Patents

Literature

176results about How to "With metallic luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal coating plumbago composite material and method of producing the same

InactiveCN101508596ABeautiful surfaceWith metallic lusterLiquid/solution decomposition chemical coatingHeat sinkChemical plating

The invention provides a metal plating (copper or nickel or zinc) graphite compound material and a preparation method thereof. One of the preparation method is degreasing and coarsening the surface of the graphite radiating material; soaking and washing the processed material in sensitizing solution and activating solution; and finally carrying out chemical plating of copper or nickel or zinc and the like in plating solution, drying and post-treatment to obtain the finish product. The other preparation method is carrying out degreasing, coarsening and other pre-processing on the surface of the graphite radiating material before electroplating, and then carrying out electroplating in electroplating solution to obtain the finish product. By both of the preparation methods provided by the invention, whether chemical plating or electroplating, a graphite board material which can beautify the graphite cooling plate, improve the strength of the graphite cooling plate and add the connecting mode (like welding) of the graphite cooling plate and the metal base material can be obtained. The metal plating graphite compound material has the characteristics of low density, high heat conductivity and strength, and easy joining with metals, is an outstanding radiating material, and can be widely used in thermal management systems of electronic products.

Owner:晟茂(青岛)能源替代产品研发有限公司

Cellulose nanocrystal/graphene composite colored film and fast preparation method thereof

The invention relates to a cellulose nanocrystal / graphene composite colored film and a fast preparation method thereof. The cellulose nanocrystal / graphene composite colored film can be prepared under the existence of a flow field by adopting a vacuum filtration method, the composite film has a cholesteric liquid crystal phase structure, and the color of the composite film can be regulated by controlling the ultrasonic time during preparation process. The prepared colored film can absorb water, and the color can be changed along with the change of humidity. The cellulose nanocrystal / graphene composite colored film has application values in the photoelectric field and the preparation of anti-counterfeit labels, anti-counterfeit paper and high-grade discoloring anti-counterfeit ink.

Owner:QINGDAO UNIV OF SCI & TECH

Method for performing neutral electronickelling following magnesium alloy chemical nickeling

InactiveCN101560662AImprove bindingHarm reductionLiquid/solution decomposition chemical coatingSuperimposed coating processBiological activationFluoride

The invention discloses a method for performing neutral electronickelling following magnesium alloy chemical nickeling, which comprises the technical steps as follows: (1) surface treatment of magnesium alloy material: performing surface treatment to the magnesium alloy material by adopting the prior art; (2) acid membrane removal: removing the membrane by using fluoride-containing acid solution; (3) alkaline erosion: performing surface erosion by using fluoride-excluding alkaline solution; (4) activation: performing surface activation by using fluoride-containing solution; (5) chemical nickeling; (6) thermal treatment; (7) subsequent neutral nickeling; and (8) regular nickeling. According to the method, neutral electronickelling is performed following magnesium alloy chemical nickeling so that double-layer nickel is covered on the magnesium alloy base material. The method has the advantages of high bonding force, good uniformity and dense property, strong wearing resistance and corrosion resistance, and simple technical process and convenient operation. In the whole process, alkaline-copper electroplating and chromium are not needed, thus reducing harm to environment and human.

Owner:李远发

Ultra-thin expansion steel structure fire-proof paint capable of resisting hydrocarbons fire and preparation method thereof

The present invention relates to one kind of fire-proof paint with high hydrocarbon fire resistance for steel structure and its preparation process. The fire-proof paint has filming material comprising fluoric polymer emulsion and organosilicon modified polyacrylate emulsion, composite fireproof assistant comprising melamine and pentaerythritol, expanding agent comprising melamine phosphate with excellent carbon forming performance and foaming performance and expandable graphite, heat resisting stuffing comprising zinc oxide, titanium dioxide, kaolin aluminum silicate fiber, and filming assistant propylene glycol. It can bear hydrocarbon fire with high temperature raising speed, and has fire resisting limit up to 90 min, simple preparation process, low cost and wide application.

Owner:TONGJI UNIV

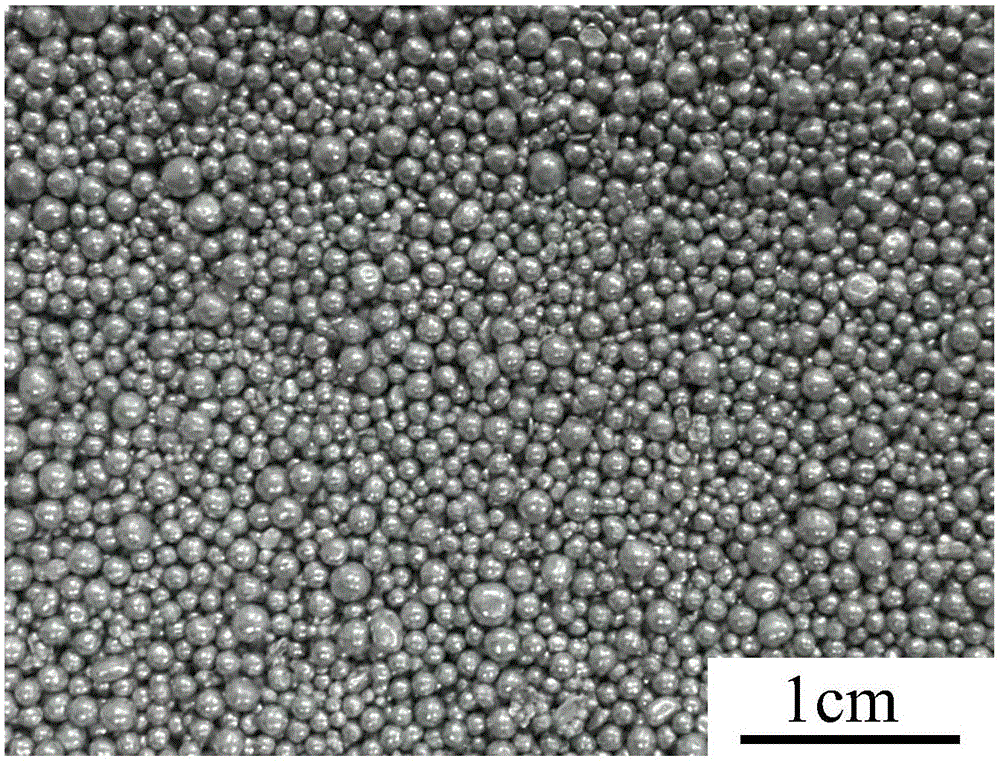

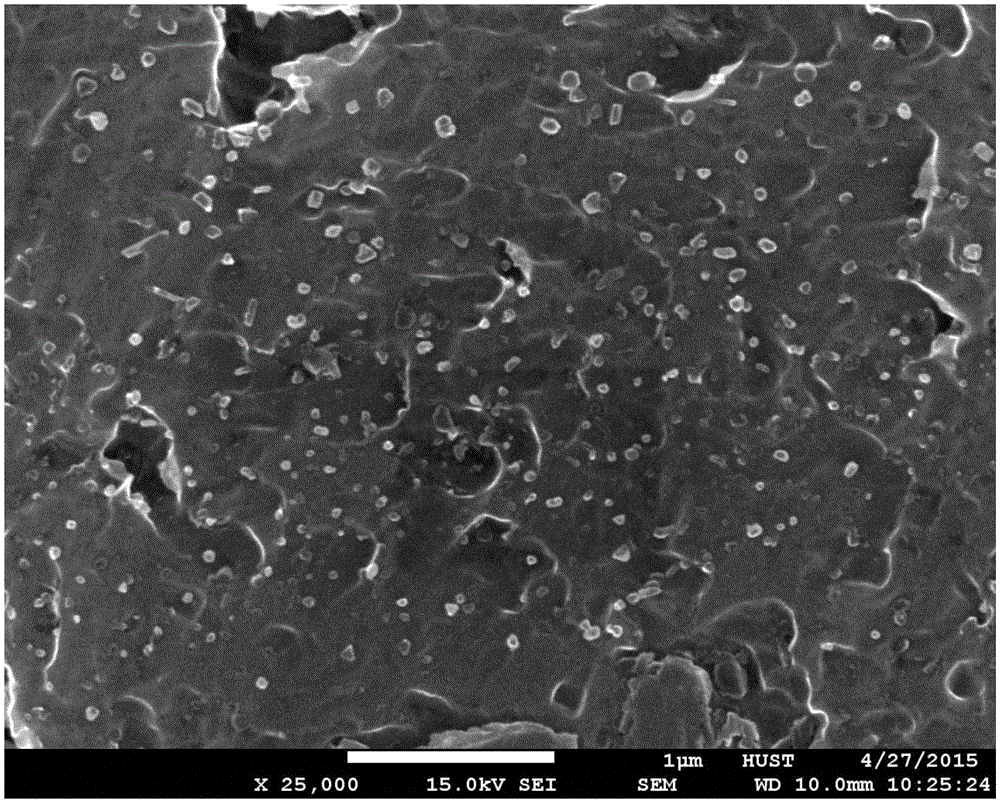

Method for preparing nano particle reinforced aluminum matrix composites

The invention discloses a method for preparing nano particle reinforced aluminum matrix composites. The method comprises the steps that firstly, mixed powder of nano ceramic powder and micron-sized aluminum or aluminum alloy powder is used for preparing millimeter-sized composite particles through a dry high-energy ball mill under the protection of vacuum or argon, wherein the volume fraction of nano ceramic particles in the millimeter-sized composite particles is 10-50%; and secondly, the millimeter-sized composite particles are melted directly or added into aluminum or aluminum melt, and supersonic vibration is applied, so that the nano ceramic particles are promoted to be uniformly dispersed in the metal melt, and the nano particle reinforced aluminum matrix composites are prepared. According to the method for preparing the nano particle reinforced aluminum matrix composites, the millimeter-sized composite particles prepared through a dry milling method can be added into the metal melt easily and completely, the problems that the wettability between the nano ceramic particles and matrix metal is poor, and adding of the particles is difficult are solved, and the advantage of low cost of a casting method for preparing metal matrix composites is given to play; the nano particles in the prepared composites are distributed uniformly, and the material performance is high.

Owner:HUAZHONG UNIV OF SCI & TECH

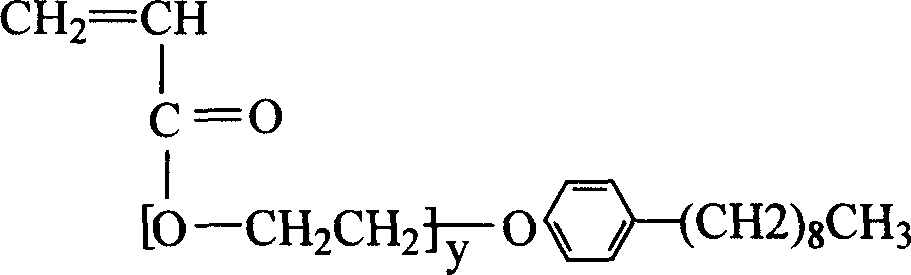

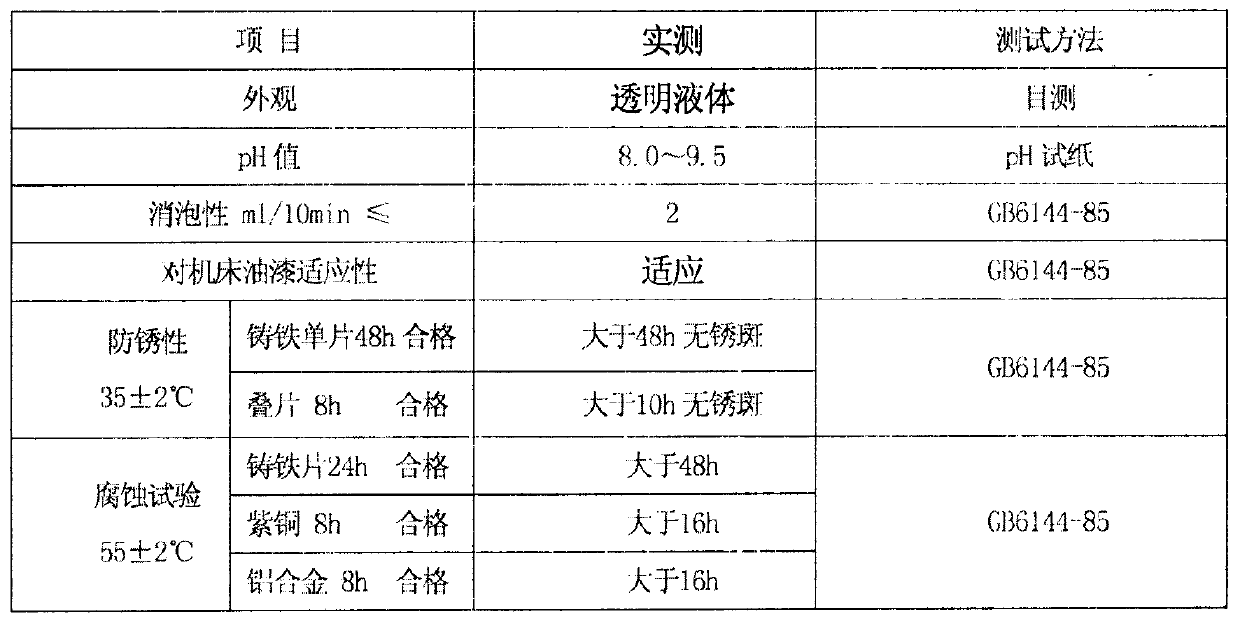

Water-based cutting fluid for metal processing and preparation method of water-based cutting fluid

