Patents

Literature

122results about How to "Alleviate environmental pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

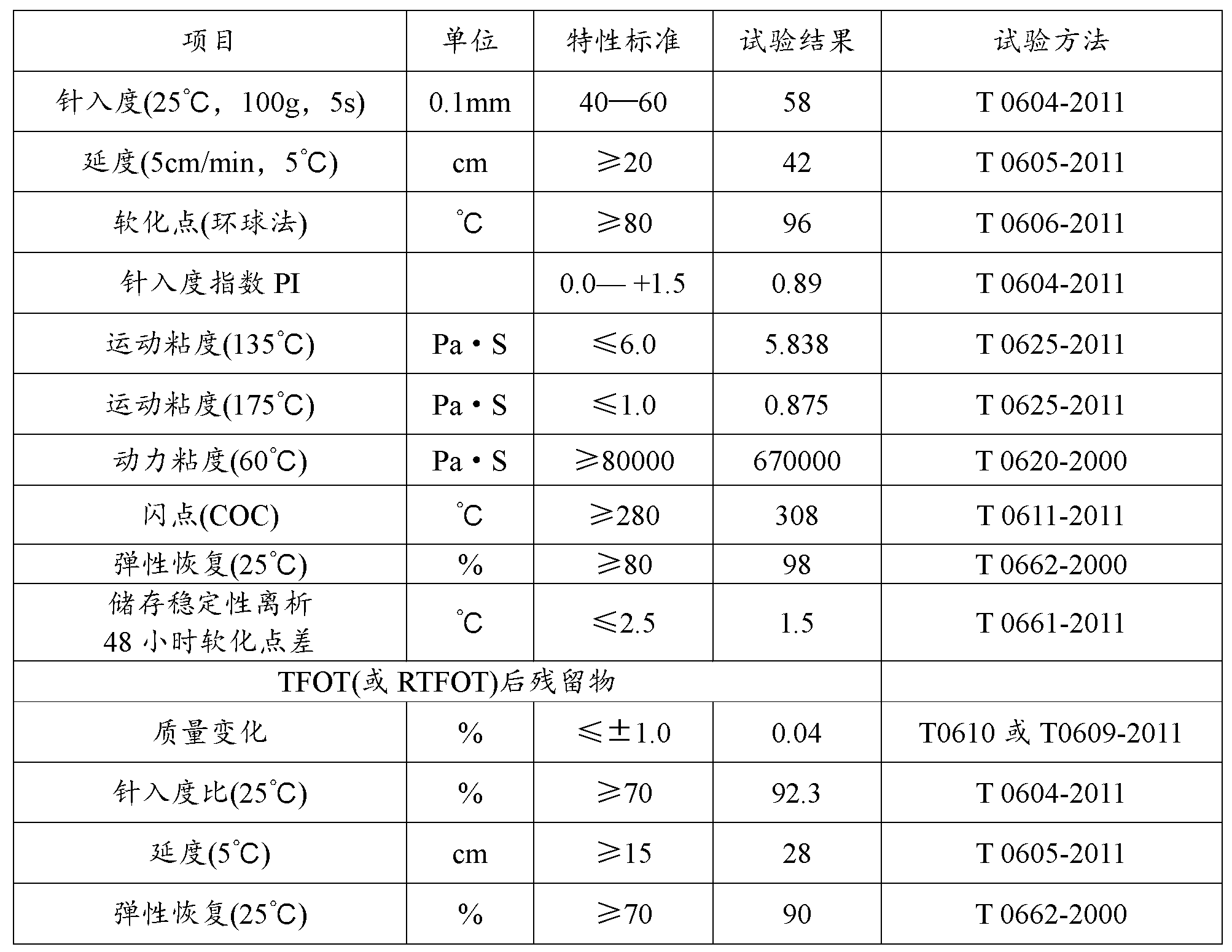

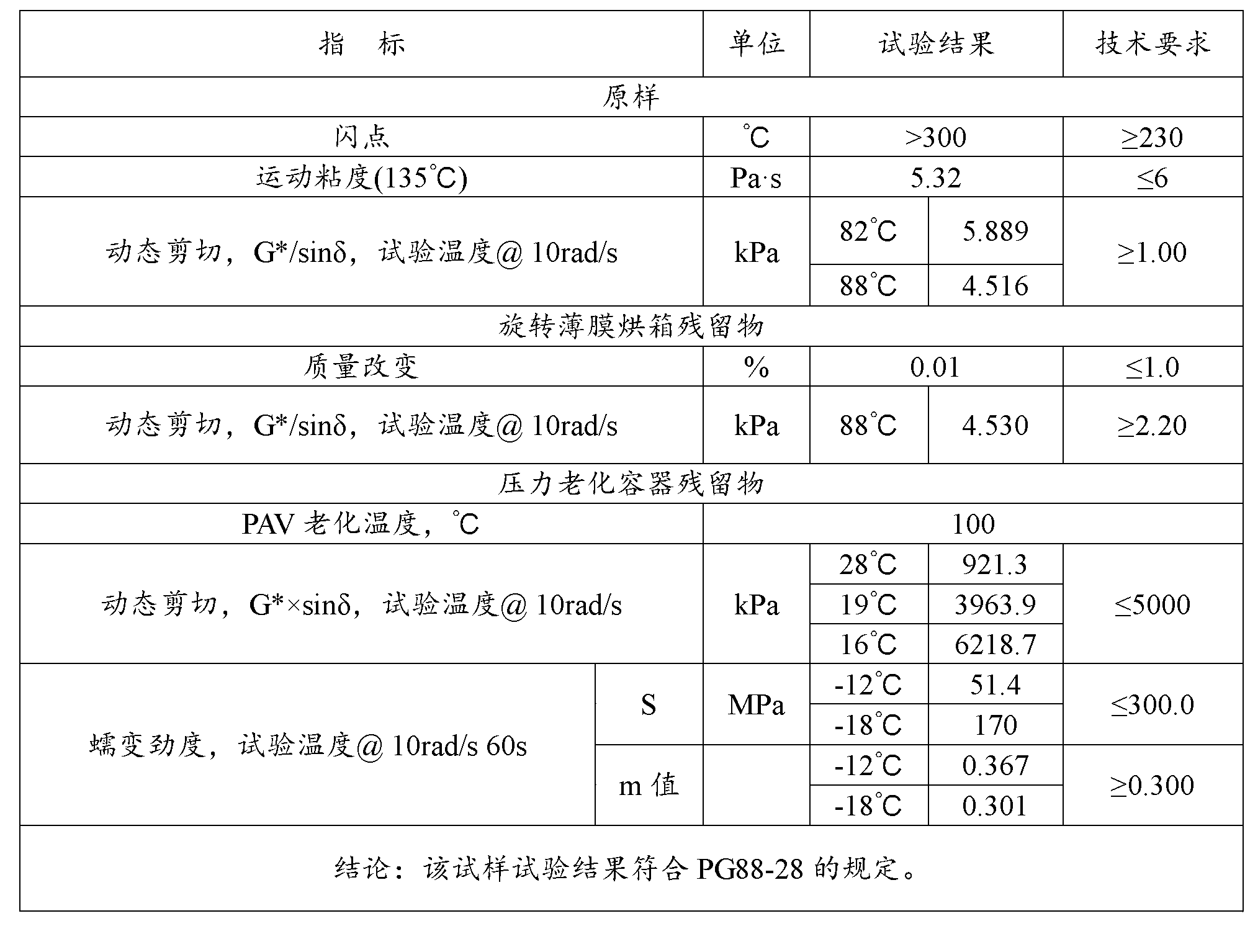

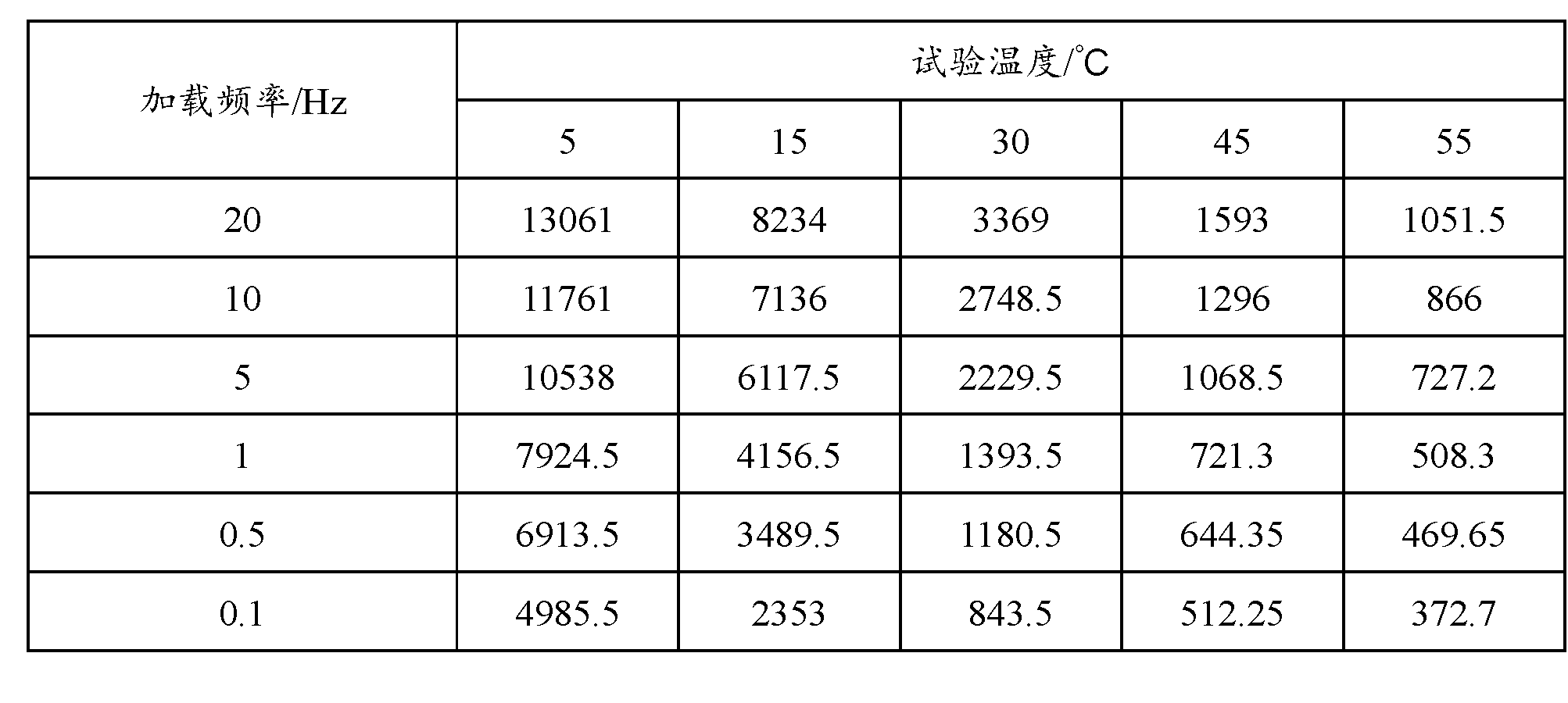

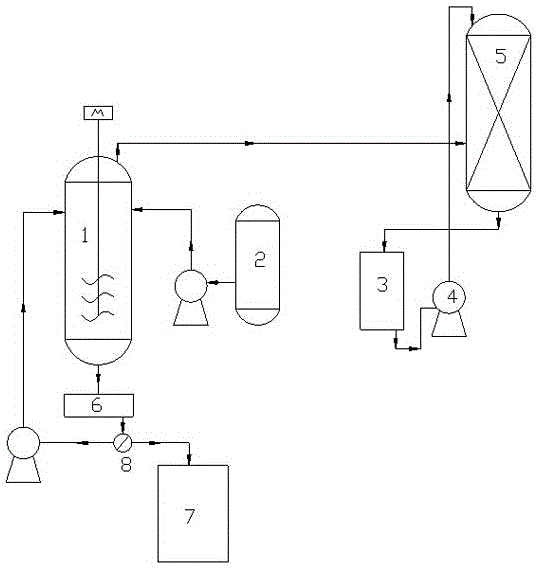

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

Method for producing electronic-stage hydrofluoric acid

ActiveCN101570318ASolve hard-to-remove problemsHigh purityFluorine/hydrogen-fluorideHydrofluoric acidBoiling point

The invention relates to a method for producing electronic-stage hydrofluoric acid. The method comprises the following steps: (1), preheating and roughly distilling a measured anhydrous hydrofluoric acid raw material to remove low boiling point matter; (2), using ultra-pure water to absorb hydrofluoric acid roughly distillated and exhausted from a condenser outlet to be 48 to 49 percent of hydrous hydrofluoric acid solution; (3), distilling an absorbed hydrofluoric acid semi-finished product by a fluoroplastic resin sub-boiling distiller, gasifying fluorine hydride liquid to generate ultra-pure electronic-stage hydrofluoric acid gas, condensing to be 48 to 49 percent of anhydrous hydrofluoric acid solution and remaining high boiling point matter and heavy metals at the bottom of the sub-boiling distiller; and (4), secondarily filtering the hydrofluoric acid semi-finished product output from the fluoroplastic resin sub-boiling distiller, and finally, automatically filling to prepare 48 percent of ultra-pure hydrofluoric acid finished product. The method fully utilizes the different of boiling points between the anhydrous hydrofluoric acid and various impurities in the anhydrous hydrofluoric acid to remove the impurities at different temperatures, particularly remove silicon so that the impurity content of the obtained ultra-pure hydrofluoric acid is decreased to the minimum.

Owner:DO FLUORIDE CHEM CO LTD

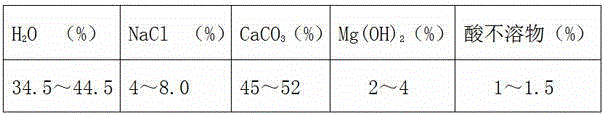

System and method for treating chlor-alkali production byproduct salt mud

ActiveCN105129822AHarden fastImprove cold resistanceCalcium/strontium/barium chloridesIron oxides/hydroxidesFiltrationCalcination

The present invention discloses a system and a method for treating a chlor-alkali production byproduct salt mud. According to the present invention, through the system, chlor-alkali calcium carbonate salt mud is treated with hydrochloric acid to remove carbonate ions, the generated carbon dioxide is conveyed into an absorption tower and reacts with caustic soda to generate soda ash for salt water refining, the pH value of the solution can be adjusted by adding the caustic soda, acid insoluble substances and magnesium ions are precipitated, pressure filtration is performed to obtain a calcium chloride clear liquid, the calcium chloride clear liquid can be used as the refrigerant of the membrane method nitrate removal refrigeration unit and can be used for export, and in the waste residue obtained after the pressure filtration, the acid insoluble substance residue is conveyed to the cement plant, and the magnesium hydroxide is subjected to high temperature calcination to obtain magnesium oxide so as to achieve the zero emission of pollutants.

