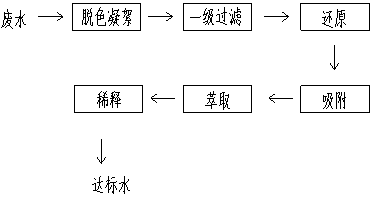

Printing and dyeing wastewater treatment process

A technology for treating process and printing and dyeing wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of fast ion exchange, high decolorization rate and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

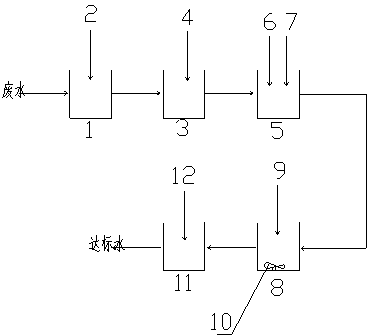

Embodiment 2

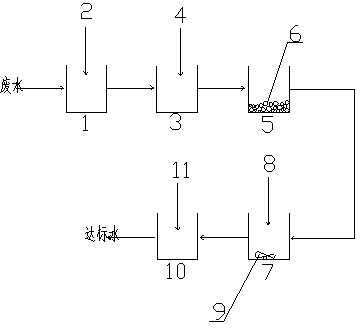

[0020] Labels in the figure: 1-filter tank, 2-filter aid, 3-reduction tank, 4-sulfur-containing reducing agent, 5-hydride initiator, 6-adsorber, 7-bentonite, 8-extractor, 9- Non-water-soluble organic solvent, 10-stirrer, 11-dilution tank, 12-water.

specific Embodiment approach

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0023] Embodiment of the invention figure 2 It is a specific embodiment of wastewater treatment process, comprising the following steps:

[0024] The COD of the wastewater before treatment is 1740, the BOD is 400.0, the SS suspended matter is 460, and the chromaticity is 1000. The wastewater is injected into the filter tank 1, and the filter aid 2 is added. After the filter aid 2 is fully mixed in the wastewater, the wastewater is flocculated , through the filtration of the filter pool 1, the suspended matter is filtered out, and the remaining filtrate is mainly colored dissolved matter and fine suspended matter. The COD of the filtrate filtered out after one filtration is 426, BOD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com