Method with zero discharge of waste water

A zero-discharge, wastewater technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, heating water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

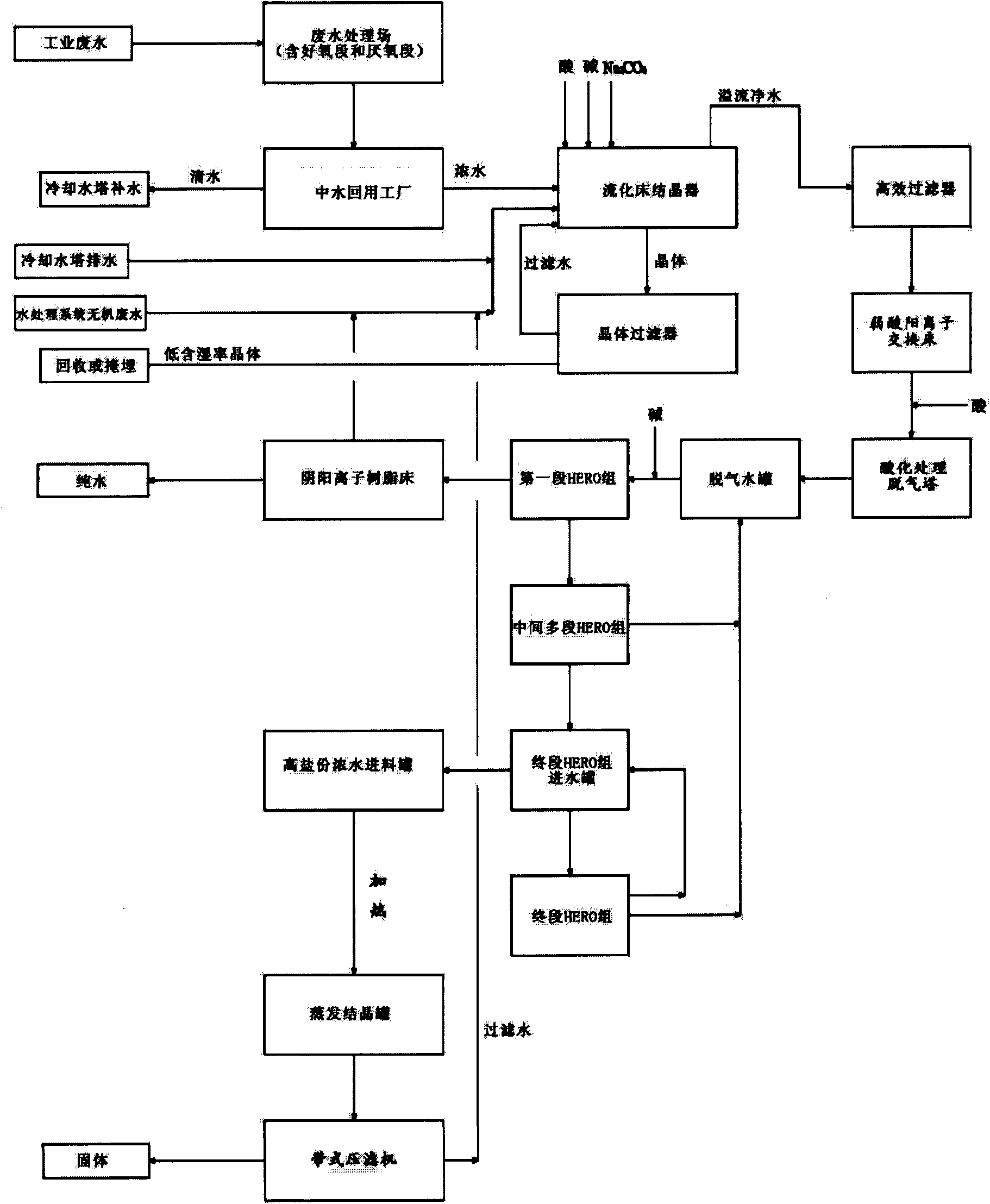

Embodiment 1

[0024] The industrial wastewater flows into the wastewater treatment plant, and after anaerobic decomposition and aerobic decomposition treatment in sequence, 70% to 90% of the organic matter in the wastewater is decomposed, and the chemical oxygen demand (COD) in the discharge water of the wastewater treatment plant is less than 60ppm. SS) <60ppm.

[0025] The obtained effluent from the wastewater treatment plant passes through a reclaimed water reuse plant composed of a simple reverse osmosis membrane group to recover clean water with relatively low water quality, which can be reused as supplementary water for cooling water towers. The concentrated water part of the reclaimed water reuse plant and the cooling water tower drainage and water treatment system inorganic waste water flow through the fluidized bed crystallizer (FBC). The fluidized bed crystallizer is filled with silica sand. By adding acid or alkali or Na 2 CO 3 Adjust the pH value to 9.0~12.0, calcium and magnes...