Owner:YIBIN HAIFENG HERUI

Ardealite road base course material and preparation method thereof

InactiveCN102491721AEasy accessAlleviate environmental pressureSolid waste disposalEnvironmental resistanceSlag

The invention discloses an ardealite road base course material and a preparation method thereof. The ardealite road base course material is prepared from the following raw materials in parts by weight: 40-80 parts of ardealite, 0.5-5 parts of diethylaminopropylamine, 0.1-0.5 part of a polycarboxylic acid water reducing agent, 10-40 parts of sandstone and 5-40 parts of water quenching slag. The preparation method comprises the following steps of: (1) dehydrating ardealite and crushing; (2) uniformly mixing the ardealite, sandstone and water quenching slag to obtain a material A; (3) uniformly mixing the polycarboxylic acid water reducing agent with the material A to obtain a material B; (4) adding the diethylaminopropylamine into the material B to obtain a material C; and (5) adding water into the material C, and stirring uniformly to obtain a finished product. In the method, the ardealite is taken as a major raw material, so that the utilization way of ardealite is expanded, the environmental protection stress is relieved, comprehensive utilization production energy consumption of ardealite is lowered, and the ardealite road base course material has a wide market prospect and is consistent with the requirements of recycling economy and sustainable development. The ardealite road base course material has the advantages of reasonable formula, simple preparation method and durability, and is suitable for road construction in ardealite-containing regions.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

Desulfurization gypsum clinker-free steel slag cement

InactiveCN102079635AReduce the pressure of resource scarcityAlleviate environmental pressureCement productionEcological environmentSlag

The invention discloses desulfurization gypsum clinker-free steel slag cement. The cement is mainly prepared from the following components in percentage by weight: 10 to 30 percent of desulfurization gypsum, 32 to 70 percent of steel slag, 10 to 55 percent of mineral slag, 2.5 to 5 percent of cement clinker and 0 to 5 percent of hemihydrate gypsum. The cement does not need calcining treatment andhas no exhaust emission, so the cement reduces the energy consumption and has good environmental coordination; and meanwhile, the cement relieves the environmentally-friendly pressure of steel-iron power enterprises, reduces the resource shortage pressure of the enterprises, and achieves the effects of lightening the exhaust emission burden of the enterprises, increasing the income and improving the ecological environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

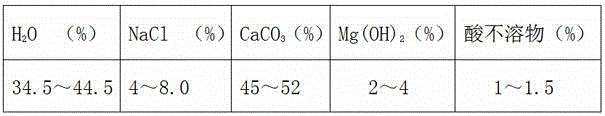

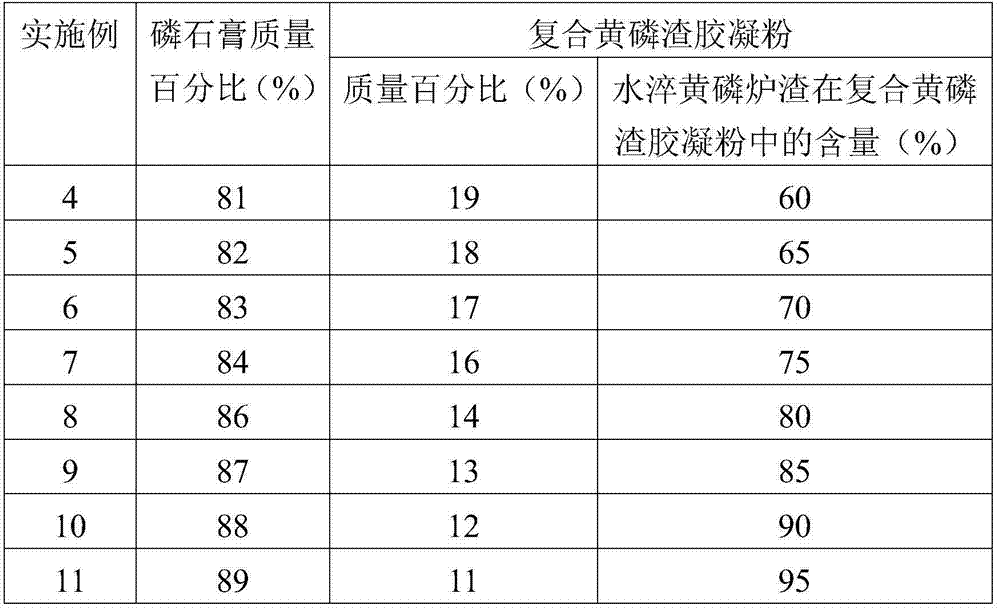

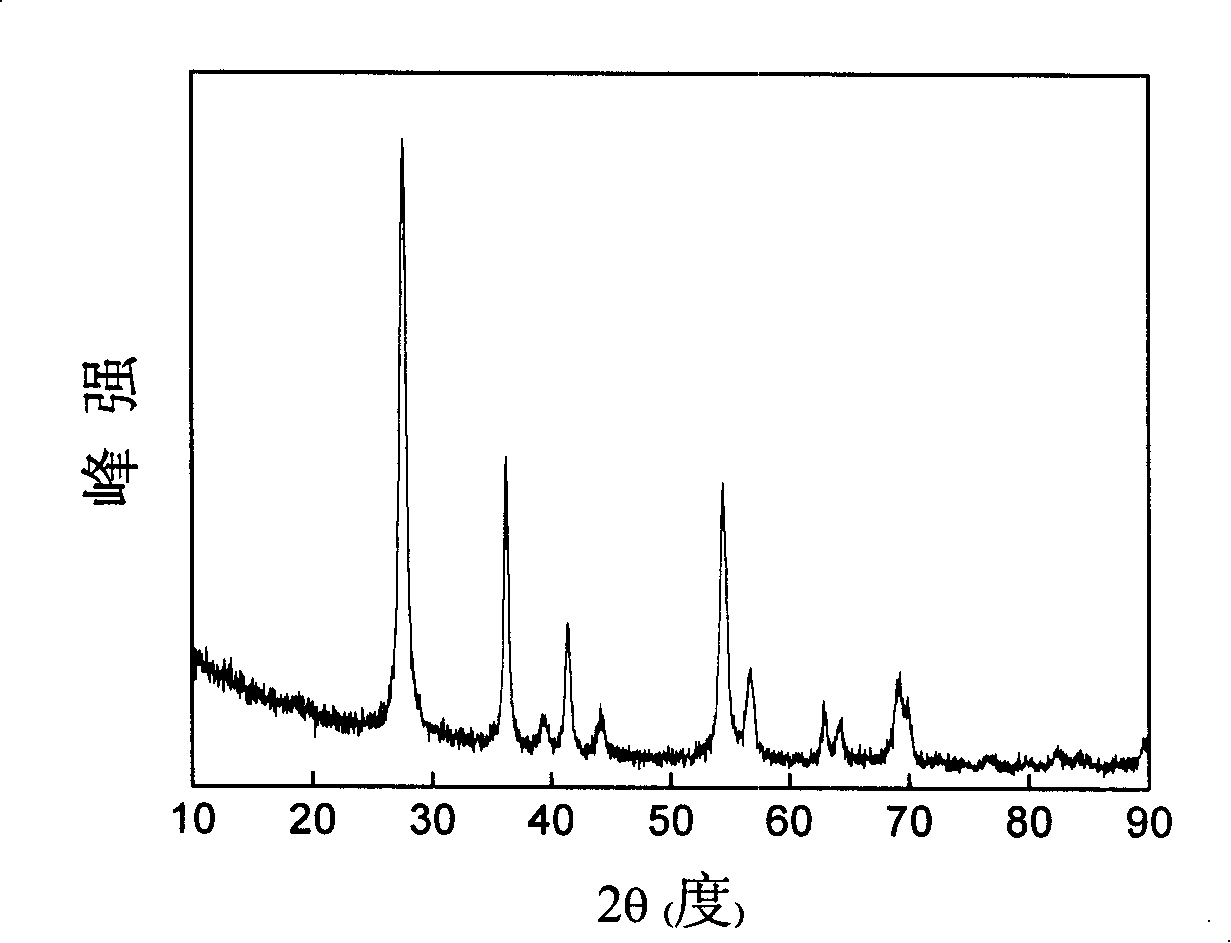

Modified phosphogypsum material used for sea reclamation

The invention discloses a modified phosphogypsum material used for sea reclamation. Phosphogypsum is modified by raw material selection and proportioning so as to make the phosphogypsum suitable for sea reclamation. The materials comprise phosphogypsum and composite yellow phosphorus slag gelling powder. The composite yellow phosphorus slag gelling powder is mixed powder composed of crushed water-quenched yellow phosphorus slag generated in a yellow phosphorus production process and cement clinker. With the characteristics of high fill strength, fast curing speed, good water resistance and high compressive strength, the modified phosphogypsum material used for sea reclamation provided by the invention not only can meet the compressive strength requirements of road building, wharf construction and the like, but also can make heavy use of the solid waste in the phosphorus chemical industry, thus solving the constraint bottleneck problem of waste residue utilization during sustainable development of the phosphorus chemical industry. And the modified phosphogypsum material suitable for sea reclamation is provided.

Owner:GUIZHOU KAILIN GRP CO LTD

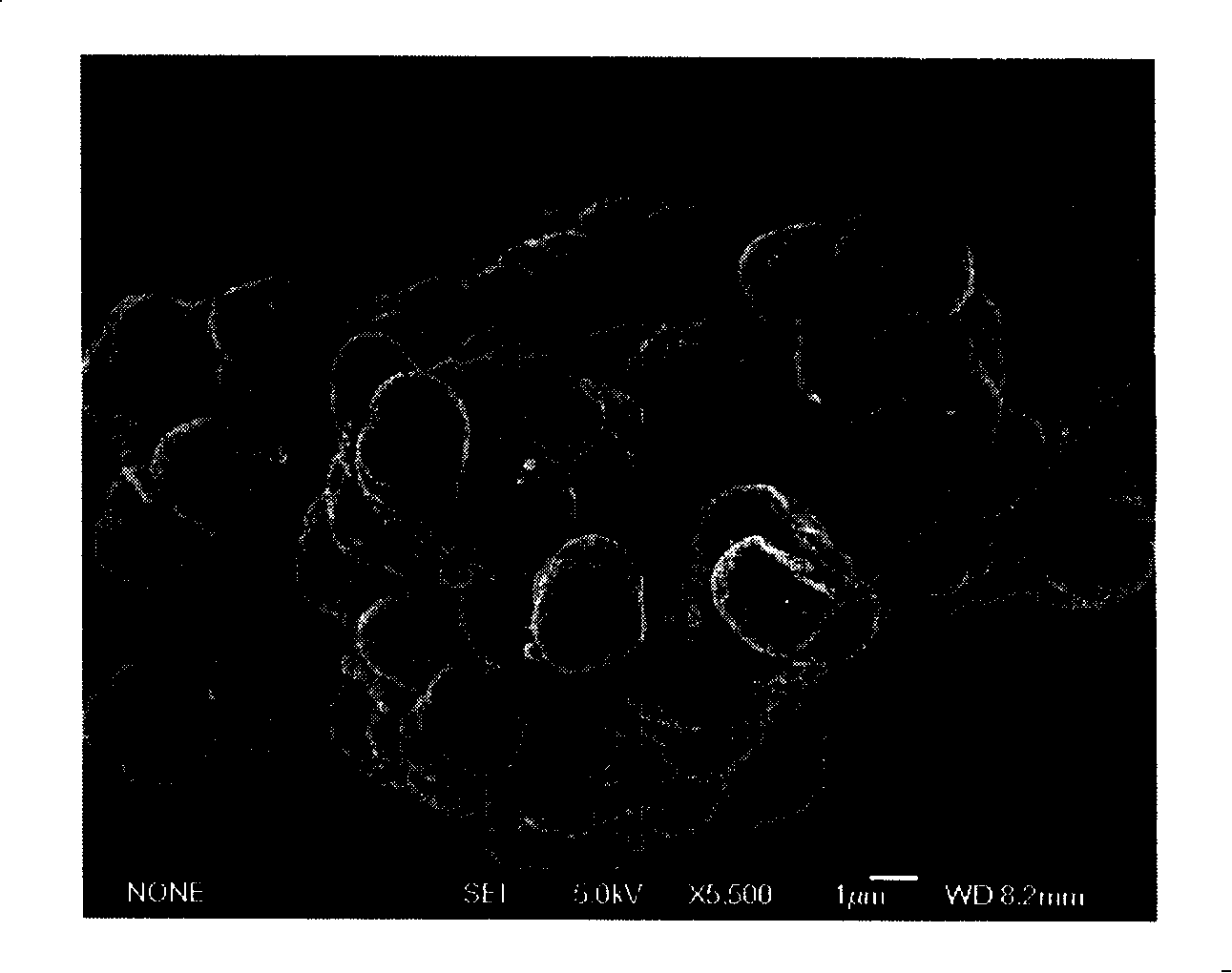

Clean method for preparing rutile-type titanium dioxide from high-titanium slag by hydrothermal method

InactiveCN101190802AProduced (processed) lessHigh titanium contentTitanium dioxideEconomic benefitsCleaning methods

The invention relates to a clean production method by high titanium slag hydrothermal method to prepare rutile titanium oxide. The method adopts high titanium slag as raw material and sodium hydroxide hydrothermal method to prepare the intermediate product of sodium titanate which is then separated from the solution and washed and hydrolyzed to obtain the rutile titanium oxide. The method of the invention adopts simple preparation technique to prepare the rutile TiO2, which spares high temperature calcination in the traditional technique; the conversion rate of titanium in the high titanium slag is of over 99.0 percent and the alkali circulation and the acid circulation are realized, which has good economic benefit and environmental benefit. Additionally, the sodium titanate which can be taken as the intermediate product for preparing titanium series obtained from the method is expected to have wide application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