The invention discloses water-based cutting fluid for metal processing and a preparation method of the water-based cutting fluid. The cutting fluid mainly consists of a lubricating agent, a metal antirust agent, an anti-wear reagent at extreme pressure, a nonionic surfactant, a dispersing agent, an antifoaming agent and water, and the cutting fluid comprises the following components in percentage by weight: 8-12 percent of oleic acid, 1.8-2.5 percent of triethanolamine, 0.3-0.6 percent of boric acid, 0.2-0.5 percent of benzotriazole, 5-8 percent of sodium carbonate, 10-12 percent of polyethylene glycol, 0.2-0.5 percent of dodecylphenol polyoxyethylene ether (OP-10), 0.7-1 percent of glycine betaine, 0.5-0.8 percent of glycerin polyoxypropylene ether and the balance of water. According to the water-based cutting fluid disclosed by the invention, the problems that the conventional water-based cutting fluid is poor in antirust and lubricating performances, low in recycling period and harmful to the human and environment are solved, and the aims of improving the lubricating effect and the antirust performance, realizing harmlessness to the environment and a human body and reducing the production cost of metal processing are achieved by virtue of synthesis of polybasic esters.

Owner:中钢集团郑州金属制品研究院股份有限公司

Metal ink

ActiveCN101240131AWith metallic lusterImprove aestheticsPigmenting treatmentInksLatent imageAluminium powder

The invention discloses a metallic printing ink, relating to an anti-counterfeiting printing ink which can form an anti-counterfeiting latent image by single-face printing has better anti-counterfeiting performance, wherein, the latent image can be identified by people without using special apparatus. The percentage of weight of each component is as following: 15 to 25% metallic paint, 10 to 15% high acid valence phenolic resin oil, 8 to 10% pure phenolic resin oil, 3 to 5% vapor phase silica, 15 to 20% transparent calcium carbonate, 5 to 7% surfactant, 6 to 8% polyethylene wax, 2 to 4% mineral oil, 0.3 to 0.5% drier, wherein the metallic paint is any one of the flake silver powder, aluminium powder, copper powder, or the mixture of the two or three components. The invention is applicable for single-face printing anti-counterfeiting perspective latent image on various carriers, such as different securities or the carriers of plastic, rubber and glass with certain transparence.

Owner:CHINA BANKNOTE PRINTING & MINTING

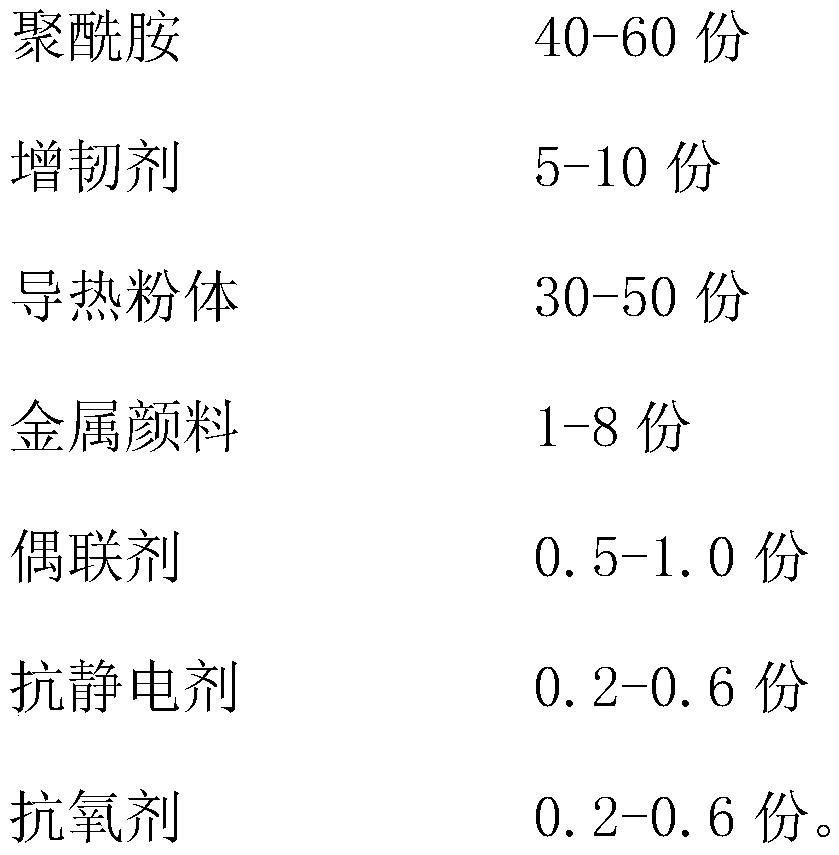

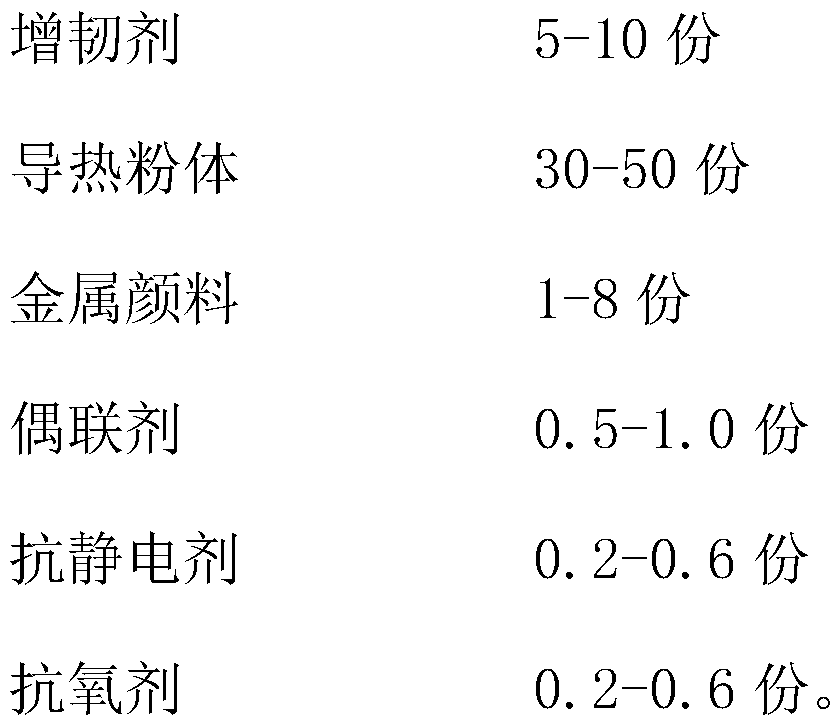

Spraying free thermal conductive nylon material for LED lighting products and preparation method thereof

InactiveCN109897368AReduce processing costsReduce spraying processHeat-exchange elementsAntistatic agentAntioxidant

The invention discloses a spraying free thermal conductive nylon material for LED lighting products and a preparation method thereof, and relates to the polymer material field. The nylon material comprises following raw materials in parts by weight: 40 to 60 parts of polyamide, 5 to 10 parts of a flexibilizer, 30 to 50 parts of thermal conductive powder, 1 to 8 parts of a metal pigment, 0.5 to 1.0part of a coupling agent, 0.2 to 0.6 part of an antistatic agent, and 0.2 to 0.6 part of an antioxidant. By adding a metal pigment into raw materials, an LED lighting product prepared from the nylonmaterial has metal luster and metal texture; the paint spraying is eliminated, the production process is simplified; the processing cost of the LED lighting product is reduced; the environment pollution caused by the spraying technology is avoided, and the health of operators is protected.

Owner:深圳市华盈工程塑料有限公司

Matte metal glaze, matte metal glaze ceramic product prepared from same and preparation method of matte metal glaze ceramic product

The invention relates to matte metal glaze, a matte metal glaze ceramic product prepared from the same and a preparation method of the matte metal glaze ceramic product, belonging to the technical field of ceramics. The matte metal glaze comprises the following components in parts by weight: 45-55 parts of nepheline orthoclase, 28-35 parts of clinkers, 4-7 parts of quartz, 2-8 parts of barium carbonate, 2-7 parts of disthene, 3-7 parts of kaolin, 22-27 parts of manganese oxide and 1-1.9 parts of copper oxide, wherein the clinkers comprise the following components in parts by weight: 38-42 parts of borax, 22-28 parts of quartz, 3-6 parts of kaolin, 12-17 parts of calcium carbonate, 8-13 parts of sodium nitrate and 2-7 parts of potassium carbonate. The matte metal glaze ceramic product is endowed with good texture and appearance by the matte metal glaze; and by integrating metal luster with low-pitched matte, the matte metal glaze ceramic product is low-pitched and luxurious.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

