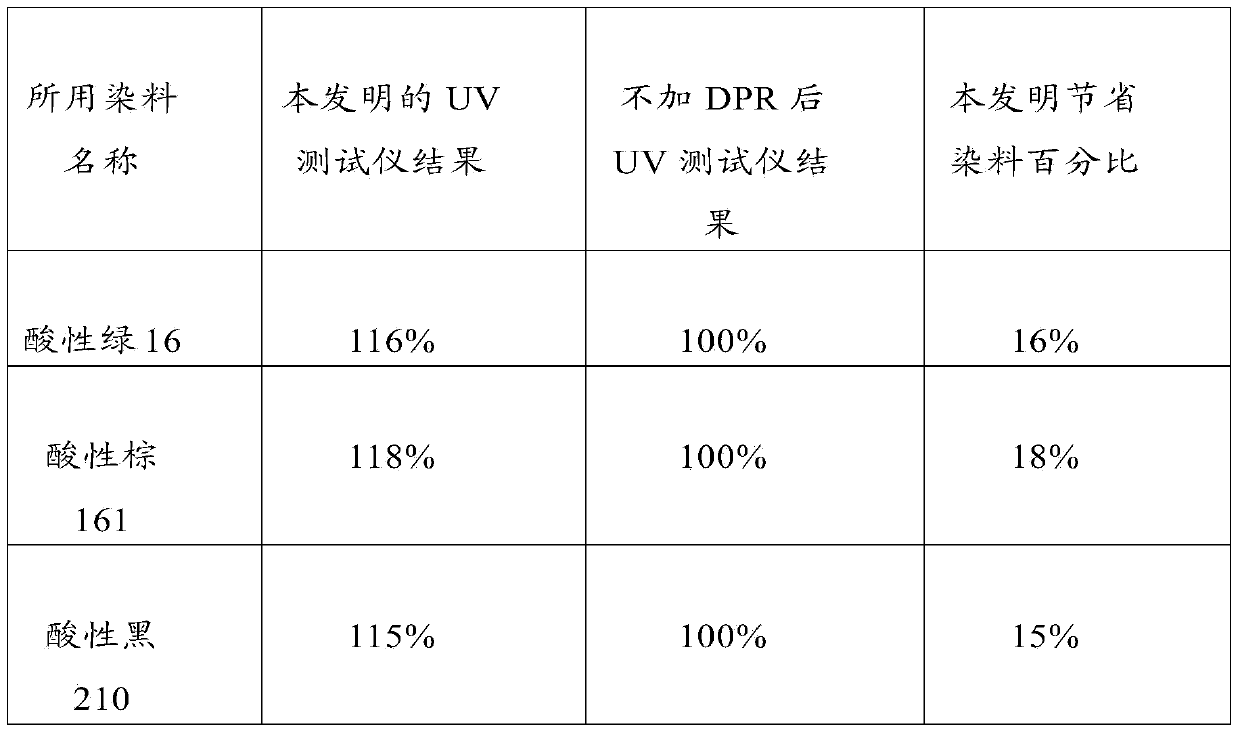

ActiveCN104004383AFirmness level increasedReduce dosageOrganic dyesDyeing processAcid dyeSubstantive dye

The invention relates to the field of leather dying, in particular to leather dye and a preparing method of the leather dye. The leather dye comprises, by weight, 10-90 parts of dye and 2-20 parts of bipolymer of acrylamide and acrylic acid. The dye is acid dye containing a sulfonic group or direct dye containing a sulfonic group. According to the leather dye, the bipolymer of the acrylamide and the acrylic acid is added to serve as a dye-fixing agent, so that the firmness of the dye is increased; compared with common leather dye without the dye-fixing agent, the firmness level of the leather dye under the circumstance of airing or dry shining or wet shining is remarkably improved; in addition, when the color of the leather dye reaches the same degree, the use amount of the leather dye can be reduced at least by 15% compared with the common leather dye without the dye-fixing agent, and thus the leather dye further has the effect of increasing the dark degree.

Owner:BEIJING FANBO CHEM

Digital printing ink, dyestuff refining method thereof and digital printing method

The invention relates to a digital stamping ink, method of dyestuff refining and method of digital stamping, wherein the digital stamping ink dyeing raw material is refined direct dyes comprising direct pigment yellow 5GL, direct sun-proof fluorescein 7GFF, direct pigment red F3B, direct pigment direct turquoise blue GL, direct pigment black G, or direct pigment black Ex. The process for refining direct dyes comprises, dissolving in organic solvent, filtering and rouging, removing organic solvent. The digital stamping process comprises the steps of, pretreating the textile materials, stamping using digital stamping machine, post-treating the textile materials.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

