Color floor prepared by automatic leveling of color terrace coating mixed high-strength cement and construction method of color floor

A floor coating and self-leveling technology, which is applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of low surface wear resistance, affecting the appearance effect, and monotonous colors The effect of water absorption and salt migration, reduction of salt migration, and good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

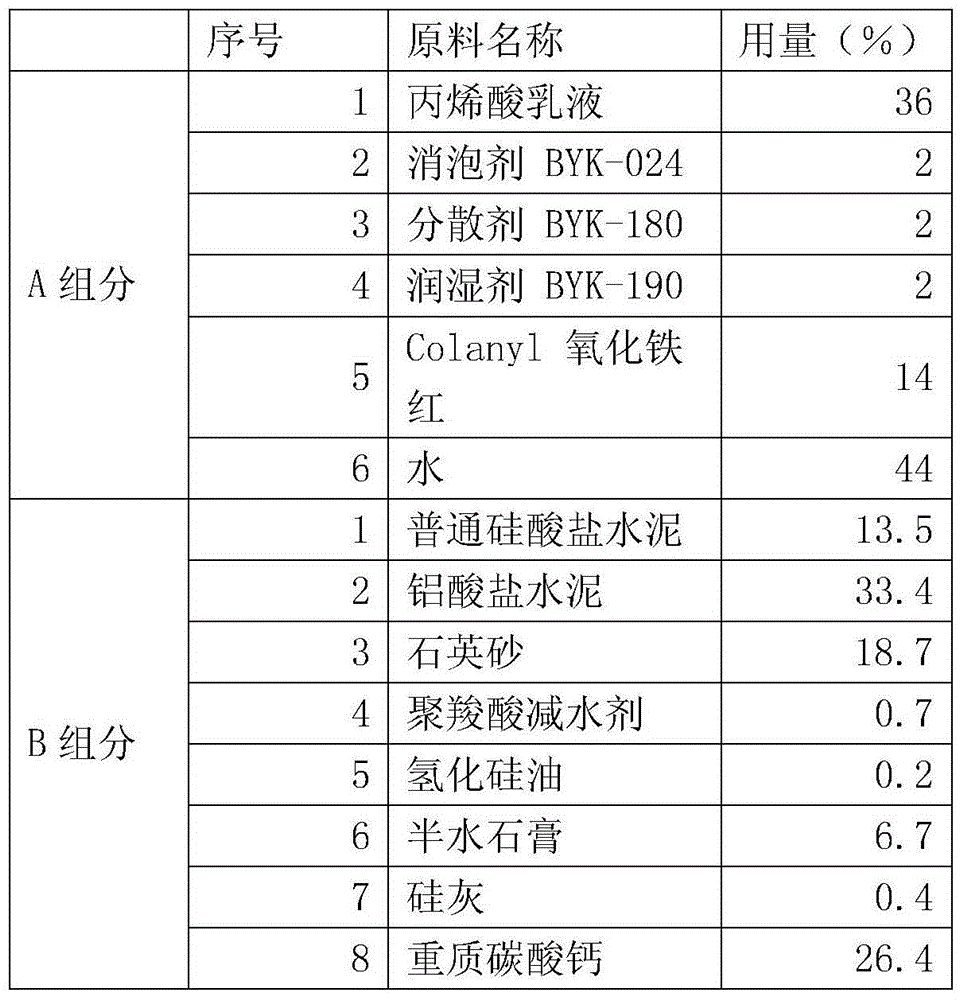

[0034] Example 1: A color floor paint mixed with high-strength cement self-leveling color floor, its ingredients are as shown in the following table:

[0035]

[0036] Where A:B=1:2, the specific construction steps are as follows:

[0037] (1) Prepare component A: fully mix the acrylic emulsion, defoamer BYK-024, dispersant BYK-180, Colanyl iron oxide red and water in the above formula; mix well at a speed of 500-800r / min Obtain the colored floor paint of A component;

[0038] (2) Preparation of component B: add ordinary Portland cement, aluminate cement, quartz sand, polycarboxylate superplasticizer, hydrogenated silicone oil, hemihydrate gypsum, silica fume, and heavy calcium carbonate into the mixer in the above formula Mix uniformly in medium to prepare high-strength self-leveling material of component B;

[0039] (3) Base-level treatment: Before construction, clean and remove sundries, oil stains, paints, and curing agents on the ground to ensure that the base-level ...

