Method for preparing rare earth polysaccharide composite fibers

A polysaccharide compounding and fiber technology, which is applied to artificial filaments made of cellulose derivatives, chemical characteristics of fibers, chemical post-treatment of cellulose/protein rayon, etc., can solve problems such as poor stability and application limitations, and achieve High water absorption, low price, effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Raw material: sodium carboxymethyl cellulose, viscosity: 200-800mPa·s (10g / L, 20°C).

[0038] A preparation method of rare earth polysaccharide composite fiber, specifically:

[0039] Add the dry sodium carboxymethylcellulose powder into deionized water to prepare a sodium carboxymethylcellulose solution with a mass fraction of 5%, stir at room temperature at a speed of 200rpm for 4 hours, let it stand for swelling for 2h, and stir at a speed of 400rpm After 6 hours, a stable and uniform spinning solution was obtained, and filtered. The filter material had a pore size of 800 mesh and a filter pressure of 0.5 MPa, and stood still for 24 hours to remove air bubbles.

[0040] Dissolve lanthanum chloride powder in deionized water to obtain a coagulation bath, and Ce in the coagulation bath 3+ The concentration is 0.5mol / L, pH=2.

[0041] Using the wet spinning process, the spinneret has 6 holes, and the diameter of a single spinneret hole is 0.1mm. The above-mentioned spi...

Embodiment 2

[0043] Raw material: sodium carboxymethyl cellulose, viscosity: 200-800mPa·s (10g / L, 20°C).

[0044] A preparation method of rare earth polysaccharide composite fiber, specifically:

[0045] Add the dry sodium carboxymethylcellulose powder into deionized water to prepare a sodium carboxymethylcellulose solution with a mass fraction of 5%, stir at room temperature at a speed of 200rpm for 4 hours, let it stand for swelling for 2h, and stir at a speed of 400rpm After 6 hours, a stable and uniform spinning solution was obtained, and filtered. The filter material had a pore size of 800 mesh and a filter pressure of 0.5 MPa, and stood still for 24 hours to remove air bubbles.

[0046] Dissolve lanthanum chloride powder in deionized water to obtain a coagulation bath, and in the coagulation bath, La 3+ The concentration is 0.5mol / L, pH=2.

[0047] Using the wet spinning process, the spinneret has 6 holes, and the diameter of a single spinneret hole is 0.1mm. The above-mentioned spin...

Embodiment 3

[0049] Raw material: sodium alginate, viscosity: 200-800m Pa·s (10g / L, 20°C).

[0050] A preparation method of rare earth polysaccharide composite fiber, specifically:

[0051] Add the dry sodium alginate powder into deionized water to prepare a sodium alginate solution with a mass fraction of 5%. Stir at room temperature at a speed of 200rpm for 4 hours, let it stand for swelling for 2 hours, and stir at a speed of 400rpm for 6 hours to obtain a stable and uniform solution. Filtration, the pore size of the filter material is 800 mesh, the filter pressure is 0.5MPa, let it stand for 24 hours to remove air bubbles.

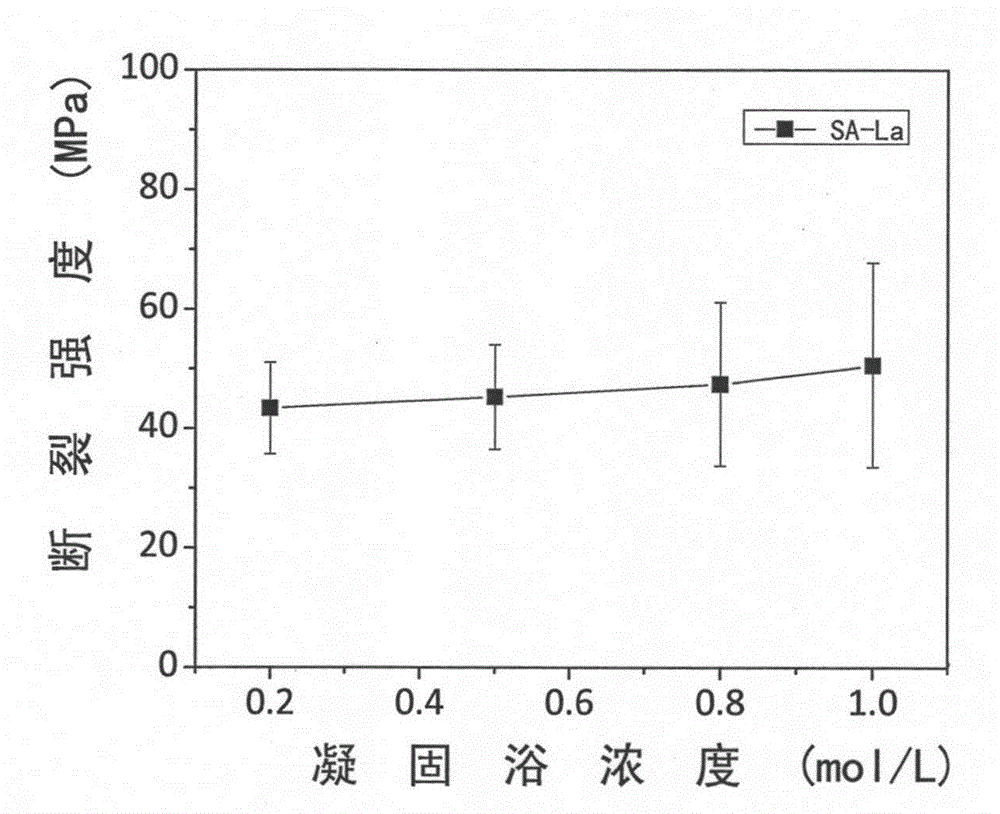

[0052] Dissolve lanthanum chloride powder in deionized water to obtain a coagulation bath, and in the coagulation bath, La 3+ The concentration is 0.5mol / L, pH=2.

[0053] Using the wet spinning process, the spinneret has 6 holes, and the diameter of a single spinneret hole is 0.1mm. The above-mentioned spinning solution is measured by a metering pump and then ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com