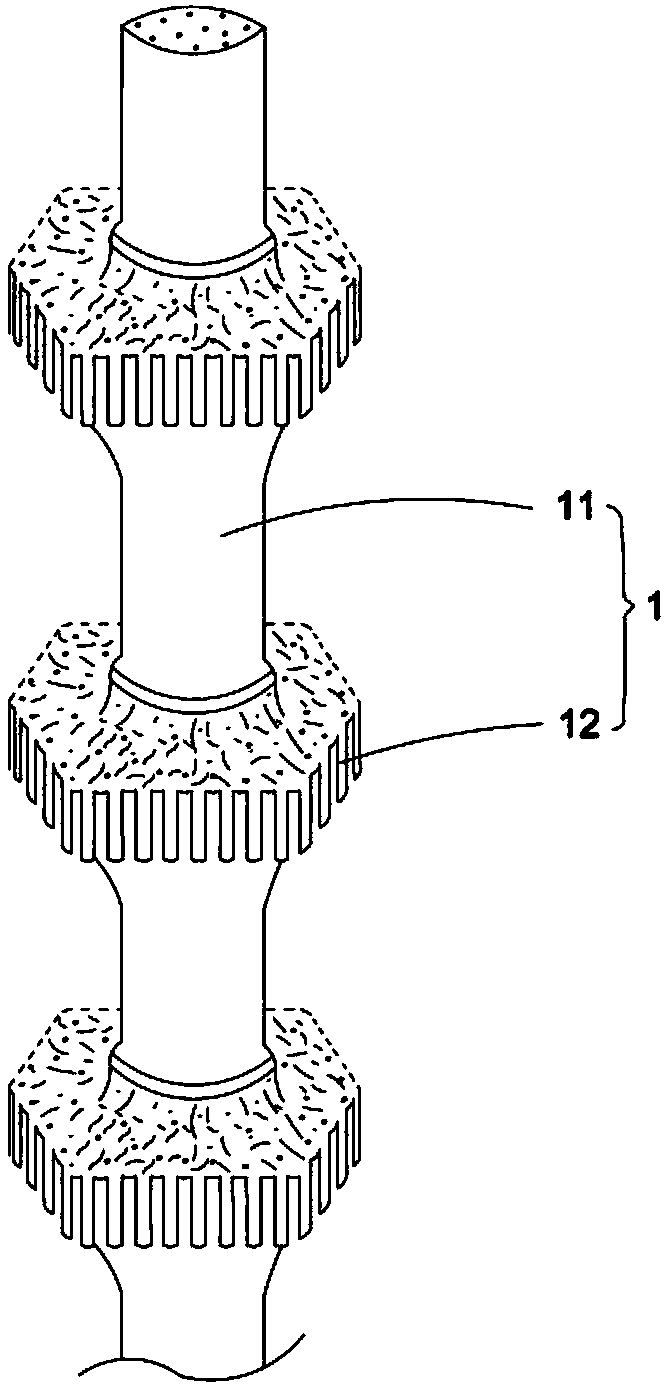

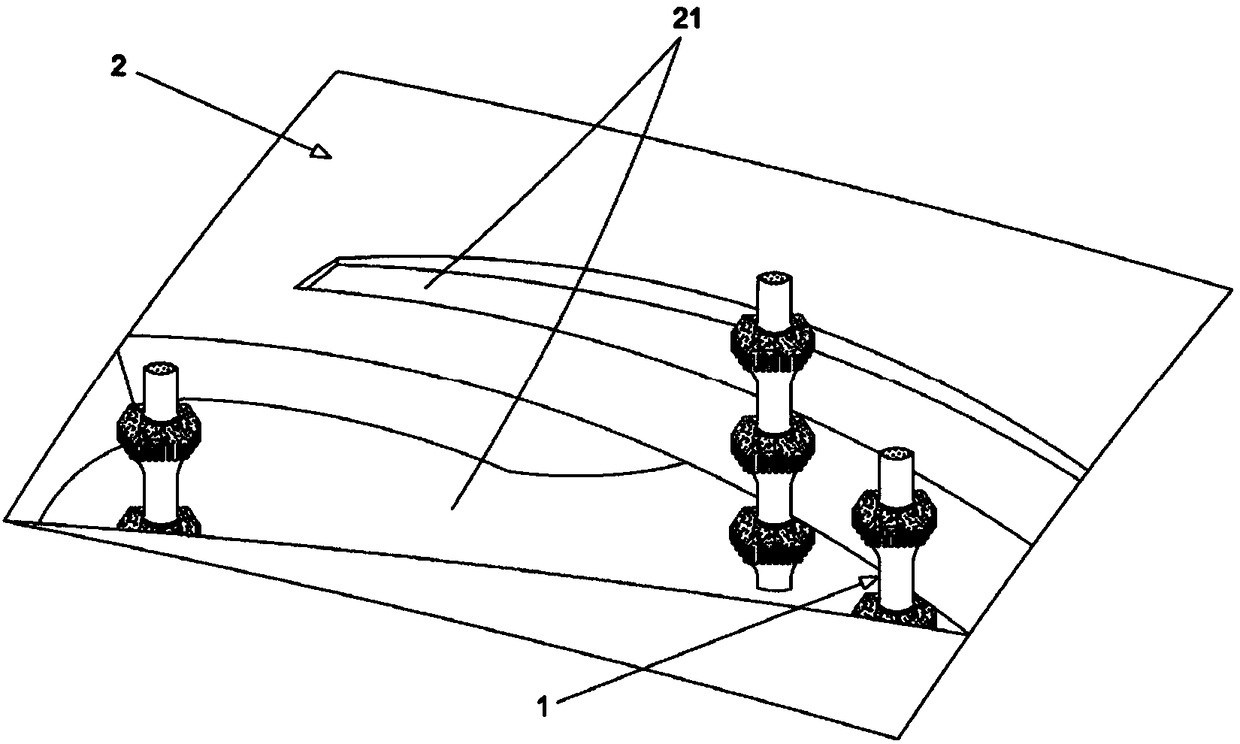

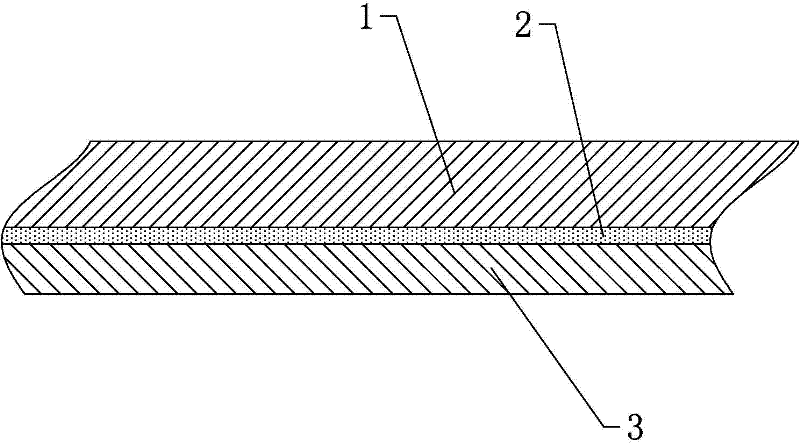

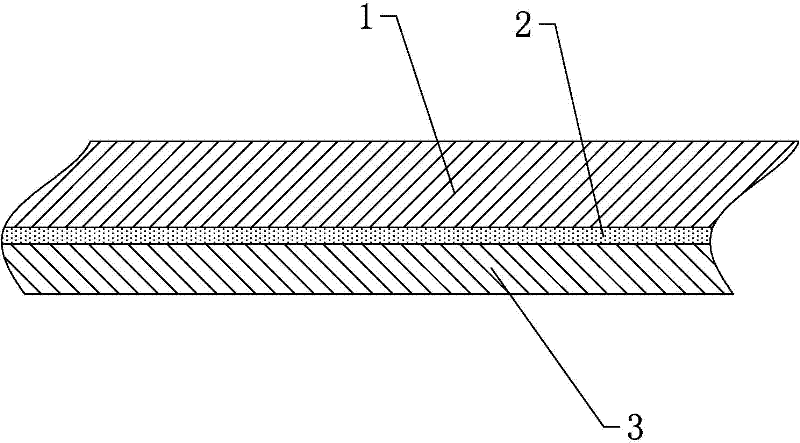

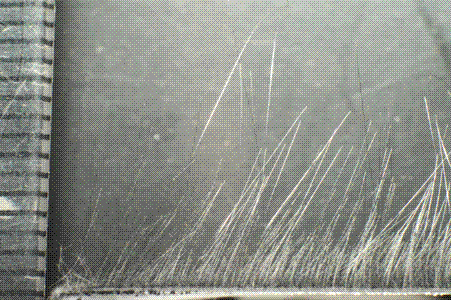

Anti-haze window screen based on electrospinning technology and preparation method thereof

ActiveCN108071332AThe overall thickness is thinHigh porosityDispersed particle filtrationInsect protectionParticulatesFiber

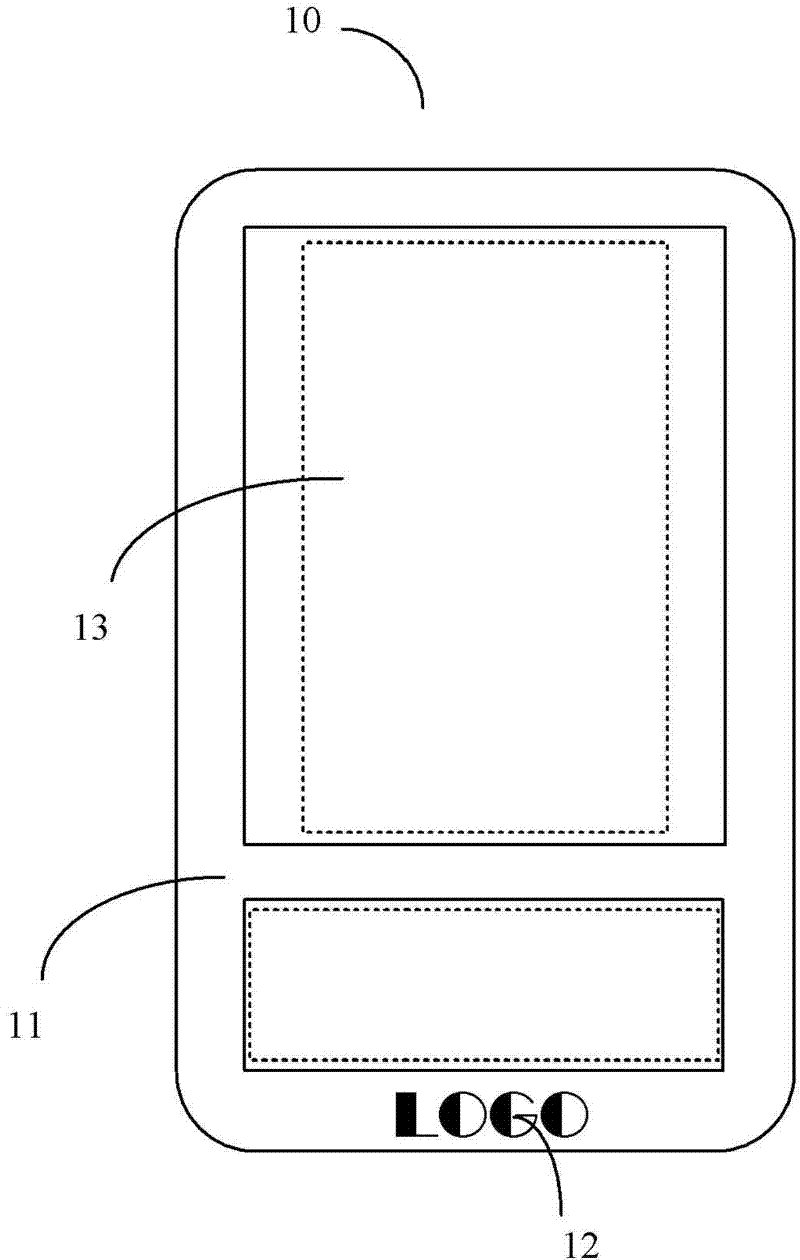

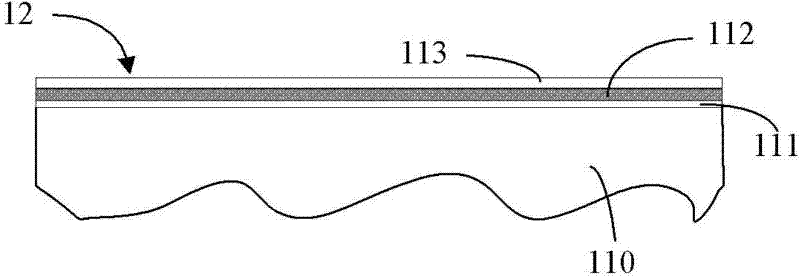

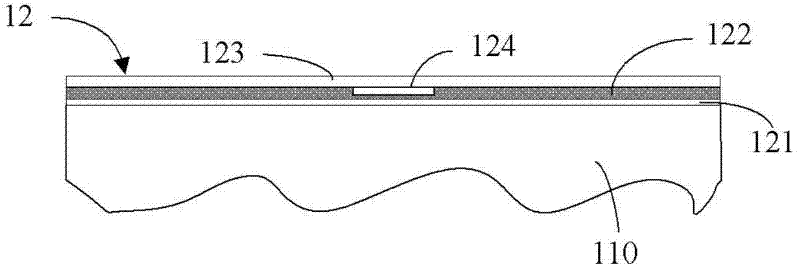

The invention discloses an anti-haze window screen based on an electrospinning technology and a preparation method thereof. The window screen is provided with a three-layer composite structure, a baselayer is a metal screen cloth, and a cyan ethyl acrylate viscous layer is compounded on the surface of the metal screen cloth in an electrostatic spray method. An intermediate layer is a nanofiber functional film directly electrospun on the surface of the metal screen cloth by electrospinning, and the nanofiber functional film is a nano-graphene / PVDF / PEO composite nanofiber film, a protective layer is compounded on the upper surface of the nanofiber functional film through a hot pressing method, and the protective layer is a nylon net. The window screen can filter outdoor air, effectively block dust and other particulate matter, and can ensure indoor and outdoor air circulation and indoor lighting. The preparation method is simple, suitable for large-scale production, and has a good application prospect.