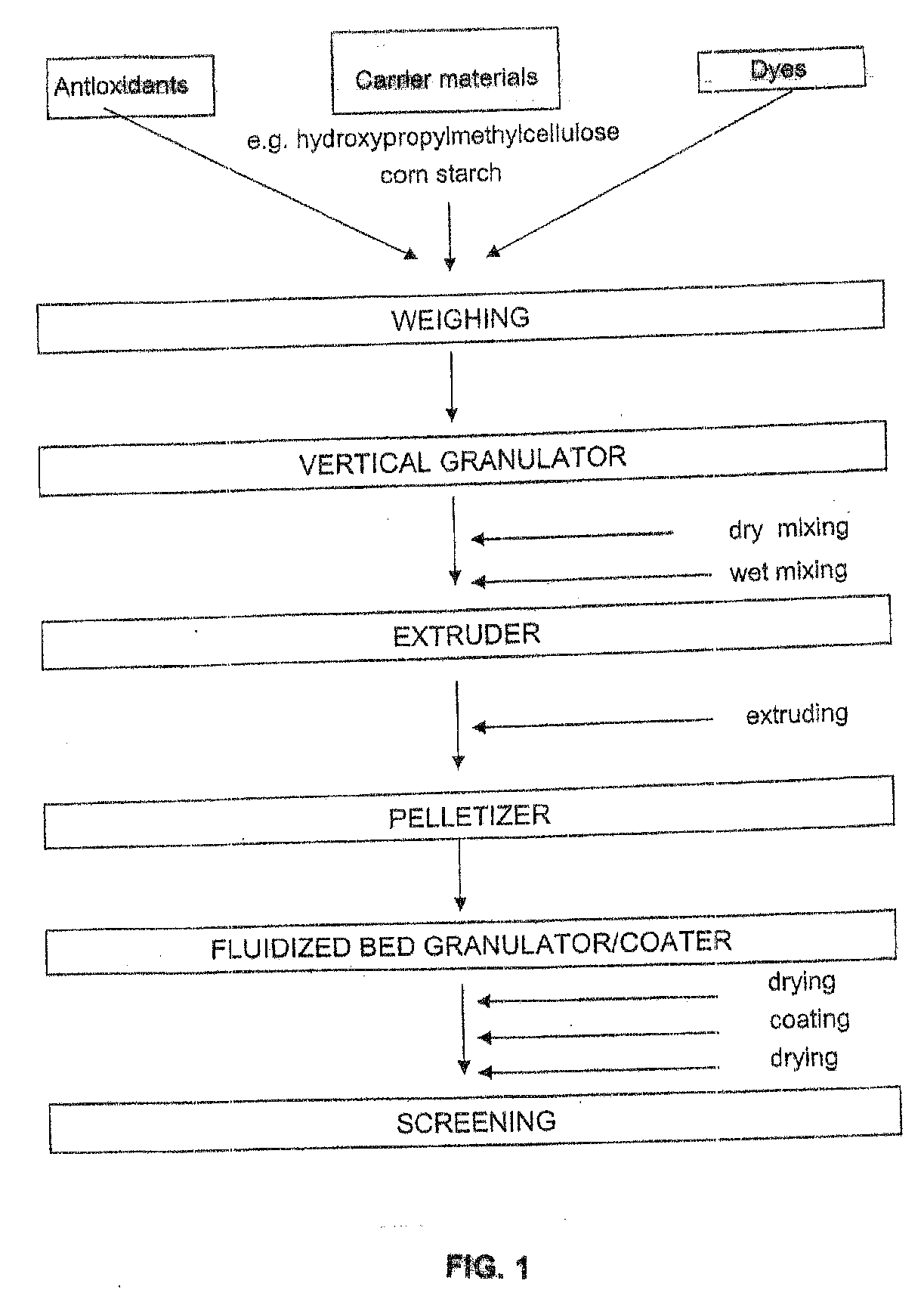

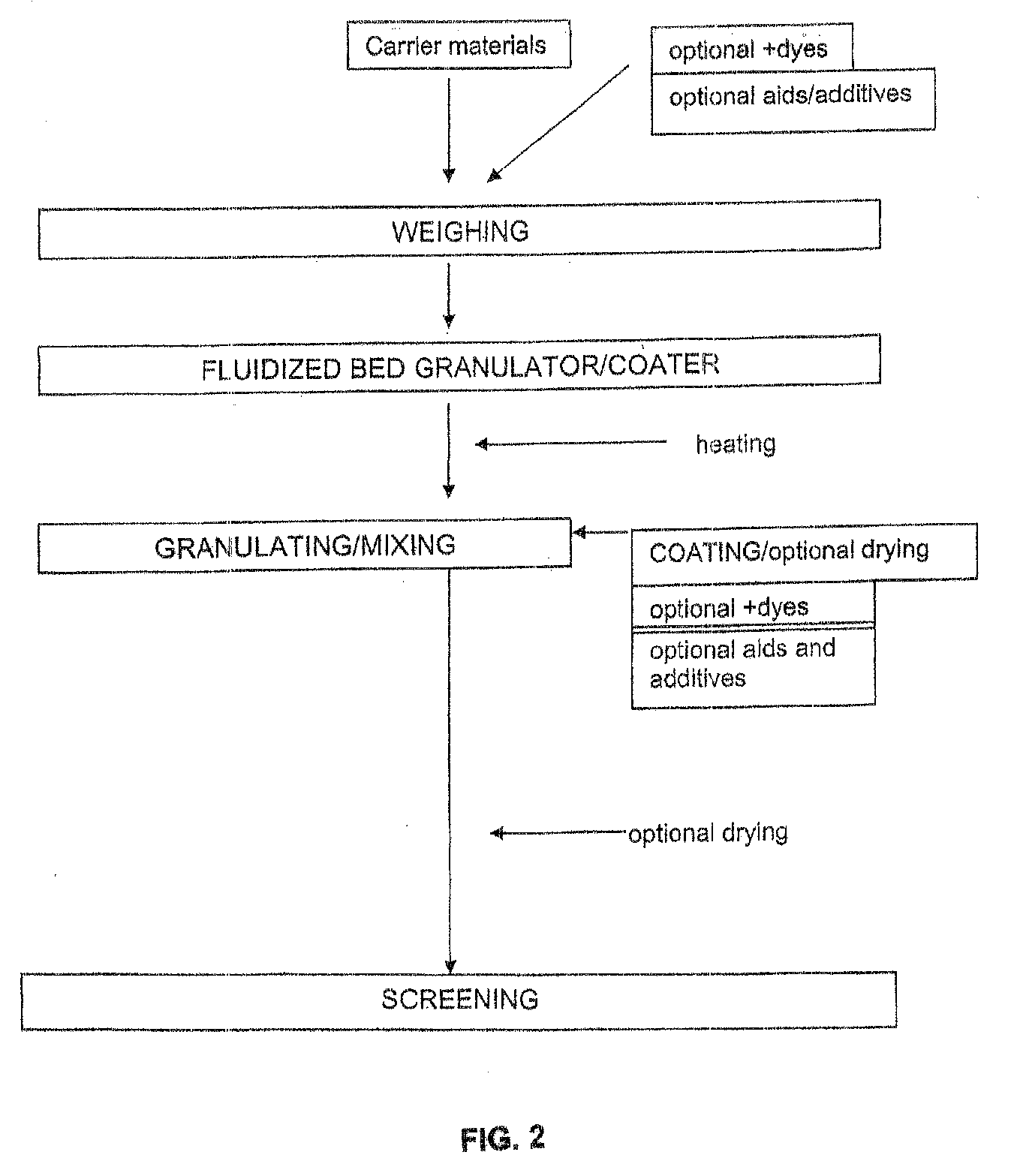

Dye-containing pellets for coloring keratin fibers

ActiveUS20090056039A1Good dosabilityGood effectCosmetic preparationsHair cosmeticsFiberWater dispersible

Owner:WELLA INT OPERATIONS SWITZERLAND SARL

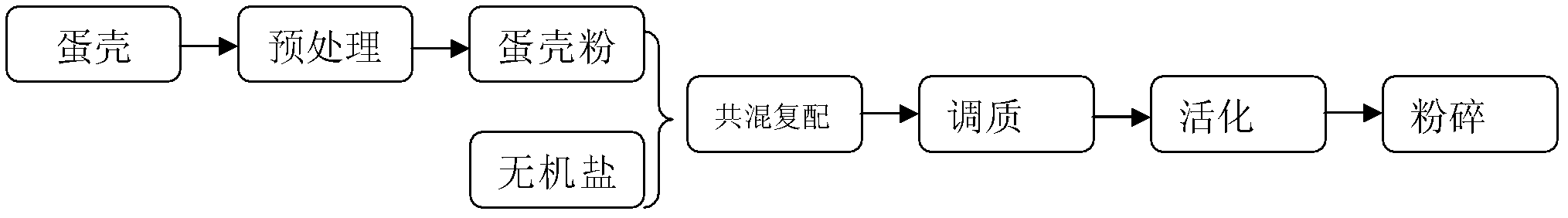

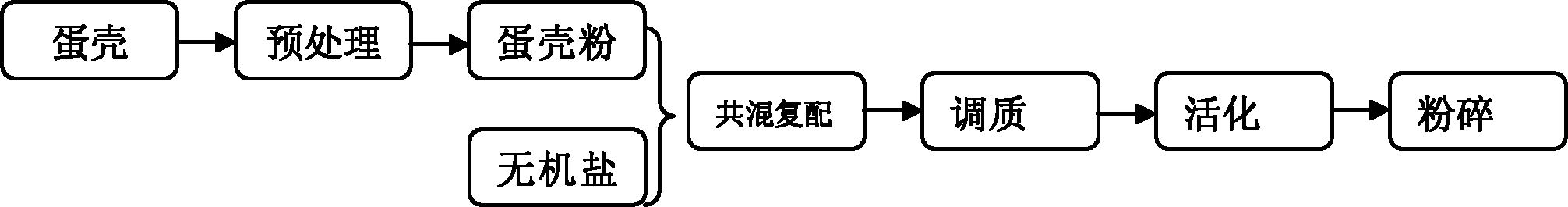

Method for preparing printing dye adsorbent by taking eggshells as matrix and treatment method

ActiveCN102671630AThe process is simple and easy to controlRealize clean and harmless productionOther chemical processesWaste water treatment from textile industryWater qualityWater soluble

The invention relates to a method for preparing a printing dye adsorbent by taking eggshells as a matrix and a treatment method. The method comprises the following steps of: crushing the pretreated eggshells, treating by using a diluted alkali NaOH or KOH solution for 2 hours, cleaning by using clear water to remove alkali liquor, and drying at the temperature of 80 DEG C for 2 to 5 hours to obtain eggshell powder; and putting the eggshell powder, sodium silicate and aluminum sulfate in a mixer and mixing to obtain a mixture, regulating the pH value of the mixture, putting the mixture in a drying oven and drying at the temperature of between 100 and 1,000 DEG C for 2 to 5 hours, cooling and crushing to obtain a treating agent for printing and dyeing wastewater. According to the treatment method, the addition amount of the printing dye adsorbent is 0.5 to 5 g / L, and the printing and dyeing wastewater is treated by the printing dye adsorbent at the temperature of between 10 and 40 DEG Cfor over 20 minutes. According to the method, the discarded eggshells are taken as main raw materials, so the production cost is low; a heating activating treatment process is adopted, the process issimple and controllable, and waste gas, wastewater and industrial residues are not discharged in the production process; and water-soluble dyes in the printing and dyeing wastewater are adsorbed fully under the adsorption action of the discarded eggshells, the addition amount is little, the decoloration rate of alkaline dyes is over 90 percent, and the decoloration rate of direct dyes is over 80 percent, so that the chroma of the wastewater is reduced effectively, and water quality is improved.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

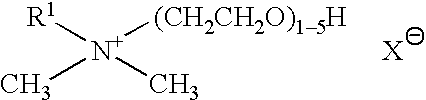

Hair conditioning composition comprising amine-type cationic surfactant and direct dye

ActiveUS20080311068A1Good colorInhibit coloringCosmetic preparationsHair removalColored hairActive agent

Disclosed is a hair conditioning composition comprising by weight: (a) from about 0.2% to about 10% of a cationic surfactant which is a salt of: (i) primary, secondary, and tertiary amines wherein the amines have one long alkyl or alkenyl group of from about 20 to about 24 carbon atoms; and (ii) acids such as 1-glutamic acid and lactic acid; (b) from about 1% to about 15% of a high melting point fatty compound; (c) from about 0.00005% to about 0.5% of a direct dye; and (d) an aqueous carrier. The composition of the present invention provide coloring benefits especially color enhancing and / or preventing color fade of colored hair, while providing improved conditioning benefits.

Owner:THE PROCTER & GAMBLE COMPANY

Method for dyeing and/or printing textile material

The invention relates to a method for dyeing and / or printing textile material containing non-split and / or at least partially split micro-fibres and / or micro-filaments, composed of at least one polyamide component and optionally at least one additional polymer component. According to said method, the textile material is treated with formic acid and is dyed and / or printed using at least one dye, selected from the group containing anionic acidic dyes, metal complex dyes, reactive dyes, direct dyes and cationic dyes.