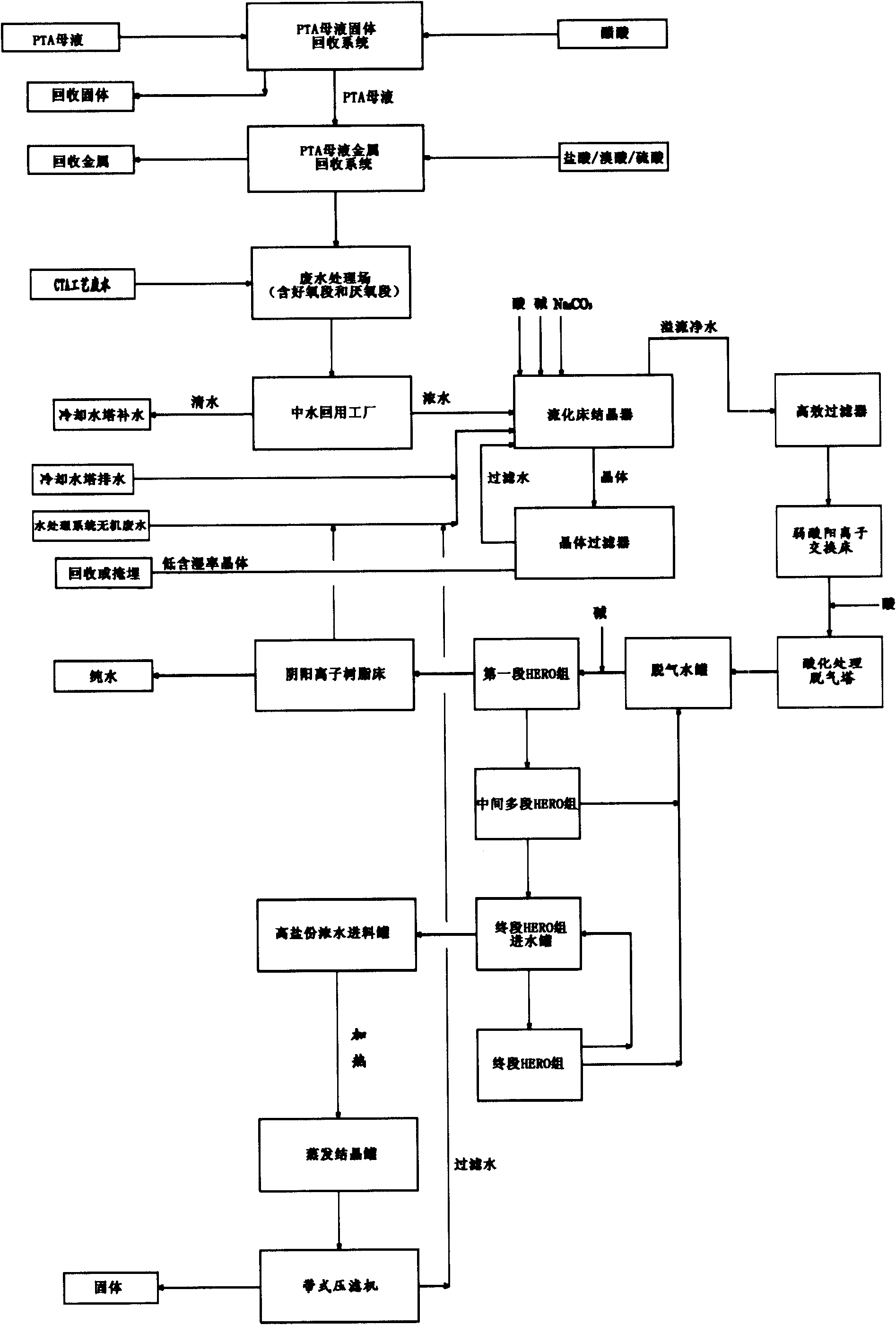

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is that the following steps are also included: the production of PTA comprising purified terephthalic acid (PTA), crude terephthalic acid (CTA), BA, PT acid, 4-CBA and HAC The waste water (PTA mother liquor) discharged in the waste water flows into the PTA mother liquor recovery system, and most of the PTA mother liquor contained in the PTA mother liquor is filtered by the filter of the PTA mother liquor solid recovery system, and the COD of the wastewater is reduced by 70% to 80%; The PTA slurry is dissolved, and the PTA solid is recovered. Then the waste water flows into the PTA mother liquor metal recovery system, and regenerated acid is added. The regenerated acid can be hydrochloric acid, bromic acid or sulfuric acid to recover heavy metal ions such as cobalt and manganese. The wastewater treated by the PTA mother liquor metal recovery system flows into the wastewater treatment plant together with the CTA process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com