Colored crystal glass with metallic luster

A technology of colored crystal glass and metallic luster, applied in the direction of metal layered products, glass/slag layered products, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below through specific examples.

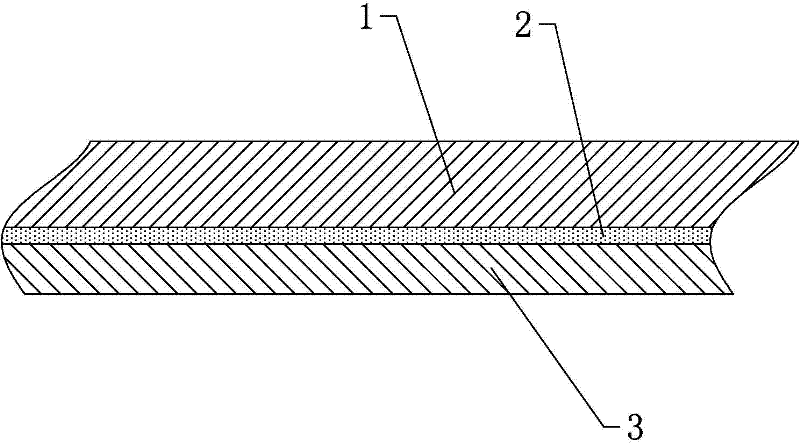

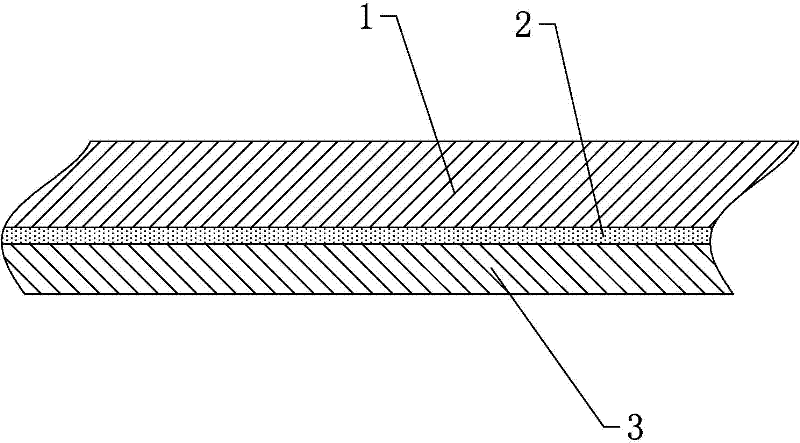

[0013] Such as figure 1 Shown is a colored crystal glass with metallic luster, comprising a tempered glass layer 1 and a metal film layer 3, the metal film layer 3 is bonded to one surface of the tempered glass layer 1 by an adhesive. The adhesive cures to form an adhesive layer 2.

[0014] Preferably, the metal film layer 3 is a metal aluminum foil layer. Of course, it can also be a film layer with special metal color such as copper and stainless steel. According to the needs of customers, the thickness of the metal film layer 3 can be made into different thickness regulations to meet different requirements.

[0015] Among them, the adhesive is mainly bonded by propylene pressure-sensitive adhesive, modified EVA film or UV glue to achieve the purpose of firm bonding.

[0016] Among them, the specific method of using UV glue and UV ultraviolet light technology to cure and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com