Owner:CARL FREUDENBERG KG

Preparation and application of colloidal sol dyeing liquor

The invention discloses a method for preparing a sol dyeing solution and an application of the sol dyeing solution in dyeing of a textile, belonging to the spinning chemical technical field. The method directly adopts a dye or an active dye, a precursor, a coupling agent, a solvent, and a catalyst to prepare the sol dyeing solution. The dyeing by the method has simple technique, does not need the independent fixing agent to perform the fixing process, has small pollution and effectively increases the dyeing depth of the textile.

Owner:JIANGNAN UNIV

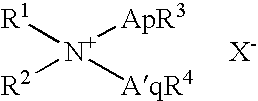

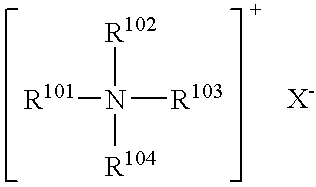

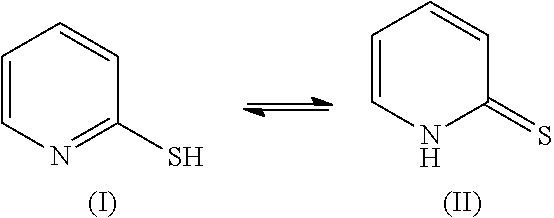

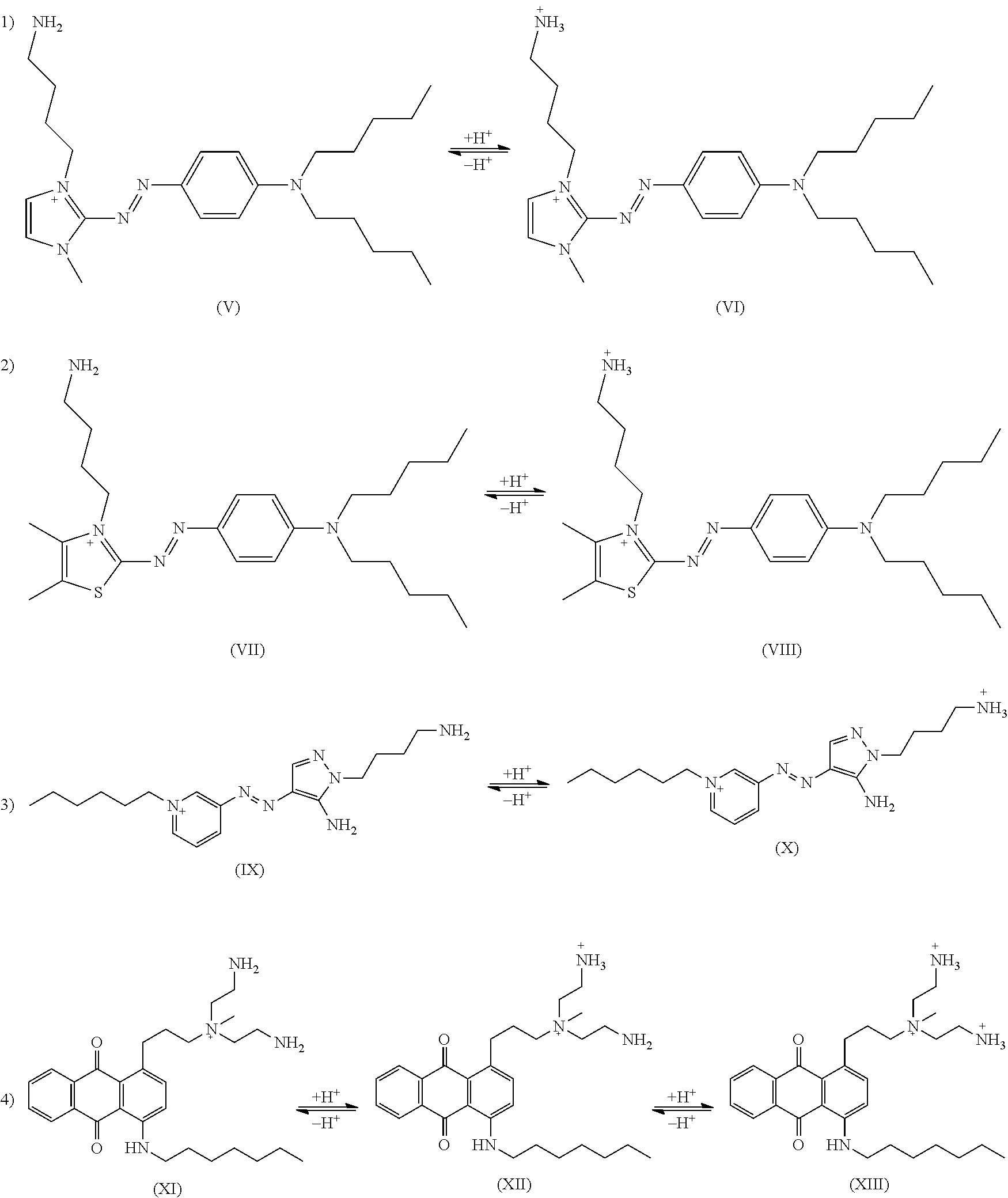

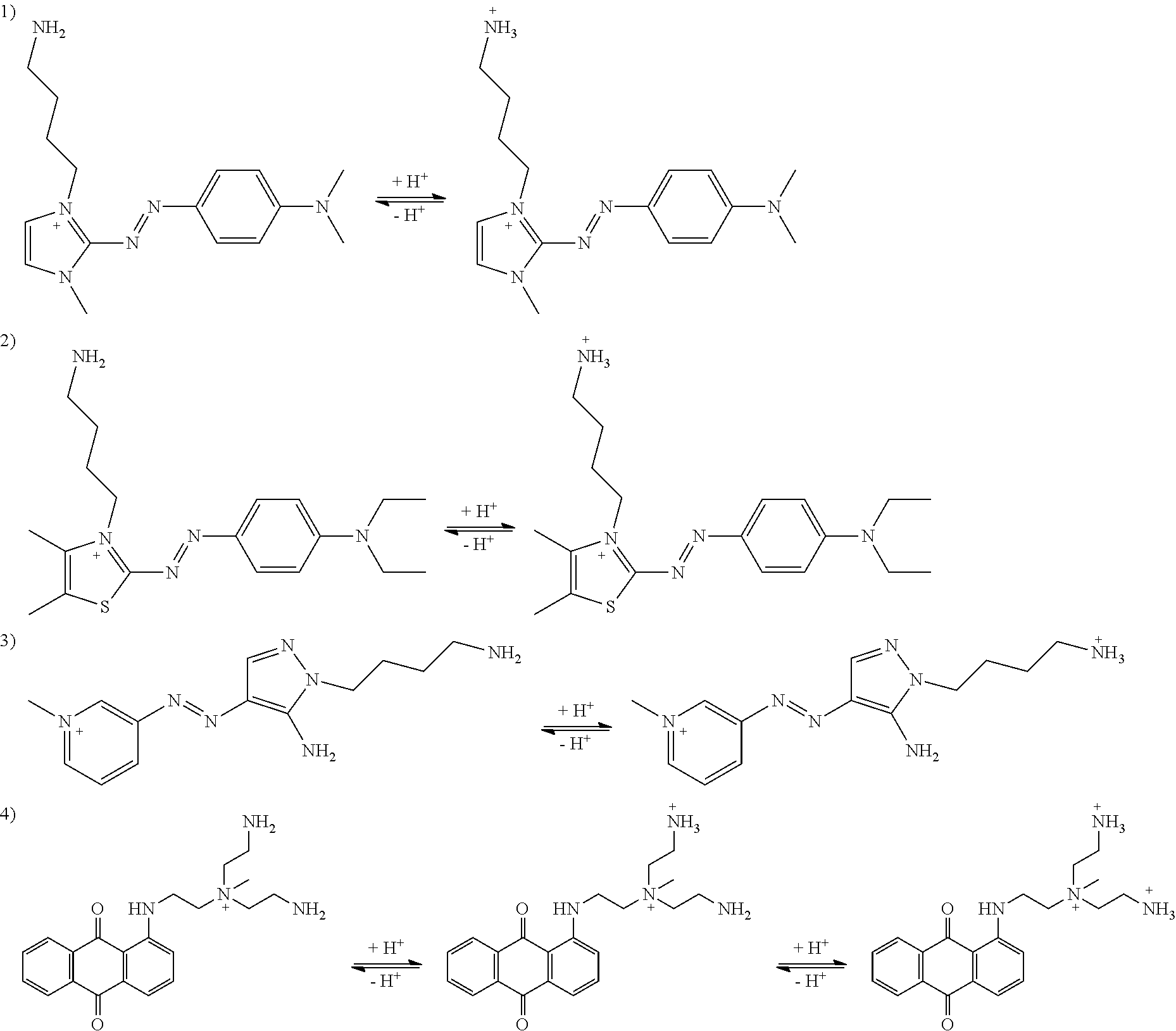

Method of Coloring Hair with Direct Dye Compounds

Described herein is a method of dyeing the hair. The method includes applying to the hair a hair color composition including one or more direct dye compounds and rinsing the hair with water. The one or more direct dye compounds each include a chromophore, one or two permanent cations, one to four incipient cations, and one or more hydrophobic moieties. The incipient cations are pendant to the core structure and are neutral. The one or more direct dye compounds enter the hair shaft after the hair color composition is applied to the hair. The hair color composition has a pH of from about 7 to about 11. The pH of the hair after rinsing is from about 3.5 to about 6. The rinsing of the hair causes one or more of the one to four incipient cations to change from neutral to positively charged inside of the hair shaft.