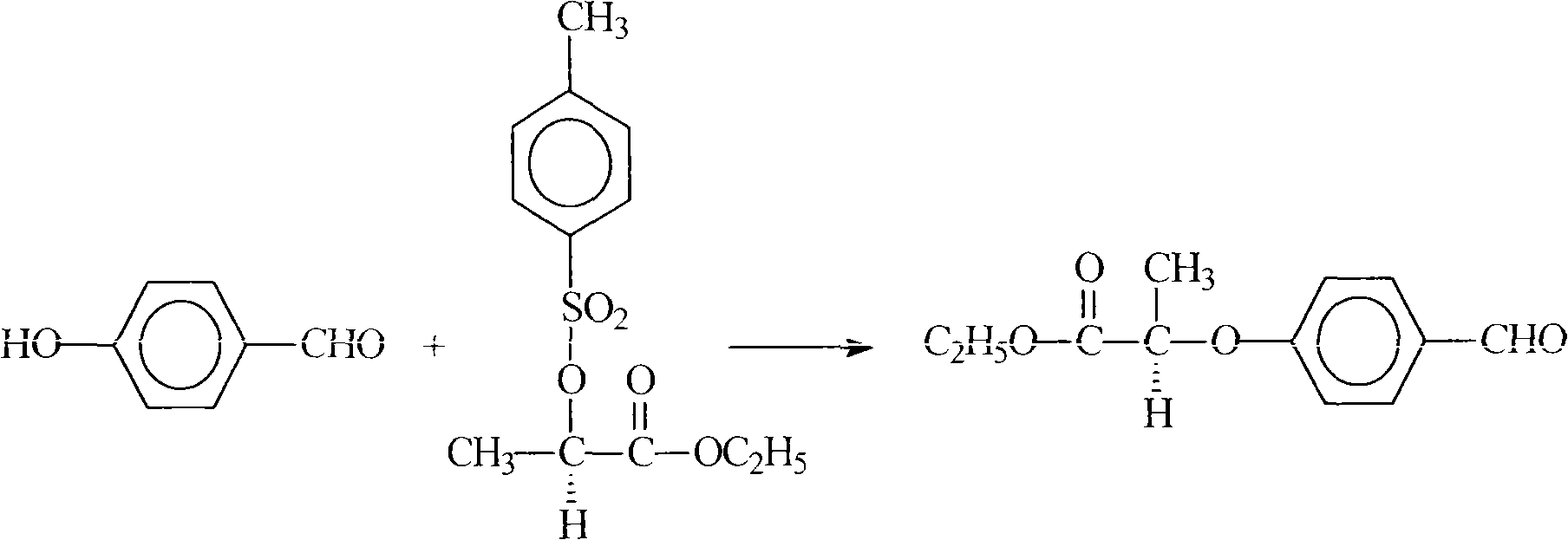

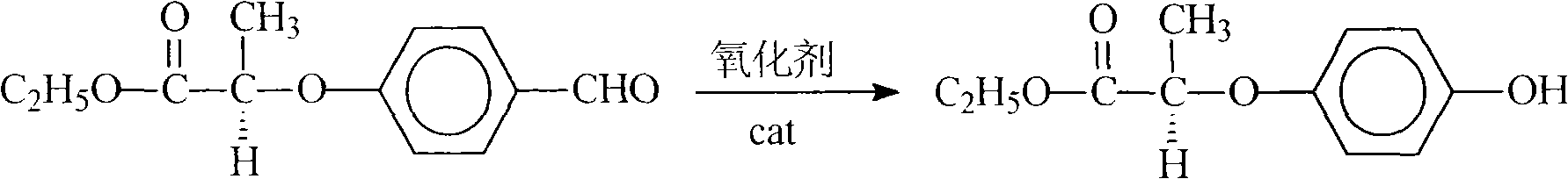

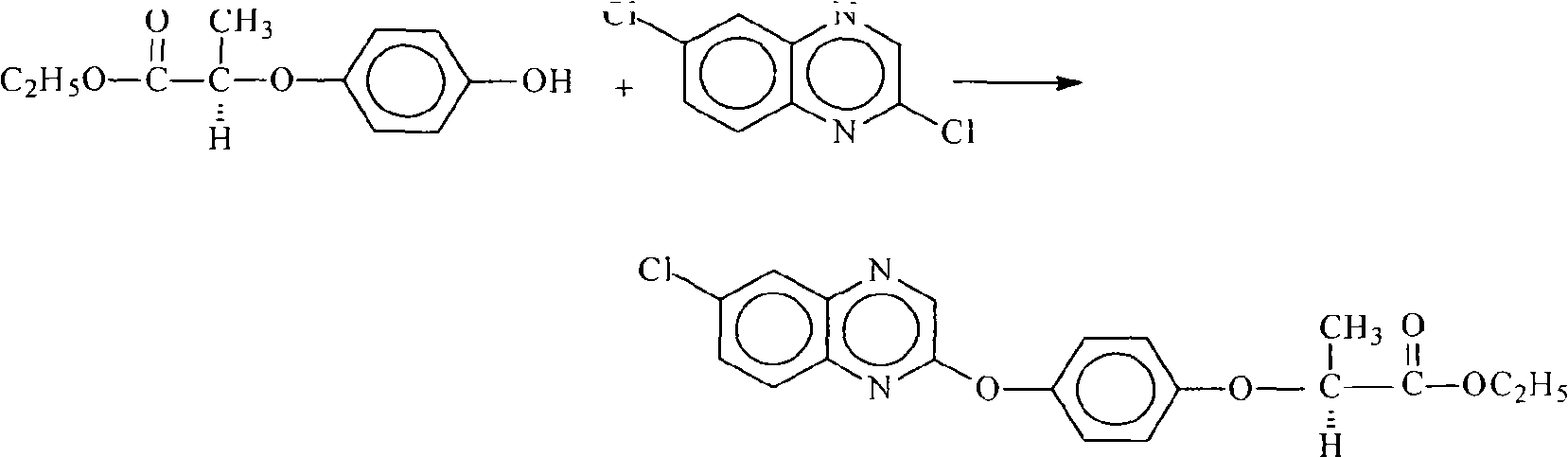

Method for preparing quizalofop-p-ethyl

InactiveCN101333194AAvoid it happening againAlleviate environmental pressureOrganic chemistryQuinoxalineEthyl propiolate

The invention relates to a preparation method for quizalofop-p-ethyl, in particular to a method which uses p-hydroxybenzaldehyde to replace the raw material hydroquinone used in the traditional technology and react with S (-)-N-tosyl ethyl lactate to prepare R (+)-2-(p-oxy) propionate which is then reacted with 2,6- dichloro-quinoxaline to prepare high-purity quizalofop-p-ethyl through condensation.

Owner:SHANDONG CHAMBROAD HLDG GRP CO LTD

Phase-change thermal insulation putty

InactiveCN103214893AReduce waste burdenAchieve energy saving and emission reductionFilling pastesThermal insulationSlag

The invention discloses a phase-change thermal insulation putty consisting of the following substances in percentage by weight: 30-40% of activated and regenerated concrete fine powder, 5-10% of ground limestone, 3-5% of talcum powder, 15-25% of quartz sand, 1-3% of alkaline mud, 3-5% of washing slurry, 3-5% of silicate cement clinker, 1-3% of aluminum slag, 8-12% of a phase-change material, 2-5% of expanded perlite powder and 0.5-1.5% of an additive. The phase-change thermal insulation putty disclosed by the invention has the characteristics of remitting the environmental pressure from urban construction and alkaline production enterprises and the pressure of the resource shortage of building material enterprises, realizing energy conservation and emission reduction of buildings, reducing the waste burden of enterprises, increasing the income and improving the ecological environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

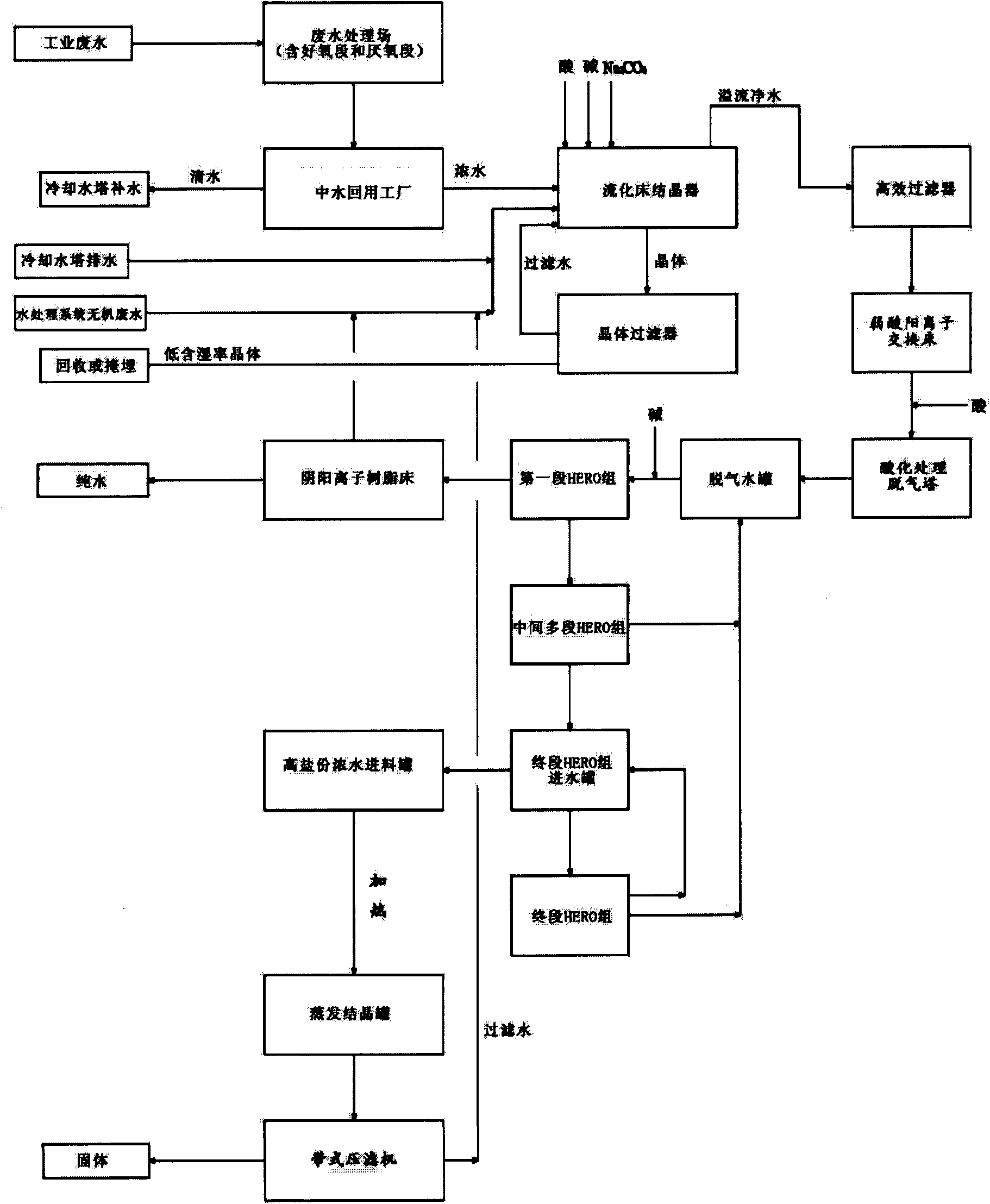

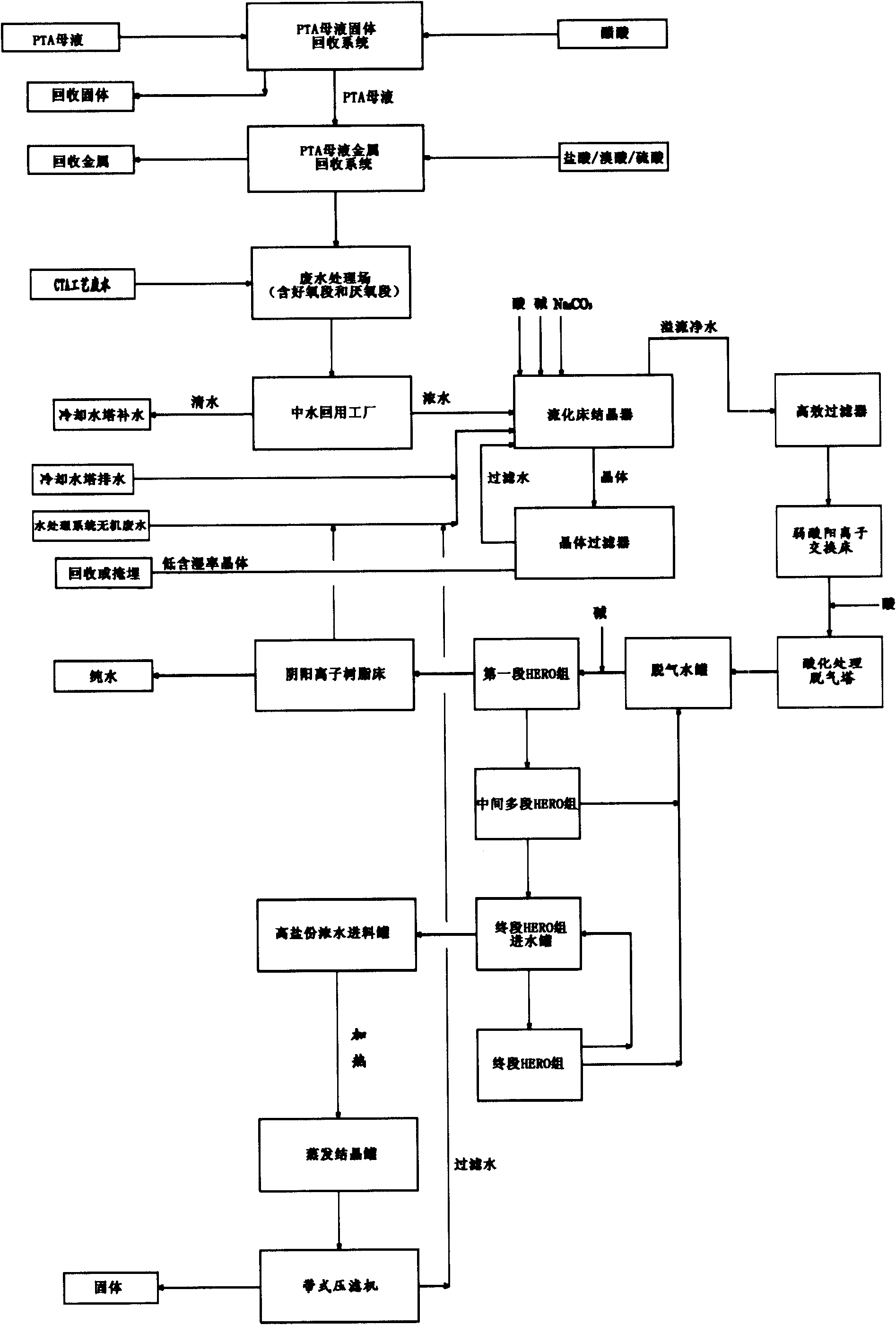

Method with zero discharge of waste water

InactiveCN101628771AEmission reductionReduce wasteWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesAnaerobic decompositionIndustrial waste water

The invention discloses a method for zero discharge of waste water, which comprises the following steps that: the industrial waste water is subjected to anaerobic decomposition treatment and aerobiotic decomposition treatment in a waste water treating field in sequence, and 70 to 90 percent of organic matters in the waste water are decomposed; water discharged from the waste water treating field is treated by a hardness removing device, a filter, a residue hardness removing device, a degassing device and a multi-segmental reverse osmosis membrane set so as to obtain the concentrated water with TDS more than 80,000ppm; and the concentrated water is subjected to evaporation concentration by an evaporation crystallizer and a pressure filter, so that the waste solid with the water content of less than 15 percent is prepared. The method has the advantages of recycling over 99 percent of the waste water for reutilization, reducing environmental pollution, and reducing waste of water resources.