Owner:聚纳达(青岛)科技有限公司

Shell and manufacturing method thereof

InactiveCN102365007AResolve shrinkageDiversifiedThin material handlingMetal layered productsMetal coatingPrinting ink

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

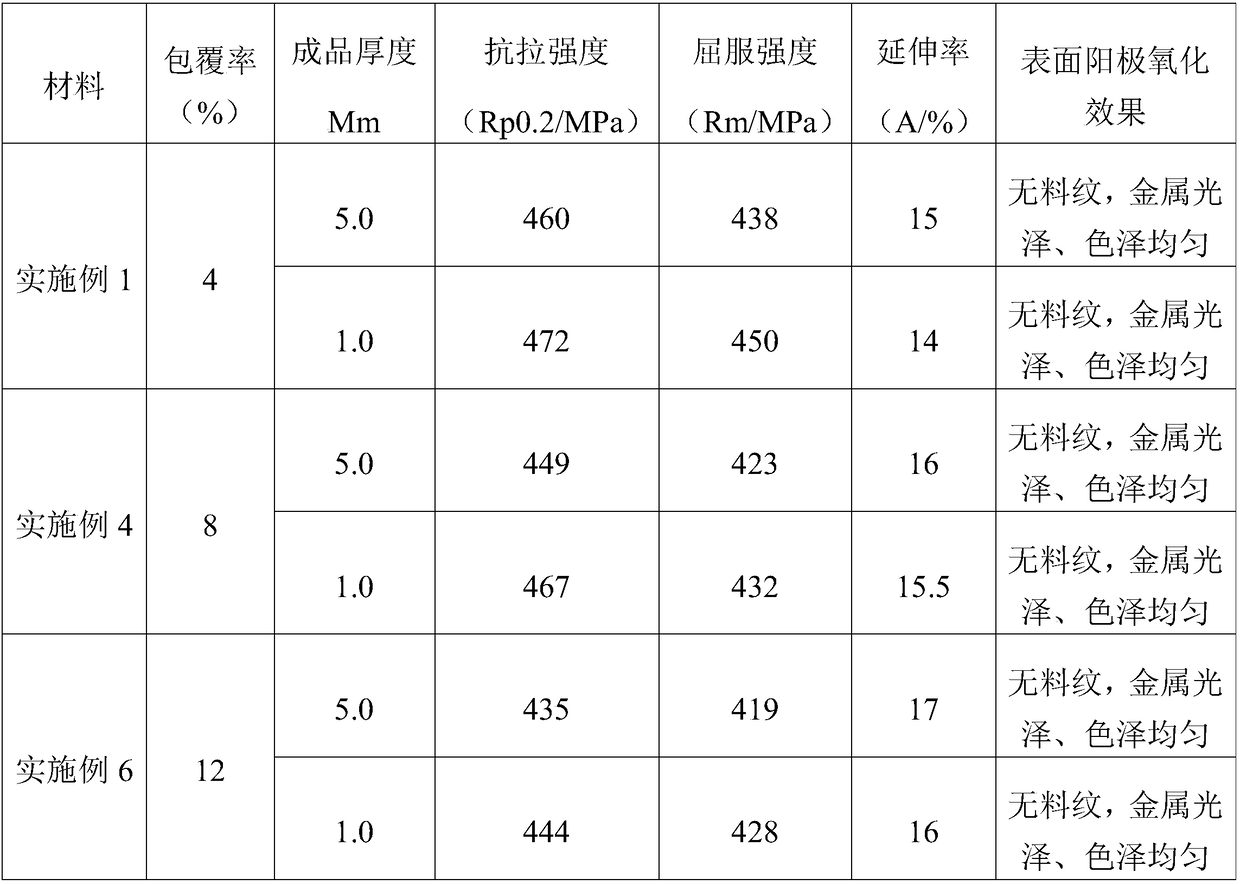

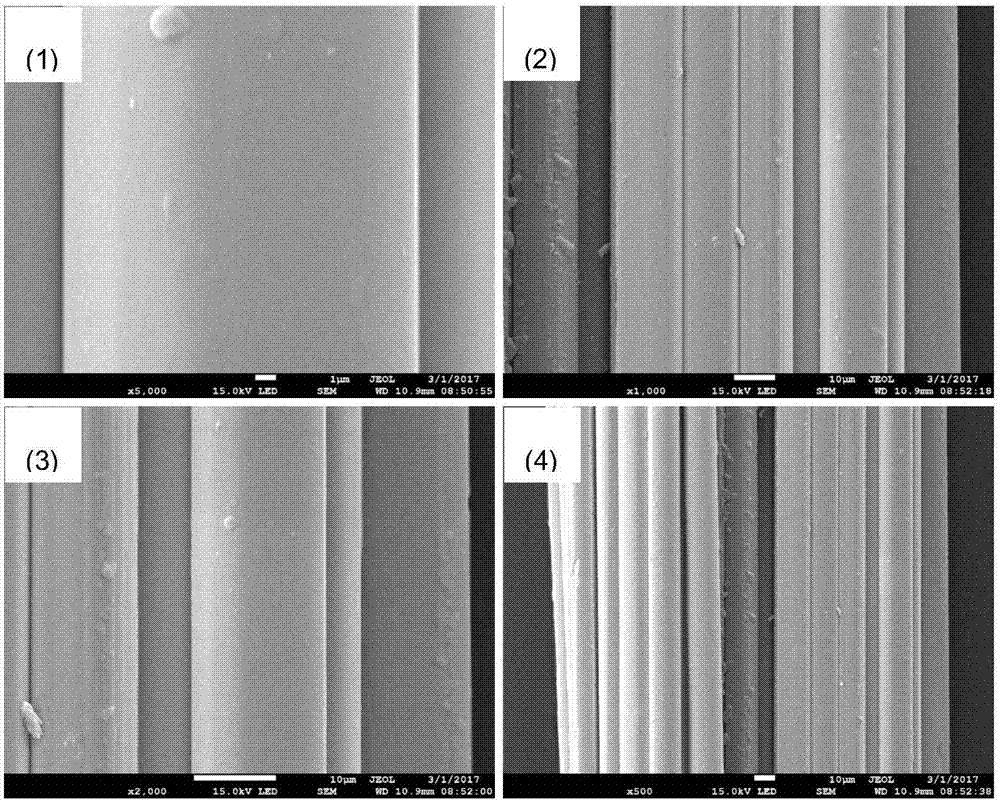

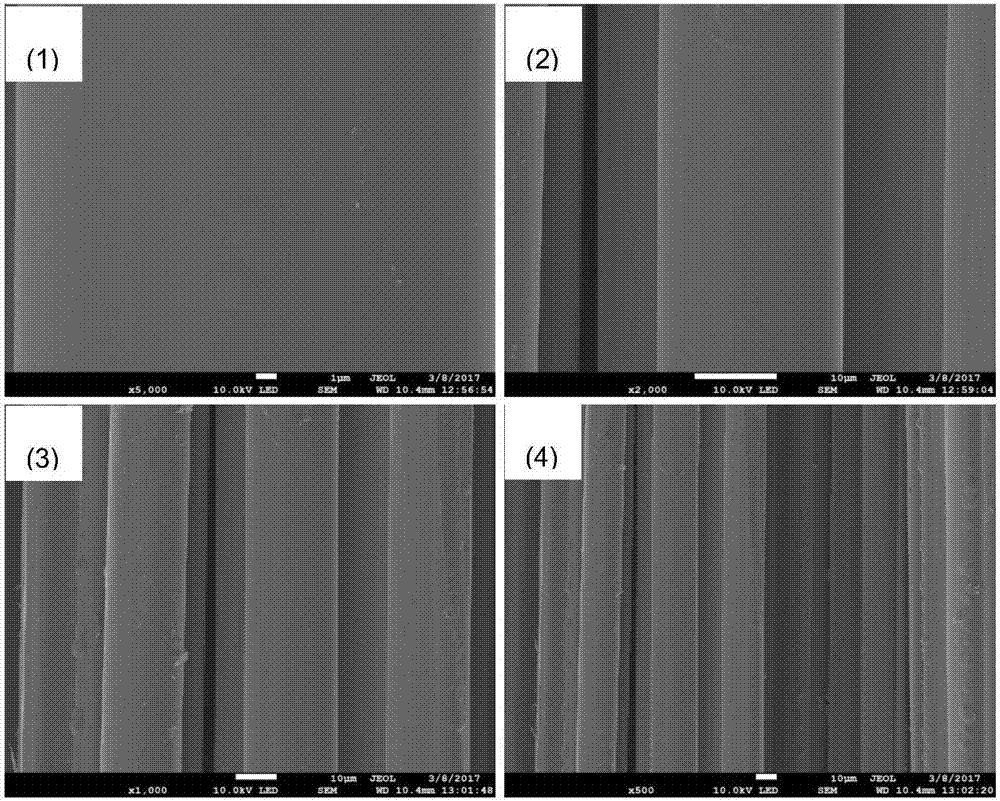

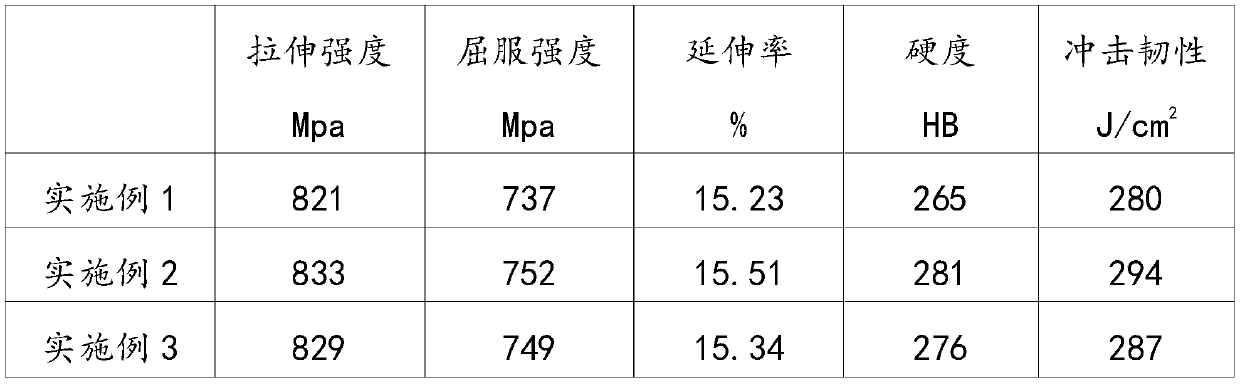

Preparation method of 1xxx/7xxx aluminium-alloy composite material

ActiveCN108909138AHigh hardnessHigh strengthLamination ancillary operationsLaminationHardnessAlloy composite

The invention discloses a preparation method of a 1xxx / 7xxx aluminium-alloy composite material. The preparation method comprises the following steps of: (1) preparation of a core-layer alloy casting plate and a coating-layer alloy casting plate; (2) surface treatment: respectively carrying out surface treatment on the core-layer alloy casting plate and the coating-layer alloy casting plate obtained in the step (1); (3) welding fixation: carrying out welding fixation on the core-layer alloy casting plate and the coating-layer alloy casting plate after surface treatment in the step (2) accordingto a coating-layer / core-layer combined mode; (4) preheating and hot rolling: preheating the alloy casting plate welded in the step (3), carrying out hot-rolling bonding and following machining according to the thickness of a finished product after the heating is finished to obtaining a product. The preparation method disclosed by the invention has the beneficial effects that two layers of aluminium-alloy composite plates have the characteristics of high hardness and high strength, meanwhile the anodic oxidation effect of an electronic product is obviously improved, so that after the anode ofthe electronic product is oxidized and colored, the surface has metallic luster and is uniform in color.

Owner:广西南南铝加工有限公司

Spray-free plastic with no flowing mark or light welding line and preparation method thereof

The invention relates to a spray-free plastic with no flowing mark or light welding line and a preparation method thereof. The spray-free plastic is prepared from the following raw materials in partsby weight: 90 to 95 parts of matrix resin, 2 to 3 parts of compatilizer, 1 to 2 parts of lubricant, 0.2 to 0.5 part of antioxidant, 0.2 to 0.5 part of ultraviolet absorber, 0.2 to 1.5 parts of effectadditive, and 2 to 6 parts of pigment master batch. Compared with the prior art, the spray-free plastic has the advantages that the weather-resistant property and size stability are excellent, the surface gloss is high, and the flowing mark is avoided; the welding line is basically avoided or the welding line is lighter in the subsequent secondary forming process; the effect of no flowing mark canbe realized without change of die; the complicated operation of traditional painting, electroplating and the like can be avoided, the procedures are greatly simplified, and more environment-friendlyeffect is realized; the toughness and anti-scratching property are excellent, and the processing fluidity is good; compared with metal resources, the longer-time use value is realized; the spray-freeplastic can be widely applied to the fields of automobile internal trims, bottom protective plates, home appliances, electronic equipment and the like.

Owner:浙江创新旭隆新材料科技有限公司

Composite and conductive polyimide/nickel fiber and preparation method thereof

The invention provides a composite and conductive polyimide / nickel fiber and a preparation method thereof and belongs to the field of electromagnetic-shielding and conductive fiber. Polyimide fiber is used as basic fiber, the surface of the polyimide fiber is supported with an ultra-thin metal layer through a surface modified ion exchange technique, then uniform precipitation of the metal nickel layer is conducted on the surface of the fiber by adopting a traditional chemical plating method, and accordingly a perfect and compact high-conductive metal nickel layer is obtained. Efficient preparation of the polyimide / nickel fiber having excellent surface metal luster, good interface caking property, high conductivity and controllable nickel layer thickness. The implementing process is simple, processizing is easy, and an application prospect is good.

Owner:BEIJING UNIV OF CHEM TECH

Novel color carbon treatment agent for leather and preparation method thereof

InactiveCN102839540ASolving Dispersion ProblemsSolve the fineness problemFibre treatmentColor effectSolvent

The invention discloses a novel color carbon treatment agent for leather and a preparation method thereof, relating to a surface treatment agent for synthetic leather. The color carbon treatment agent disclosed herein comprises 10-40% of alkyd resin, 1-10% of nitro-cotton, 0.5-1% of levelling agent, 1-10% of matting powder, 5-25% of carbon black, 5-25% of color pigment, 30-60% of solvent, 0.5-2% of dispersant, and 1-5% of stripping aid. According to the invention, the problems of dispersion and fineness of the carbon black and color pigment are solved, by adding the color pigment to compound with the carbon black and simultaneously polishing the product, the leather surface presents a synthetic and complete color effect and has a certain metal luster, the formula design is reasonable, the component cooperation is advanced, the product performance is excellent and stable, the technology is advanced, and the operationality is strong.