Owner:NOXELL CORP

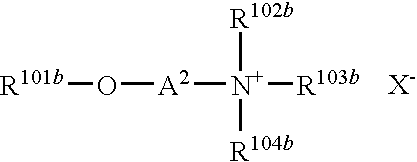

Composition comprising a hydrophobic dye, a particular organic and/or mineral alkaline agent, a particular compound (i) and a particular organic compound (II), and dyeing use thereof

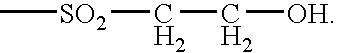

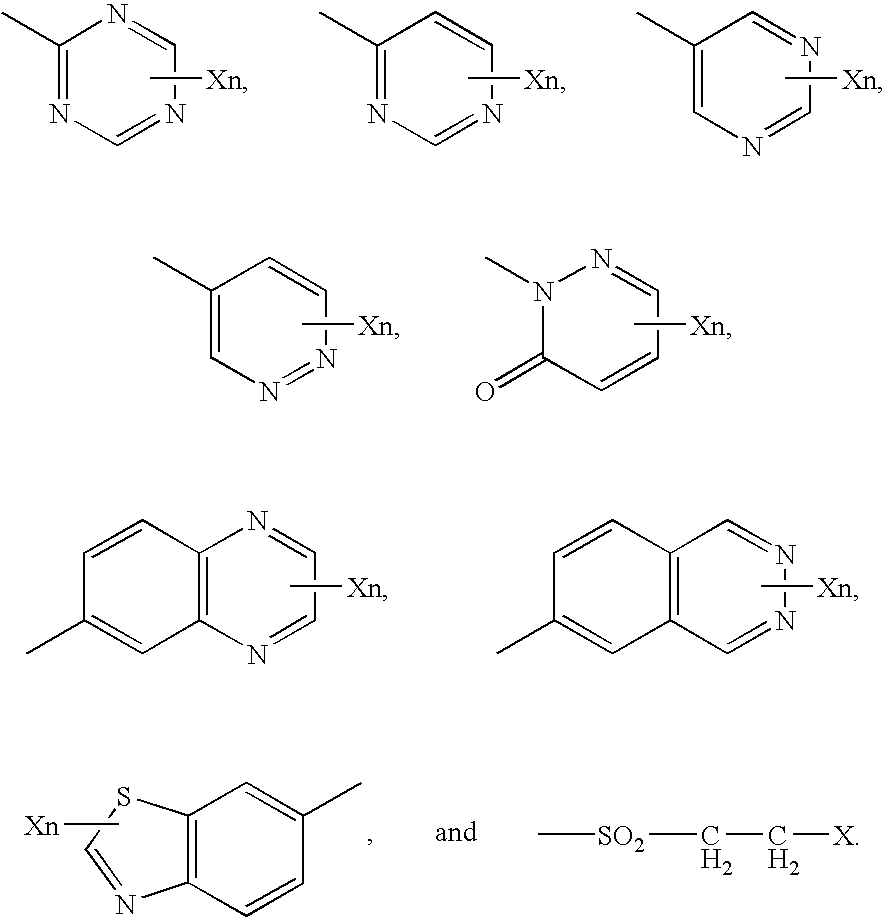

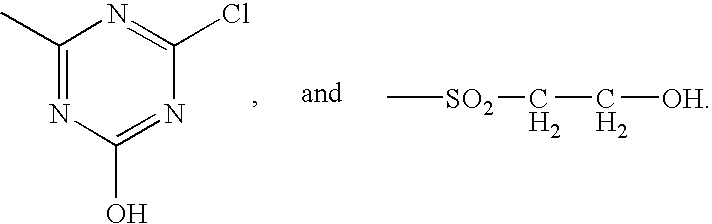

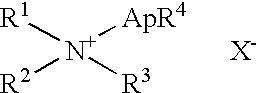

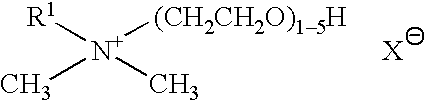

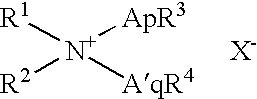

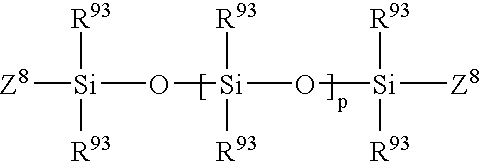

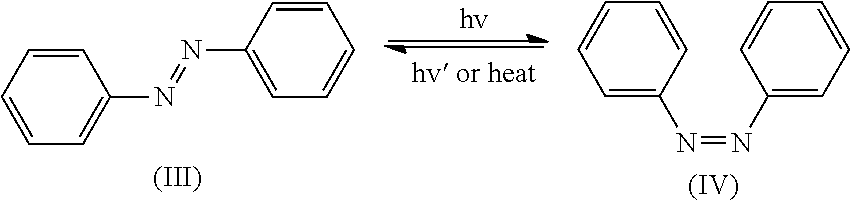

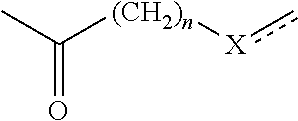

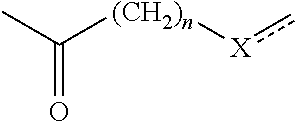

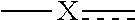

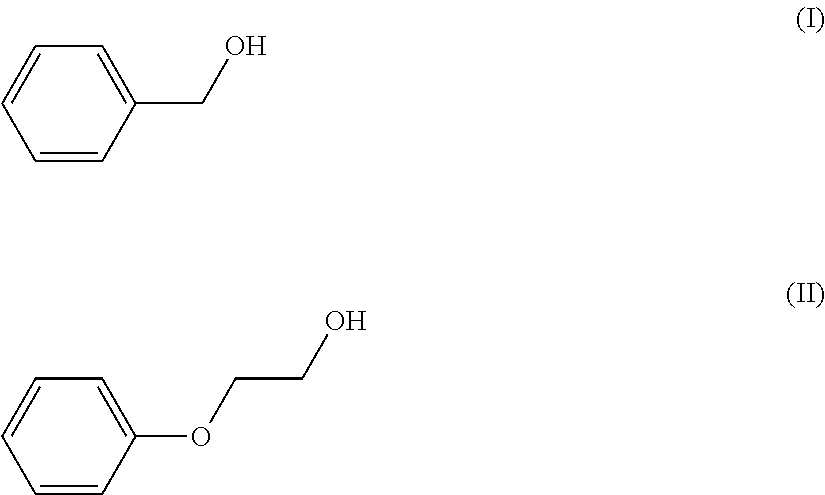

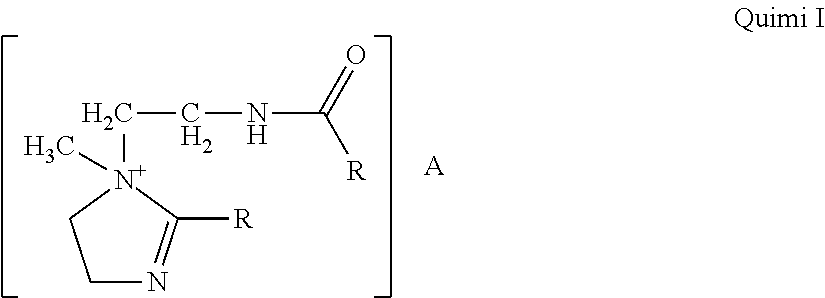

Composition comprising a hydrophobic dye, a particular organic and / or mineral alkaline agent, a particular compound (I) and a particular organic compound (II), and dyeing use thereof. The present invention relates to a dye composition comprising one or more hydrophobic direct dyes with a log P of greater than or equal to 2, one or more organic alkaline agents, and / or one or more mineral alkaline agents chosen from carbonates, hydrogen carbonates, sodium hydroxide and potassium hydroxide, and mixtures thereof, one or more compounds (I) comprising in their structure a sequence:and one or more organic compounds (II) with a Hansen solubility parameter δH of less than or equal to 16 MPa1 / 2 and with a molecular weight of less than 250 g / mol. The invention also relates to a dyeing process that consists in applying such a composition to keratin fibers.

Owner:LOREAL SA

Hair dye including direct dyes and inorganic buffer systems

ActiveUS20170239152A1High fastnessGood gray coverageCosmetic preparationsHair cosmeticsInorganic saltsFiber

Sn agent for coloring keratinic fibers, particularly human hairs, including in a cosmetic carrier(a) at least one direct dye, and(b) an inorganic buffer system comprising at least one inorganic acid (b1) and at least one inorganic salt of this acid or these acids (b2), and(c) water.Further, a cosmetic product includes the aforementioned colorant which is packaged in a pressurized aerosol container, with the pressurized aerosol container possessing an aerosol dispensing device with spray valve.Finally, a method for increasing the nuance stability of colorants includes adding the aforementioned ingredients (a), (b), and (c) in the agent.

