High-fluidity scratch-resistant spraying-free metallic-silvery-color modified polypropylene material for vehicles

A polypropylene material and high fluidity technology, applied in the field of polymer materials, can solve problems such as the compatibility difference between spray paint and polypropylene, the health risks of on-site employees, and the high requirements for injection molding processes, so as to improve gloss and overcome Inconsistent fluidity, the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

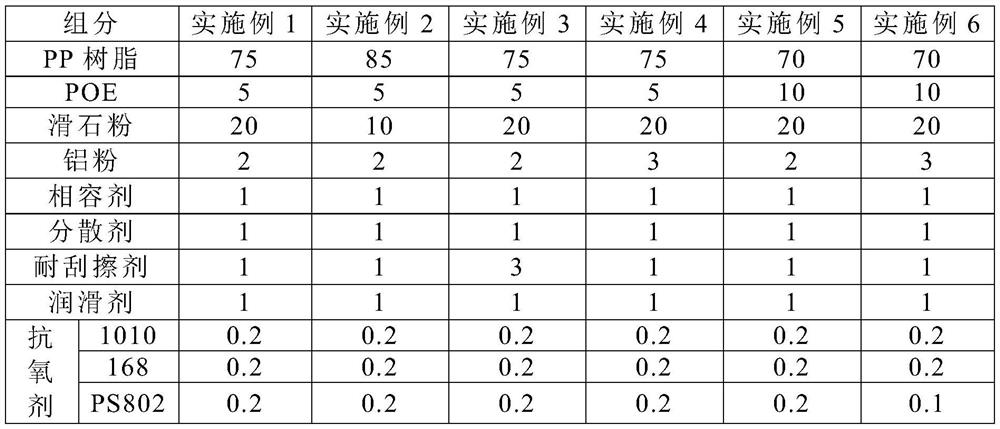

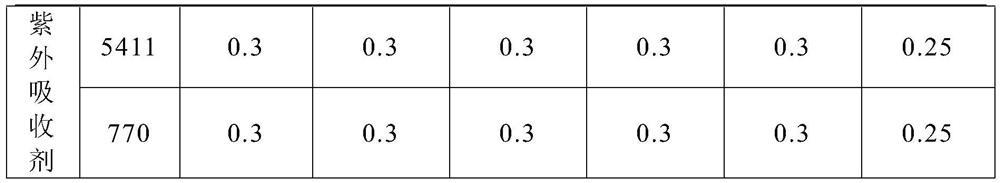

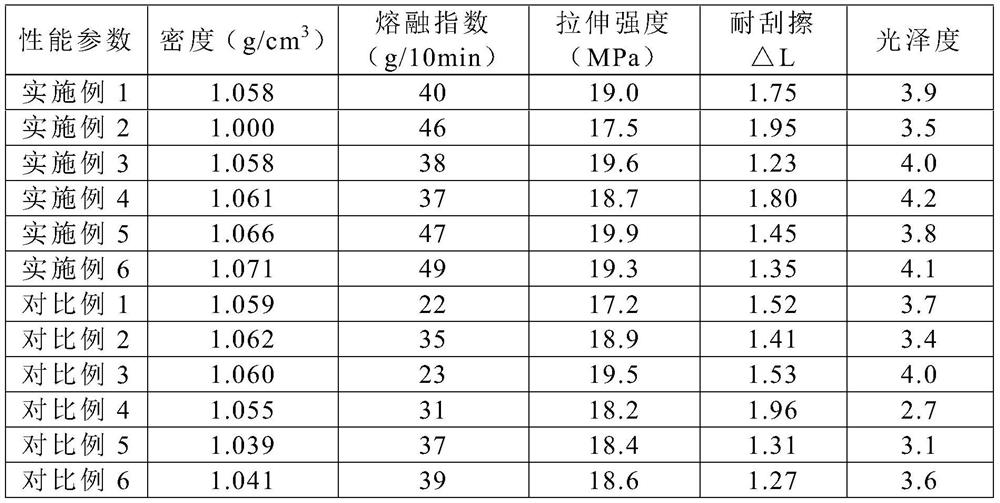

Embodiment 1-6

[0075] Examples 1-6 provide high-fluidity, scratch-resistant, spray-free metallic silver-colored modified polypropylene materials for vehicles, and the parts by weight of the raw material components are shown in Table 1. The PP resin used in Examples 1-6 is Formosa Plastics Copolymerized PP Resin 3500. Under the test conditions of 230°C and 2.16KG, the melt mass flow rate is 60g / 10min, which has high fluidity; ethylene-octene copolymerization is elastic The body is SK 875L, and the soft chain segment of octene makes its glass transition temperature lower than that of ethylene-butene copolymerized elastomers, endowing it with better toughness at room temperature and low temperature; The mesh number and purity of the same product above are extremely high; the aluminum powder is ECKARTDE MP 34-20C, the particle size is 34μm; the dispersant is Sinochem Plastics EBS P130; the antioxidant is BASF 1010, 168 and PS802 compound antioxidant; The ultraviolet absorber is Cytec 5411 and 77...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com