Owner:HANGZHOU COLORICH CHEM MATERIALS

Metal cobalt electrodeposition method by ion liquid

InactiveCN1884622AImprove conductivityWith metallic lusterPhotography auxillary processesChemical reactionAlloy

This is the method of electrodeposition of metals cobalt in Ionic Liquids. It resolve the problem that electrodeposition of metals cobalt in Ionic Liquids which content EMIC can form crystalline alloy on the surface of substrate. The steps are: (1) mixed anhydrous EMIC, cobalt chloride and organic alkoxide by the molar ratio of 1:0.3 - 2:2.5 - 18 in vacuum glovebox; (2) emerge the substrate into Ionic Liquids, with the current density of 30 - 150A / m2, temperature of 60-100 DEG C electrodeposition under constant current. The anode doesn't react with Ionic liquids. The distance between anode and substrate is 1 - 10cm; (3) take the substrate with electrodepositing coatings out of the Ionic liquids, then wash with ethanol and distilled water, and dry it. This method can get even, pure depositing coating with metallic luster.

Owner:HARBIN INST OF TECH

Method for preparing activated carbon used for flue gas demercuration

InactiveCN101844074AImprove removal effectUnique process methodOther chemical processesDispersed particle separationActivated carbonFlue gas

The invention relates to a method for preparing activated carbon, in particular to the method for preparing the activated carbon used for flue gas demercuration. The method is characterized by comprising the following steps of: preparing feed coal, and performing anoxybiotic dry distillation, milling, stirring while adding coal tar, extrusion molding, carbonization, activation, milling and dipping on the feed coal to obtain finished products. The method for preparing the activated carbon used for the flue gas demercuration has the advantages of unique process, high technical indexes of produced products and wide application range.

Owner:NINGXIA HUAHUI ACTIVATED CARBON

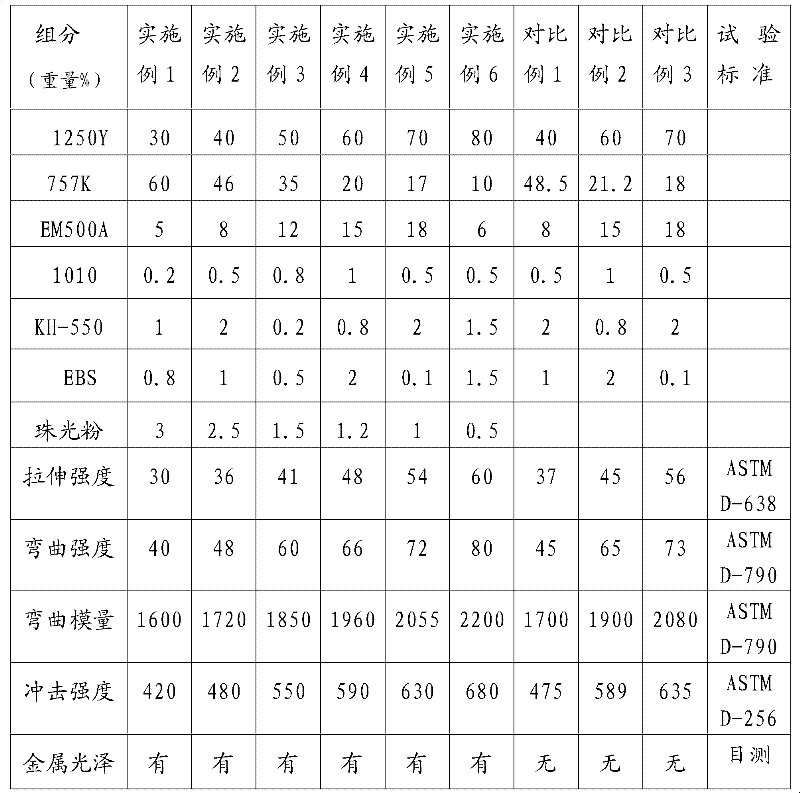

PC/ABS alloy possessing metal luster and its preparation method

The invention discloses a PC / ABS alloy possessing metal luster and its preparation method. The PC / ABS alloy possessing metal luster comprises the following ingredients by weight percentage: 30-80% of polycarbonate, 10-60% of acrylonitrile-styrene-butadiene copolymer; 5-20% of flexibilizer; 0.2-2% of coupling agent; 0.2-1% of anti-oxidant; 0.5-2% of processing auxiliary agent and 0.5-3% of pearl powder. According to the invention, the pearl powder replaces of metal powder, the fire hazard and blast are not easy to happen during the preparation process, so that the potential safety hazard can be eliminated. The pearl powder has small influence on the material performance; the material keeps good mechanical property. The material has metal luster which is a substitution of metal material in certain extent, thereby the production cost of the product can be effectively reduced.

Owner:SHENZHEN KEJU NEW MATERIAL

Magnesium alloy chemical nickel plating solution and electroplating pretreatment method

ActiveCN101435077AImprove bindingWith metallic lusterLiquid/solution decomposition chemical coatingNickel saltCerium nitrate

The invention provides a magnesium alloy chemical nickel plating solution, which contains water, nickel salt, a reducing agent and a compounding agent; wherein, the nickel plating solution also contains cerium nitrate. The invention also provides a magnesium alloy electroplating pretreating method, which comprises the following steps: under the chemical nickel plating condition, the magnesium alloy and the chemical nickel plating solution are contacted; wherein, the chemical nickel plating solution is the one provided by the invention. In the chemical nickel plating solution provided by the invention, as the cerium nitrate is added, the binding force of a base material and a plating layer is obviously increased. The magnesium alloy electroplating pretreating method provided by the invention has simple technique, convenient operation, little pollution to the environment, high binding force of the base material and the plating layer, smooth and beautiful workpiece surfaces, low cost and high economic benefit.

Owner:BYD CO LTD

Furniture wood board surface metallic paint spraying method

InactiveCN108480166AImprove adhesionPrevent disengagementPretreated surfacesCoatingsTouch sensationAcrylic paint

The invention provides a furniture wood board surface metallic paint spraying method. The furniture wood board surface metallic paint spraying method comprises the following steps that mixed priming paint is prepared, specifically, 0.1-0.5% of shish-kebab-structure polymer is added into acrylic paint, and uniform mixing is conducted; mixed finish paint is prepared, specifically, 10-20% of metal powder is added into the acrylic paint, and uniform mixing is conducted; primary polishing is conducted, specifically, the surface of a wood board is polished through a polishing machine, and thus, thesurface of the wood board is smooth; the priming paint is sprayed, specifically, the mixed priming paint is sprayed onto the surface of the wood board through a spraying technology, leveling is conducted, and after baking, a priming paint layer which is 25-40 [mu]m thick is formed; secondary polishing is conducted, specifically, the surface of the priming paint layer is polished through fine sandpaper so as to be smooth; and the finish paint is sprayed, specifically, the mixed finish paint adheres to the priming paint layer through the spraying technology, leveling is conducted, and after baking, a finish paint layer which is 100-120 [mu]m thick is formed. After metallic finish paint is sprayed onto the surface of furniture, the surface of furniture has metallic luster, the paint surface is high in stereoscopic impression and smooth when being touched with a hand, and the good visual effect and touch sensation are achieved.

Owner:GUANGDONG HULUBAO CULTURE TECH CO LTD

High temperature and high pressure direct synthesis method of cubic boron nitride in titanium nitride plated coating

InactiveCN103272527AHigh hardnessImprove wear resistanceUltra-high pressure processesAlkaline earth metalHexagonal boron nitride

The invention relates to a high temperature and high pressure direct synthesis method of cubic boron nitride in a titanium nitride plated coating, relating to a high temperature and high pressure synthesis method of an ultra-hard material. The method takes hexagonal boron nitride as a raw material, an alkali metal nitride or alkaline-earth metal nitride or boron nitride as a catalyst, and metallic titanium powder or a metallic titanium compound as an additive. The method comprises the following steps of: mixing the hexagonal boron nitride and the alkali metal nitride or the alkaline-earth metal nitride or the boron nitride according to a weight proportion of 1:(0.1-0.3), adding the metallic titanium powder or the metallic titanium compound accounting for 0.5wt%-10wt% of the total mixture, and synthesizing a cubic boron nitride product with the titanium nitride plated coating at a high temperature and a high pressure, wherein the synthesis temperature is 1000 to 1800 DEG C, the synthesis pressure is 4.0-6.0 GPa, and the temperature and the pressure last for 3-15 minutes. The cubic boron nitride provided by the invention has the characteristics of high hardness, good abrasion resistance, good high temperature resistance, good tenacity, thermal conduction and electrical conduction, and is particularly suitable for preparation of polycrystalline cubic boron nitride products and tools.

Owner:柳州市大荣非金属材料有限公司

Colored crystal glass with metallic luster

InactiveCN102514292AWith metallic lusterGlass/slag layered productsMetal layered productsMetallic aluminumHome appliance

The invention discloses colored crystal glass with metallic luster. The colored crystal glass comprises a toughened glass layer and a metal film layer, wherein the metal film layer is adhered on one surface of the toughened glass layer through adhesive and is a metal aluminum foil layer. The colored crystal glass has a simple structure and metallic luster, can be made into products with various specifications and thicknesses according to different requirements of customers and meets the use requirement in the field of home appliances.