Owner:HENKEL KGAA

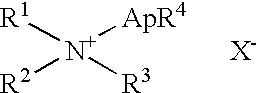

Compositions for Dyeing Hair with Cationic Direct Dyes

Described herein is a hair color composition for dyeing the hair. The hair color composition includes one or more direct dye compounds and one or more additional ingredients. The one or more direct dye compounds each include a chromophore, one or two permanent cations, and one to four incipient cations. The one to four incipient cations are pendant to the core structure and are neutral. The one or more direct dye compounds enter the hair shaft after the hair color composition is applied to the hair. The hair color composition has a pH of from about 7 to about 11.

Owner:NOXELL CORP

Conditioning dyeing agent for keratinous fibers

ActiveUS20140196222A1Good effectImprove combabilityCosmetic preparationsHair cosmeticsFiberSubstantive dye

Owner:HENKEL KGAA

Ink composition and method for producing dyed polyamide-based fiber

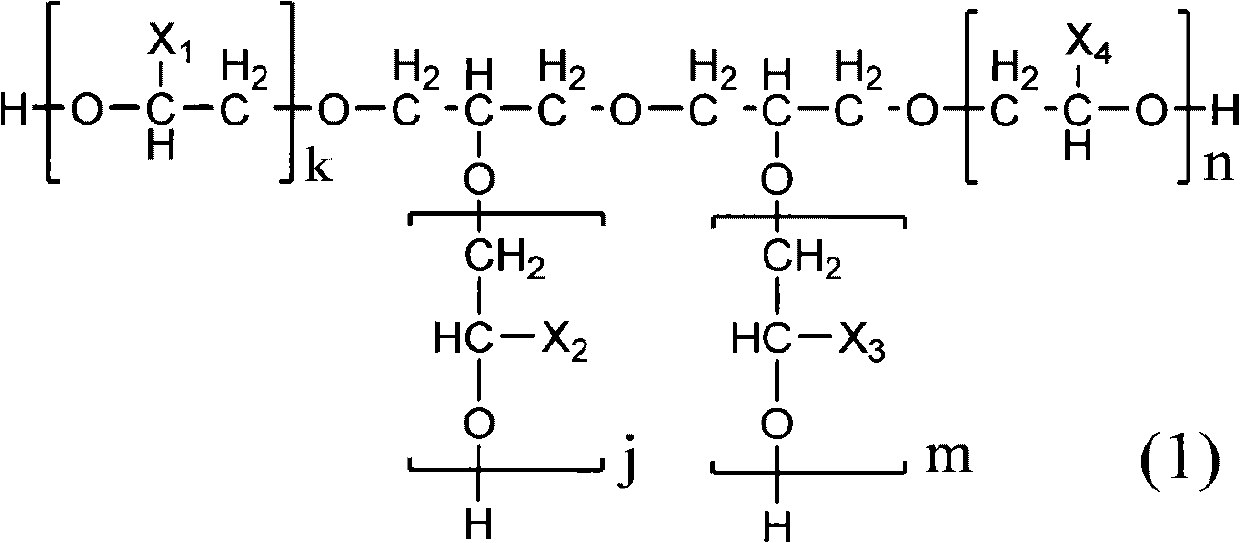

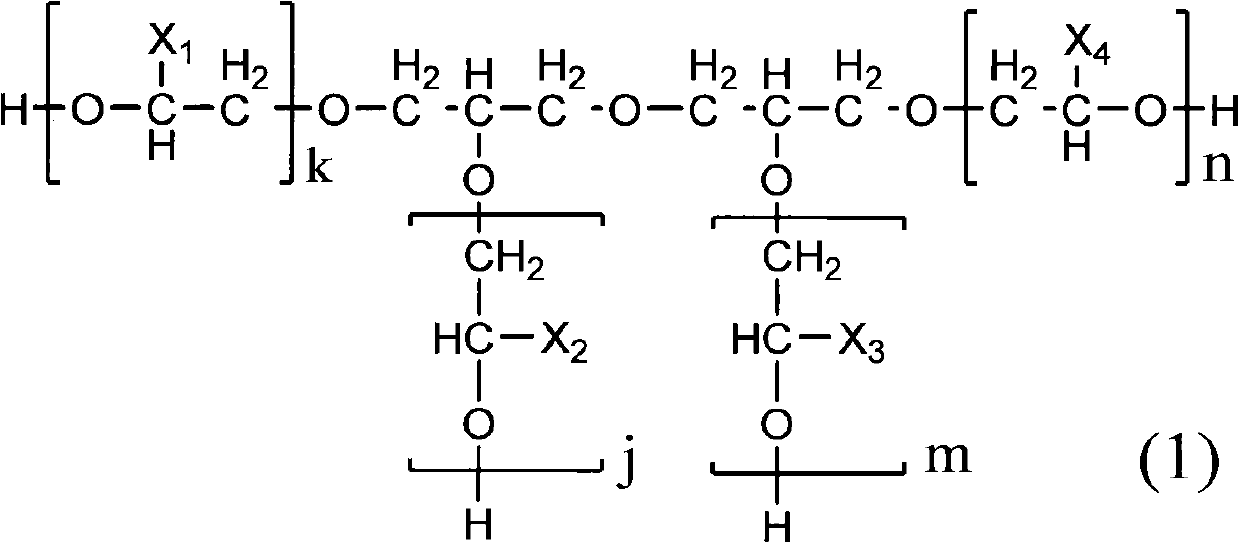

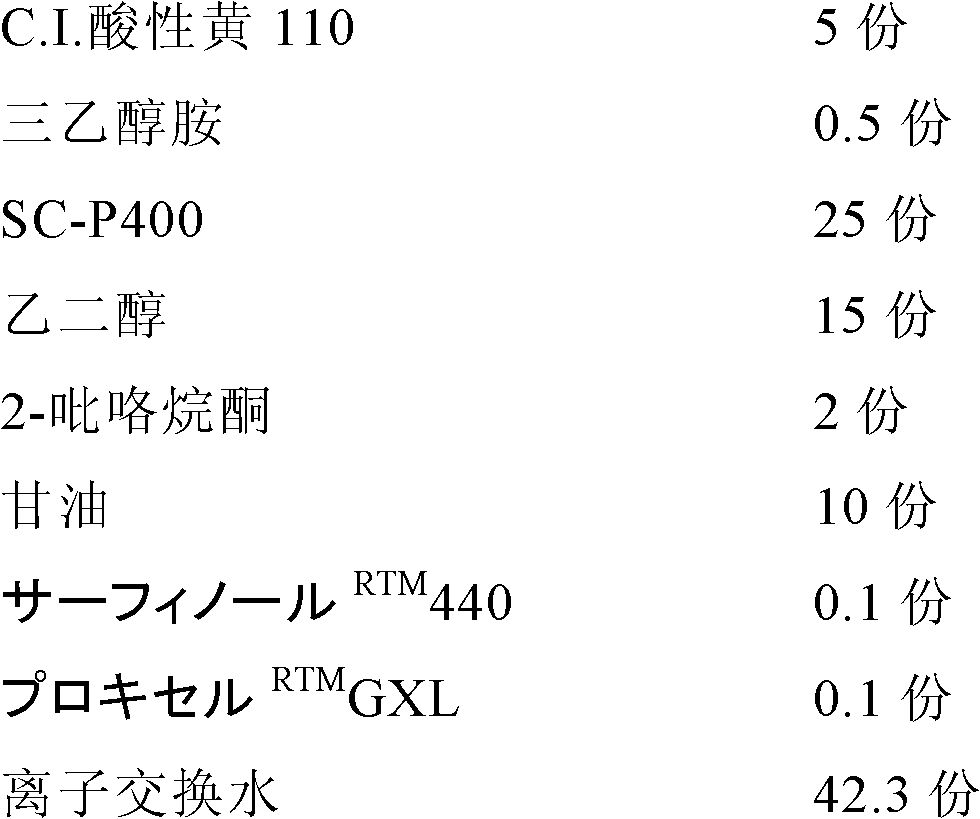

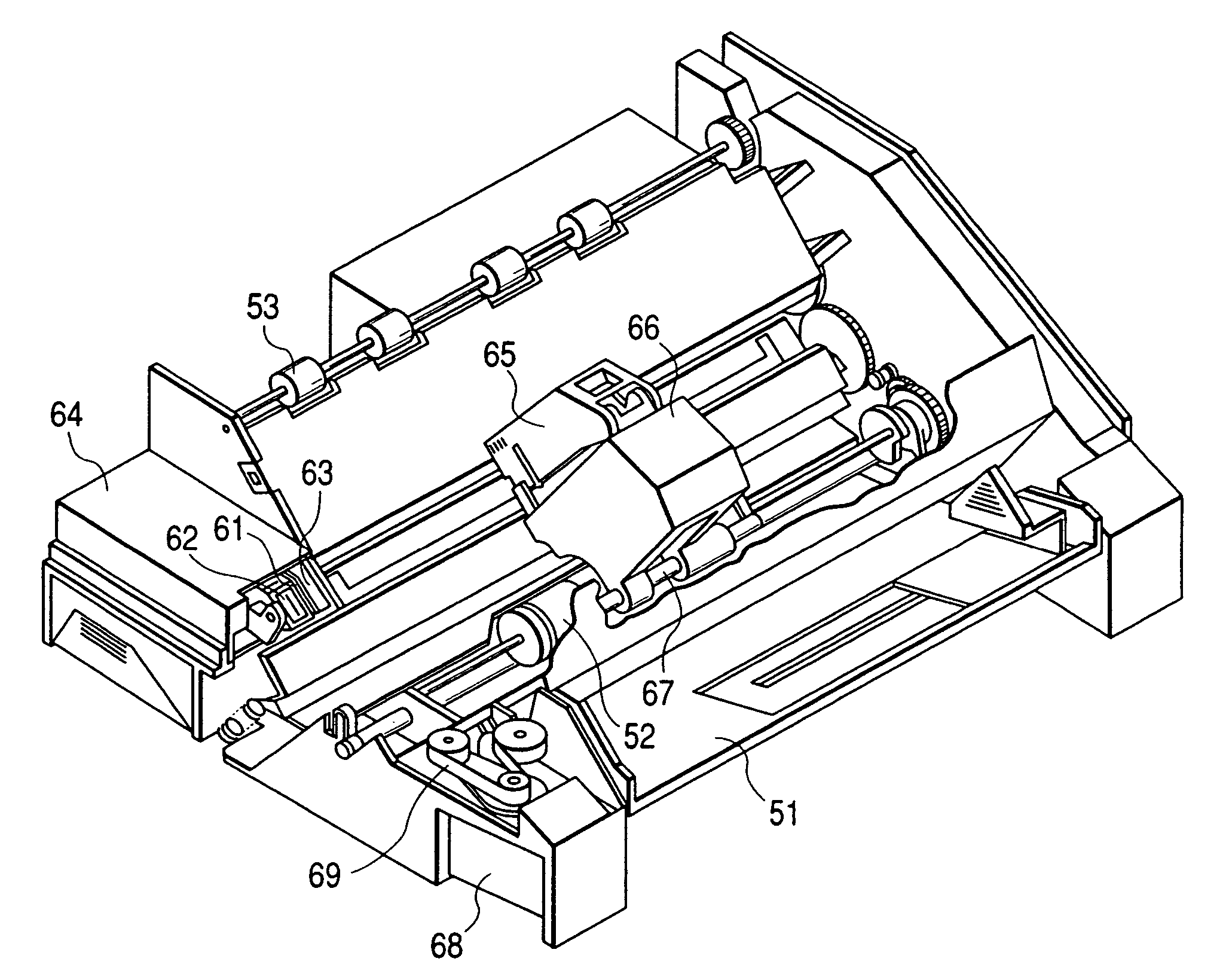

InactiveCN102365336AExcellent storage stabilityImprove fixation effectDuplicating/marking methodsInksFiberHydrogen atom