example 2

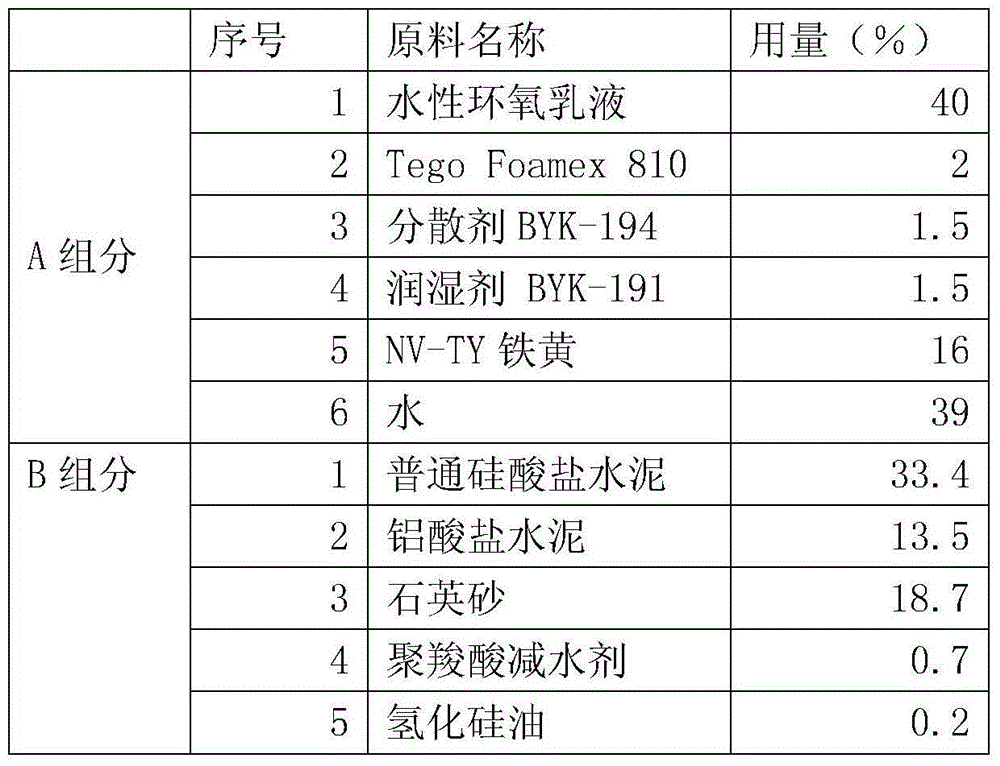

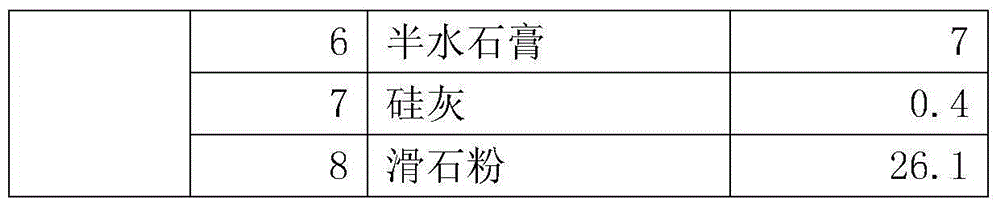

[0045] Example 2: A color floor paint mixed with high-strength cement self-leveling color floor, its ingredients are as follows:

[0046]

[0047]

[0048] Its specific construction steps are as follows:

[0049] (1) Preparation of component A: fully mix the water-based epoxy emulsion, defoamer Tego Foamex 810, dispersant BYK-194, wetting agent BYK-191, NV-TY iron yellow and water in the above formula; ~800r / min rotation speed, mix well and evenly to get the color floor coating of component A;

[0050] (2) Preparation of component B: add ordinary Portland cement, aluminate cement, quartz sand, polycarboxylate superplasticizer, hydrogenated silicone oil, hemihydrate gypsum, silica fume, and talc in the mixer to mix Uniformly prepare high-strength self-leveling materials of component B;

[0051] (3) Base-level treatment: Before construction, clean and remove sundries, oil stains, paints, and curing agents on the ground to ensure that the base-level ground is clean and fr...

example 3

[0057] Example 3: A color floor paint mixed with high-strength cement self-leveling color floor, its ingredients are as follows:

[0058]

[0059] Its specific construction steps are as follows:

[0060] (1) Preparation of component A: fully mix the water-based polyurethane emulsion, defoamer BYK-028, dispersant SN-5034, wetting agent BYK-190, HP 6042 iron oxide yellow and water in the above formula; The rotating speed of 800r / min is fully mixed to obtain the color floor coating of component A;

[0061] (2) Preparation of component B: Add ordinary Portland cement, aluminate cement, quartz sand, polycarboxylate superplasticizer, hydrogenated silicone oil, hemihydrate gypsum, silica fume, and heavy calcium carbonate in the above formula to the double helix The high-strength self-leveling material of component B is obtained by mixing uniformly in a conical mixer;

[0062] (3) Base-level treatment: Before construction, clean and remove sundries, oil stains, paints, and curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com