Owner:ACTION PERFECT ENG XIAMEN

Recycled concrete commercial mortar

The invention discloses recycled concrete commercial mortar which consists of the following components in percentage by weight: 15-25% of recycled concrete micro powder, 50-60% of recycled concrete fine aggregate, 7-10% of desulfurized gypsum, 10-15% of caustic sludge, 3-5% of washing slurry, 3-5% of portland cement clinker, 1-3% of aluminum slag and 0.5-1.5% of additive. The recycled concrete commercial mortar disclosed by the invention relieves the environmental protection stress on the urban construction, alkali production and power enterprises and the stress in lack of resources of building material enterprises, reduces the burden of waste discharge on enterprises, increases the income and improves the ecological environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

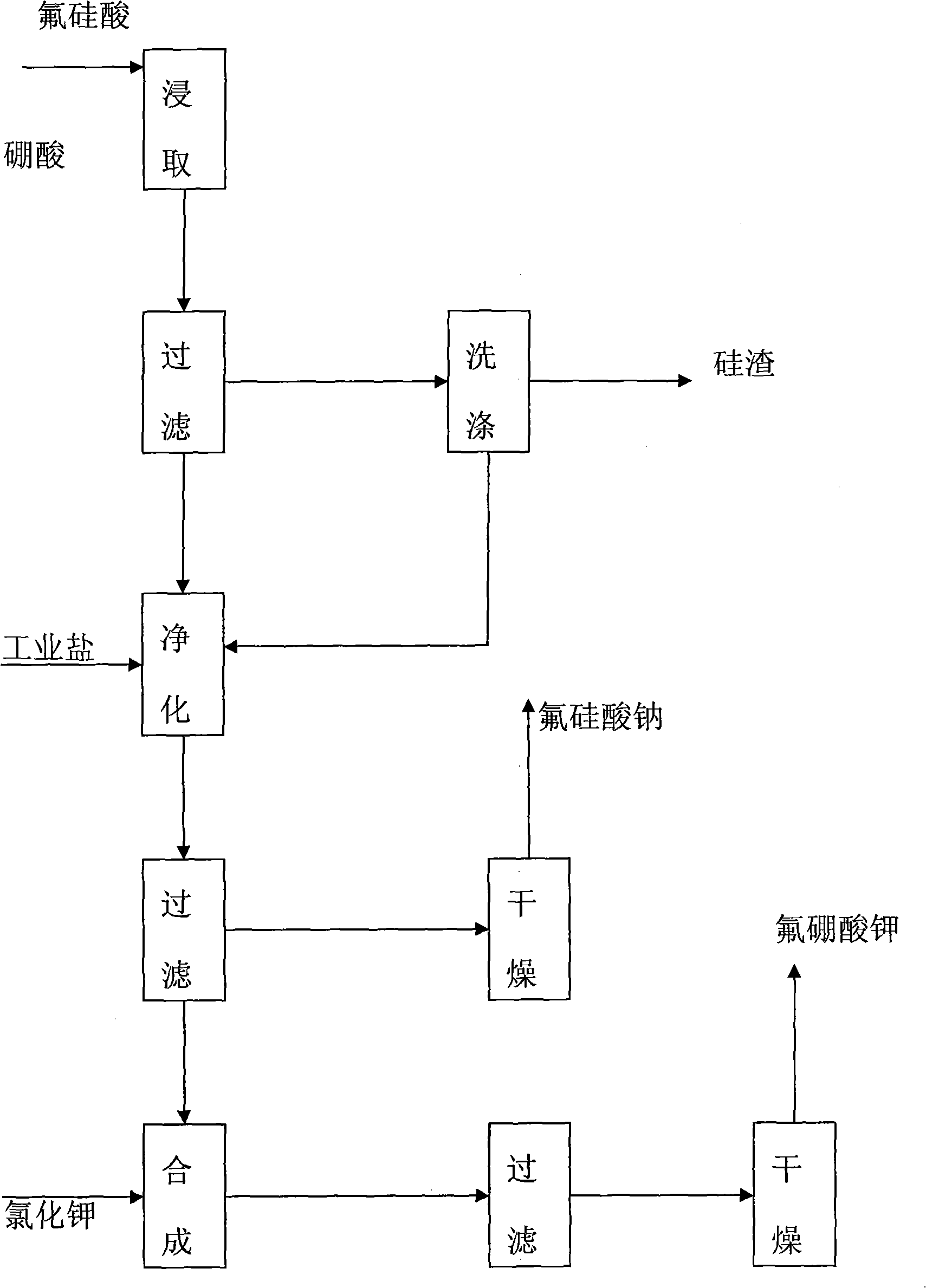

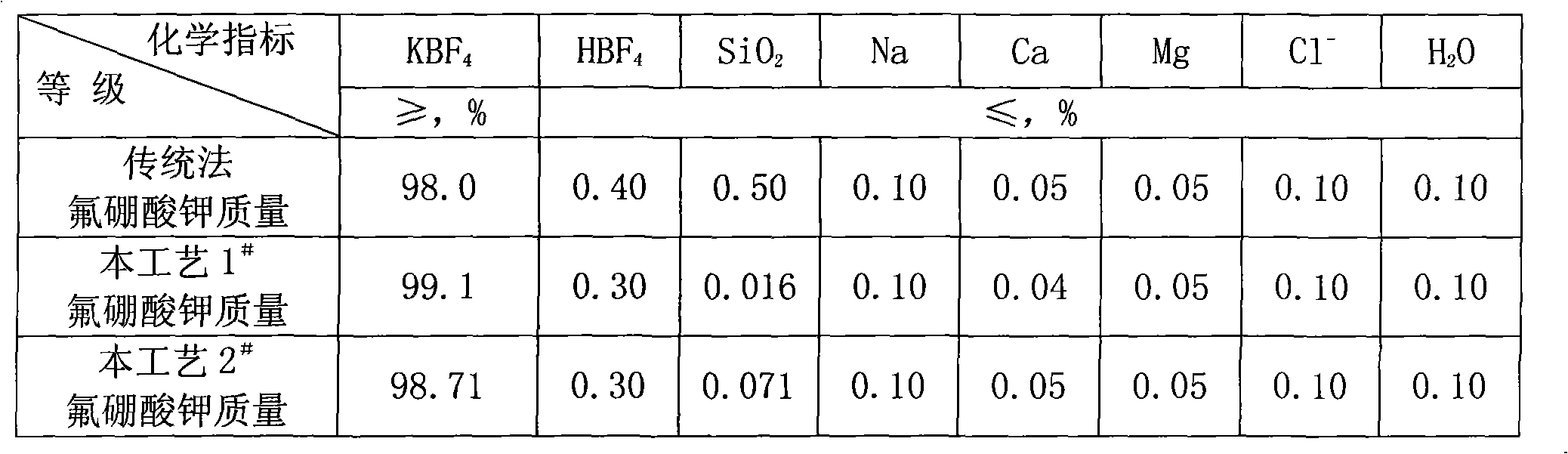

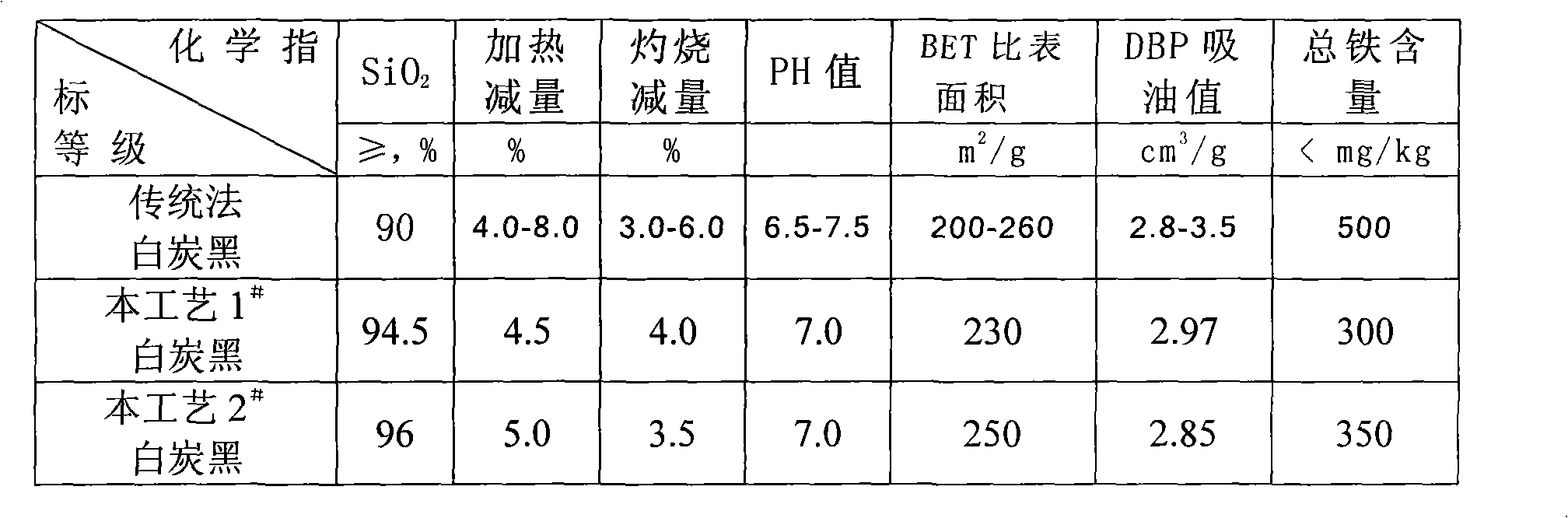

Process for preparing potassium borofluoride and co-production of white carbon black and sodium fluosilicate

InactiveCN101289195ARaw materials are easy to getLow costSilicaSilicon halogen compoundsPotassium borohydrideFiltration

The invention relates to a method for preparing potassium fluoborate with the co-product of white carbon black and sodium fluosilicate, which takes hydrofluosilicic acid, boric acid, industrial salt and potassium chloride as main raw materials and particularly comprises the steps as follows: (1) the hydrofluosilicic acid is firstly added into a leaching tank which is then preheated to 60 DEG C to 100 DEG C and then opened for carrying out stirring, theoretical quantity of boric acid is added into the hydrofluosilicic acid, then the leaching tank is obturated and reaction is carried out continuously for 2.0 hours to 6.0 hours, and leaching is carried out at the constant temperature of 60 DEG C to 100 DEC G; (2) qualified fluoboric acid solution after being leached is filtered, the white carbon black is dried after progressive concentration and washing by levels of water to produce the white carbon black; (3) the filtrate obtained and a first lotion are added with the industrial salt for purifying and disiliconization, then theoretical quantity of industrial salt is added for carrying out reaction for 10 minutes to 30 minutes to prepare sodium fluosilicate slurry; (4) the sodium fluosilicate slurry prepared is filtered, washed and dried to obtain sodium fluosilicate products, and the filtrate obtained is used for synthetizing the potassium fluoborate; (5) theoretical quantity of potassium chloride is added into the filtrate obtained in step (4) for carrying out reaction for 10 minutes to 30 minutes; (6) after the reaction in step (5) completes, filtration is carried out, an ointment is washed by primary water and dried to obtain the potassium fluoborate.

Owner:DO FLUORIDE CHEM CO LTD

Method for producing ultra-clean high-pure hydrofluoric acid

ActiveCN101570319ASolve hard-to-remove problemsHigh purityFluorine/hydrogen-fluorideHydrofluoric acidDistillation

The invention relates to a method for producing ultra-clean high-pure hydrofluoric acid. The method comprises the following steps: (1), emptying air in a system; (2), adding a measured liquid hydrogen fluoride raw material to a rough distillation kettle with a heat exchanger for rough distillation; (3), controlling the inside pressure of the rough distillation kettle to be lower than 0.2MPa and adding an oxidant; (4), repeatedly condensing, refluxing and vaporizing in the rough distillation kettle; (5), pumping gas guided from a top outlet of a water condenser into the bottom of a spraying absorption tower so as to be absorbed by spraying absorption liquid which is sprayed in from the top of the absorption tower; (6), gasifying and pumping hydrofluoric acid into the absorption tower to be absorbed; (7), pumping the hydrofluoric acid at the outlet of the condenser into the absorption tower and using ultra-pure water to absorb into 48 percent to 49 percent of hydrous hydrofluoric acid solution; (8), secondarily rectifying the 48 percent to 49 percent of hydrous hydrofluoric acid solution; and (9), filtering the 48 percent to 49 percent of hydrous hydrofluoric acid solution after secondary rectification at two stages to prepare 48 percent of ultra-clean high-pure hydrofluoric acid finished product. The invention not only improves the purity of the ultra-clean high-pure hydrofluoric acid, but also increases the economic benefits and the environmental-protection benefits.

