Method for preparing printing dye adsorbent by taking eggshells as matrix and treatment method

An adsorbent and eggshell technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., to achieve the effect of improving water quality, low production cost, and reducing chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

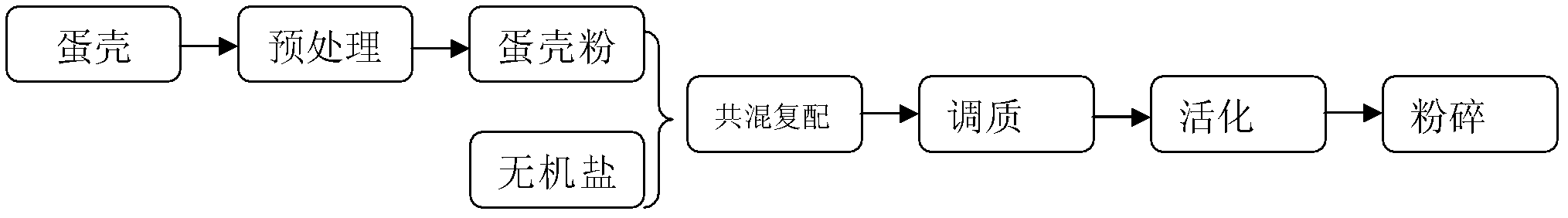

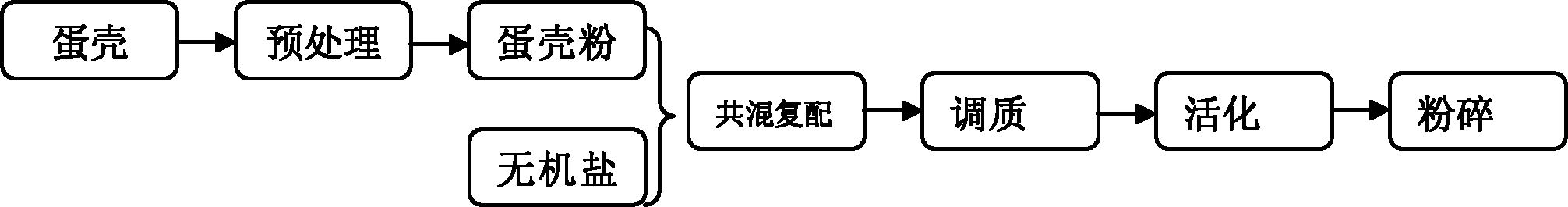

Method used

Image

Examples

Embodiment 1

[0021] (1) After rolling the discarded duck egg shells, sieving to remove impurities, blood stains and shell membrane pretreatment, crushing to a particle size of more than 100 mesh, treating with 0.05mol / L dilute alkali NaOH solution for 2 hours, washing with water to remove the lye Dry at 80°C for 2 hours to obtain eggshell powder;

[0022] (2) Eggshell powder, sodium silicate and aluminum sulfate are placed in a mixer and mixed to obtain a mixture. The mass ratio of processed eggshell powder: sodium silicate: aluminum sulfate=15:4:3;

[0023] (3) Adjust the pH value of the mixture obtained in step (2) to 6, place the mixture in an oven to dry at 500° C. for 2 hours, and pulverize after cooling to obtain a printing and dyeing wastewater treatment agent.

[0024] The amount of wastewater treatment agent added is 1g / L, and the decolorization rate of direct violet is 80.1% and the decolorization rate of basic violet is 90.2% after adsorption in printing and dyeing wastewater at...

Embodiment 2

[0026] (1) After rolling the discarded egg shells, sieving to remove impurities, blood stains and shell membrane pretreatment, crushing to a particle size of more than 100 mesh, treating with 0.1mol / L dilute alkali NaOH solution for 2 hours, washing with water to remove the lye Dry at 80°C for 3 hours to obtain eggshell powder;

[0027] (2) Eggshell powder, sodium silicate and aluminum sulfate are placed in a mixer and mixed to obtain a mixture. The mass ratio of processed eggshell powder: sodium silicate: aluminum sulfate=25:5:5;

[0028] (3) Adjust the pH value of the mixture obtained in step (2) to 6.5, place the mixture in an oven to dry at 1000° C. for 2 hours, and pulverize after cooling to obtain a printing and dyeing wastewater treatment agent.

[0029] The amount of wastewater treatment agent added is 0.5g / L, and after being adsorbed in printing and dyeing wastewater at 20°C for more than 20 minutes, the decolorization rate of direct violet is 90.1%, and the decoloriz...

Embodiment 3

[0031] (1) After rolling the discarded goose egg shells, sieving to remove impurities, blood stains and shell membrane pretreatment, crushing to a particle size of more than 100 mesh, treating with 0.1mol / L dilute alkali KOH solution for 2 hours, washing with water to remove the lye After drying at 80°C for 4 hours, eggshell powder was obtained;

[0032] (2) Eggshell powder, sodium silicate and aluminum sulfate are placed in a mixer and mixed to obtain a mixture. The mass ratio of processed eggshell powder: sodium silicate: aluminum sulfate=20:2:4;

[0033] (3) Adjust the pH value of the mixture obtained in step (2) to 7.0, place the mixture in an oven to dry at 550° C. for 4 hours, and pulverize after cooling to obtain a printing and dyeing wastewater treatment agent.

[0034] The amount of wastewater treatment agent added is 2g / L, and after being adsorbed in printing and dyeing wastewater at 15°C for more than 20 minutes, the decolorization rate of direct violet is 81.4%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com