Owner:JIANGSU OBON PLASTIC

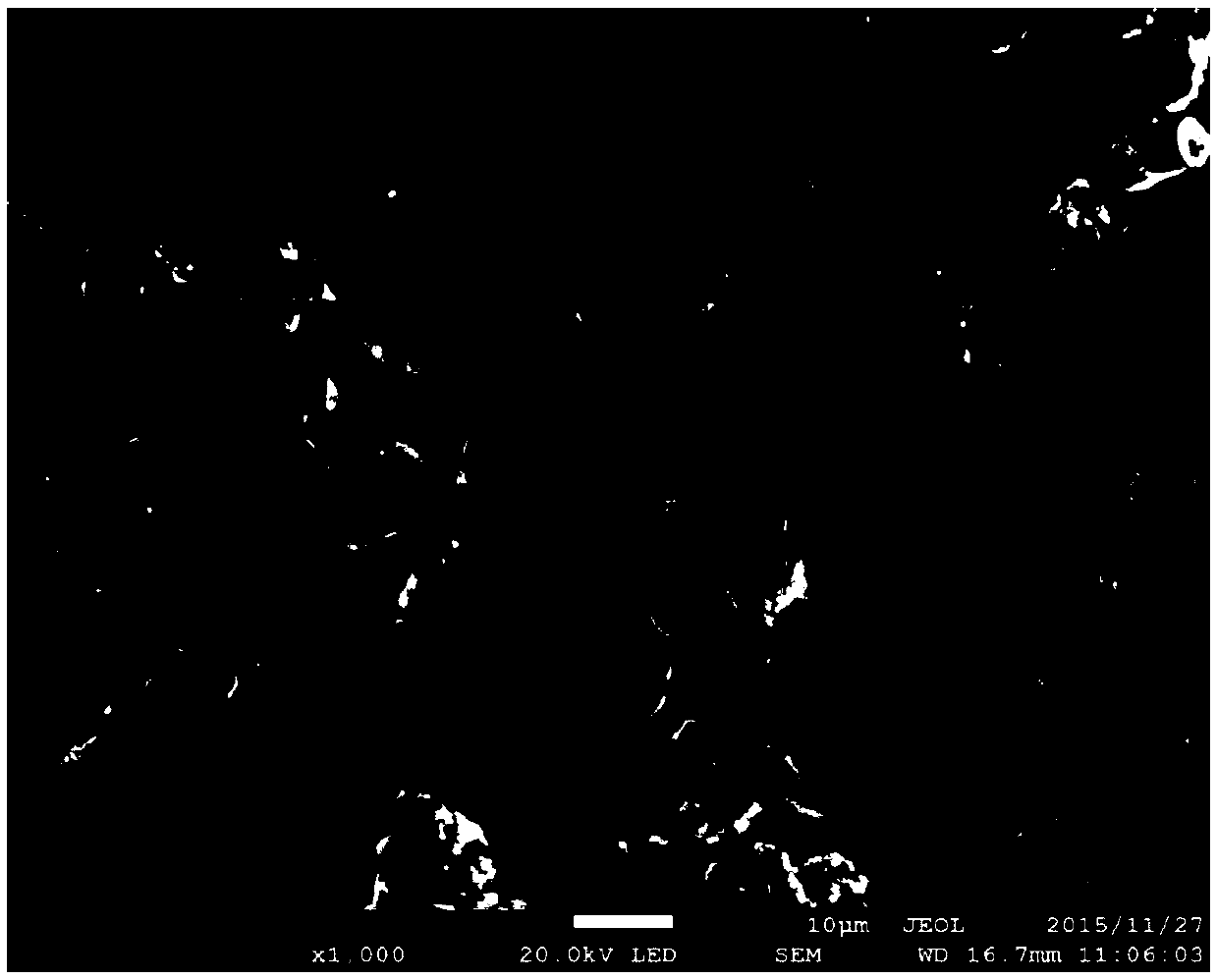

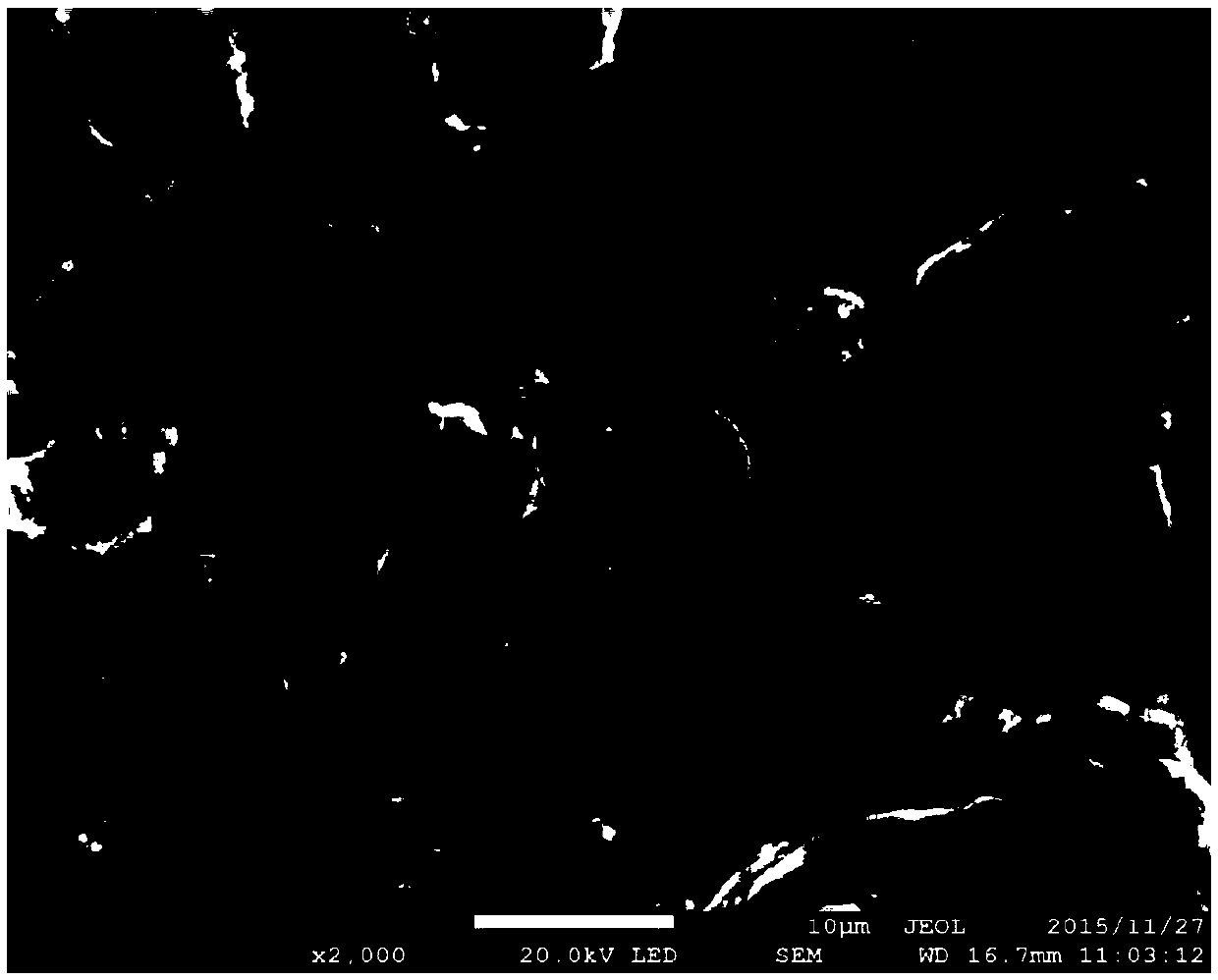

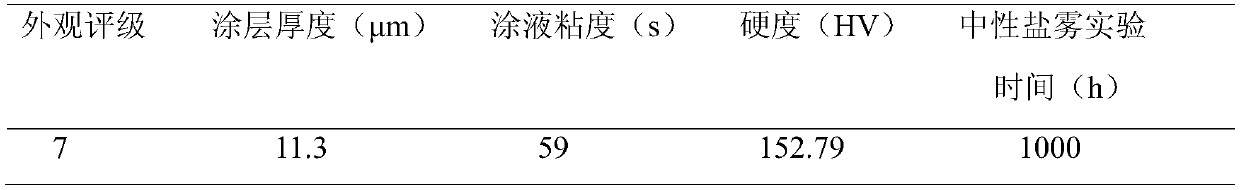

Al2O3 nano-particle enhanced chromium-free Dacromet anti-corrosion paint, coating, and reparation method of paint and coating

ActiveCN105542540AImprove compactnessAccelerated corrosionAnti-corrosive paintsChromium freeSodium molybdate

The invention discloses an Al2O3 nano-particle enhanced chromium-free Dacromet anti-corrosion paint. The paint comprises the following raw materials in percentage by mass: 50 to 55 percent of metal slurry, 42 to 48 percent of chromium-free passivation solution, 1 to 2 percent of modified Al2O3 nano particles, and 0.5 to 1 percent of an assistant. According to the paint, sodium molybdate, boracic acid, a rare earth material and silane coupling agent are selected and used to replace chromic anhydride to serve as the chromium-free passivation solution, and the chromium-free passivation solution is high in corrosion resistance and is environmentally friendly; the modified Al2O3 nano-particles are combined and are dispersed in the paint, so that the hardness, the abrasion resistance and the corrosion resistance of a coating can be effectively improved; the prepared paint has stable performance, smooth and flat coating surface, metal luster, high hardness, and excellent corrosion performance.

Owner:随州武汉理工大学工业研究院

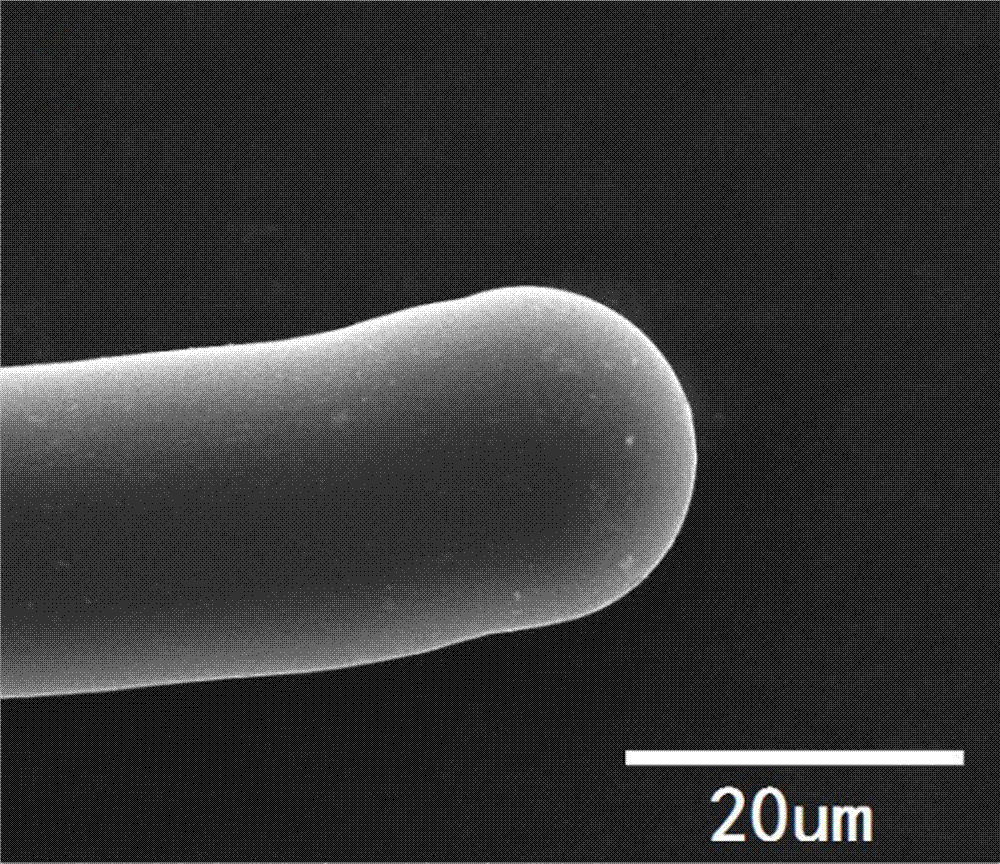

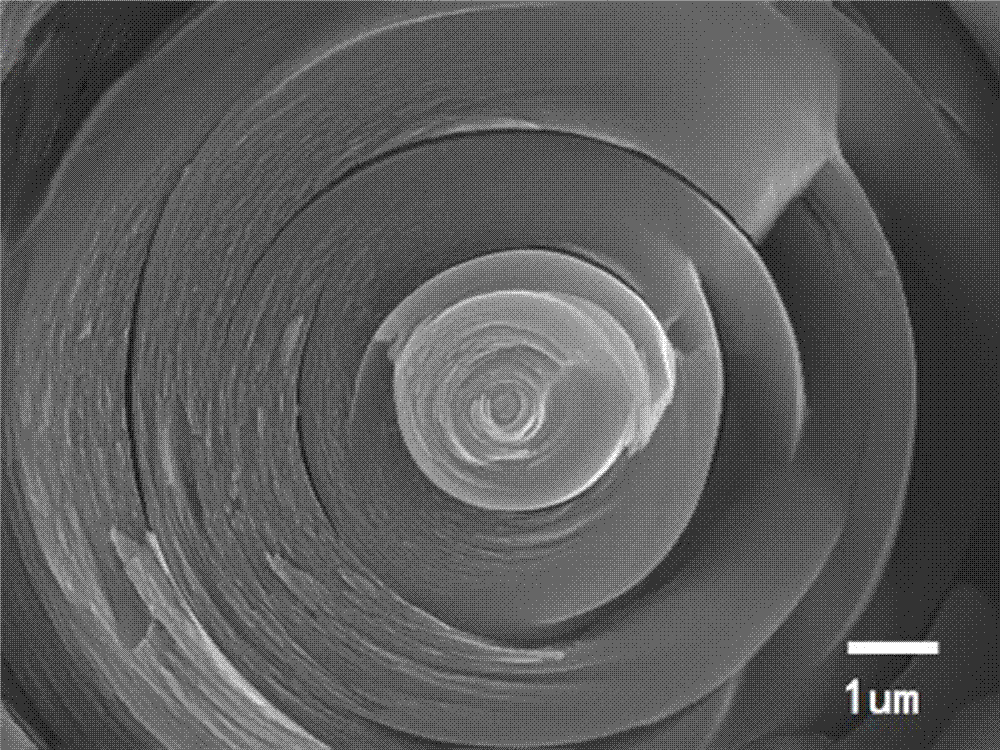

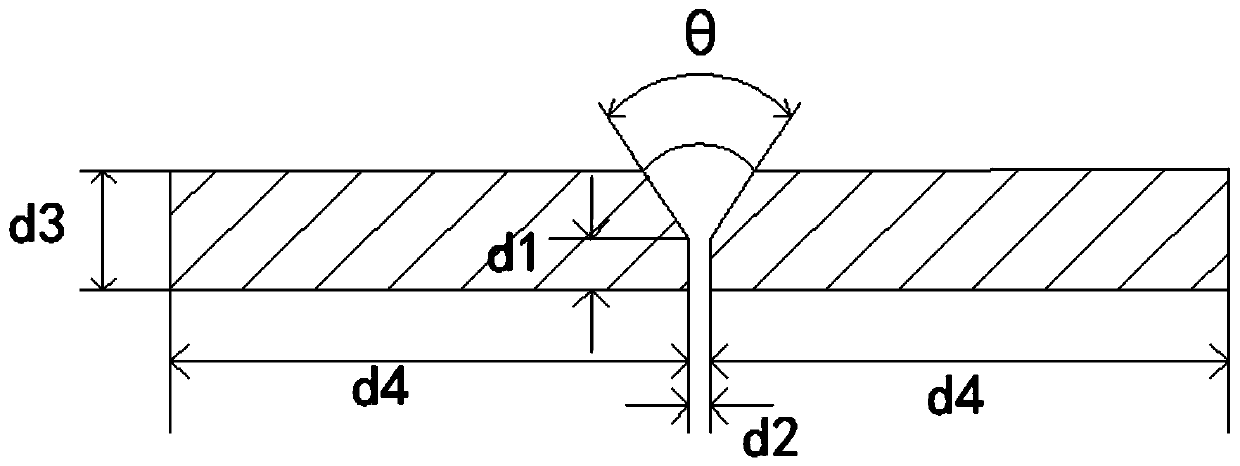

Graphite fiber and preparation method thereof

ActiveCN107119348AHas a large spanHigh purityElectroconductive/antistatic filament manufactureFiberGas phase