Owner:DO FLUORIDE CHEM CO LTD

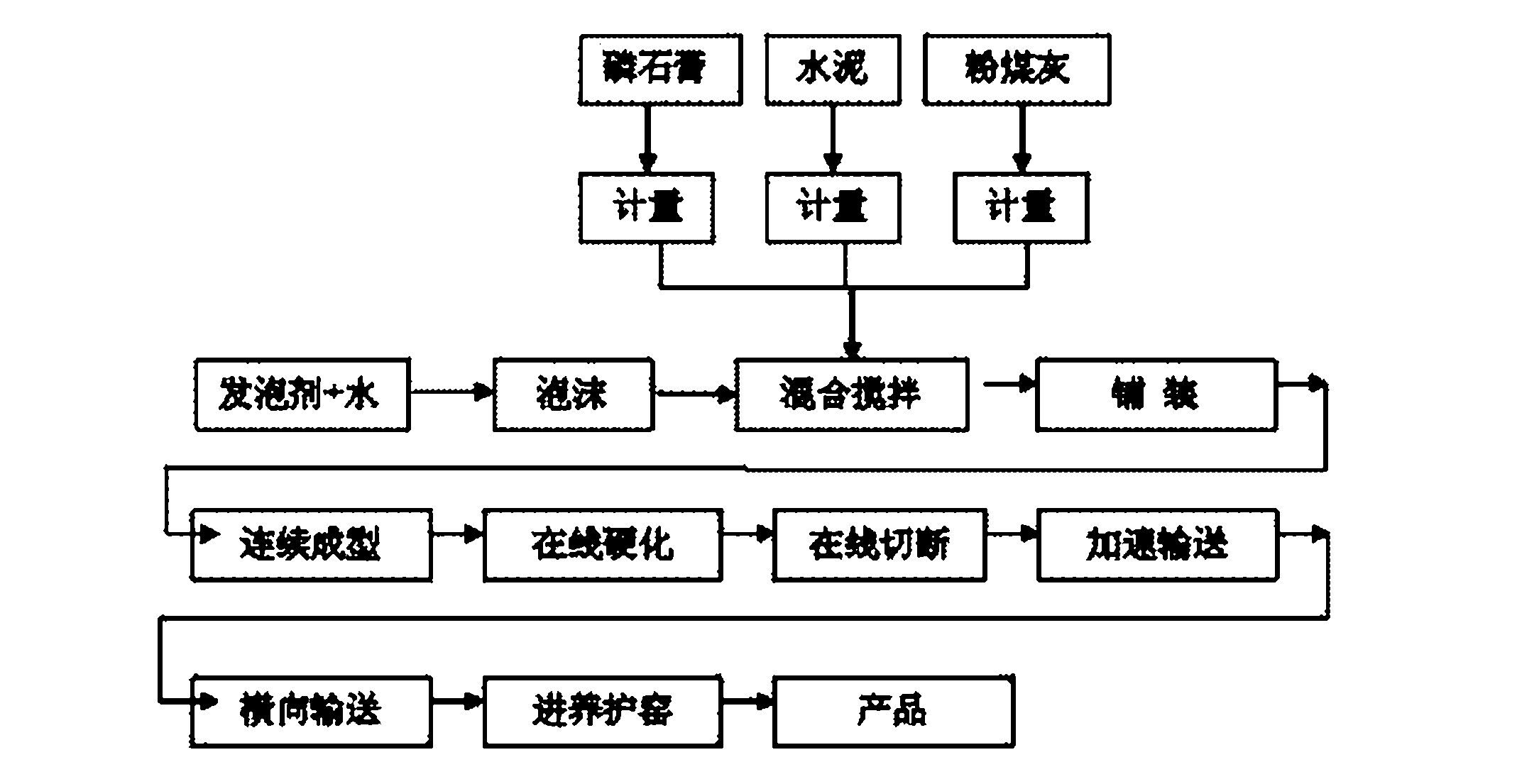

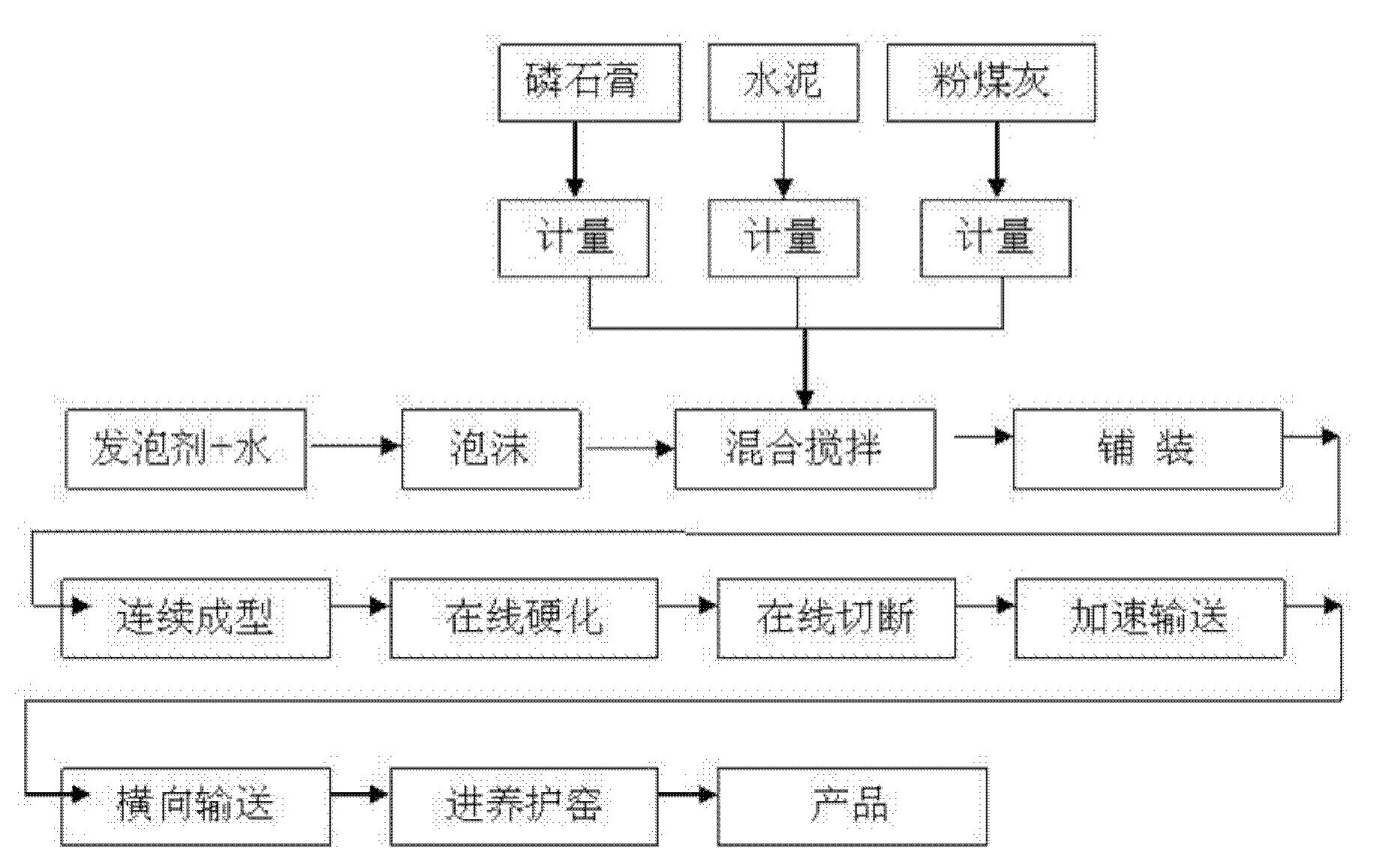

Building phosphogypsum powder thermal insulation material and preparation method thereof

ActiveCN102417369ALight weightLow thermal conductivityCeramicwareThermal insulationAdditive ingredient

The invention discloses a building phosphogypsum powder thermal insulation material and a preparation method thereof. The thermal insulation material comprises the following ingredients: 40-50 wt% of building gypsum powder, 10-15 wt% of cement, 8-13 wt% of fly ash, 1-2 wt% of foaming agent, and 30-40 wt% of water. The preparation method comprises the following steps: (1) putting building gypsum powder, cement, fly ash and other solid raw materials in a mixer for dry mixing, putting a mixture of water and foaming agent in the mixer, and stirring to form an uniform slurry; (2) injecting the prepared gypsum foamed slurry in a mould; and (3) demoulding and carrying out maintenance to obtain a finished product. The thermal insulation material has the following advantages: (1) low unit weight, low thermal conductivity, thermal insulation, and energy saving property; (2) functions of fire resistance, sound resistance, and air humidity adjustment; and (3) reduction of storage quantity of industrial waste residues.

Owner:LUXI CHEM GRP

Production method of cryolite

InactiveCN102219249AAchieve recyclingSolve processing problemsAluminium fluoridesChemical industryWaste treatment

The invention discloses a production method of cryolite. With electrolytic aluminium fluorine-containing waste residues from flotation and single cryolite which is the byproduct of polysilicon material production as the raw material, and the method comprises the steps of: weighing the electrolytic aluminium fluorine-containing waste residues from flotation and the single cryolite as the byproduct of polysilicon material production; mixing the weighed electrolytic aluminium fluorine-containing waste residues from flotation and the single cryolite as a byproduct of polysilicon material production with a fluorine containing hydrochloric acid solution, then leaving the mixture reacting for 1-6 hours under stirring DEG C, filtering the mixture, washing a filter cake with water and drying the filter cake, thus obtaining the cryolite product. And the generated filtrate and washing liquid can be treated with lime so as to be discharged or used in calcium chloride production. By combining the current development situation of fluorine chemical industry, the invention makes fully use of low grade fluorine resources and makes the recycling of fluorine resources come true. In addition, the invention also provides a solution to the waste treatment problem that restricts the development of the fluorine chemical industry.

Owner:DO FLUORIDE CHEM CO LTD

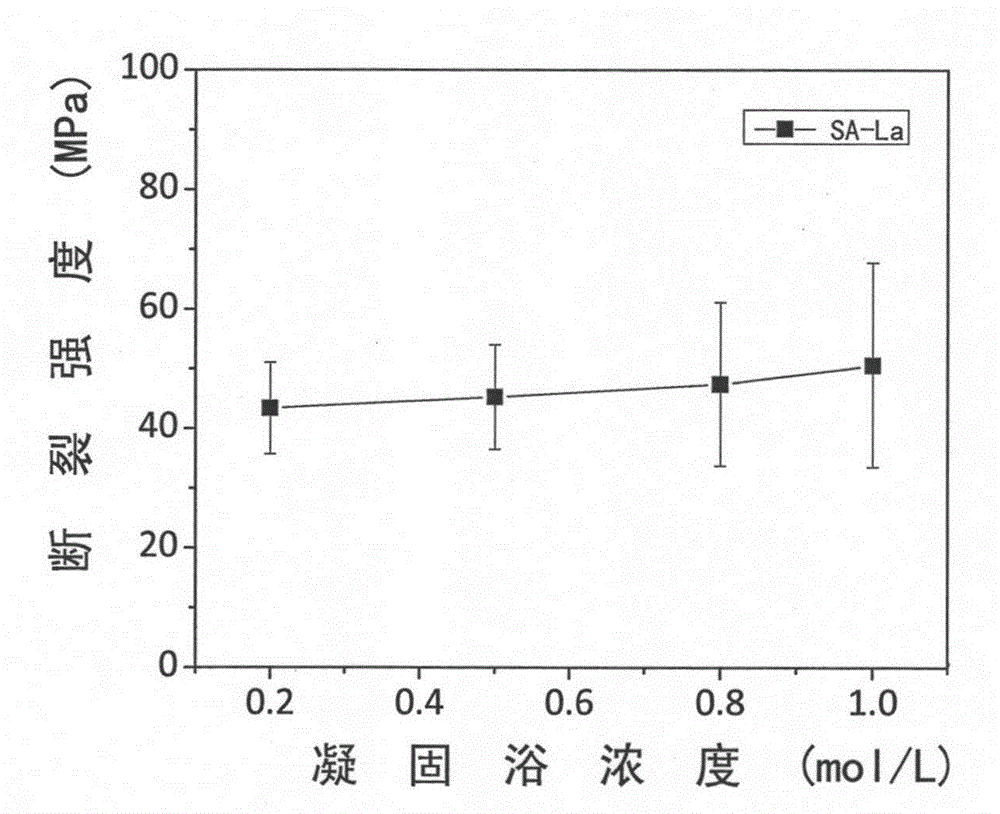

Method for preparing rare earth polysaccharide composite fibers

InactiveCN104451931AImprove water absorptionGood biocompatibilityArtificial filaments from cellulose derivativesWet spinning methodsFiberRare earth

The invention provides a method for preparing rare earth polysaccharide composite fibers. The method is characterized by comprising the following specific steps: step 1, dissolving polysaccharides to prepare a spinning solution; step 2, preparing a coagulating bath, wherein the coagulating bath contains rare earth metal ions; step 3, metering the spinning solution obtained in the step 1 by virtue of a metering pump, extruding the spinning solution to enter the coagulating bath obtained in the step 2 by virtue of a spinning nozzle, wherein the polysaccharides and the rare earth metal ions are subjected to coordination complexation, and the fibers are subjected to coagulation forming; and step 4, cleaning the obtained fibers by virtue of deionized water and drying, thus obtaining the rare earth polysaccharide composite fibers. According to the method disclosed by the invention, the spinning solution with a certain concentration is prepared by utilizing the polysaccharides, the rare earth metal ions are prepared into the coagulating bath of a certain concentration, and the rare earth polysaccharide composite fibers are prepared by virtue of coordination of the polysaccharides and the rare earth metal ions. The spinneret orifice is not blocked during wet spinning, and the spinning operation has high production continuity.

Owner:DONGHUA UNIV

Plastic-injected tooth-cleaning pet chew food for pets and preparation method thereof

ActiveCN107927407APromote digestionPromote absorptionAnimal feeding stuffAccessory food factorsMechanical equipmentBone shape

The invention belongs to the field of pet food, in particular to a plastic-injected tooth-cleaning pet chew food for pets and a preparation method thereof. The sandwich layer of the food is in a porkrib shape or a knot-bone shape, and a meat layer rolls up or wraps the sandwich layer, so that the food is unique in appearance and more attractive to the pets, and has more interestingness. The foodhas good toughness and chewiness and strong biting resistance, and is suitable for pet tooth grinding. The food of the invention is easy to digest and absorb for the pets, and mechanical equipment ina processing process is often adopted so as to reduce labor, reduce cost and improve processing efficiency. Leather pet food (cattle hide and pigskin products) needs to be washed with chemical agentsto clean leather, which causes pollution to environment. The food of the invention replaces the leather food, and relieves environmental protection pressure.

Owner:烟台好氏宠物食品科技有限公司

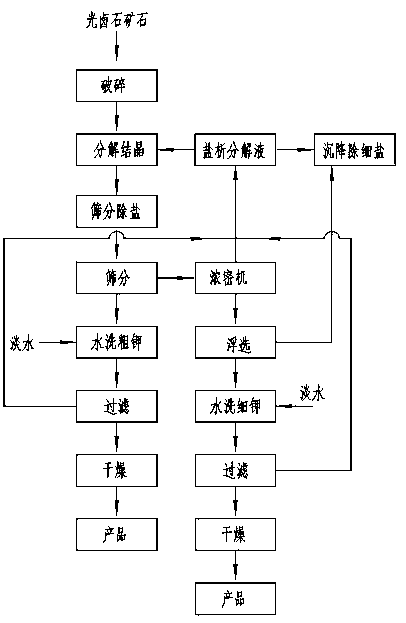

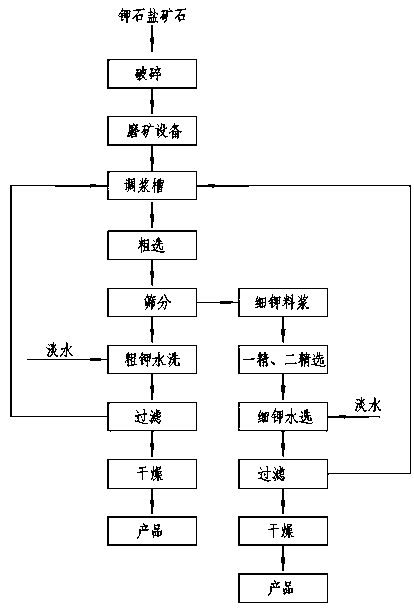

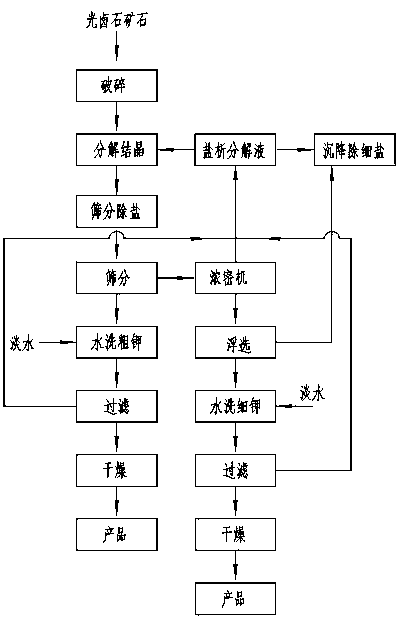

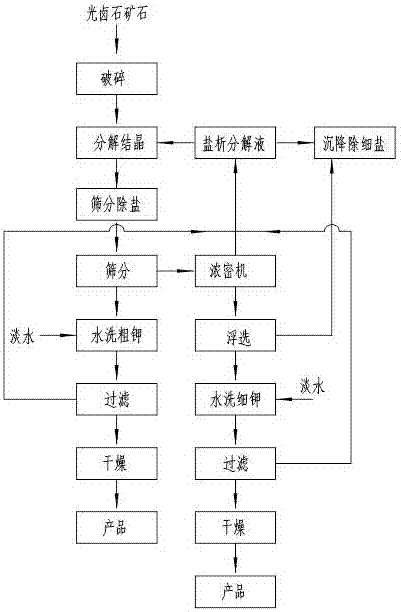

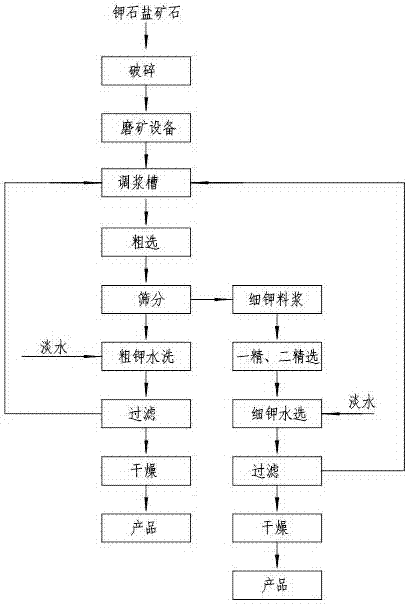

A kind of method for stepwise separation and high-efficiency flotation of potassium salt ore to produce KCl

ActiveCN107188200BQuality improvementEfficient quality productionAlkali metal chloridesGranularityPotassium

The invention discloses a method for efficient flotation production of KCL through sequential separation of sylvite ore, and relates to a method for producing KCl from sylvite ore. According to the technical scheme, the method comprises the steps that after the sylvite ore is manufactured into the certain granularity, pulping, desalting, coarse KCL grain separation, coarse KCl grain washing, fine KCl grain floatation, fine KCl grain washing, dehydration and drying are performed to obtain crude KCl grain products and fine KCl grain products with the purity being 95% or more are obtained; on the basis of advanced separation of some NaCl tail salt and crude KCL grains before KCL floatation or during floatation, the KCL floatation amount is decreased, the floatation strength is lowered, the equipment input is decreased, the building investment is lowered, the floatation reagent consumption is reduced, the environment-friendly pressure is relieved, the mineral separation energy consumption is reduced, the production cost is lowered, the product type is optimized, the product quality is improved, and the KCL recycling rate is increased; the method is mainly used for washing machining of carnallite and sylvine ore of deposit mining.

