Spraying free thermal conductive nylon material for LED lighting products and preparation method thereof

A LED lighting, spray-free technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of complicated spraying process and increased processing cost of nylon parts, avoid environmental pollution, reduce processing costs, and reduce paint The effect of spraying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

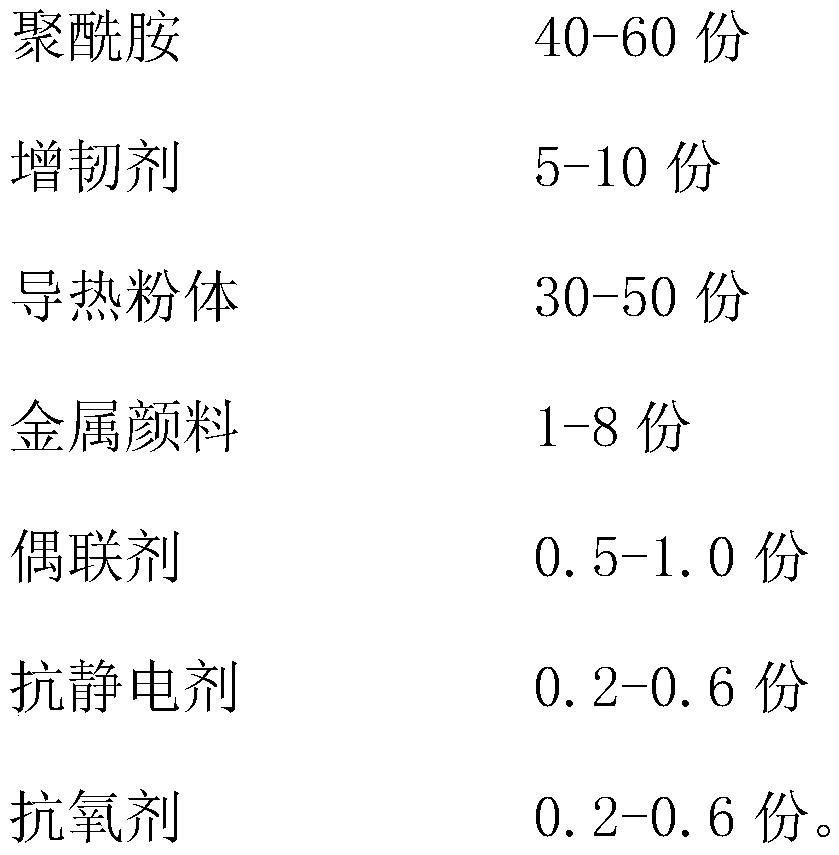

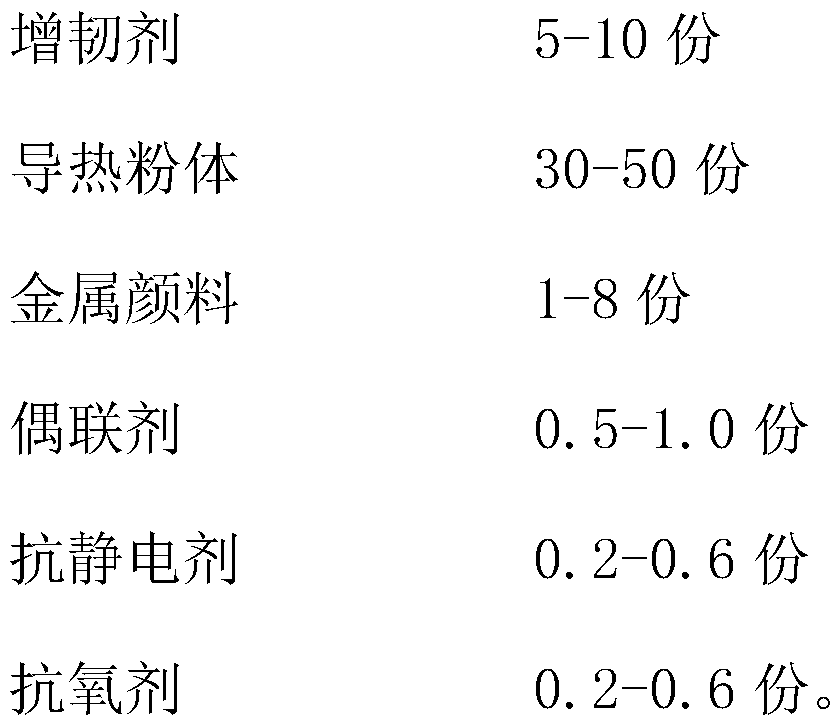

[0038] The preparation method of the spray-free thermally conductive nylon material for LED lighting products provided by the invention comprises:

[0039] Respectively add polyamide, toughening agent, metal pigment, thermally conductive powder, coupling agent, antistatic agent, and antioxidant into the mixer for mixing to obtain premixed raw materials;

[0040] The premixed raw materials are added into a twin-screw extruder to extrude and granulate, and the obtained LED lighting products are spray-free thermally conductive nylon materials.

Embodiment 1

[0042] This embodiment provides a method for preparing a spray-free thermally conductive nylon material for LED lighting products. The specific preparation process includes:

[0043] S1: Heat the mixer to 80°C;

[0044] S2: adding 30 parts by weight of alumina powder into the mixer and mixing and dehydrating for 5 minutes, then adding 0.5 parts by weight of silane coupling agent KH-560, surface treatment for 2 minutes;

[0045] S3: 40 parts by weight of polyamide, 5 parts by weight of maleic anhydride grafted POE toughening agent, 1 part by weight of metal aluminum pigment, and 0.2 parts by weight of SAS 93 antistatic agent 1. The phenolic antioxidant of 0.2 parts by weight is added to the mixer and mixed for 1 minute to obtain the premixed raw material;

[0046] S4: Set the temperature in the parallel co-rotating twin-screw extruder as follows: the first zone 200°C, the second zone 260°C, the third zone 260°C, the fourth zone 250°C, the fifth zone 250°C, the sixth zone Zone...

Embodiment 2

[0049] This embodiment provides a method for preparing a spray-free thermally conductive nylon material for LED lighting products. The specific preparation process includes:

[0050] S1: Heat the mixer to 90°C;

[0051] S2: the magnesium oxide powder that is 40 parts by weight is added to the blender and mixed and dehydrated for 6 minutes, then silane coupling agent KH-560 that is 0.7 parts by weight is added, and the surface is treated for 2 minutes;

[0052] S3: the polyamide that is 50 parts by weight, the maleic anhydride grafted POE toughening agent that is 7 parts by weight, the metal copper pigment that is 4 parts by weight, the SAS 93 antistatic agent that is 0.4 parts by weight 1. The phenolic antioxidant of 0.4 parts by weight is added to the mixer and mixed for 2 minutes to obtain the premixed raw material;

[0053] S4: Set the temperature in the parallel co-rotating twin-screw extruder as follows: the first zone 200°C, the second zone 260°C, the third zone 260°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com