System and method for treating chlor-alkali production byproduct salt mud

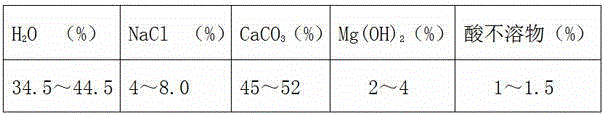

A treatment system and by-product salt technology, applied in the direction of carbonate preparations, calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems of unfavorable environmental protection, waste of transportation costs, etc., to alleviate environmental protection The effect of pressure, less impurities, and high calcium carbonate content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

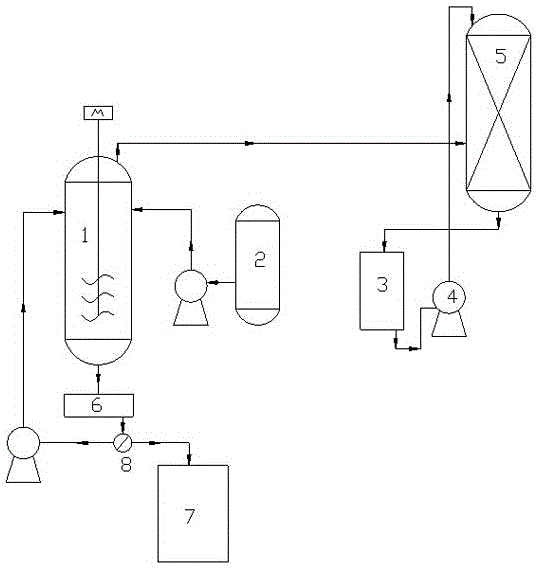

Method used

Image

Examples

Embodiment 1

[0035] (1) Feed the calcium carbonate salt mud into the reaction kettle through the belt conveyor, and use the hydrochloric acid barrel to input the hydrochloric acid with a concentration of 22%-29% into the reaction kettle and stir with the salt mud in it for 2 hours, and control the pH value of the reaction 1~4;

[0036] (2) Add caustic soda with a concentration of 12%-20% into the circulation tank, and the caustic soda enters the absorption tower through the circulation pump, and the CO produced after the reaction in step (1) 2 The gas enters the absorption tower and reacts with caustic soda to produce soda ash solution. After the reaction of the gas in the absorption tower is completed, the liquid in the absorption tower is returned to the circulation tank to obtain caustic soda-soda ash solution for brine refining process, wherein the content of soda ash in the mixed solution is 200 ~260g / L;

[0037] (3) Add caustic soda with a concentration of 12%-20% to the reaction ke...

Embodiment 2

[0040] (1) Feed the calcium carbonate salt mud into the reaction kettle through the belt conveyor, and use the hydrochloric acid bucket to input the hydrochloric acid with a concentration of 22%-29% into the reaction kettle to stir and react with the salt mud in it for 3 hours, and control the pH value of the reaction 1;

[0041] (2) Add caustic soda with a concentration of 12%-20% into the circulation tank, and the caustic soda enters the absorption tower through the circulation pump, and the CO produced after the reaction in step (1) 2 The gas enters the absorption tower and reacts with caustic soda to produce soda ash solution. After the reaction of the gas in the absorption tower is completed, the liquid in the absorption tower is returned to the circulation tank to obtain caustic soda-soda ash solution for brine refining process, wherein the content of soda ash in the mixed solution is 15 %-20%;

[0042] (3) Add caustic soda with a concentration of 12%-20% to the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com