Owner:山东瑞源钾盐工程技术股份有限公司

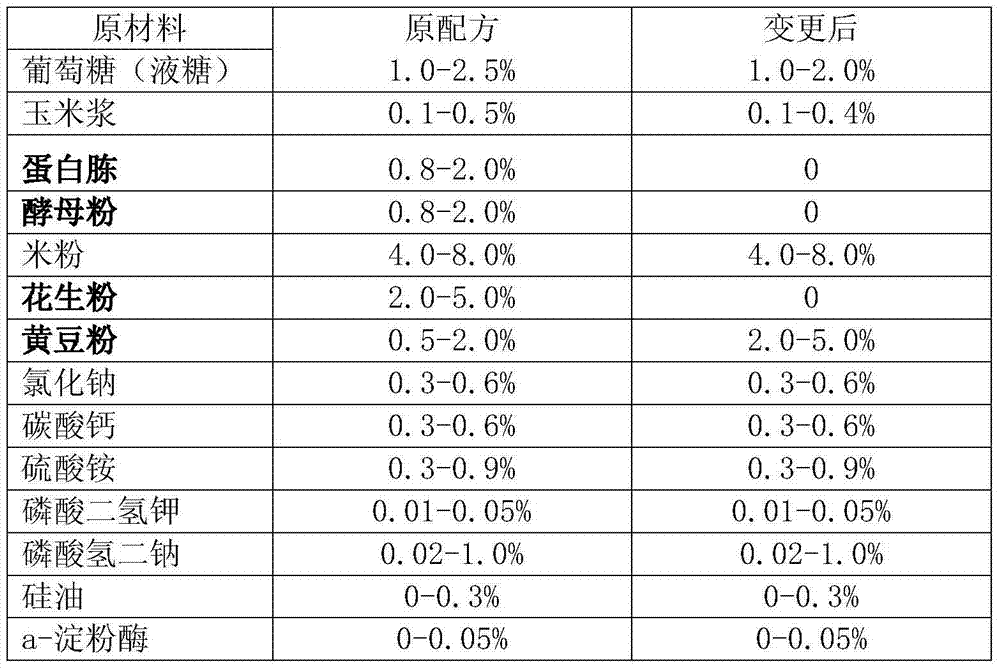

Method for producing neomycin by replacing part of fermenting raw materials with soybean meal

The invention discloses a method for producing neomycin by replacing part of fermenting raw materials with soybean meal. The method consists of the following steps: (1) culturing bevel spores; (2) culturing a bevel spore suspension; (3) performing seeding tank culturing: putting the bevel spore suspension into a seed culture tank for culturing; (4) performing fermentation tank culturing: feeding a culture solution subjected to the seed tank culturing into a fermentation culture tank for culturing, wherein the culture solutions in the seed tank and the fermentation tank include soybean meal of which the mass content is 2.0-5.0 percent the mass of the culture solution in the fermentation tank, and the culture solution in the fermentation tank does not contain peptone, yeast powder and peanut powder; (5) terminating fermentation, diluting a fermentation solution, neutralizing till the pH value becomes 6.4-7.0 to obtain a diluted fermentation solution, thereby finishing the fermentation step. According to the method for producing the neomycin by replacing part of the fermenting raw materials with the soybean meal, the problems of complex raw material formula and high cost of the culture solution are solved, the formula is simplified effectively, the cost is reduced, and the production of the neomycin is guaranteed.

Owner:YICHANG SANXIA PHARMA

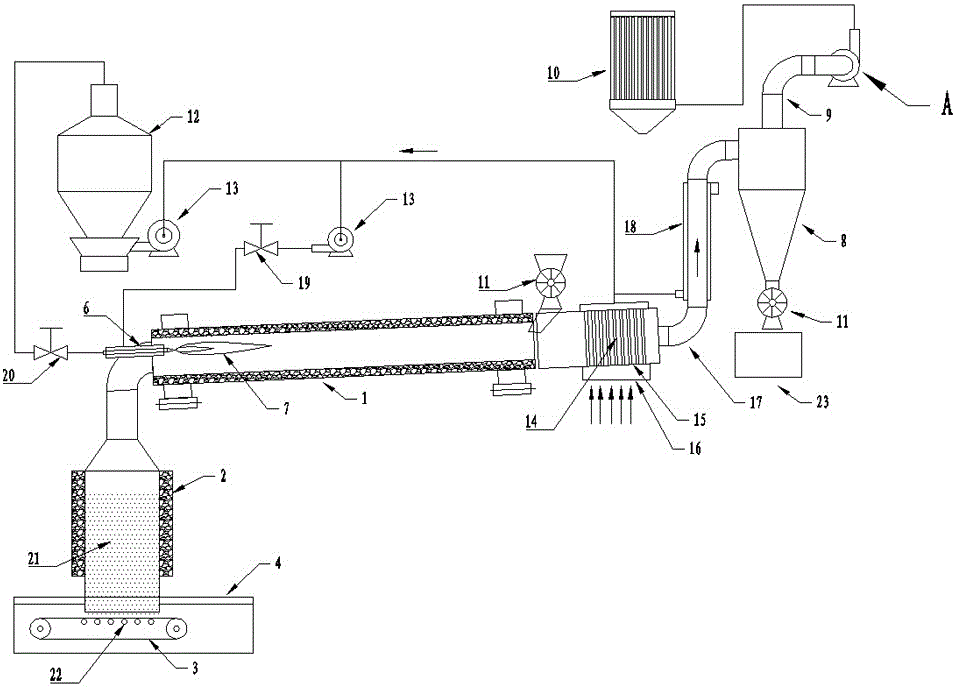

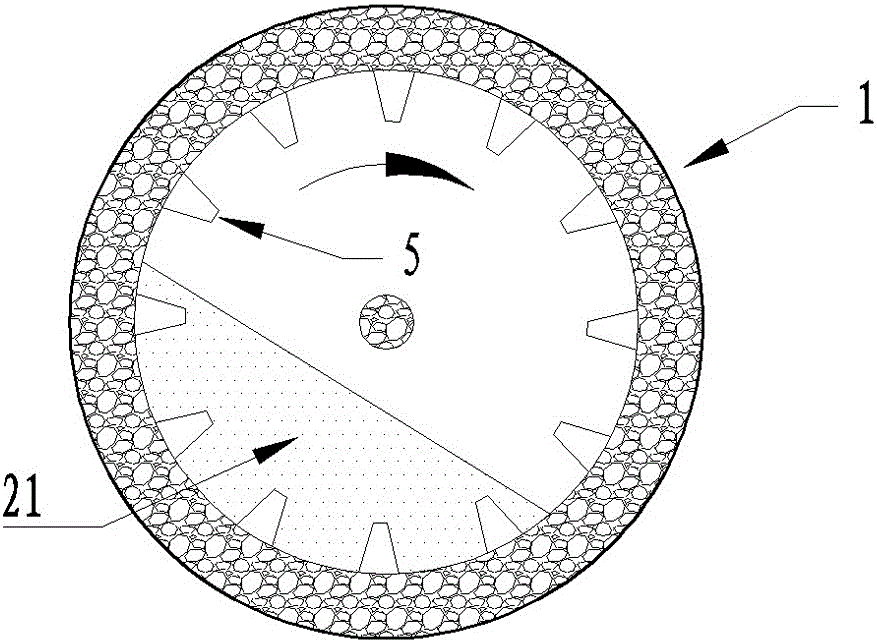

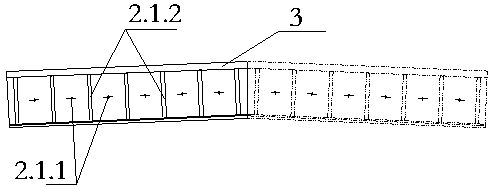

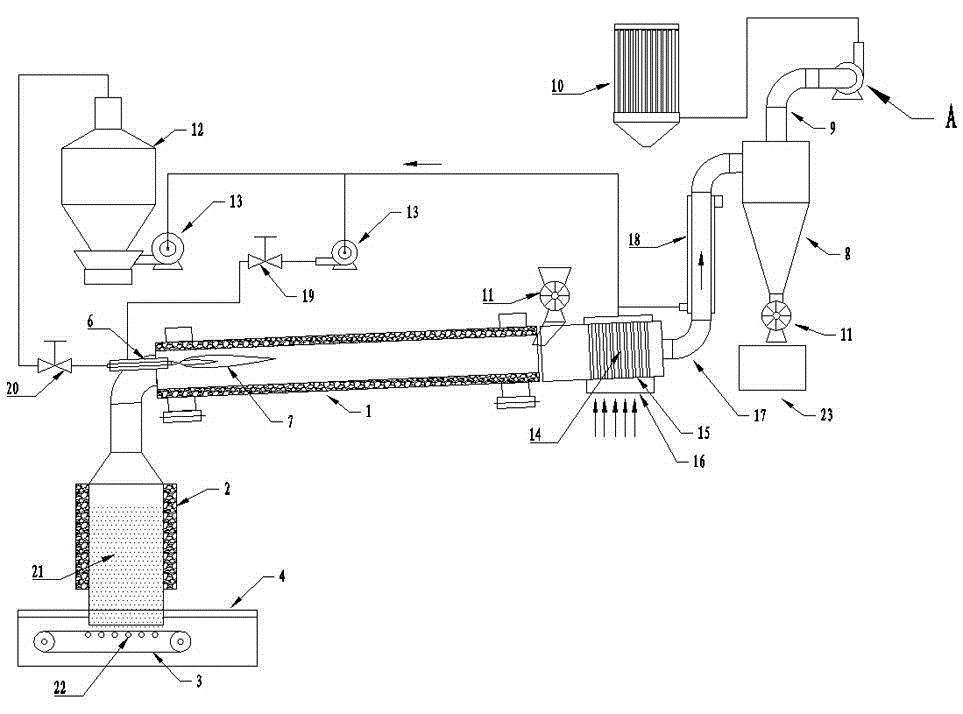

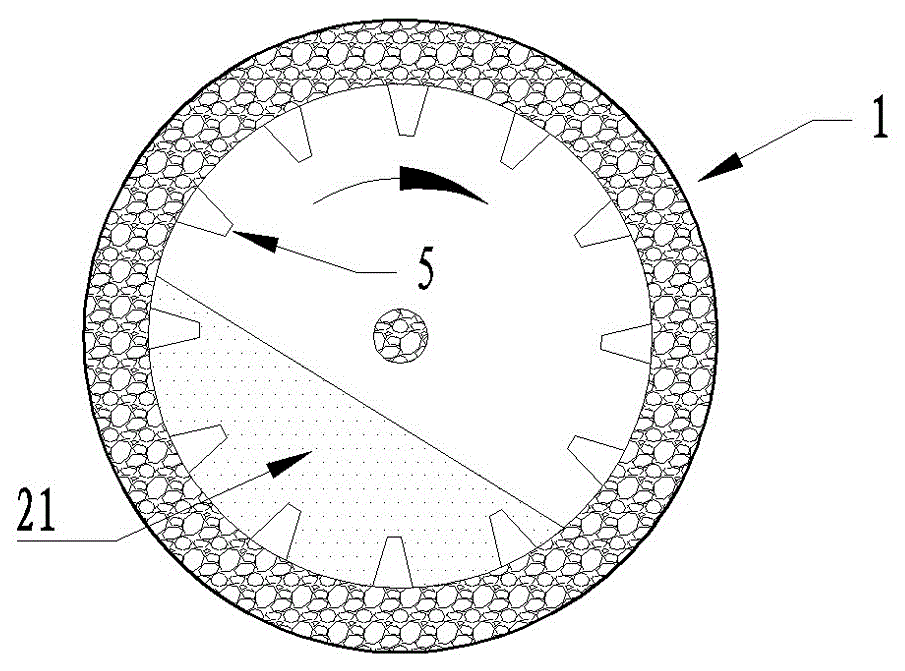

Manganese processing rotary kiln with gas furnace supplying heat

InactiveCN105043092AEasy flipIncrease the heating areaRotary drum furnacesEnvironmental resistanceManganese

The invention discloses a manganese processing rotary kiln with a gas furnace supplying heat. The rotary kiln is characterized in that the rotary kiln is arranged obliquely, and is internally provided with a burner; the burner is connected with an air control valve and a gas control valve; an air-lock valve is arranged at the high end of the rotary kiln for feeding, and is connected with a dust collector through a fin section and an air pipe; the fin section is externally provided with a cover cylinder; the air pipe is externally provided with an extension-type air heat exchanger; after the cover cylinder and a lower air exhaust port of the air heat exchanger are converged, one branch is connected with the gas control valve through an air blower and the gas furnace, and the other branch is connected with the air control valve through the air blower; and the rotary kiln is internally provided with raised fire-resistant plates. The raised fire-resistant plates increase a heat transfer area of the rotary kiln, and facilitate stirring a material and reaching the reaction temperature rapidly, so that the heat efficiency is improved; the fin section and the air heat exchanger achieve waste heat utilization, and facilitate burning; rapid cooling is performed on a pellet material by a rapid cooling liquid bath, and a large amount of water can be evaporated through a reaction, so that environment protection pressure due to production liquid expansion can be alleviated effectively; and the rotary kiln is particularly suitable for burning processing of manganese ore and has broad application prospects.

