Preparation and application of colloidal sol dyeing liquor

A technology of dyeing liquid and sol, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of prolonging the dyeing process of fabrics, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

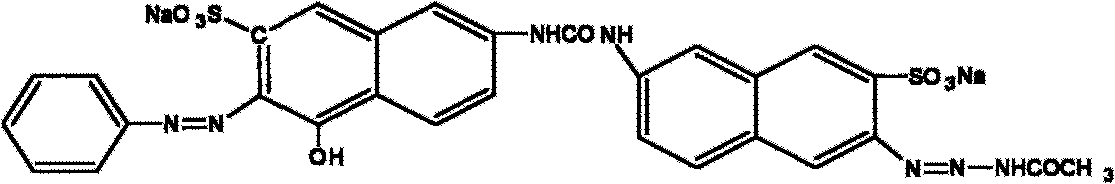

[0033] The preparation of example 1 direct scarlet dye sol dyeing solution

[0034] 45 parts of ethanol, 6 parts of ethyl orthosilicate, 40 parts of water and 1 part of 3-glycidyl ether trimethoxysilane (GPTMS) were successively added into the three-necked flask. Stir on a magnetic stirrer (300r / min) for 20min. Under this condition, 2 parts of hydrochloric acid with a concentration of 0.01mol / L is added dropwise to the above-mentioned mixed solution at a speed of 40 drops / min, and then added to the mixed solution at 55 Add 6 parts of direct scarlet 4BS staining solution (concentration 2%) dropwise at a rate of drop / min. After the dropwise addition, the rotating speed of the magnetic stirrer was adjusted (400r / min), and the stirring was continued at room temperature for 24 hours to obtain a sol staining solution.

[0035] Direct Red 4BS (C.I.Direct Red 23) structural formula:

[0036]

example 2

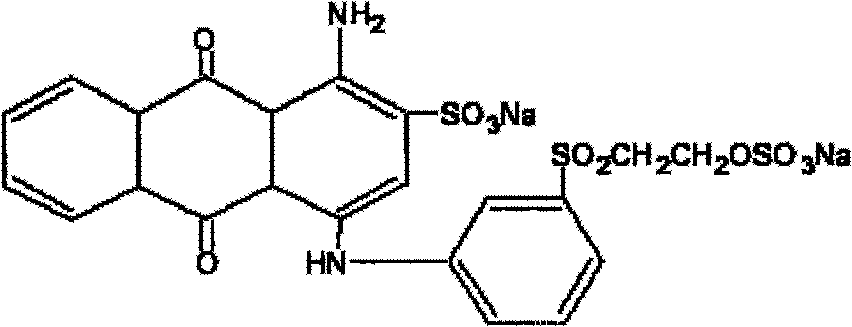

[0037] The preparation of example 2 reactive brilliant blue dye sol dyeing solution

[0038] 50 parts of ethanol, 9 parts of ethyl orthosilicate, 33 parts of water, and 2 parts of 3-glycidyl ether trimethoxysilane (GPTMS) were successively added to the three-necked flask. Stir on a magnetic stirrer (300r / min) for 20min. Under this condition, add 1 part of 0.01mol / L formic acid dropwise to the above mixed solution at a speed of 50 drops / min, and then add it to the mixed solution at a rate of 60 drops / min. Add 5 parts of Reactive Brilliant Blue KN-R dye solution (concentration 1%) dropwise at a speed of min. After the dropwise addition, the rotating speed of the magnetic stirrer was adjusted (400r / min), and the stirring was continued at room temperature for 24 hours to obtain a sol staining solution.

[0039] Reactive Brilliant Blue KN-R (C.I.Reactive Blue 19), the structural formula is:

[0040]

Embodiment 3

[0041] Embodiment 3 direct scarlet dye sol dyeing solution pad dyeing

[0042] Under the action of magnetic stirrer stirring (200r / min), directly add 5% sodium chloride to the dyeing liquid of scarlet dye sol. Using the colored sol solution as the dyeing solution, pad-dye the plain poplin cotton fabric (the dye concentration is 1%), dipping twice and padding, the excess rate is 80%, pre-baking at 50°C for 30min, and then baking at 150°C 5min. Finally, the fabric is washed, soaped, washed and dried to complete the dyeing.

[0043] The plain poplin cotton fabric dyed by the above has a soaping fading fastness of grade 3.5, a soaping staining fastness of 4 grades, a dry rubbing fastness of 3 grades, and a wet rubbing fastness of 2.5 grades. At the same time, the dyeing K / S value reaches Got 27.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com