The invention relates to a graphite fiber and a preparation method thereof. The graphite fiber serving as a monomer fiber directly grows by adopting a vapor deposition method under the condition of no catalyst; the purity of obtained products is greater than 99.99 percent; the obtained products are straight and filamentous in appearance, the diameter range is 0.1 to 50mu m and the length range is 3 to 100mm; the products are generally parallel to one another; a hemispherical sealing cover is arranged at the top of each product and the interior of the fiber is solid; Raman spectrum shows that the intensity of a G peak is greater than that of a D peak in the graphite fiber; the graphite fiber has a metallic luster under the irradiation of visible light, and the resistivity of the graphite fiber is equivalent to that of graphite. The graphite fiber uses a quartz plate as a substrate, adopts argon and hydrogen as carrier gases, selects methane as a carbon source, and is prepared by cleaning the substrate, charging into a furnace, carrying out vapor deposition growth and sampling. With a special form and physical properties, the performance consistency between devices can be ensured when the graphite fiber prepared by the method is used for producing vacuum electronic devices such as a cold field emission electric gun filament.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

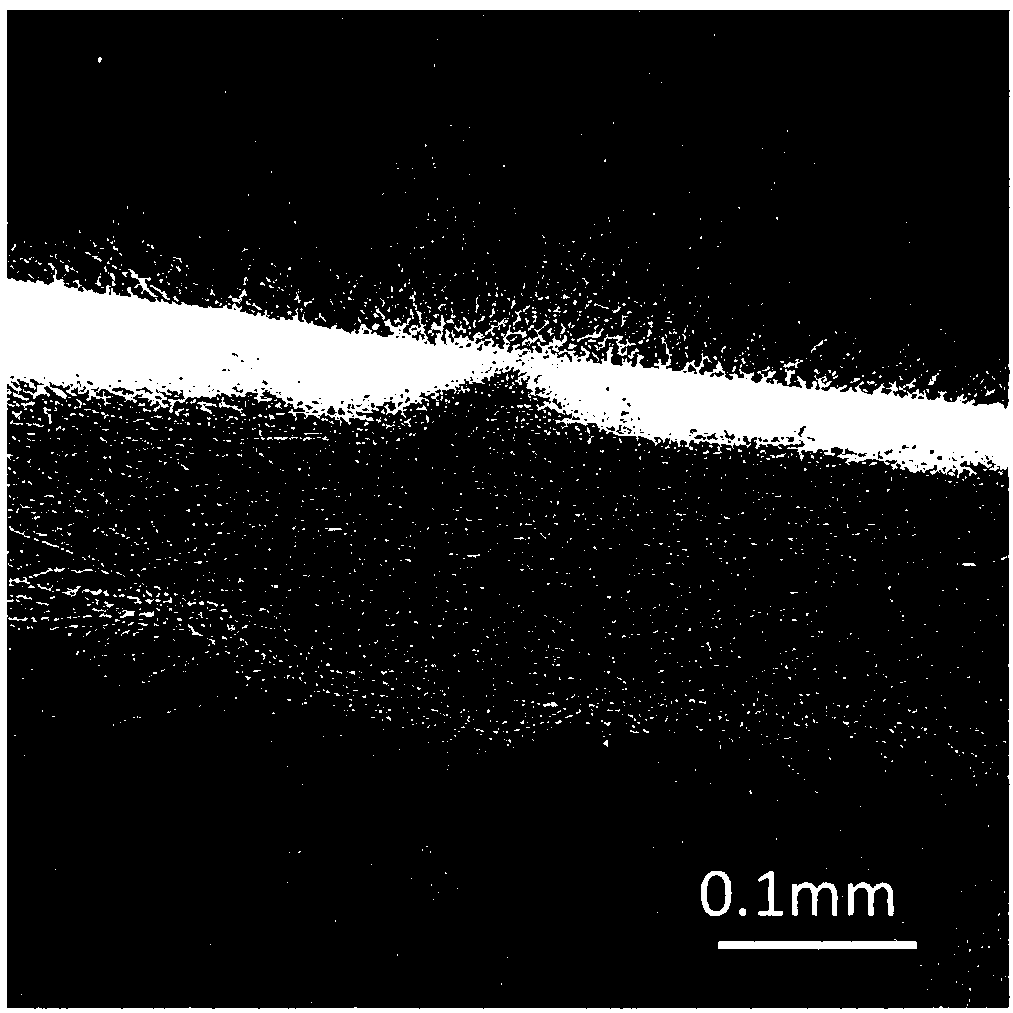

Laser and arc composite welding method of martensite precipitation-hardening stainless steel

InactiveCN110293322AUniform weld formationReduce distortionLaser beam welding apparatusButt jointMartensite

The invention relates to a laser and arc composite welding method of martensite precipitation-hardening stainless steel. The method includes the steps that butt joint connection ports of two to-be-welded workpieces are machined into grooves; the two to-be-welded workpieces are assembled and fixed, and a gap is reserved between the two to-be-welded workpieces; laser is adopted for performing backing welding on the bottoms of the grooves, and bottom weld joints are performed; and laser and arc composite welding is adopted for performing wire filling and face covering welding on the grooves, anda welding process is completed. According to the method, due to the fact that the laser backing welding is firstly performed on the bottoms of the grooves formed after machining of the to-be-welded workpieces, penetration fusion welding is achieved, through welding of the bottom of a truncated edge can be guaranteed, so that the weld joints at the bottoms of the grooves are uniform in forming, deformation is small, and the welding precision is guaranteed; then laser-arc composite welding is adopted for performing wire filling and face covering welding on the grooves, and therefore the high-quality weld joints are formed; and work procedures are simple, operation is easy, the process cost is low, and a good welding effect is achieved on the special material of the martensite precipitation-hardening stainless steel.

Owner:WUHAN JINDUN LASER TECH CO LTD

Method for electrodepositing lithium-copper alloy in ionic liquid system

The invention discloses a method for electrodepositing a lithium-copper alloy in an ionic liquid system, which relates to a method for electrodepositing the lithium-copper alloy. The method solves the problems that the conventional smelting method for preparing the lithium-copper alloy cannot control the lithium element content easily and has high energy consumption. The method comprises the following: step one, adding LiBF4, Cu(BF4)2 and an additive into BMIMBF4 in turn to prepare an electrolyte; and step two, immerging an anode material and a cathode material into the electrolyte, and adopting a constant current mode and controlling the current density and the electrodepositing time to realize the preparation of the lithium-copper alloy, wherein the two steps are performed in a glove box. The method has the advantages of concise process, simple equipment and low energy consumption; the metal lithium content in the lithium-copper alloy is adjusted and controlled by adjusting components and electrodepositing technological parameters of the electrolyte; the metal lithium content is controllable; and the atomic mass percent content is 7 to 40 percent. Simultaneously, the method realizes co-deposition of lithium and copper which have large electrode potential differences; and the obtained lithium-copper alloy can be used as a cathode material for a lithium ion battery.