Disclosed is an aqueous ink composition for dyeing polyamide-based fibers which comprises: at least one kind of dye arbitrarily selected from dyes of three categories including acid dyes, direct dyes and reactive dyes; a compound which is represented by formula (1) [wherein X1, X2, X3 and X4 independently represent each a hydrogen atom or a methyl group; and j, k, m and n represent numbers, provided that the sum thereof is 4 to 40 inclusive] and has an average molecular weight of 340 to 2200; and ethylene glycol. Also disclosed is a method for producing a dyed polyamide-based fiber which comprises a step for applying said aqueous ink composition to a polyamide-based fiber by using an inkjet printer. Thus, it is possible to provide a dye ink for dyeing polyamide-based fibers, which has a high ejection stability in a printer equipped with an industrial inkjet head requiring a high-viscosity ink, has a high storage stability of the ink and shows a good fixability to fibers.

Owner:NIPPON KAYAKU CO LTD

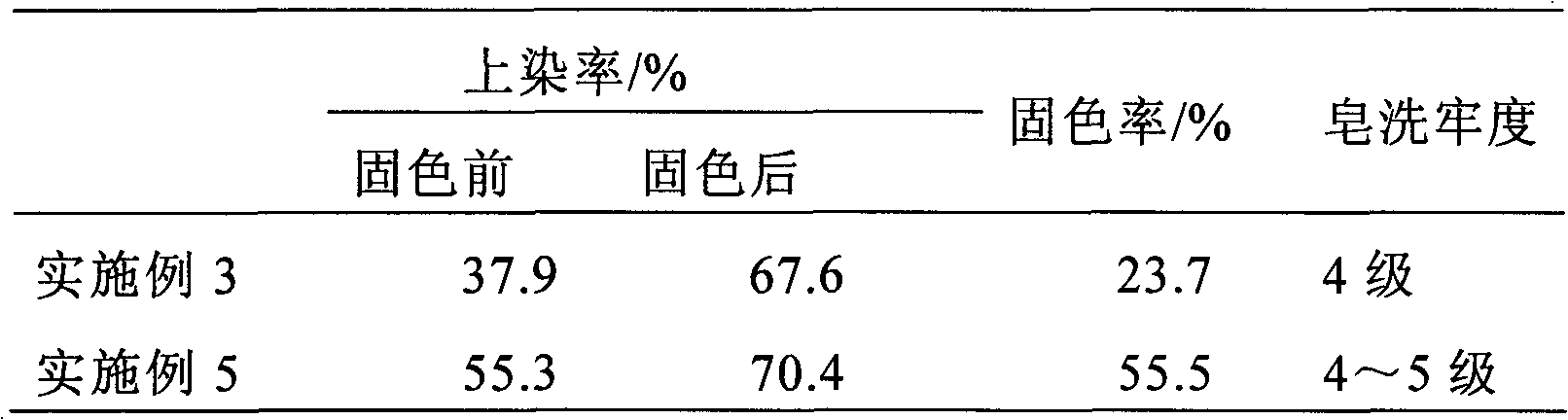

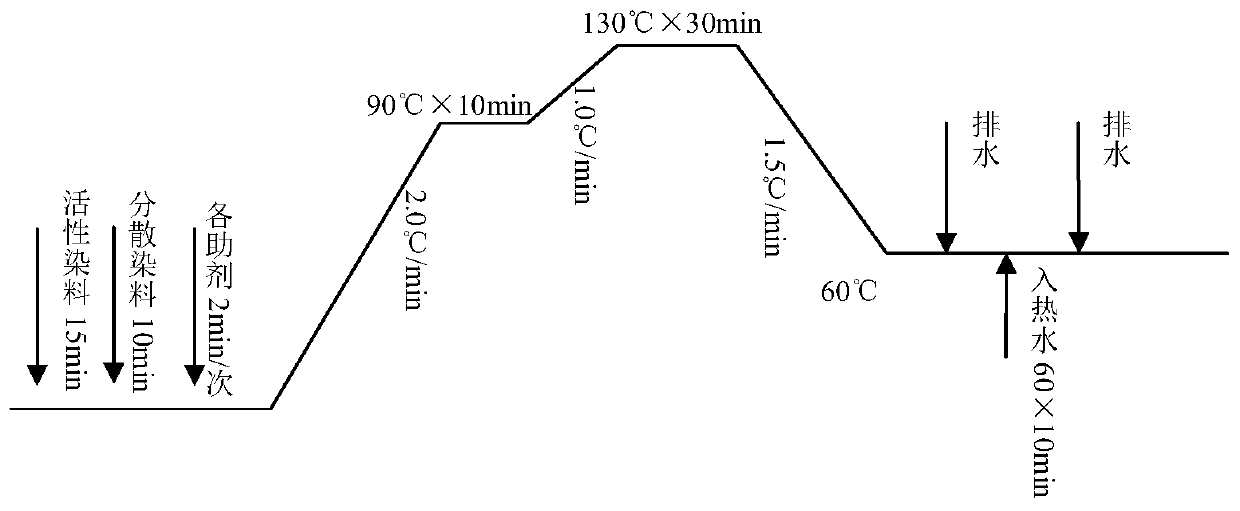

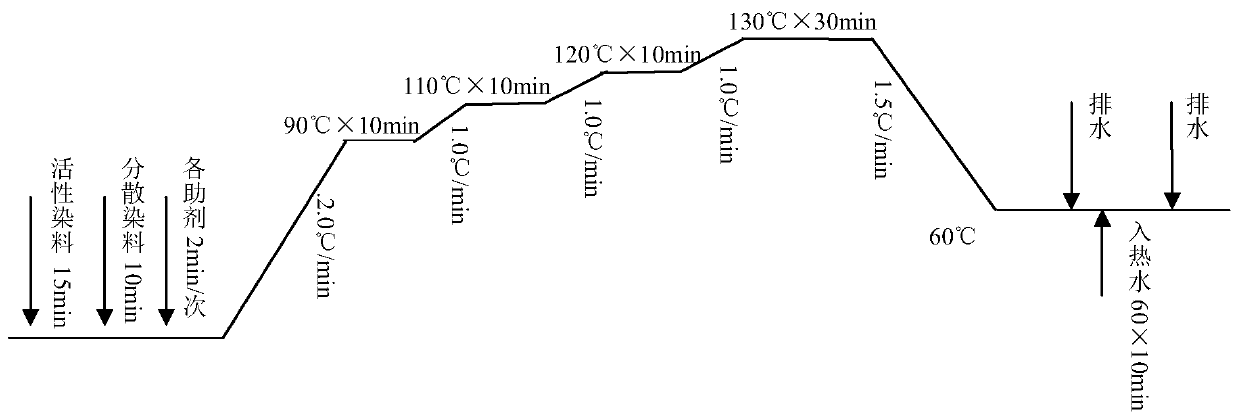

Direct dyeing process for chemical fiber

InactiveCN104762828AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsColour fastness

