Preparing method for anti-slipping marble tile

A marble and anti-skid treatment technology, applied in stone processing equipment, manufacturing tools, stone processing tools, etc., can solve the problem of inability to use polished products, and achieve the effect of improving product competitiveness, not affecting the environment, and improving anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

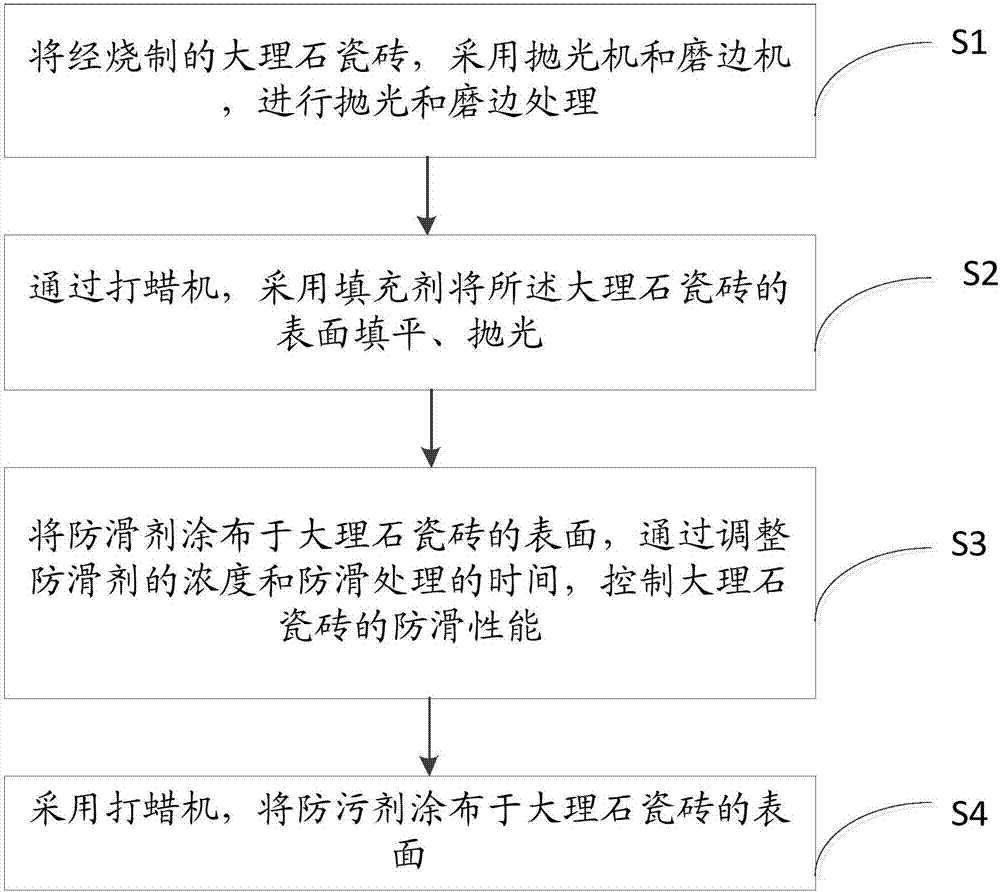

[0027] see figure 1 , is a flowchart of the preparation method of the non-slip marble tile provided in this embodiment. The method includes the steps of:

[0028] S1: The fired marble tiles are polished and edged with a polishing machine and an edger.

[0029] This step is used for polishing and edging. Specifically, in this step, the marble tiles are polished and edged respectively by a polishing machine and an edger. The polished and edged marble tiles have a smooth surface. Tiles or polished tiles with an enamelled surface.

[0030] S2: using a waxing machine to fill and polish the surface of the marble tile with a filler.

[0031] This step is used for filling processing.

[0032] In this step, the filler is nano-silica sol, and the filler is filled onto the surface of the marble tiles through a waxing machine.

[0033] In this embodiment, preferably, the filler is nano-silica sol, and the filler is filled on the surface of the polished and edged marble tiles through...

Embodiment 2

[0043] This embodiment provides a preparation method of anti-slip marble tiles. The difference between this preparation method and Example 1 is that in step S2, a spin coater is used to apply the anti-slip liquid to the surface of the marble tiles, and the concentration of the anti-slip agent is: 0.2mol / L, the processing time is 20s.

[0044] The product produced by the preparation method of the anti-slip marble tile provided in this example has a sliding friction coefficient of 0.71 and a glossiness of 65 degrees, and the texture, color, permeability, texture and other properties of the marble tile have no obvious changes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com