Owner:HARBIN INST OF TECH

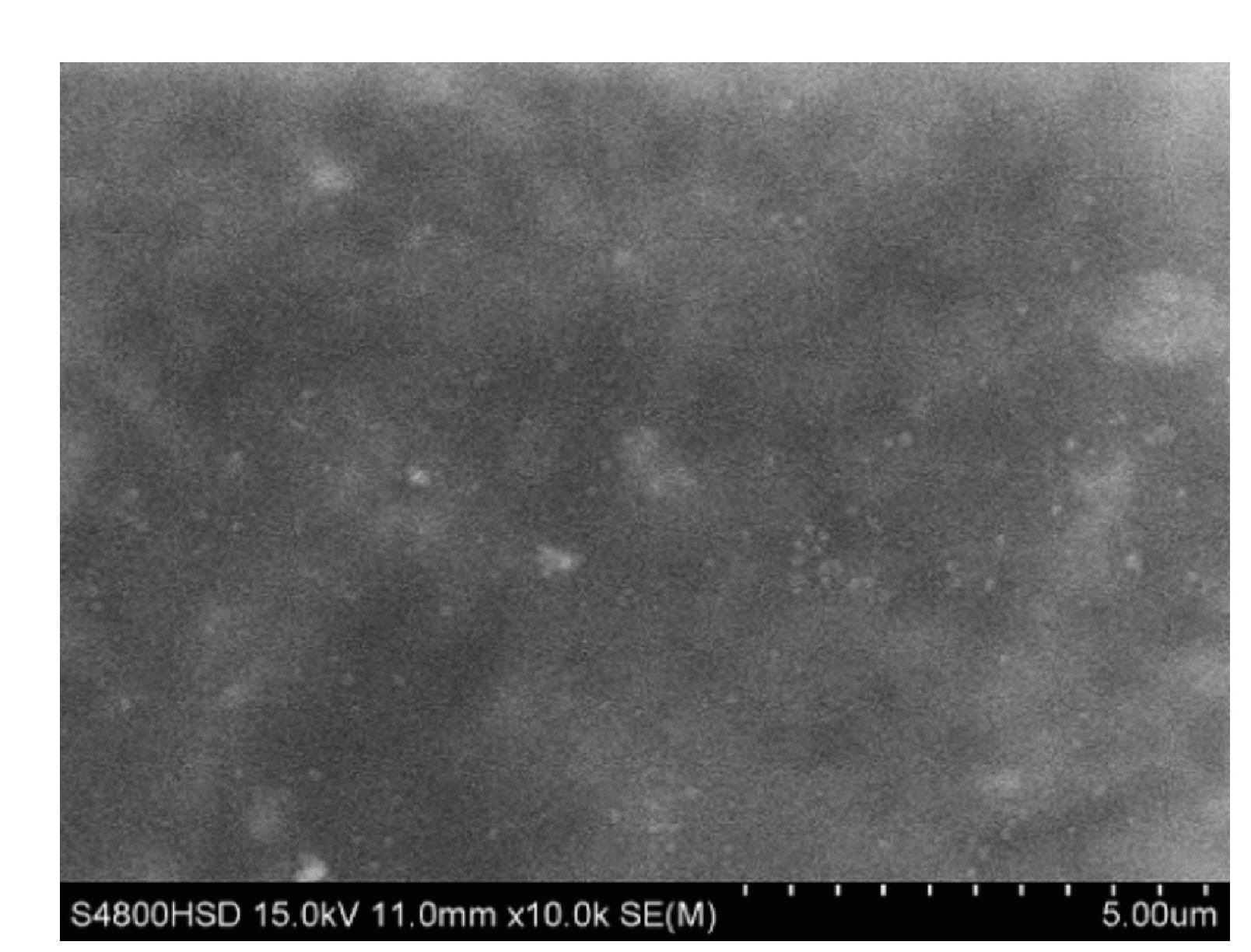

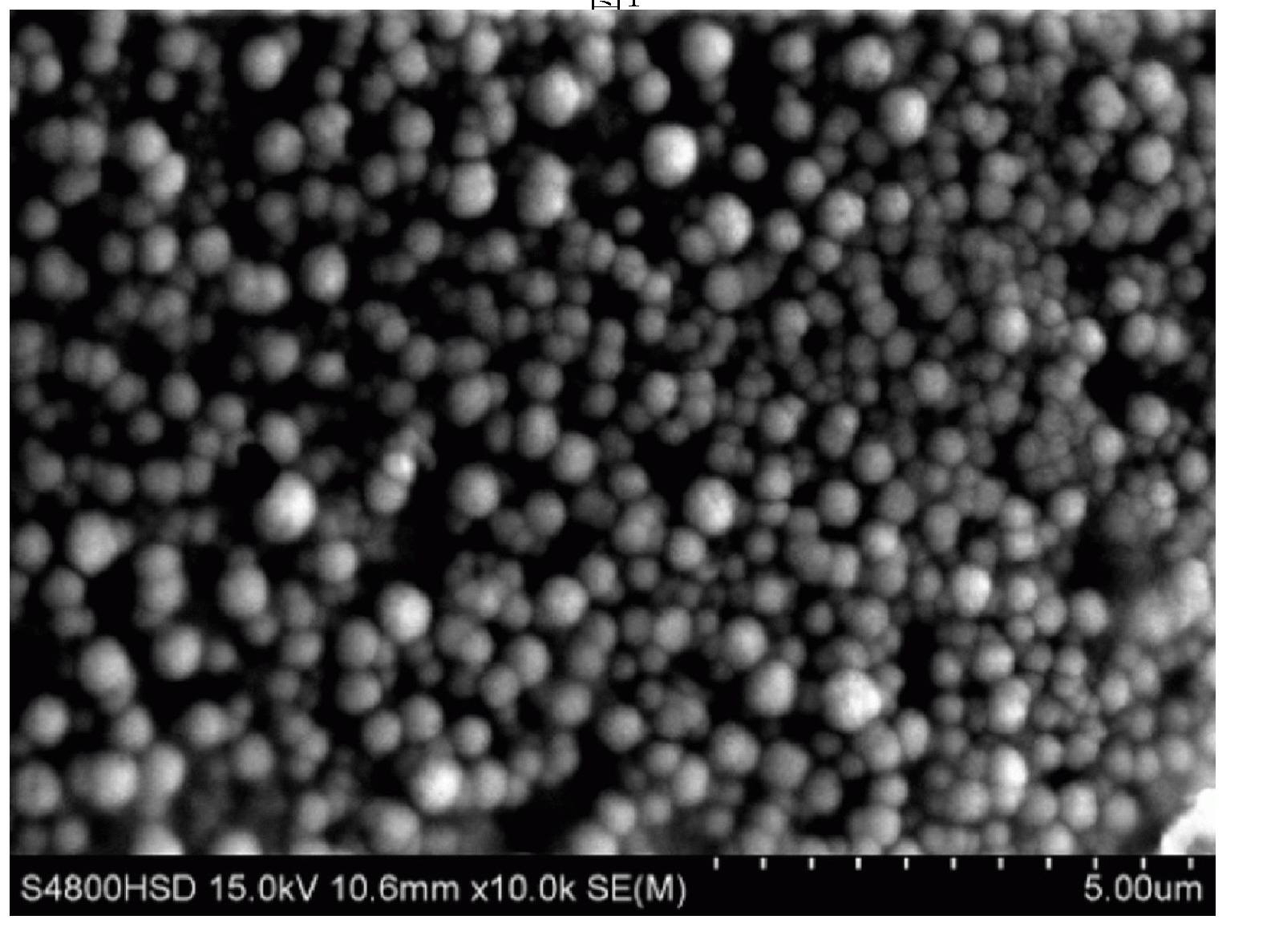

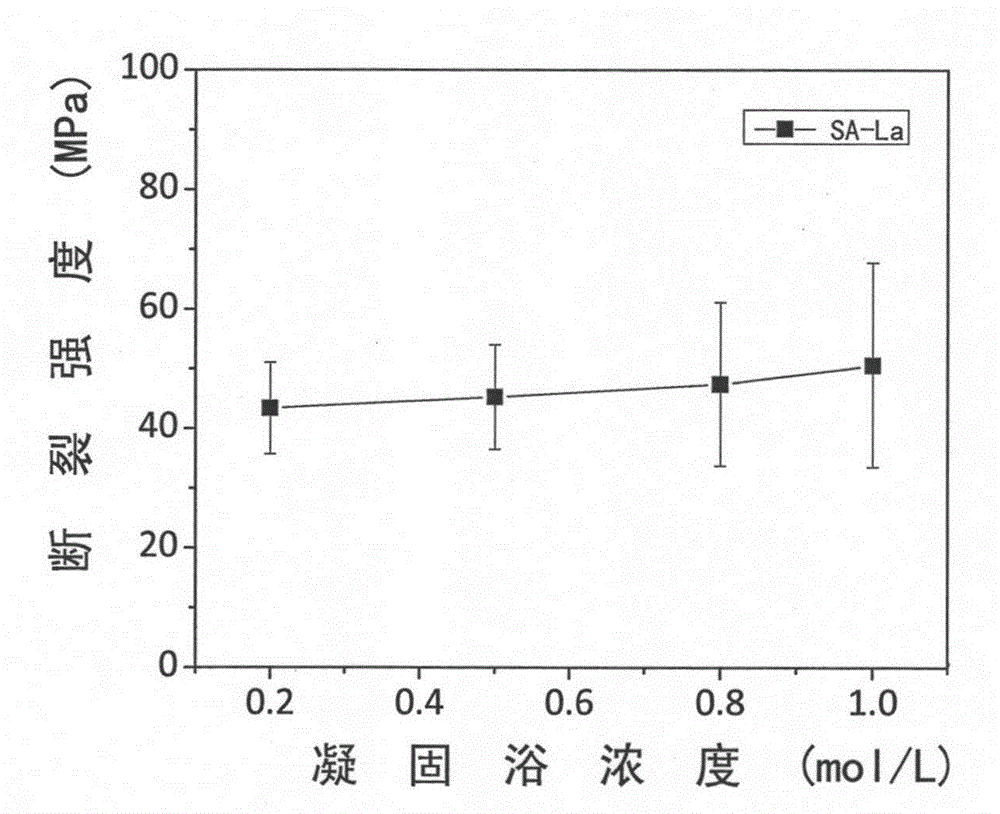

Method for preparing rare earth polysaccharide composite fibers

InactiveCN104451931AImprove water absorptionGood biocompatibilityArtificial filaments from cellulose derivativesWet spinning methodsFiberRare earth

The invention provides a method for preparing rare earth polysaccharide composite fibers. The method is characterized by comprising the following specific steps: step 1, dissolving polysaccharides to prepare a spinning solution; step 2, preparing a coagulating bath, wherein the coagulating bath contains rare earth metal ions; step 3, metering the spinning solution obtained in the step 1 by virtue of a metering pump, extruding the spinning solution to enter the coagulating bath obtained in the step 2 by virtue of a spinning nozzle, wherein the polysaccharides and the rare earth metal ions are subjected to coordination complexation, and the fibers are subjected to coagulation forming; and step 4, cleaning the obtained fibers by virtue of deionized water and drying, thus obtaining the rare earth polysaccharide composite fibers. According to the method disclosed by the invention, the spinning solution with a certain concentration is prepared by utilizing the polysaccharides, the rare earth metal ions are prepared into the coagulating bath of a certain concentration, and the rare earth polysaccharide composite fibers are prepared by virtue of coordination of the polysaccharides and the rare earth metal ions. The spinneret orifice is not blocked during wet spinning, and the spinning operation has high production continuity.

Owner:DONGHUA UNIV

Antibacterial material as well as preparation method and application thereof

ActiveCN104719339AGood antibacterial effectFast actingBiocideDisinfectantsGranularityMontmorillonite

The invention relates to an antibacterial material, as well as a preparation method and application thereof. The antibacterial material comprises a carrier, an inorganic bacteriostatic agent and an organic bacteriostatic agent, wherein the carrier comprises montmorillonite, the granularity of the inorganic bacteriostatic agent is 1-50 nm. The antibacterial material provided by the invention is rapid in interaction speed, excellent in antibacterial effect and long in effective acting time and cannot loss the antibacterial activity due to the dissolution and loss.

Owner:BYD CO LTD

Anticorrosive nanometer aqueous architectural coating and preparation method thereof

ActiveCN101857737AStrong anti-ultraviolet absorption abilityStrong corrosion resistanceAnti-corrosive paintsSolventChemistry

The invention provides an anticorrosive nanometer aqueous coating which is prepared by using modified nano-scale pigment (particularly modified nano-zirconia) as a basis and then mixing with other nonpoisonous materials, has good anticorrosive effect, particularly resists ultraviolet rays, does not contain solvents, is nonpoisonous and environment-friendly and is particularly applicable for the anticorrosion of metals, particularly, outdoor metal components.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

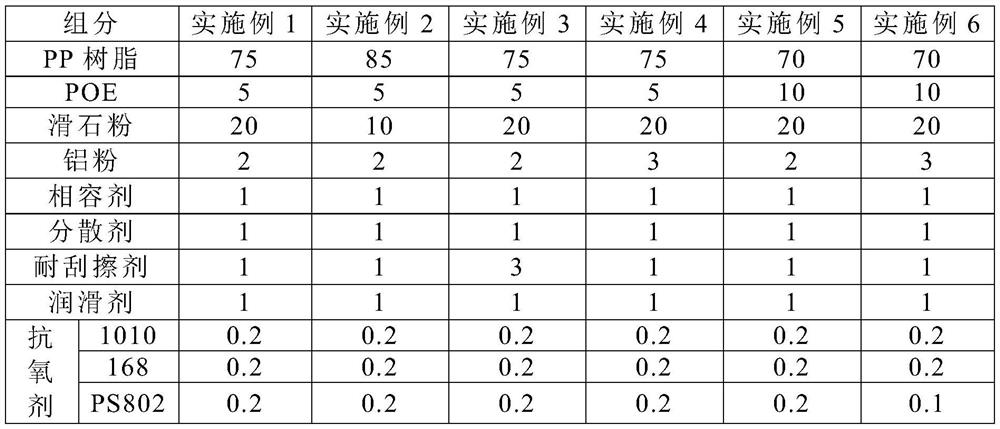

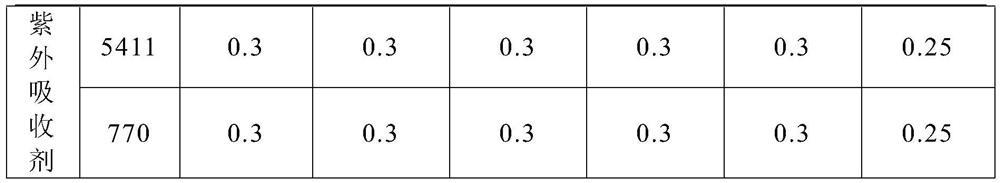

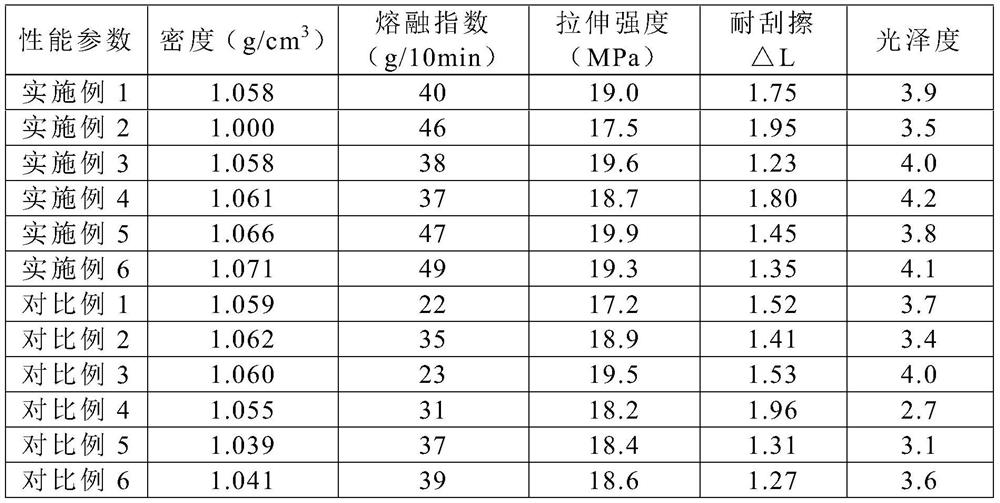

High-fluidity scratch-resistant spraying-free metallic-silvery-color modified polypropylene material for vehicles

The invention belongs to the technical field of polymer materials, and particularly relates to a high-fluidity scratch-resistant spraying-free metallic-silvery-color modified polypropylene material for vehicles. Raw materials comprise the following components in parts by weight: 50 to 80 parts of PP resin, 5 to 20 parts of polyolefin elastomer, 10 to 40 parts of talcum powder, 0.5 to 5 parts of metal powder, 0.5 to 2 parts of a compatilizer, 0.5 to 2 parts of a dispersing agent, 1 to 3 parts of a scratch-resistant agent, 0.5 to 2 parts of a lubricant, 0.5 to 1 part of an antioxidant and 0.5 to1 part of an ultraviolet absorbent. On the basis of a common polypropylene formula, high-fluidity PP resin is used as a matrix; POE, small-particle-size talcum powder and medium-particle-size aluminum powder are added for modification and cooperate with a compatilizer, the dispersing agent, the scratch-resistant agent and the lubricant to prepare the spraying-free material with high fluidity andscratch resistance, so that the product meets the appearance requirements of high gloss and metallic silvery color and has the advantages of high quality, low cost, safety, environmental friendlinessand the like.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com