Owner:JISHOU UNIVERSITY

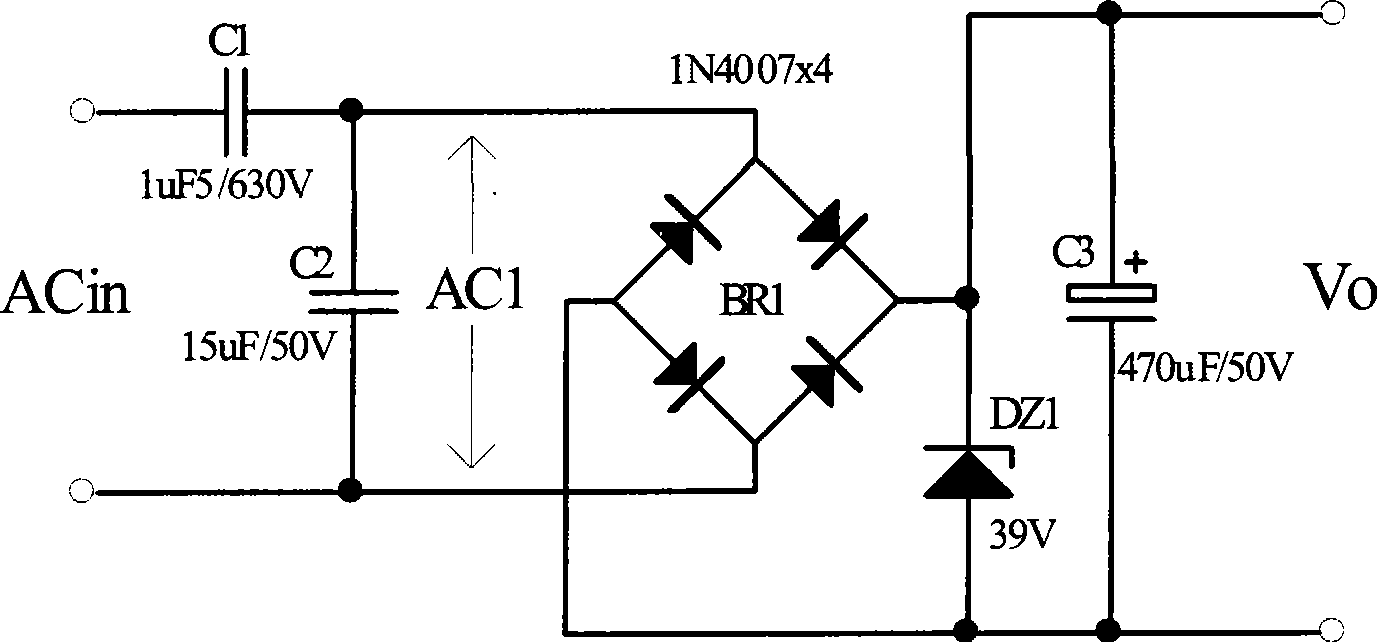

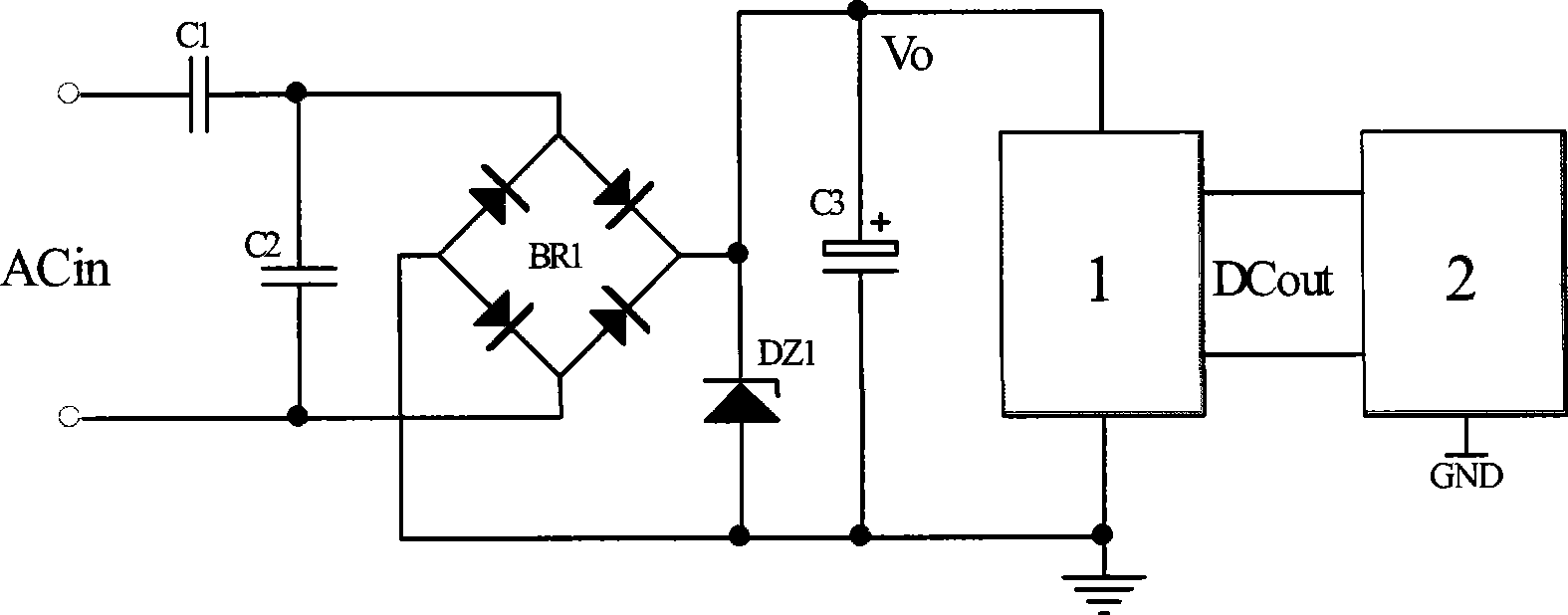

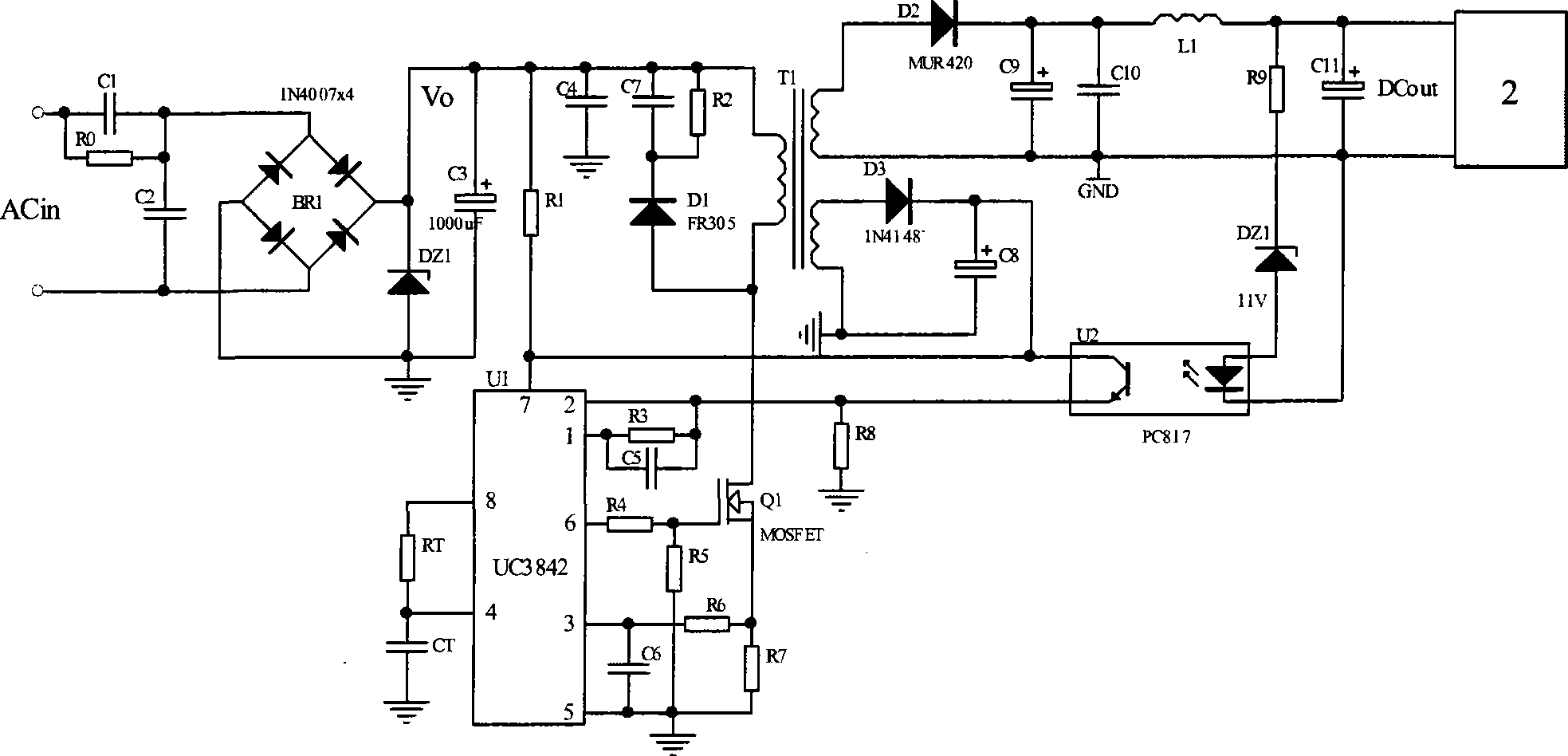

Capacitance partial pressure isolated low power consumption standby power supply

InactiveCN101465608AReduce pollutionIncrease profitAc-dc conversion without reversalEfficient power electronics conversionCapacitancePower factor

The invention aims to provide a capacitive voltage-division isolation low power-consumption standby power supply with power factor compensation function. The technical proposal for realizing the purpose includes that low-voltage ac is obtained through the capacitive voltage division of ac commercial power; then the low-voltage ac is processed with rectification filtering, low-voltage switch power supply isolation voltage-regulation to obtain stable ac voltage; the stable ac voltage is supplied for standby circuit of an electrical appliance as standby power supply. Capacitor is the most commonly used power factor compensation device; as the invention adopts capacitive voltage-division and is capacitive in power grid, and has power factor compensation effect. The invention solves the high standby power consumption problem of standby power supply in various electrical appliances, and has the reactive power compensation effect at the same time.

Owner:张飞然

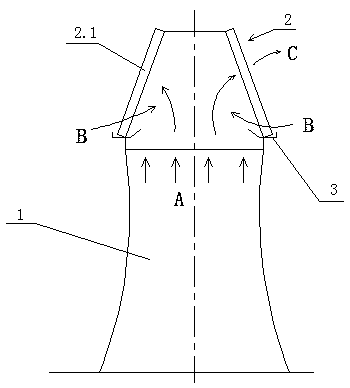

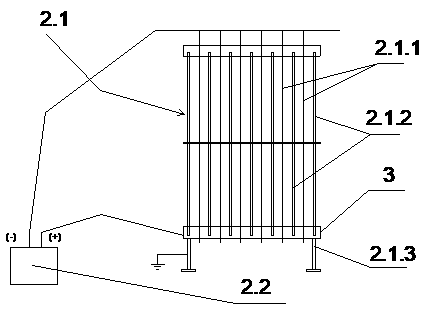

Demisting water-saving cooling tower and water-saving method thereof

The invention relates to a demisting water-saving cooling tower. The cooling tower comprises a tower body, an electrostatic demisting device and a water collecting tank. The electrostatic demisting device comprises a demisting unit and a matched power supply, the demisting unit is arranged at a top outlet of the tower body, and the water collecting tank is arranged below the demisting unit. When waste gas A in the tower and cold air B outside the tower are gathered at the top outlet of the tower body, temperature is reduced to generate mist (white smoke), the mist is captured by the electrostatic demisting device, accumulated water is formed and collected in the water collecting tank for recycling, and therefore the purpose of saving water of the cooling tower is achieved. The electrostatic demisting device is used for water saving of the cooling tower, the water-saving effect is good, and the environmental pollution is less.

Owner:江苏双良冷却系统有限公司

A method of producing electronic grade hydrofluoric acid

ActiveCN101570318BSolve hard-to-remove problemsHigh purityFluorine/hydrogen-fluorideHydrofluoric acidBoiling point

The invention relates to a method for producing electronic-grade hydrofluoric acid, which specifically comprises the following steps: (1) after preheating the measured anhydrous hydrofluoric acid raw material, carry out crude distillation to remove low-boiling substances; After crude distillation, the hydrofluoric acid discharged from the outlet of the condenser is absorbed with ultrapure water, and the absorption is 48-49% aqueous hydrofluoric acid solution; Boiling distiller distillation, hydrogen fluoride liquid gasification to generate ultra-pure electronic grade hydrofluoric acid gas, condensed into 48 ~ 49% aqueous hydrofluoric acid solution, high boiling point substances and heavy metals remain at the bottom of the sub-boiling distiller; (4 ) The semi-finished product of hydrofluoric acid from the sub-boiling distiller of fluoroplastics is filtered through the second stage and finally made into 48% ultra-high-purity hydrofluoric acid finished product through automatic filling. The method of the present invention makes full use of the different boiling points of anhydrous hydrofluoric acid and impurities in anhydrous hydrofluoric acid, and removes different impurities, especially silicon, at different temperatures, so that the impurity content of the obtained ultra-high-purity hydrofluoric acid is reduced to lowest.

