Leather dye and preparing method thereof

A dye and leather technology, applied in the field of leather dyeing, can solve the problems of unsatisfactory fastness of leather dyes and failure to meet the requirements of consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

[0018] The formula of the leather dye that table 1 embodiment 1-11 provides

[0019]

Dyes (parts by weight)

The binary copolymer of acrylamide and acrylic acid (parts by weight)

1

10

2

2

40

10

3

30

6

4

20

8

5

70

4

6

60

20

7

50

14

[0020] 8

90

18

9

80

12

10

10

20

11

90

2

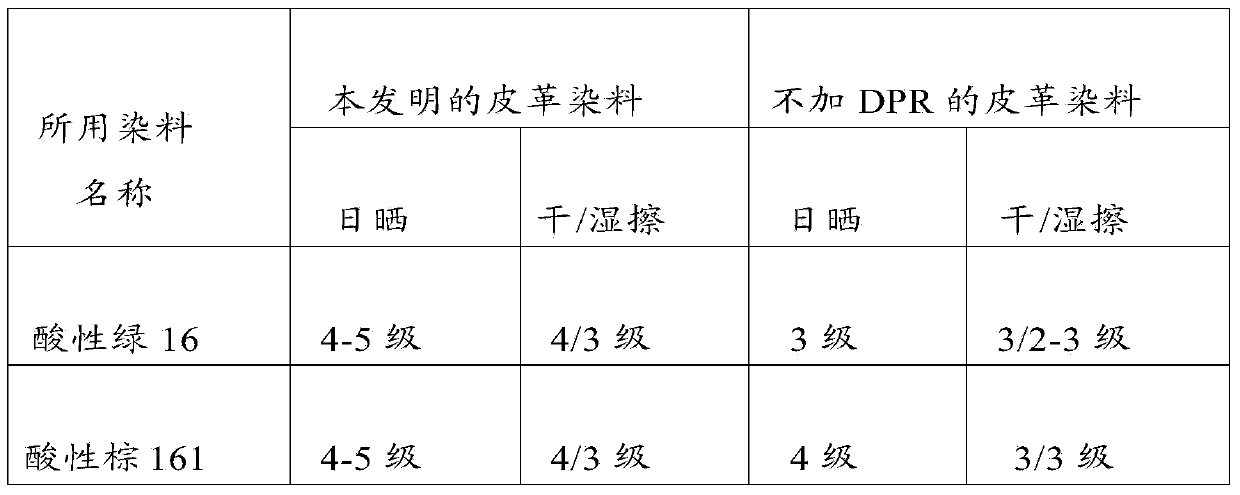

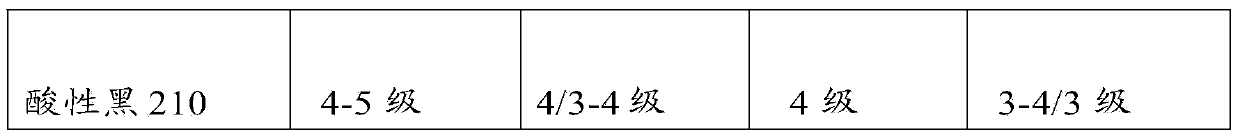

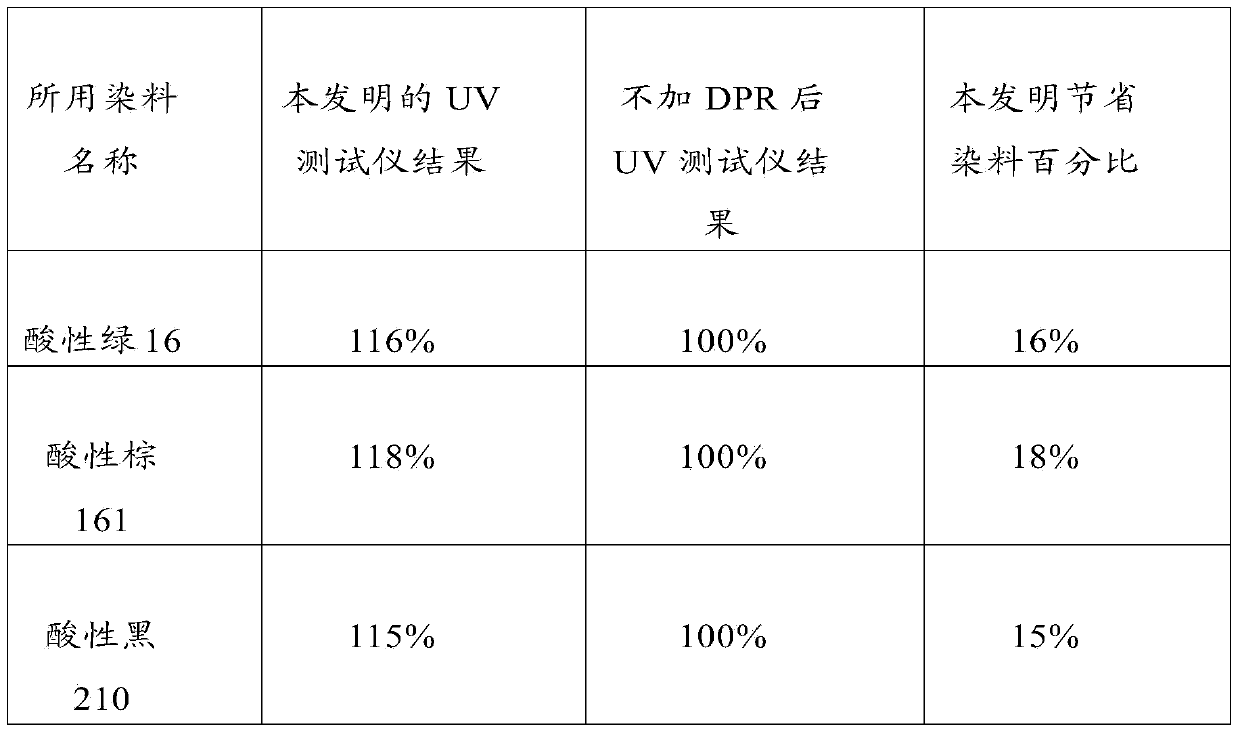

[0021] The leather dyes of all the above examples have the technical effects of deepening and color fixing, and all of them are realized by the binary copolymer of acrylamide and acrylic acid (hereinafter referred to as DPR). DPR can be combined with sulfonic acid groups in dyes, thereby reducing the amount of water-soluble groups in dyes, and achieving the purpose of deepening and fixing colors.

[0022] The leather dyes of all the above-mentioned embodiments can also be other functional auxiliary agents, such...

Embodiment 12

[0029] A kind of leather dye and preparation method thereof

[0030] (1) Add 40 parts of Acid Black 210 and 28 parts of Direct Black 168 into the mixing kettle.

[0031] (2) Make the temperature reach 30°C, add 10 parts of DPR, 5 parts of sodium xylene sulfonate, 2 parts of diffusing agent, 2 parts of sodium lignosulfonate, 8 parts of pull-off powder, and 5 parts of silicone brightening agent.

[0032] (3) Stir for 8 hours to fully mix the dye with the mixing aid to obtain a leather dye.

Embodiment 13

[0034] A kind of leather dye and preparation method thereof

[0035] (1) Add 10 parts of Acid Green 16 into the mixing kettle;

[0036] (2) Make the temperature reach 10°C, add 20 parts of DPR, 20 parts of sodium xylene sulfonate, 5 parts of diffusing agent, 5 parts of sodium lignosulfonate, 20 parts of pulling powder, and 20 parts of silicone brightening agent;

[0037] (3) Stir for 2 hours to fully mix the dye and the mixing aid to obtain a leather dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com