Demisting water-saving cooling tower and water-saving method thereof

A cooling tower, water-saving technology, applied in the direction of water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve the problems of environmental pollution, water consumption, etc., to reduce environmental pollution, alleviate The effect of environmental protection pressure and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

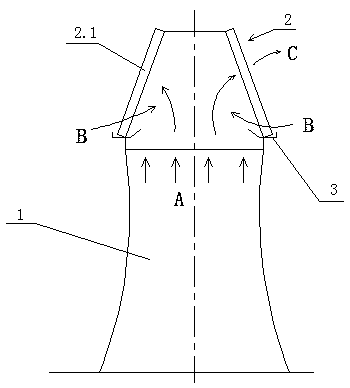

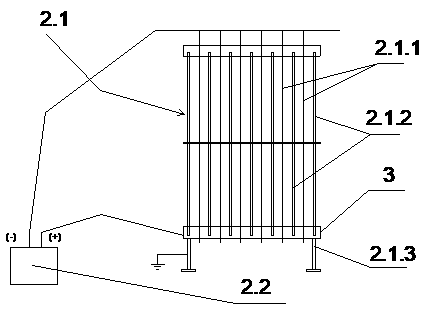

[0024] see figure 1 , figure 2 and image 3 , a fog-eliminating and water-saving cooling tower, including a tower body 1 and an electrostatic defogging device 2, the electrostatic defogging device 2 is connected to a plurality of demisting units 2.1 through a power supply 2.2, and the plurality of demisting units 2.1 are arranged on the tower body 1, a water collection tank 3 is provided between the demister unit 2.1 and the tower body 1, and the water collection tank 3 is used to collect the water that flows down after the demist unit 2.1 catches the water mist. Collect, accumulated water flows downwards and collects in the sump 3. The water collection tank 3 corresponds to the demisting unit 2.1, and each demisting unit 2.1 includes a cathode 2.1.1, an anode 2.1.2 and a support 2.1.3. The cathode 2.1.1 is a discharge electrode connected to the negative electrode of the power supply 2.2; the anode 2.1.2 is a fog collecting electrode connected to the positive electrode of ...

Embodiment 2

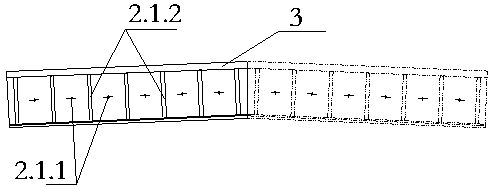

[0030] see Figure 4 and Figure 5 The difference between embodiment 2 and embodiment 1 is that the defogging unit 2.1 is arranged horizontally, a single defogging unit 2.1 is rectangular, and multiple defogging units 2.1 are combined to form a stepped polygon, covering the top of the tower body 1 exit section. The water collection tank 3 is matched with a polygon formed by a plurality of demisting units 2.1. The water collection tank is a plurality of V-shaped grooves, and a plurality of V-shaped grooves are combined to form a stepped polygon. The V-shaped groove is used to collect the water flowing down from the anode 2.1.2 of the demisting unit 2.1, and the arrangement of the water collecting groove 3 can reduce the flow resistance when the exhaust gas passes through.

[0031] All the other technical features of embodiment 2 are the same as embodiment 1, and the water-saving method of embodiment 2 is identical with the method of embodiment 1.

Embodiment 3

[0033] see Figure 6 and Figure 7 , the difference between embodiment 3 and embodiment 1 is: a charging unit 4 is also arranged in the tower body 1, and the charging unit 4 is horizontally arranged below the outlet at the top of the tower body 1, and the charging unit 4 includes a charged cathode 4.1, a charged anode 4.2, a charged support 4.3 and a charged power source 4.4. The function of the charging unit 4 is to pre-charge the exhaust gas A in the tower. It is combined with the demisting unit 2.1 on the top outlet to form a two-stage demisting, that is, the whole demisting process is divided into a charging section (charging unit ) and defogging section (defogging unit), so that the defogging effect of the electrostatic defogging device 2 is better.

[0034] All the other technical features of embodiment 3 are the same as embodiment 1, and the water-saving method of embodiment 3 is the same as that of embodiment 1.

[0035] Embodiment 3 can also be used in the case whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com