The invention provides a direct dyeing process for a chemical fiber. The direct dyeing process for the chemical fiber comprises the steps of pretreatment, pre-shaping, modification treatment, dyeing, soaping, color fixing, after-treatment, drying, sizing, calendaring and rolling. According to the direct dyeing process for the chemical fiber, the modification treatment is added, so that performances of a chemical fabric are subjected to the modification treatment basically, the dyeing degree of the fabric is increased, and the difficulty of a subsequent dyeing step is reduced; during dyeing, the mass utilization of inorganic salt is avoided; furthermore, substitute alkali is used for replacing a conventional sodium carbonate substance, so that the consumption is reduced, a color fixation effect is also improved, and the washing fastness of the chemical fiber is further improved; soaping and color fixing processes are added, so that the dyeing fastness is good; environment-protection formaldehyde-free TCD-R is utilized in the color fixing process, and color-fixed fibers are gradually dried, so that the firmness of the fibers is greatly improved; the post-treatment process is added, so that the color fastness and the flexibility of the fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and has high resilience.

Owner:TAICANG CHENGLE CHEM FIBER

Compositions comprising discrete particles aggregates and discrete particle agglomerates for application to keratin fibers

Discrete particle aggregates and / or discrete particle agglomerates for application onto keratin fibers, preferably hair, optionally combined with one or more oxidative and / or direct dyes.

Owner:TREMBLAY MARIO ELMEN +3

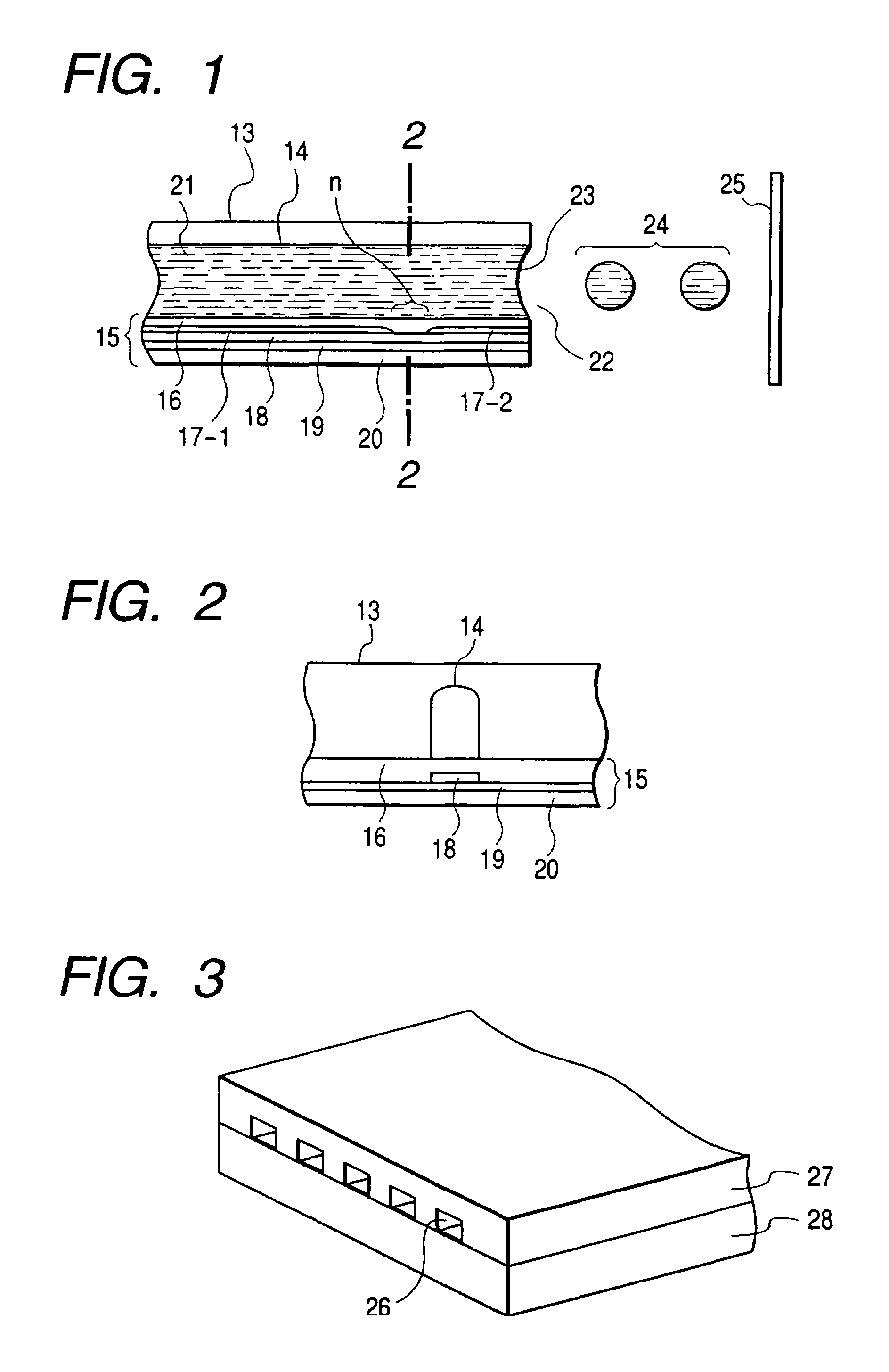

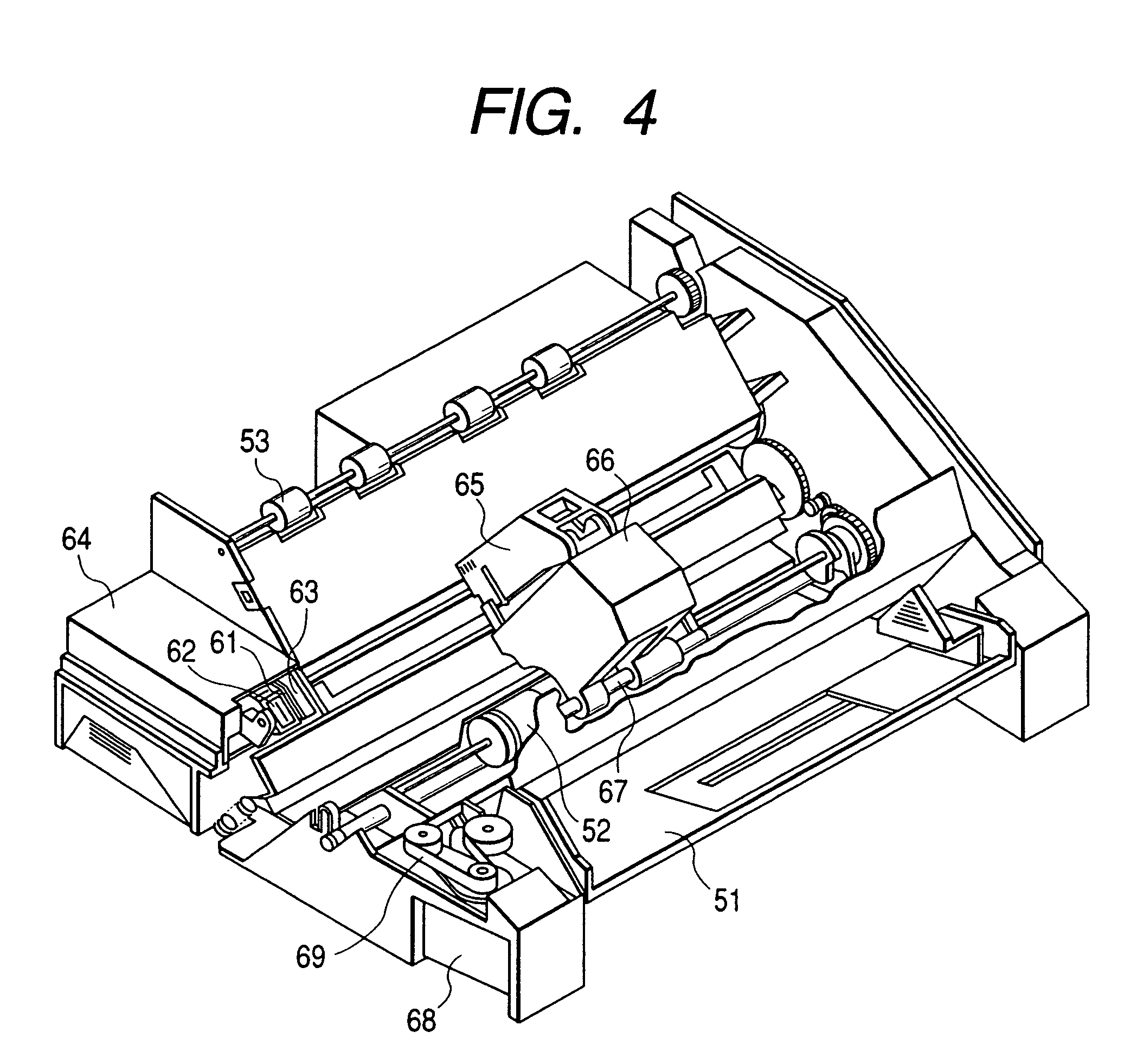

Fluorescent ink, and ink cartridge recording unit, ink-jet recording method, and ink-jet recording apparatus employing the fluorescent ink