Owner:DO FLUORIDE CHEM CO LTD

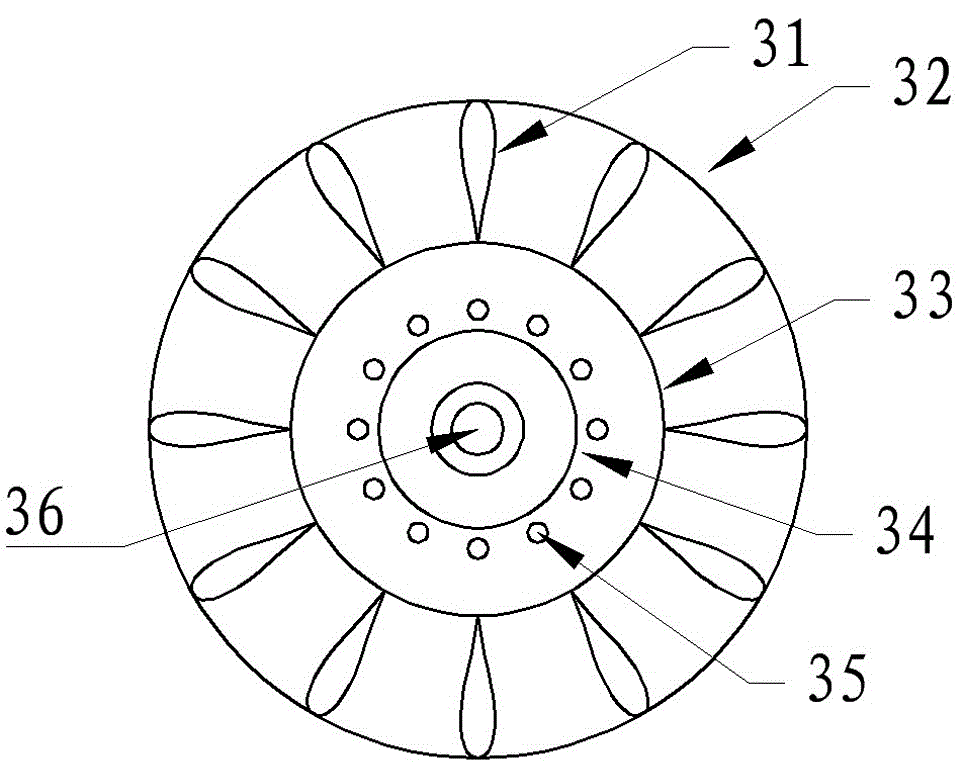

Manganese processing rotary kiln system with gas furnace supplying heat and draught fan being free of dust accumulation

ActiveCN105066684AEasy flipIncrease the heating areaPump componentsRotary drum furnacesCombustorManganese

The invention discloses a manganese processing rotary kiln system with a gas furnace supplying heat and a draught fan being free of dust accumulation. A rotary kiln is arranged in an inclined mode. A combustor is arranged in the rotary kiln and connected with an air control valve and a gas control valve. An air lock is arranged at the higher end of the rotary kiln for feeding and connected with a dust remover through a fin section and an air pipe. A cover cylinder is arranged outside the fin section, a sleeve type air heat exchanger is arranged outside the air pipe, and the cover cylinder is connected with the gas control valve and the air control valve after being joined with a lower air suction port of the air heat exchanger. The draught fan is of a structure with blades being in a reverse drop shape and a back plate being in a butterfly shape. A convex refractory plate is arranged in the rotary kiln. Through the convex refractory plate, the heat transfer area of the rotary kiln is increased, material stirring is promoted, and heat efficiency is easily improved; through the fin section and the air heat exchanger, tail heat is utilized, and combustion is facilitated; through shock chilling liquid, the environmental protection pressure of production liquid expansion is effectively relieved; because the draught fan is free of dust accumulation, safety accidents are effectively eradicated. The manganese processing rotary kiln system is especially suitable for manganese ore firing processing and has broad application prospects.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

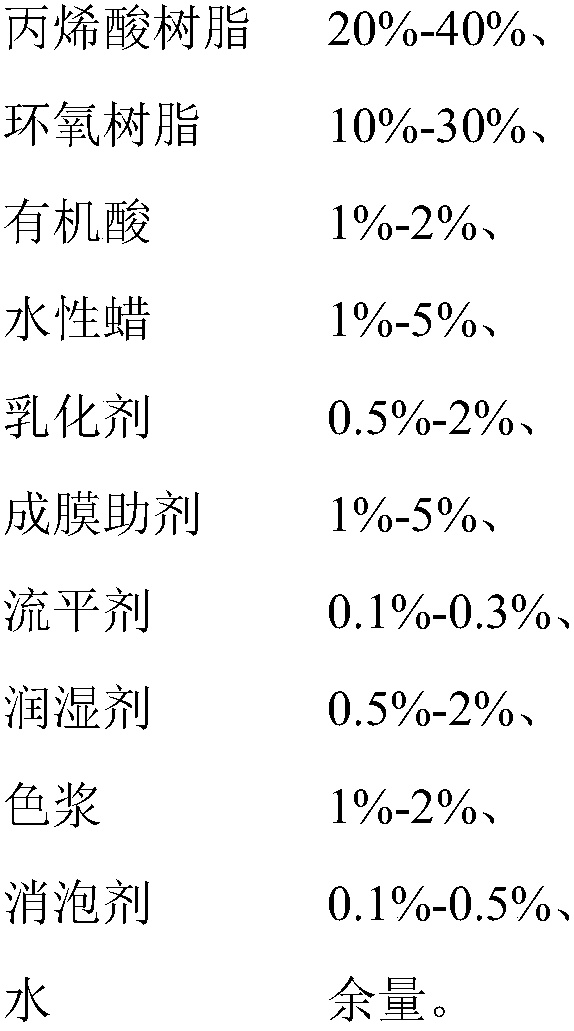

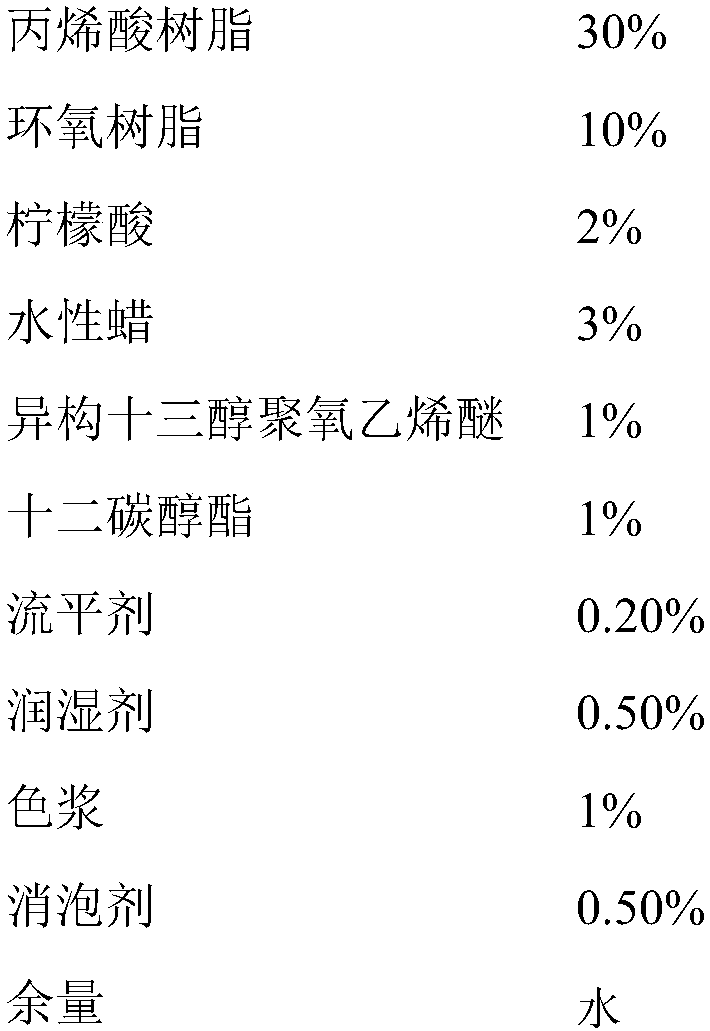

Self-deposition coating based on acrylic acid/epoxy resin as main material and preparation method and application thereof

The invention discloses self-deposition coating based on acrylic acid / epoxy resin as a main material and a preparation method and application thereof, and belong to the technical field of metal coating. The self-deposition coating is prepared from acrylic resin, epoxy resin, organic acid, water-based wax, an emulgator, a coalescing agent, a leveling agent, a wetting agent, color paste and a defoaming agent. Acrylic resin and epoxy resin are blended at the certain proportion, the organic acid is utilized to condition the acidity, so that a formed continuous self-deposition coating has the goodcorrosion resistance and glossiness, as well as the good adhesive force and flexibility, and has the advantages of acrylic resin and epoxy resin simultaneously. A steel base material workpiece subjected to degreasing and acid pickling is dipped into self-deposition working fluid to react to form a layer of even resin coating, the coating has the certain water washing resistance and wet film adhesive force, and after being washed with water and dried, the resin coating has the corrosion resistance similar to common electrophoretic primer.

Owner:SHENYANG PARKERIZING

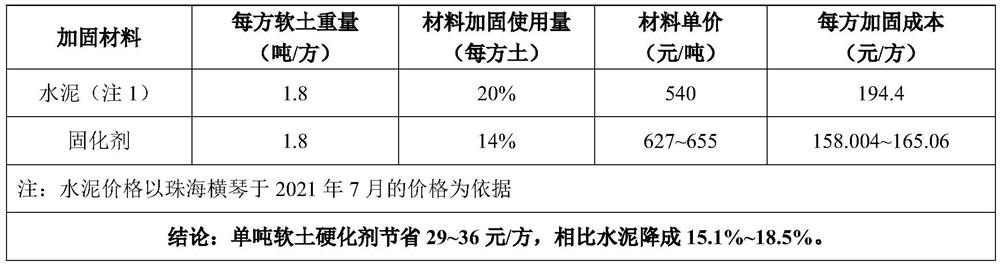

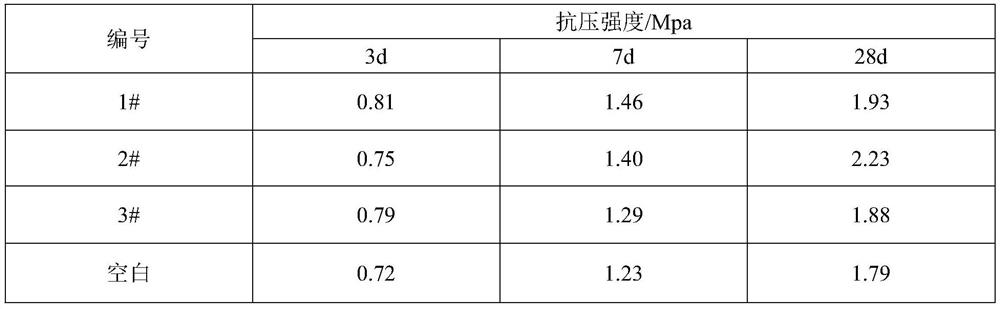

Soft soil hardening agent for sea area environment

PendingCN113735526AReduce economic costsShorten the construction periodOrganic fertilisersSoil conditioning compositionsSoil scienceEnvironmental engineering

The invention relates to the technical field of soft soil solidification, in particular to a soft soil hardening agent for a sea area environment, which comprises the following components in parts by weight: 20-40 parts of cement, 8-12 parts of ground fly ash, 34-50 parts of slag powder, 13-15 parts of gypsum and 3-5 parts of an early strength activator. The soft soil hardening agent is suitable for soft foundation treatment processes of deep mixing piles, high-pressure jet grouting piles and the like in a sea area environment, marine silt and mucky soil with high water content, high organic matter content and high salt content are solidified, and compared with traditional cement, the soft soil hardening agent has better gelling property and economic value; and the soft soil hardening agent has the advantages of simple production process, low cost, wide raw material source, environmental protection and the like.

Owner:北京安科兴业科技股份有限公司

The preparation method of two [propyltriethoxysilane] disulfide

ActiveCN103772427BWide variety of sourcesLarge industrial production operation safetyGroup 4/14 element organic compoundsPtru catalystOrganic solvent

The object of the present invention is to provide a kind of method that does not contain buffering agent and synthesizes two [propyltriethoxysilane] disulfides under aqueous phase conditions, comprising the following steps: A, making sodium polysulfide aqueous solution, chloropropane Base triethoxysilane reacts under the aqueous phase condition of phase-transfer catalyst and water-insoluble organic solvent, produces reaction mixture; B, separates two [propyl triethoxysilane] disulfides from above-mentioned reaction mixture . The method for separating the product bis[propyltriethoxysilane] disulfide from the reaction mixture in the step B comprises the following steps: a, organic phase separation: the upper layer of the reaction mixture obtained in step A is an organic phase, and the lower layer is water phase, separate the organic phase; b, purify the organic phase: distill and purify the above organic phase to obtain the product bis[propyltriethoxysilane] disulfide. Using the method of the invention improves the yield, reduces the generation of three wastes, and eases the pressure on environmental protection.

Owner:南京曙光新材料有限公司

Method for preparing potassium fluozirconate through fluosilicic acid

InactiveCN102874868AReduce total usageProtection mitigationZirconium compoundsPotassiumHexafluorosilicic acid

The invention provides a method for preparing potassium fluozirconate through fluosilicic acid. The method comprises the steps as follows: (1) adding a fluosilicic acid solution to a leaching groove, then heating to reach 40 to 100 DEG C, starting to agitate, and adding the zirconium oxychloride with the theoretical amount to the fluosilicic acid solution; reacting and leaching for 1 to 5 hours under constant temperature condition; (2) filtering the fluosilicic acid obtained by leaching; washing the filter residue, then parching the filter residue to obtain a white carbon black product; (3) adding sodium chloride with theoretical amount to the mixture of the filtrate and the first washing water to obtain the sodium fluosilicate size; (4) filtering the obtained size, washing, and drying to obtain sodium fluosilicate; (5) adding the filtrate in step (4) into the potassium chloride solution with the theoretical amount to react for 30 to 60 minutes, and filtering to obtain paste; and (6) washing the obtained paste through water, and then parching to obtain the finished product. According to the method provided by the invention, the raw materials are easy to obtain, and low in cost, thus the producing cost can be greatly reduced; and meanwhile, the valuable white carbon black and sodium fluosilicate can be produced.

Owner:HUNAN NONFERROUS FLUORIDE CHEM

Method for efficient flotation production of KCL through sequential separation of sylvite ore

ActiveCN107188200AQuality improvementEfficient quality productionAlkali metal chloridesGranularityMachining

The invention discloses a method for efficient flotation production of KCL through sequential separation of sylvite ore, and relates to a method for producing KCl from sylvite ore. According to the technical scheme, the method comprises the steps that after the sylvite ore is manufactured into the certain granularity, pulping, desalting, coarse KCL grain separation, coarse KCl grain washing, fine KCl grain floatation, fine KCl grain washing, dehydration and drying are performed to obtain crude KCl grain products and fine KCl grain products with the purity being 95% or more are obtained; on the basis of advanced separation of some NaCl tail salt and crude KCL grains before KCL floatation or during floatation, the KCL floatation amount is decreased, the floatation strength is lowered, the equipment input is decreased, the building investment is lowered, the floatation reagent consumption is reduced, the environment-friendly pressure is relieved, the mineral separation energy consumption is reduced, the production cost is lowered, the product type is optimized, the product quality is improved, and the KCL recycling rate is increased; the method is mainly used for washing machining of carnallite and sylvine ore of deposit mining.

Owner:山东瑞源钾盐工程技术股份有限公司

Environmentally-friendly low-heat-conductivity-coefficient ultrafine glass fiber spraying cotton particle for building and preparation method thereof

InactiveCN108101374AAlleviate environmental pressureMeet the requirementsGlass making apparatusGlass fiberMaterials science

The invention relates to an environmentally-friendly low-heat-conductivity-coefficient ultrafine glass fiber spraying cotton particle for building and a preparation method thereof, and belongs to thetechnical field of glass fibers. The ultrafine glass fiber spraying cotton particle comprises the following components in percentage by mass: 57.5-67.5% of SiO2, 7-10.5% of R2O, wherein R is Na or K,3-6% of B2O3, 3.5-9% of CaO, 1.5-7% of Al2O3, 1-8% of MgO, 0.5-1.5% of Fe2O3, and not greater than 0.5% of ZnO+BaO. The ultrafine glass fiber spraying cotton particle is high in specific surface area,high in fluffiness, low in heat conductivity coefficient, and free from any aldehyde resin glue and processing additives, and meets the requirement of green and environmentally-friendly building materials; and meanwhile, the preparation processes are simple; the equipment requirements are small; the production cost is low; the yield is high; and massive production can be carried out.

Owner:重庆纤维研究设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com