Modified phosphogypsum material used for sea reclamation

A technology for land reclamation and phosphogypsum, which is applied in the field of modified phosphogypsum materials for land reclamation, can solve problems such as lack of modified phosphogypsum, and achieve the effects of improving water resistance, high filling strength, and reducing environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

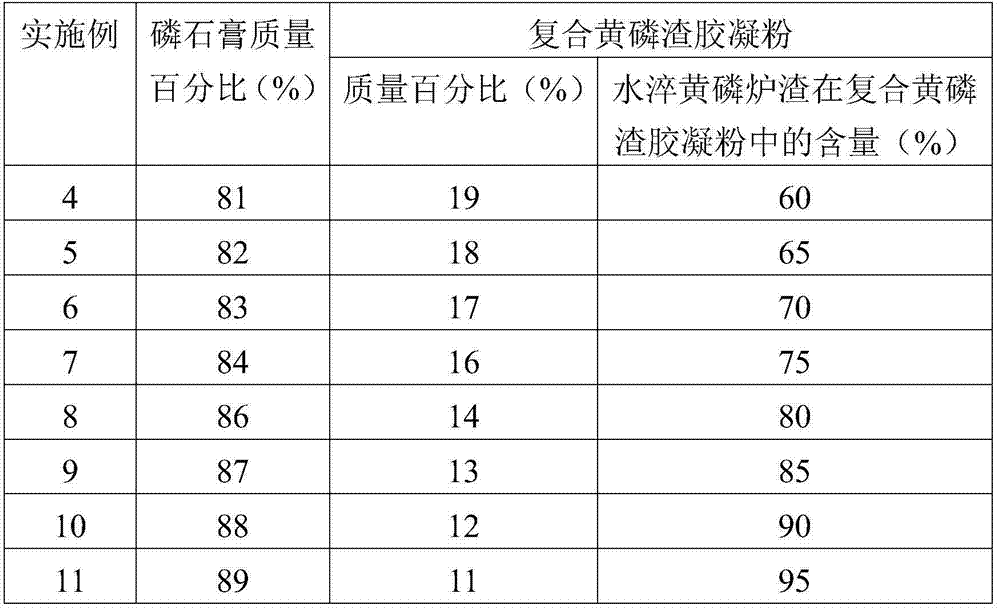

Examples

Embodiment 1

[0045] According to the mass percentage, 80% of phosphogypsum and 20% of composite yellow phosphorus slag gelatinized powder are taken and sent to a mixer, and after being stirred evenly, water is added to continue stirring evenly; the modified phosphogypsum material for land reclamation is obtained. The composite yellow phosphorus slag gelatinized powder is a mixture composed of water-quenched yellow phosphorus slag and cement clinker materials produced in the yellow phosphorus production process.

[0046] The 14-day compressive strength of the material reached 2.9MPa.

Embodiment 2

[0048] According to the mass percentage, 85% of phosphogypsum and 15% of composite yellow phosphorus slag gelatinized powder are taken out and sent to a mixer for uniform mixing, and then water is added to continue stirring evenly; the modified phosphogypsum material for land reclamation is obtained. The composite yellow phosphorus slag gelatinized powder is a mixture composed of water-quenched yellow phosphorus slag and cement clinker materials produced in the yellow phosphorus production process.

[0049] The 14-day compressive strength of the material reached 2.3MPa.

Embodiment 3

[0051] 90% of the phosphogypsum and 10% of the composite yellow phosphorus slag gelatinized powder are collected according to the mass percentage and sent to a mixer for uniform mixing, then adding water and continuing to stir evenly; the modified phosphogypsum material for land reclamation is obtained. The composite yellow phosphorus slag gelatinized powder is a mixture composed of water-quenched yellow phosphorus slag and cement clinker materials produced in the yellow phosphorus production process. The phosphogypsum is the phosphogypsum stockpiled in the production process of wet-process phosphoric acid.

[0052] The 14-day compressive strength of the material reached 1.1 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com