InactiveUS7060123B2Increase resistanceExcellent toneMeasurement apparatus componentsInksLiquid mediumFluorescence

A novel fluorescent ink is provided which contains at least a coloring material and an aqueous liquid medium for dissolving the coloring material, wherein the coloring material comprises C.I. Acid Red 52 and at least one direct dye, the content of the C.I. Acid Red 52 ranging from 0.1 to 0.4% by weight based on the total amount of the ink, and the content of the direct dye ranging from 0.15 to 0.4% by weight based on the total amount of the ink, and the weight ratio of the direct dye to the C.I. Acid Red 52 is not higher than 1.6. This fluorescent ink is capable of forming prints with fluorescence of high intensity and with high water resistance.

Owner:CANON KK

One-bath dyeing method of polyester-cotton knitted fabrics

The invention discloses a one-bath dyeing method of polyester-cotton knitted fabrics, which comprises the specific steps of (1) placing a polyester-cotton knitted fabric in a modifying liquid, carrying uniform padding with a padder, and piling at normal temperature, wherein the modifying liquid is made with 30-100 g / L of a cationic modifier, 15-30 g / L of sodium hydroxide, 5-15 g / L of a penetrant and the balance of water; (2) neutrally washing the cation-modified polyester-cotton knitted fabric in an overflow vat; (3) carrying out one-bath dyeing; (4) treating after dyeing. Cotton fibers are modified herein through the cation modification technique, so that the binding mode of active dye / direct dye and cotton fibers is changed; therefore, degree of dyeing can be increased, and wastewater chromaticity can be decreased. Dyeing acceleration by salts and color fixation by bases are not required, so that environmental pollution is avoided. One-bath dyeing along with conventional disperse dyes is available herein, dye screening is not required, and therefore, the dyeing and finishing process is greatly shortened and production efficiency is improved; the wash fastness is good, so that customers' needs are met.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

Hair dye composition

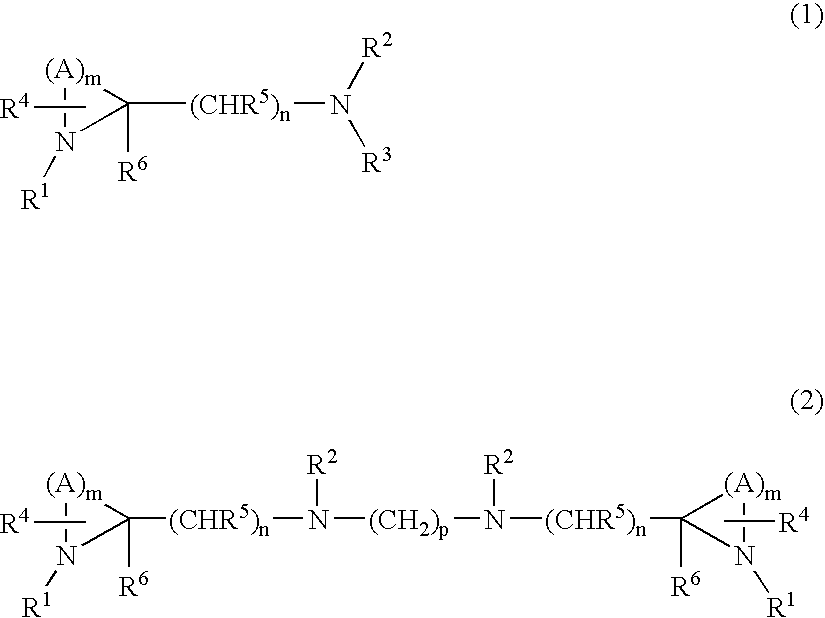

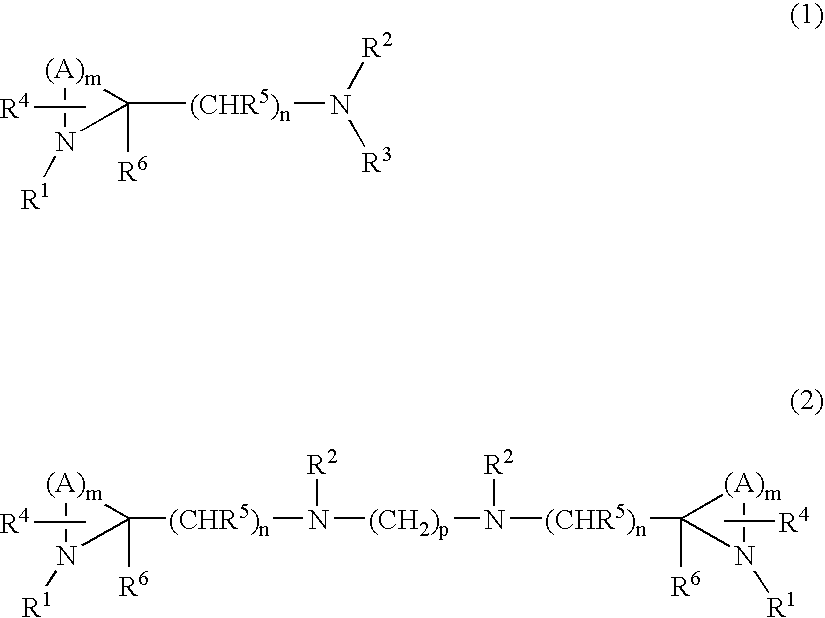

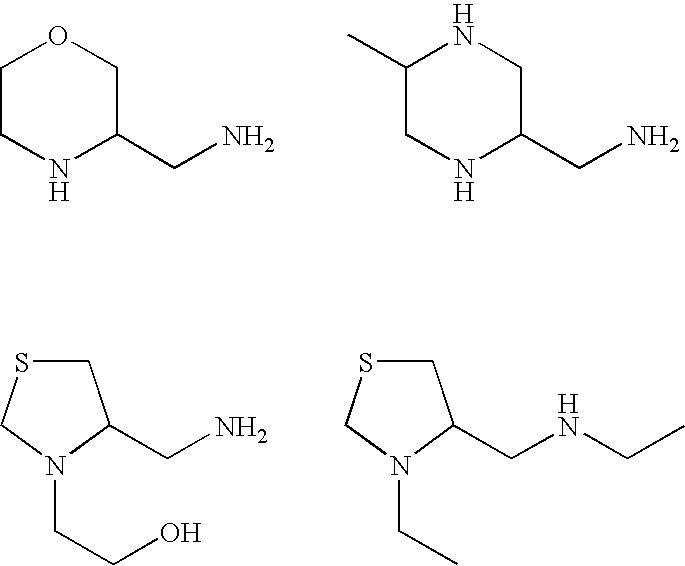

InactiveUS7211116B2Lowering bleaching power and hair dyeing powerAvoid damageCosmetic preparationsHair cosmeticsHair ColorantsBleach

Provided are a hair bleach composition, hair dye composition and a hair treatment additive having excellent bleaching power, capable of dyeing the hair with a bright and good color, and less damaging to the hair and less irritating to the scalp.Described specifically, they are a two-part hair bleach composition, which contains (a) a nitrogenous compound represented by the following formula (1) or (2):or salt thereof, or (A) a nitrogenous compound having a solubility parameter log P in octanol / water ranging from −1 to 4 and a hydrogen peroxide remaining ratio of from 5 to 90%, or salt thereof, (b) an oxidizing agent, and optionally (c) an alkali agent and, after mixing, has a pH of from 7.5 to 12; a two-part hair dye composition comprising (a) or (A), (b) and (c) and further (d) an oxidation dye or direct dye; and an additive used therefor.

Owner:KAO CORP

Method for coloring hair

A method for coloring keratin fibers is provided that includes at least two steps. In one step, the keratin fibers are treated with a pretreatment composition containing at least one substantive dye. In another step, the keratin fibers are treated with a composition containing at least one synthetic dye or synthetic dye precursor after applying the pretreatment composition.

Owner:HENKEL KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com