Building phosphogypsum powder thermal insulation material and preparation method thereof

A technology of building gypsum powder and thermal insulation materials, applied in the field of building thermal insulation materials, can solve the problems of not using gypsum and low comprehensive utilization rate of phosphogypsum, and achieve the effects of overcoming easy combustion and aging, increasing thermal insulation effect, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

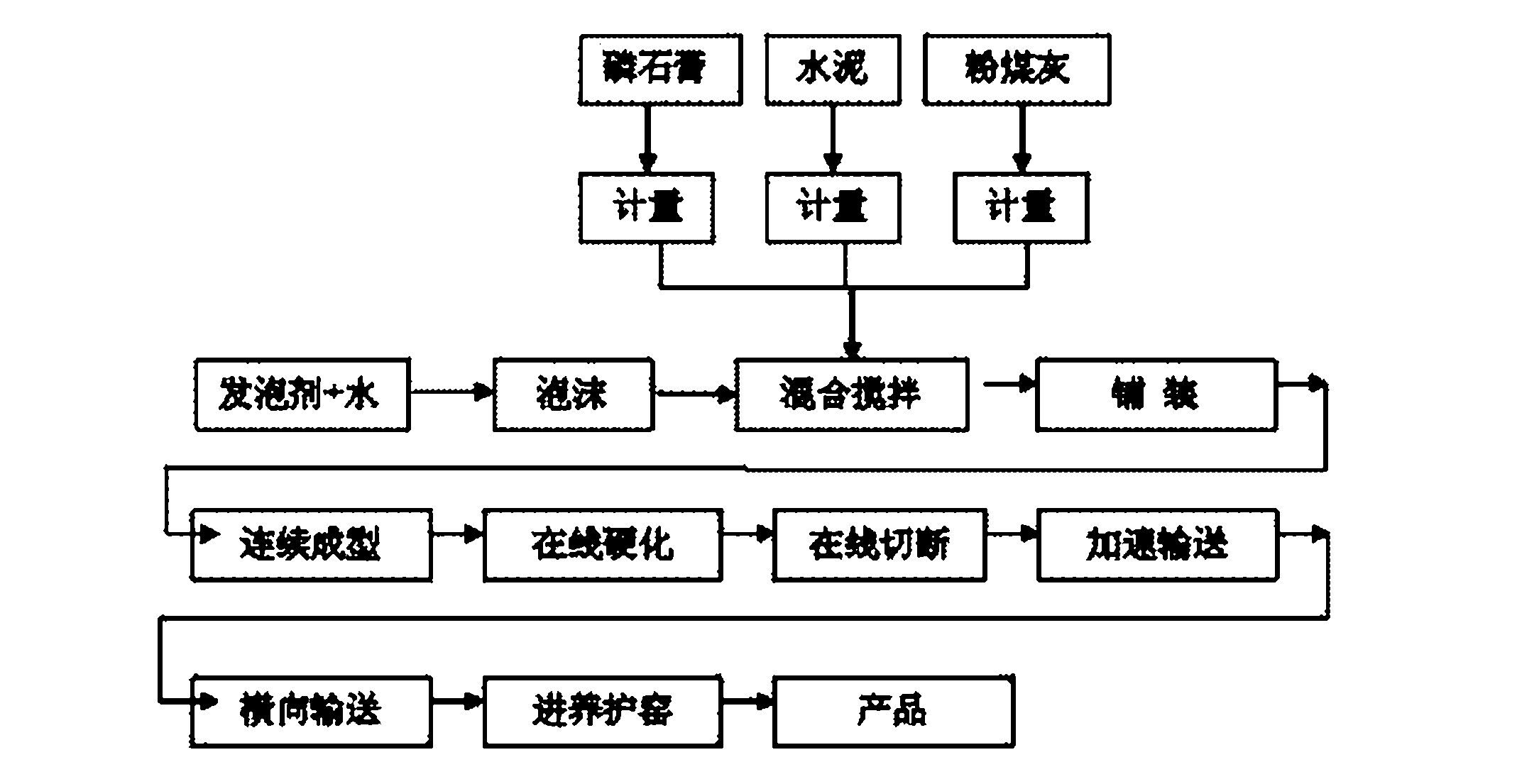

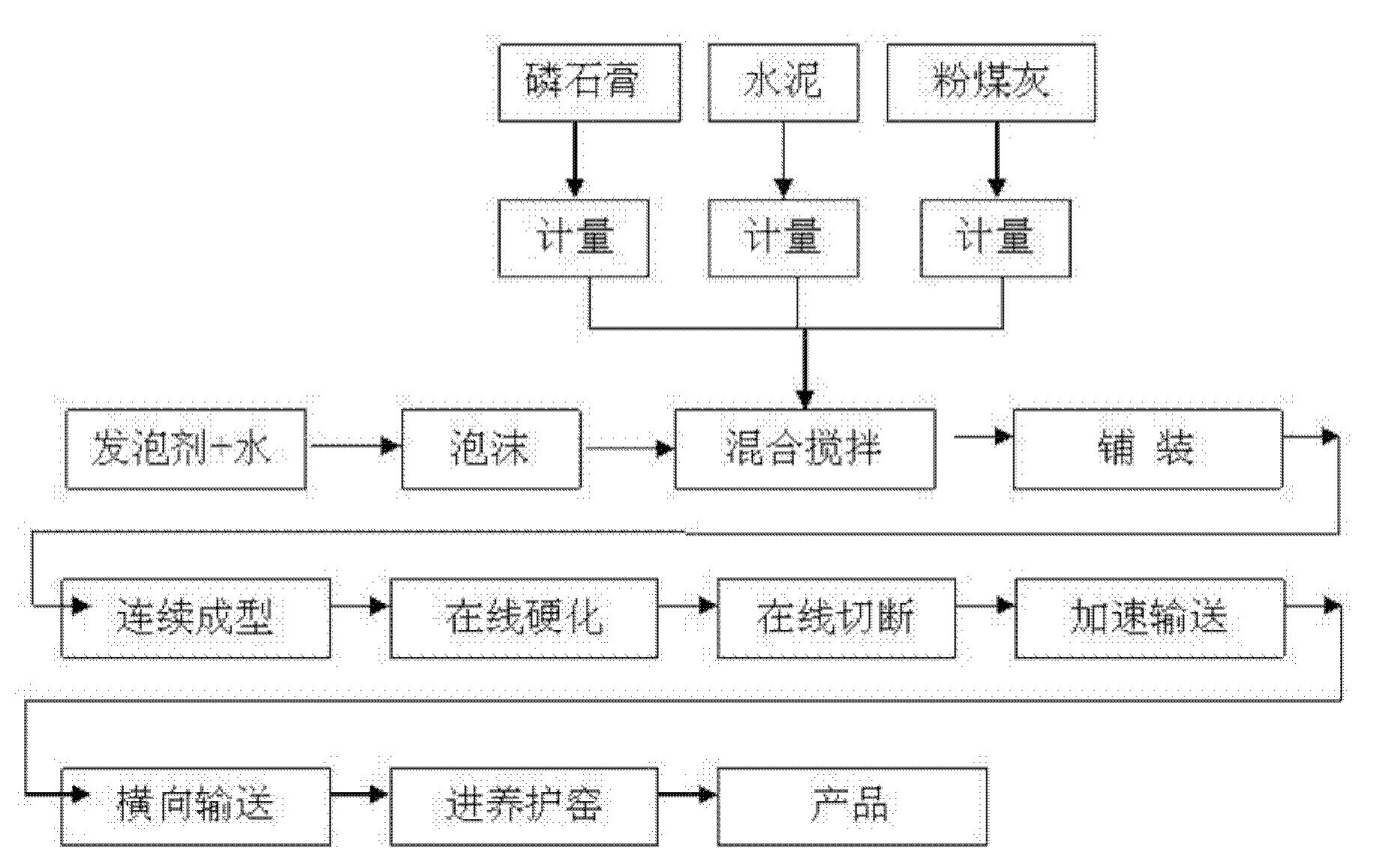

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of external wall insulation board produced with phosphogypsum, cement, fly ash, etc. as main raw materials, is characterized in that its used raw materials and formula are (calculated by weight percentage)

[0027] (1) Construction gypsum powder 50%

[0028] (2) Cement 10%

[0029] (3) Fly ash 8%

[0030] (4) Hydrogen peroxide (concentration 20%) 2%,

[0031] (5) Water 30%

Embodiment 2

[0032] Embodiment 2: A kind of external wall insulation board produced with phosphogypsum, cement, fly ash, etc. as main raw materials, is characterized in that its used raw materials and formula are (calculated by weight percentage)

[0033] (1) Construction gypsum powder 45%

[0034] (2) Cement 12%

[0035] (3) Fly ash 11%

[0036] (4) Hydrogen peroxide (concentration 20%) 2%,

[0037] (5) Water 30%

Embodiment 3

[0038] Embodiment 3: A kind of external wall insulation board produced with phosphogypsum, cement, fly ash, etc. as main raw materials, is characterized in that its used raw materials and formula are (calculated by weight percentage)

[0039] (1) Construction gypsum powder 40%

[0040] (2) Cement 15%

[0041] (3) Fly ash 13%

[0042] (4) Hydrogen peroxide (concentration 20%) 2%,

[0043] (5) Water 30%

[0044] The performance indicators of the insulation board produced by the above three ratios are as follows:

[0045] Bulk density (kg / m 3 )

[0046] It can be seen from the above table that the thermal conductivity and strength of the external wall insulation material made of building phosphogypsum powder meet the external wall insulation standards, and have obvious advantages in fire protection. The above comparison shows that the phosphogypsum exterior wall insulation material has the advantages of heat preservation and heat insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com